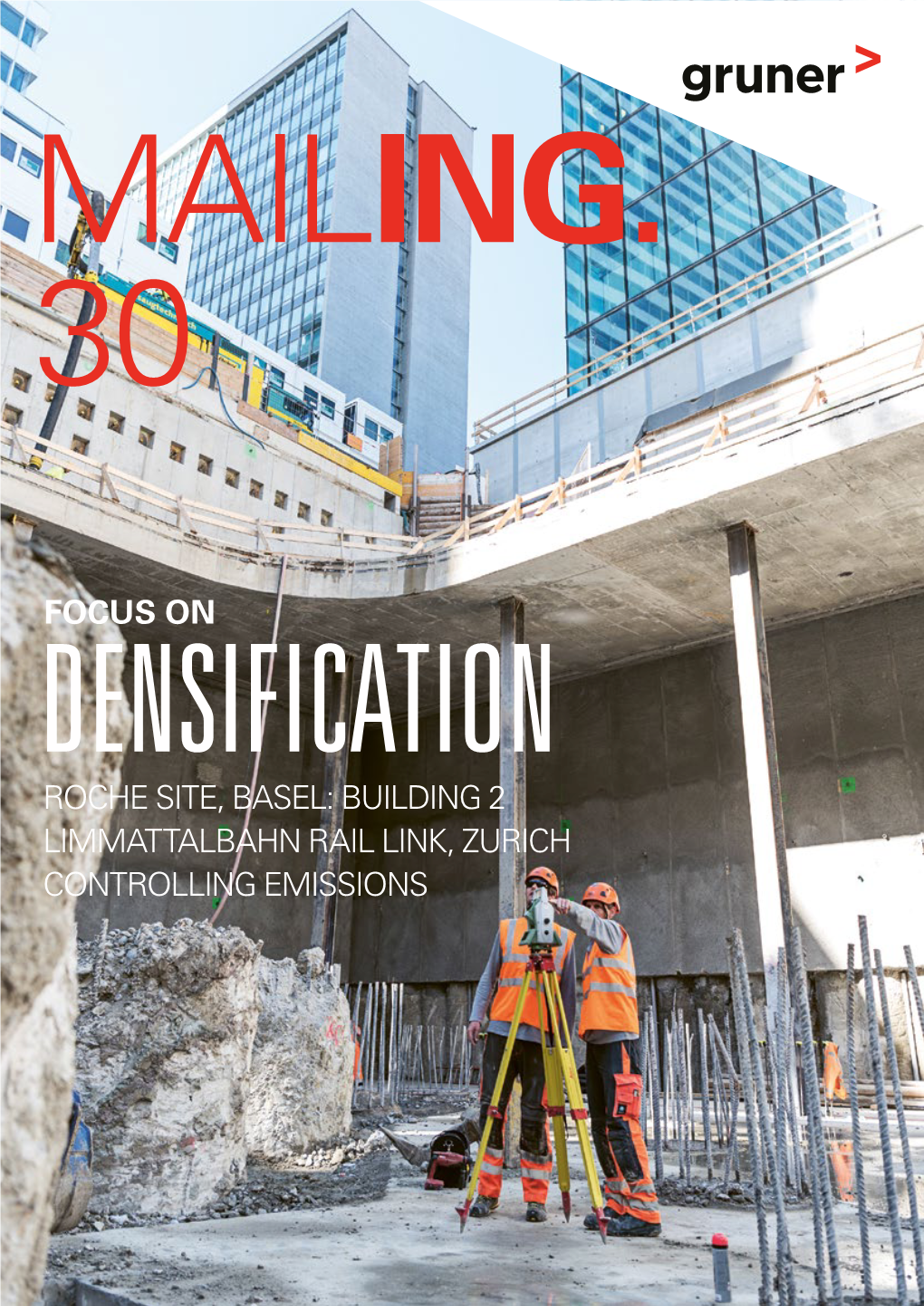

Focus on Roche Site, Basel: Building 2 Limmattalbahn Rail Link, Zurich Controlling Emissions

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Das Offizielle Monatsmagazin Für Dürrenäsch 10/ 2018

Das offizielle Monatsmagazin für Dürrenäsch 10/ 2018 Titelbild: Pflegeeinsatz Weiher Weid und Chüeloch Onlineausgaben: www.dorfheftli.ch www.facebook.com/dorfheftli DORFHEFTLI DUERRENAESCH-OKTOBER_Layout 1 28.09.2018 07:29 Seite 1 GEMEINDE Gemeinde Dürrenäsch IMMOBILIEN AG Gemeindenachrichten ZURBUCHEN IHR REGIONALER IMMOBILIENPARTNER Turnhallenbenützung • Jenzer Peter und Karin, Hellmattring 16, 5724 In der Zeit vom 15. Oktober 2018 bis 12. April Dürrenäsch, für den Anbau eines unbeheiz- 2019 wird dem Damenturnverein die Turnhalle ten Wintergartens anstelle der Sitzplatzüber- jeweils am Montag, von 09.45 bis 10.45 Uhr, für dachung an das Gebäude Nr. 561 auf Parzelle das Muki-Turnen und am Dienstag, von 16.45 871 am Hellmattring 16 Uhr bis 17.45 Uhr, für das Kinderturnen zur • Bertschi AG, Hutmattstrasse 22, 5724 Dürre- Verfügung gestellt. Der Musikgesellschaft Dür- näsch, für den Neubau einer Niederspannungs- renäsch wurde für die Durchführung des Jah- verteilstation mit Notstromversorgung auf Par- reskonzertes am Samstag, 27. Oktober 2018 die zellen 539 an der Hutmattstrasse Bewilligung zur Benützung der Turnhalle erteilt. Abfallbeseitigung – Erhöhung Grundgebühr Erteilte Baubewilligungen pro Haushalt • Binder Michael und Andrea, Baumgartenweg Per 1. Januar 2019 werden die Grundgebühren 9, 5724 Dürrenäsch, für den Einbau einer Sitz- für die Kehrichtabfuhr pro Betrieb und pro private platztüre im Gebäude Nr. 143 auf Parzelle 378 Haushaltung und Jahr von bisher CHF 10.00 auf am Baumgartenweg 9 CHF 25.00 angehoben. Die restlichen Gebühren- 28. Verkaufsobjekt in der Gemeinde Dürrenäsch Impressum Herausgeberin: Dorfheftli GmbH, Hauptstrasse 2, Postfach 50, 5734 Herzlichen Reinach, 062 765 60 00, dorfheftli.ch, [email protected] Dank Verlags-/Geschäftsleitung: Heinz Barth Redaktionsleitung: Thomas Moor (tmo.). -

Jahresbericht 2019 Der Regionalen Bibliothek Oberkulm Unterkulm Teufenthal

Jahresbericht 2019 der Regionalen Bibliothek Oberkulm Unterkulm Teufenthal Regionale Bibliothek Öffnungszeiten: Hauptstrasse 28 Montag 15.00 – 17.30 5726 Unterkulm Dienstag 15.00 – 17.30 062 776 10 37 Mittwoch 13.00 – 15.00 [email protected] Donnerstag 10.00 – 11.00 www.biblikulm.ch 17.00 – 19.00 Samstag 09.30 – 12.00 RÜCKBLICK Das Bibliotheksteam (Elisabeth Krack, Esther Kyburz und Sandra Reusser) schaut auf ein arbeitsintensives Jahr zurück und freut sich, zahlreiche Besucherinnen und Besucher betreuen und beraten zu dürfen. Per Ende 2019 sind 113 Benutzer (inkl. Schüler) mehr registriert als im Vorjahr. Die Bibliothek als «Dritter Ort» wird immer wichtiger. Das Bibliotheksteam schätzt die sehr gute Zusammenarbeit mit der Kreisschule mittleres Wynental, den 6. Klassen Primarschule Oberkulm, Unterkulm und Teufenthal sowie den Kindergärten Unterkulm. Mit dem Angebot von eMedien bzw. dem Beitritt zum Verein ebook+ im April 2019 konnte für die Kundinnen und Kunden das Medienangebot auf attraktive Art und Weise erweitert werden. Arbeitsaufwand / Öffnungszeiten Per 1. Januar 2019 wurden die Öffnungszeiten angepasst. Neu ist die Bibliothek am Mittwoch Nachmittag von 13 – 15 Uhr geöffnet, was wesentlich besser frequentiert ist, als die vorherigen Öffnungszeiten am Morgen. Neu geöffnet ist am Donnerstag von 10 – 11 Uhr, die Zeiten am Abend wurden vorverschoben auf 17 – 19 Uhr. Die wöchentlichen Öffnungszeiten betragen neu 12,5 Stunden (bisher 11,5 Stunden). Klassenbesuche und Veranstaltungen fanden ausserhalb der regulären Öffnungszeiten statt. Insgesamt wurden 1’337 Stunden Bibliotheksarbeit geleistet. 23 Veranstaltungen aller Art wurden im Jahr 2019 durchgeführt und bereicherten so das kulturelle Angebot von Oberkulm, Unterkulm und Teufenthal. Einführung E-Medien Mit dem Beitritt zum Verein ebook+ im April 2019 konnte des Angebot der Bibliothek mit eMedien erweitert werden. -

Fladeblatt.Html/16 Oder

PDF AUF DER HOMEPAGE DER GEMEINDEN FlADE BLATT INFORMATIONSBLATT DER GEMEINDEN FLAWIL UND DEGERSHEIM 6. JAHRGANG | AUSGABE 10 | 5. MÄRZ 2021 PLANAUFLAGE Den Kontakt zu den Jugendlichen Im Zuge des Wasserbauprojekts Bueben- taler- und Aeschbach wird die Brücke beim nicht verlieren Bubentalweg ersetzt. Das Bauvorhaben sieht eine einfache Brücke für Fussgängerinnen und Fussgänger sowie für Radfahrerinnen und Radfahrer vor. ››› SEITE 2 BIOABFALL Die Trennung von Bioabfällen vom nor- malen Abfall spart nicht nur Geld, sondern trägt auch viel zur Schonung der Umwelt bei. So konnten im letzten Jahr in Degersheim 45 Tonnen CO2 eingespart werden. ››› SEITE 9 Das OJA-Team mit einheitlichem Look (von links): Domenica Del Tiglio, René Hirschi und Stellenleiter Tobias Marti. FLAWIL Seit bald einem Jahr wird das Leben Monate zurückblickt. Vor allem im März und durch das Coronavirus bestimmt. Auch für die April 2020, als der Jugendtreff geschlossen blei- Mitarbeitenden der Offenen Jugendarbeit ben musste, war das OJA-Team ganz besonders (OJA) waren die vergangenen zwölf Monate gefordert. «Die Beziehung ist das Kernelement FAHRVERBOT eine Herausforderung. Immer wieder mussten der Offenen Jugendarbeit. Ein professioneller Die Gemeinden Degersheim und Neckertal sie die Angebote anpassen. «In erster Linie Beziehungsaufbau ist aber nur schwer möglich, haben beschlossen, das Fahrverbot auf der ging es darum, den Kontakt zu den Jugendli- wenn der Jugendtreff geschlossen ist», sagt Tobias Berg-Wolfensbergstrasse auf alle Wochen- chen nicht zu verlieren», sagt Tobias Marti, Marti. Die OJA-Mitarbeitenden mussten nach tage auszudehnen. Das Verbot gilt ab sofort. Stellenleiter der Offenen Jugendarbeit Flawil. neuen Wegen suchen und fanden sie vor allem in digitalen Angeboten. Diese hatten in erster Linie ››› SEITE 9 Ein Jahr dauert die Corona-Krise nun schon an. -

8. Januar 2021

PDF AUF DER HOMEPAGE DER GEMEINDEN FlADE BLATT INFORMATIONSBLATT DER GEMEINDEN FLAWIL UND DEGERSHEIM 6. JAHRGANG | AUSGABE 1/2 | 8. JANUAR 2021 KONSTITUIERUNG Erfolgreiche Rezertifizierung: Flawil Nach dem Gemeinderat hat sich auch der Schulrat für die Amtsdauer 2021 bis 2024 bleibt «Kinderfreundliche Gemeinde» konstituiert. Drei Bisherige und vier Neue bilden in der kommenden Legislatur das Gremium. Wie bisher wurde dabei das «An- ciennitätsprinzip» angewendet. ››› SEITE 3 PRÄMIENVERBILLIGUNG Versicherte in bescheidenen wirtschaftlichen Verhältnissen haben Anrecht auf individu- elle Prämienverbilligungen (IPV). Anmel- dungen sind bis am 31. März 2021 möglich. ››› SEITE 7 Das Label «Kinderfreundliche Gemeinde» wurde Flawil für weitere vier Jahre verliehen. INFORMATIONSVERANSTALTUNG FLAWIL Ende 2016 wurde die Gemeinde Fla- Oktober 2018 bescheinigt. Aufgrund des einge- Vor Beginn des Auflageverfahrens findet wil von Unicef Schweiz als «Kinderfreundliche reichten Zwischenberichts hielt Unicef Schweiz am 11. Januar 2021 eine Informationsveran- Gemeinde» ausgezeichnet. Damit verbunden fest, dass «die Beteiligten in umfassender Weise staltung zum Sanierungsprojekt der Haupt- war die Umsetzung eines Acht-Punkte-Akti- die Umsetzung des Massnahmenplans angehen». strasse statt. Die Veranstaltung kann via onsplans bis ins Jahr 2020. Im März 2019 be- Zudem wurde die Freude über das weitere En- Livestream verfolgt werden. auftragte der Gemeinderat das Projektteam, gagement ausgedrückt und die Gemeinde Flawil die Rezertifizierung anzugehen und einen -

6½-Zimmer-Einfamilienhaus 5734 Reinach CHF 745'000.–

6 ½-Zimmer-Einfamilienhaus Stumpenbachstrasse 36 5734 Reinach CHF 745'000.– 1 Eckdaten PLZ / Ort 5734 Reinach Adresse Stumpenbachstrasse 36 ursprüngliches Baujahr 1932 Renovationen ca. 1986: Ersatz der Heizung (inkl. Boiler) ca. 1998: Neuanstrich der Fassade und Spenglerarbeiten ca. 2001: Auffrischung der Böden, Wände und Treppen ca. 2005: Neugestaltung des Dachraums ca. 2013: Teilersatz der Fenster ca. 2015: Teilersatz der Fenster und Malerarbeiten ca. 2017: Erneuerung Küche Objekt 6½-Zimmer-Einfamilienhaus Stockwerke 3 (exkl. Keller) Nettowohnfläche 180 m2 Kubatur Einfamilienhaus: 755 m3 Schopf: 137 m3 Grundstückfläche 1’185 m2 Bauzone Wohn-/Gewerbezone bis 3 und mehr Geschosse Ausnützungsziffer 0.80 Fenster Kunststofffenster mit Isolierverglasung Wetterschutz Holzfensterläden, rot gestrichen Heizung Grundkonzept: Öl-Zentralheizung Raumheizung: Radiatoren Parkmöglichkeiten zwei Aussenparkplätze Verkaufspreis CHF 745'000.-- Kontaktadresse dh Immobilien Treuhand AG Bahnhofstrasse 5c / Wynenhof 5734 Reinach Denise Hausmann Eidg. dipl. Immobilien-Treuhänderin Tel. 062 737 17 37 Fax. 062 737 17 30 [email protected] d hEckdaten 2 Objektbeschrieb Inmitten des grossen, charmanten Gartens liegt dieses einzigartige Einfamilienhaus. Erbaut im Jah- re 1932 strahlt es noch heute eine zeitlose Anmut aus. Trotz der grünen Umgebung liegt das Haus an zentraler Lage, nur fünf Gehminuten von Einkaufsmöglichkeiten, Schulen und den öffentlichen Verkehrsmitteln entfernt. Zahlreiche Renovationen während der letzten Jahre hielten das Haus in gutem -

Die Kleine Zeitung Für Gontenschwil Und Die Region 10/ 2020

Die kleine Zeitung für Gontenschwil und die Region 10/ 2020 Titelbild: Manuel Metz von green milion dorfheftli.ch facebook.com/dorfheftli instagram.com/dorfheftli GEMEINDE Gemeinde Gontenschwil Aus dem Gemeinderat Gemeindeverwaltung Gontenschwil Liebe Gontenschwiler Turnhallestrasse 623, 5728 Gontenschwil Telefon: 062 767 10 40, Telefax: 062 767 10 41 «Wenn man Entscheidun- E-Mail: [email protected] gen treffen muss, braucht Web: www.gontenschwil.ch man nicht Zeit, sondern Mut». (Unbekannt) Öffnungszeiten Montag 08.00 – 12.00 14.00 – 17.00 Eine Gemeindeversammlung ist eine Versamm- Dienstag 08.00 – 12.00 14.00 – 17.00 lung der stimmberechtigten Bevölkerung einer Mittwoch 08.00 – 12.00 14.00 – 17.00 Gemeinde und damit ein direktdemokratisches Donnerstag 08.00 – 12.00 14.00 – 18.00 politisches Organ. In der Schweiz ist sie ein Teil der Freitag 07.00 – 14.00 durchgehend «schweizerischen direktdemokratischen Kultur». In anderen Ländern, z. B. in Deutschland, kommt Für Termine ausserhalb der ordentlichen Öff- diese kommunale Selbstregierung der Bürger nur nungszeiten wenden Sie sich bitte direkt an die sehr, sehr selten vor. Sie müssen zuerst abstim- zuständige Abteilung. men, ob sie abstimmen können. Impressum Herausgeberin: Dorfheftli AG, Baselgasse 6a, 5734 Reinach, 062 765 60 00, dorfheftli.ch, [email protected] Verlags-/Geschäftsleitung: Heinz Barth Redaktionsleitung: Thomas Moor (tmo.). Redaktoren: Fabienne Hunziker (fhu), Dirk C. Buchser (dcb). Reporter: Peter Siegrist (psi), Debora Mazza (dem), Elsbeth Haefeli (eh), Peter Eichenberger (ei), Silvia Gebhard (sg) Verkaufsleitung: Nicole Schmid (Seetal). Werbeberatung: Janine Murer (Wy- nental), Sylvie Minnig (Region) Erscheinung: Einmal pro Monat, jeweils am zweiten Mittwoch Drucktermin: Erster Mittwoch des Monats, 6.00 Uhr Online: dorfheftli.ch, facebook.com/dorfheftli, instagram.com/dorfheftli WEMF-beglaubigte Gratisauflage 2020: Auflage Dorfheftli Gontenschwil: 1073, Gesamtauflage: 16 964 Abopreise: CHF 50.–/Jahr (inklusive MWST). -

Fladeblatt.Html/16 Oder Kinderfasnacht Familientreff Flawil Kath

PDF AUF DER HOMEPAGE DER GEMEINDEN FlADE BLATT INFORMATIONSBLATT DER GEMEINDEN FLAWIL UND DEGERSHEIM 5. JAHRGANG | AUSGABE 7 | 14. FEBRUAR 2020 MOBILFUNKANLAGEN Ein Stück «Kultur» wird auf den Ein Mobilfunkanbieter will in Flawil auf zwei gemeindeeigenen Grundstücken ein Pausenplatz der Oberstufe gezügelt Mobilfunkantennenprojekt realisieren. Der Gemeinderat erachtet es zurzeit als nicht an- gebracht, gemeindeeigene Grundstücke für Mobilfunkanlagen zur Verfügung zu stellen. ››› SEITE 2 CORONAVIRUS Die Schweiz verfolgt die Situation im Zu- sammenhang mit dem neuen Coronavirus aufmerksam und passt die Massnahmen laufend an. Der Kanton St.Gallen ist auf die Versorgung von Verdachts- und Erkran- kungsfällen vorbereitet. ››› SEITE 7 FLOHMARKTKISTEN Das letzte Flawiler Kioskgebäude wird zum Pausenkiosk auf dem Areal des Oberstufenzentrums. Noch gut eine Woche kann in den Floh- marktkisten der Bibliothek Ludothek De- gersheim nach nicht (mehr) gefragten FLAWIL Ende 2016 wurde der Kiosk an der Ort wieder aufgebaut wird, lohnt sich ein Blick «Worstsellern», aussortierten Büchern und Wilerstrasse 29 im Dorfzentrum von Flawil ge- in die Vergangenheit. Am 19. Januar 1954 er- Spielen gesucht werden. Im letzten Jahr wur- schlossen. Der seither leerstehende Dorfkiosk teilte die Gemeinde Flawil die Baubewilligung den so 1200 Medien und Spiele ausgemus- wäre demnächst abgebrochen worden. Doch für den Kiosk an der Wilerstrasse 29. Betrieben tert. nun wird er zu neuem Leben erweckt. Er wird wurde der Dorfkiosk von Ottilia Böni, die zu- auf das Areal der Oberstufe gezügelt. Dort wird gleich auch Besitzerin des Grundstücks war. Die ››› SEITE 15 er zum neuen alten Pausenkiosk. Der Gemein- Unterlagen, die Silvia Keller in ihrem Archiv zu derat hat zur Erhaltung eines Stücks «Kultur» in Tage förderte, lassen vermuten, dass der Kiosk Flawil einen Nachtragskredit genehmigt. -

Label-Übergabe Vom 17. Februar 2017 an Den Turnverein Niederhelfenschwil

Mit dem Label „Sport -verein -t“ ausgezeichnet Seite 1 von 5 infowilplus.ch Orte Zucikenriet: 20.02.2017 Home Wil / Bronschhofen Uzwil Flawil / Degersheim Ober- / Niederbüren Niederhelfenschwil Zuzwil Oberuzwil / Jonschwil Südthurgau Region Spezial Business Forum Über uns Übergabe des Labels Sport-verein-t, von links: Bruno Schöb, Monique Näf, Ursula Künzle, Philipp Hengartner. Vorstand, von links: Ueli Moser, Monique Näf, Marcel, Allenspach, Ursula Künzle, Thomas Bühler, Marco Künzle, Philipp Hengartner. Mit dem Label „Sport-verein-t“ ausgezeichnet Der TV Niederhelfenschwil ist stolz auf das begehrte Gütesiegel. Ernst Inauen http://www.infowilplus.ch/_iu_write/artikel/2017/KW_8/Niederhelfenschwil/Artikel_ ... 20. 02. 2017 Mit dem Label „Sport -verein -t“ ausgezeichnet Seite 2 von 5 Die Bewerbung des TV Niederhelfenschwil für das Label „Sport-verein-t“ ist von Erfolg gekrönt. An der Hauptversammlung vom 17. Februar wurde die Label- Urkunde offiziell überreicht. Die Turnerinnen und Turner des TV Niederhelfenschwil (TVNH) trafen sich im Landgasthof Adler in Zuckenriet zur 10. Hauptversammlung nach der Fusion zum Gesamtverein. Ein willkommenes Jubiläumsgeschenk bekam der Verein mit der offiziellen Überreichung des Labels „Sport-verein-t“. Das notwendige Dossier reichte der TVNH im vergangenen Jahr ein. Ende September teilte die Kommission „Sport-verein-t“ dem Verein mit, dass dem Turnverein Niederhelfenschwil unter Würdigung seiner Bewerbung das Gütesiegel „Sport- verein-t“ für zwei Jahre erteilt wird. Vereine sind wichtig Bruno Schöb, Geschäftsführer der IG St.Galler Sportverbände übergab vor der Jahresversammlung persönlich das Label der TVNH-Präsidentin Ursula Künzle. „Vereine sind wichtig für die Ursula Künzle, Präsidentin TVNH. Gesellschaft. Ebenso wichtig ist aber auch eine gute Vereinsführung, deren Funktionäre viel Freizeit investieren. -

Fladeblatt.Html/16 Oder

PDF AUF DER HOMEPAGE DER GEMEINDEN BLATT INFORMATIONSBLATTFlA DER GEMEINDEN FLAWIL UNDDE DEGERSHEIM 6. JAHRGANG | AUSGABE 3 | 15. JANUAR 2021 STEUERABSCHLUSS Netzwerk Gesundheit Degersheim Die aktuellen Einnahmen über alle Steuer- arten liegen knapp über dem Budget. Beim Steuereingang der natürlichen Personen wurde das Budget nicht erreicht. ››› SEITE 3 STEUEREINNAHMEN Die Steuereinnahmen der Gemeinde Flawil für 2020 fallen 5,52 Millionen Franken bes- ser aus als budgetiert. Die Abrechnung zeigt ein erfreuliches Total von 35,92 Millionen Franken. 75 Prozent der Steuereinnahmen stammen von Einzelpersonen. ››› SEITE 8 Vertreter der Gesundheitsberufe in Degersheim haben sich zu einem Netzwerk vereint. Leyla Cozzio, Domenica Bischof und Thomas Schneider sind im Vorstand des neuen Vereins. DEGERSHEIM Die in einem Gesundheitsbe- Kreativere Behandlungen ruf tätigen Personen aus Degersheim und der Das «Netzwerk Gesundheit» soll aber nicht nur näheren Umgebung haben sich zum «Netz- dazu dienen, den Klientinnen und Klienten die werk Gesundheit» zusammengeschlossen, um Angebote bekannt zu machen. «Für uns Fachper- SBB-DRITTVERKAUFSSTELLE die vielfältigen Gesundheitsberufe in Degers- sonen ist es sehr wichtig, sämtliche Angebote zu heim besser bekannt zu machen. Damit soll kennen, damit wir eine gesamtheitliche Behand- Ende Dezember 2020 wurde die SBB-Dritt- eine ganzheitlichere therapeutische Behand- lung ins Auge fassen können», sagt die gelernte verkaufsstelle im Migrolino-Shop in Flawil lung erreicht werden. Physiotherapeutin Leyla Cozzio, die in Degers- für immer geschlossen. Seit 17 Jahren stand heim eine Akupunkturpraxis betreibt. «Mit der Jürg Kälin hinter dem SBB-Schalter. Er hat Die therapeutischen Angebote in Degersheim Billette verkauft, Reiserouten herausgesucht sind vielfältig. Sehr vielfältig sogar. Neben den und Fragen beantwortet. Das Netzwerk dient vor allem den allgemein bekannten Ärztezentren und Physio- Patientinnen und Patienten. -

Die Kleine Zeitung Für Dürrenäsch Und Die Region 03/ 2021

Die kleine Zeitung für Dürrenäsch und die Region 03/ 2021 Titelbild: Ein Teil des Teams der Roth Bau & Planungs AG dorfheftli.ch facebook.com/dorfheftli instagram.com/dorfheftli GEMEINDE Gemeinde Dürrenäsch Tankrevisionen Hauswartungen Gemeindeverwaltung Entfeuchtungen Gemeindekanzlei Dürrenäsch Sedelstrasse 1, 5724 Dürrenäsch Grüngutabfuhr Telefon: 062 767 71 11, Telefax: 062 767 71 15 04. und 18. März 2021 Erismann AG E-Mail: [email protected] 5616 Meisterschwanden Tel. 056 667 19 65 www.erismannag.ch Öffnungszeiten Altpapier Kanzlei, Einwohnerkontrolle, SVA-Zweigstelle 23. April 2021 Montag 09.00 – 11.30 14.00 – 17.00 Dienstag 09.00 – 11.30 14.00 – 18.00 Mittwoch 09.00 – 11.30 geschlossen Gemeindeversammlung Gartenbau Unterhalt Donnerstag 09.00 – 11.30 14.00 – 17.00 30. April, 25. Juni und 19. November 2021 Neuanlagen Maurerarbeiten Freitag 09.00 – 11.30 14.00 – 16.00 Steuern Feiertage Erwin Werder Eintrachtweg 24 [email protected] Montag 09.00 – 11.30 14.00 – 17.00 02. und 05. April 2021 079 669 69 03 5615 Fahrwangen www.gartenbau-werder.ch Dienstag 09.00 – 11.30 14.00 – 18.00 Impressum Herausgeberin: Dorfheftli AG, Baselgasse 6a, 5734 Reinach, 062 765 60 00, Spezial Tiefbau dorfheftli.ch, [email protected] Das nächste Dorfheftli erscheint am Verlags-/Geschäftsleitung: Heinz Barth Diamantbohren und Fräsen Redaktionsleitung: Thomas Moor (tmo.). Redaktoren: Fabienne Hunziker Mittwoch (fhu), Debora Mazza (dem), Dirk C. Buchser (dcb), Patrick Tepper (pte). Re- porter: Peter Siegrist (psi), Elsbeth Haefeli (eh), Peter Eichenberger (ei), Silvia Gebhard (sg) 07. April Verkaufsleitung: Nicole Schmid (Seetal). Werbeberatung: Janine Murer (Obe- Gebr. Faes AG res Wynental), Sylvie Minnig (Mittleres Wynental) Redaktionsschluss 062 768 50 20 / [email protected] Erscheinung: einmal monatlich, 1. -

24.11.2016 St. Galler Tagblatt

Datum: 24.11.2016 Hauptausgabe St. Galler Tagblatt Medienart: Print Themen-Nr.: 715.004 9001 St. Gallen Medientyp: Tages- und Wochenpresse Abo-Nr.: 3003972 071 227 69 00 Auflage: 25'272 Seite: 19 www.tagblatt.ch Erscheinungsweise: 6x wöchentlich Fläche: 118'844 mm² SteuerfüsseSteuerfüsse 20152015 20162018 2017.2017* StSt. Gallen Gallen 144 144144 144 WittenbachWittenbach Häggenschwil = Muolen 142 142142 - Müden Mörschwil 87 82 Steinach Tübach GoldachGoldach 111 107 - I Goldach SteinachSteinach 124 119119 HäggenschwilHäggensch Rorschach RheineckRheineck Berg 128 Niederhelfenschwil Berg Rorschach Thal 128128 - Tübach 90 85 - St.St MargrethenMargrethen Untereggen 140 134134 - örschwilRo ch Zuzwil WaldkirchWaldkirch chacherberg 11.416 10814242 Niederbüren . Unteregge,ntereg EFcrhsra'cetherbergRuschachef berg 111111. 101k Wi Rorschach 149 149149 - OberbürenOberburen Andwil St.GallenSt. G Eggersriet BerneckBerneck - ThaiThal 114 114 GUser:4dGaiserwü -Au Rheineck 139 134 Goss au Oberuzwilberuzwil wich.. St.St Margrethen Margrethen 135 132132 - Balgach - Widnau Rebsteinin Au-Heerbrugg 95 95 Beineck 92 92 LütisburgLMsburg Markachch Balgach 85925 80 - , Altstätten Diepoldsau 92 Butschwd-Litschwil- - DegershelmDegersheim WidnauWidnau 103 98 - Gantersetwa antersc Rheintal DiepoldsauDiepoldsau Rebsteinstein 119 119119 - Eichberg- Marbach 1,40,..,..140 Obe schwil Eichberg- Altstätten 151 148145- Eichberg 146 139139 - NeckertalKeckertet OberrietOberriet 135135 133133 - Lichtensteleeig Oberriet Oberriet Rüthi 143 139139 - Toggenburgoggenburg SennwaldSennwald -

Der Neue Anzeiger Von Kulm Für Unterkulm Und Die Region 06/ 2021

Der neue Anzeiger von Kulm für Unterkulm und die Region 06/ 2021 Titelbild: Musikgesellschaft: Proben während Corona dorfheftli.ch facebook.com/dorfheftli instagram.com/dorfheftli GEMEINDE Gemeindeverwaltung Gemeindeverwaltung Unterkulm Hauptstrasse 22 Grüngutabfuhr Postfach 115 15. und 29. Juni 2021 5726 Unterkulm Telefon: 062 768 82 40 Telefax: 062 768 82 42 Papiersammlung E-Mail: [email protected] 17. Juni 2021 Web: www.unterkulm.ch Tankrevisionen Hauswartungen Entfeuchtungen Öffnungszeiten Gemeindeversammlung Montag 08.30 – 11.30 14.00 – 17.00 10. Juni und 25. November 2021 Dienstag 08.30 – 11.30 14.00 – 17.00 Mittwoch 08.30 – 11.30 geschlossen Erismann AG Donnerstag 08.30 – 11.30 14.00 – 18.00 Feiertage 5616 Meisterschwanden 01. August 2021 Tel. 056 667 19 65 Freitag 07.00 – 14.00 durchgehend www.erismannag.ch 1995 | 2020 Impressum Haben Sie einen Herausgeberin: Dorfheftli AG, Baselgasse 6a, 5734 Reinach, 062 765 60 00, Haben Sie einen dorfheftli.ch, [email protected] HabenDefektSiemitmiteinenIhrIhremem Verlags-/Geschäftsleitung: Heinz Barth DefektVelo, Mofa, Rollermit, RollatorIhr, Rollstuhl,em Redaktionsleitung: Thomas Moor (tmo.). Redaktoren: Fabienne Hunziker Kinderwagen,Velo, Mofa, RollerKarrette, Rollatorusw...?, Rollstuhl, Kaufen oder lieber Mieten? (fhu), Cornelia Suter (csu), Dirk C. Buchser (dcb), Patrick Tepper (pte). Re- Offen porter: Peter Siegrist (psi), Elsbeth Haefeli (eh), Peter Eichenberger (ei), Silvia VeKinderwagen,lo, Mofa, Roller,KarrRollatorette, Rollstuhl,usw...? Top Neubau-Wohnungen Kinderwagen, Karrette usw...? fen Offen Gebhard (sg) Wir reparieren es, egal wo gekauft!Of Verkaufsleitung: Nicole Schmid (Seetal). Werbeberatung: Janine Murer (Obe- WirWirrereparierparieren es,enegales, woegalgekauft!wo gekauft! res Wynental), Sylvie Minnig (Mittleres Wynental) Erscheinung: einmal monatlich, 1. Mittwoch des Monats Redaktionsschluss: Freitag vor Erscheinung, 12.00 Uhr Gesamtauflage: 23 730.