Identification of Failure Precursor Parameters for Insulated Gate Bipolar Transistors (Igbts)

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Failure Precursors for Insulated Gate Bipolar Transistors (Igbts) Nishad Patil1, Diganta Das1, Kai Goebel2 and Michael Pecht1

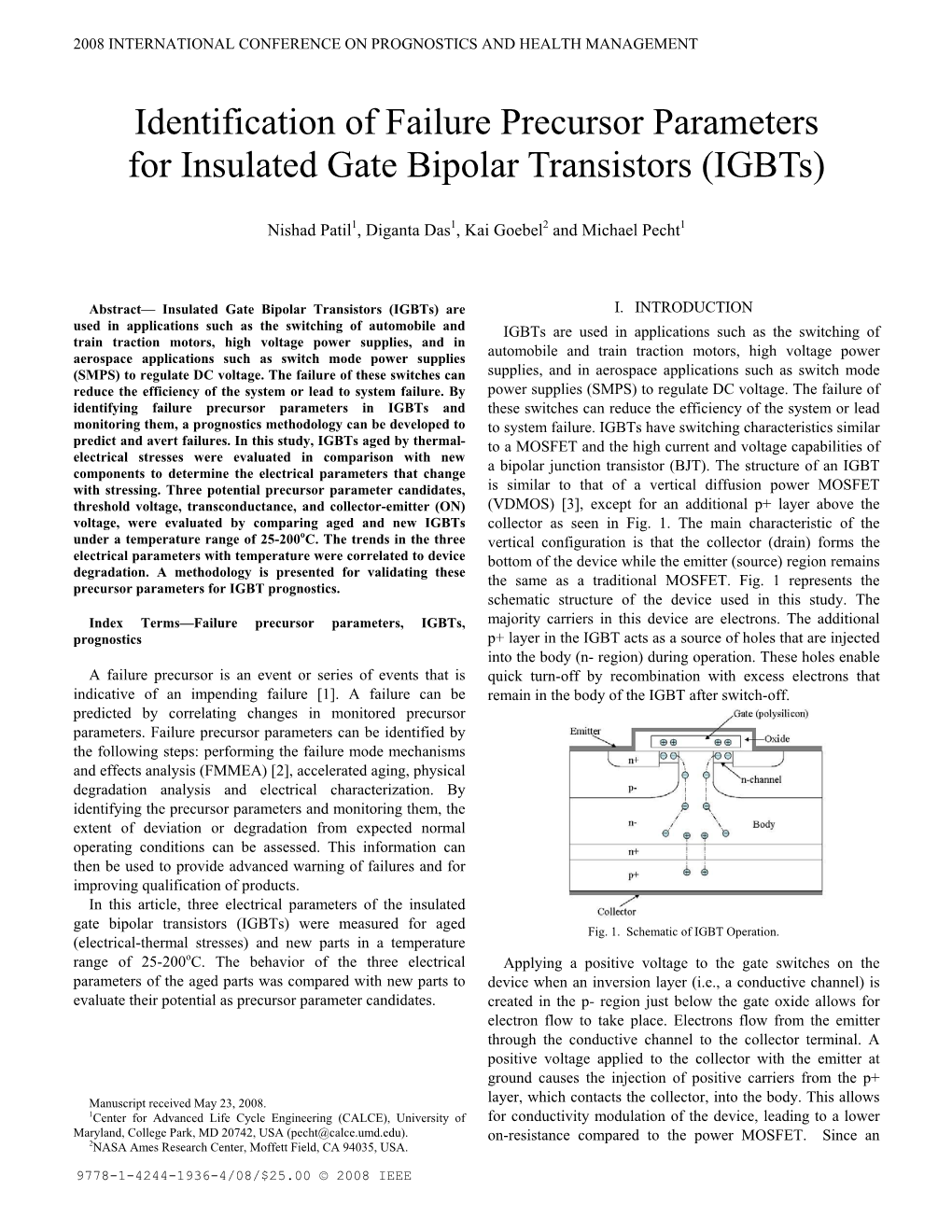

Failure Precursors for Insulated Gate Bipolar Transistors (IGBTs) 1 1 2 1 Nishad Patil , Diganta Das , Kai Goebel and Michael Pecht 1Center for Advanced Life Cycle Engineering (CALCE) University of Maryland College Park, MD 20742, USA 2NASA Ames Research Center Moffett Field, CA 94035, USA Abstract Failure precursors indicate changes in a measured variable that can be associated with impending failure. By identifying precursors to failure and by monitoring them, system failures can be predicted and actions can be taken to mitigate their effects. In this study, three potential failure precursor candidates, threshold voltage, transconductance, and collector-emitter ON voltage, are evaluated for insulated gate bipolar transistors (IGBTs). Based on the failure causes determined by the failure modes, mechanisms and effects analysis (FMMEA), IGBTs are aged using electrical-thermal stresses. The three failure precursor candidates of aged IGBTs are compared with new IGBTs under a temperature range of 25-200oC. The trends in the three electrical parameters with changes in temperature are correlated to device degradation. A methodology is presented for validating these precursors for IGBT prognostics using a hybrid approach. Keywords: Failure precursors, IGBTs, prognostics Failure precursors indicate changes in a measured variable structure of an IGBT is similar to that of a vertical that can be associated with impending failure [1]. A diffusion power MOSFET (VDMOS) [3] except for an systematic method for failure precursor selection is additional p+ layer above the collector as seen in Figure 1. through the use of the failure modes, mechanisms, and The main characteristic of the vertical configuration is that effects analysis (FMMEA) [2]. -

MOSFET - Wikipedia, the Free Encyclopedia

MOSFET - Wikipedia, the free encyclopedia http://en.wikipedia.org/wiki/MOSFET MOSFET From Wikipedia, the free encyclopedia The metal-oxide-semiconductor field-effect transistor (MOSFET, MOS-FET, or MOS FET), is by far the most common field-effect transistor in both digital and analog circuits. The MOSFET is composed of a channel of n-type or p-type semiconductor material (see article on semiconductor devices), and is accordingly called an NMOSFET or a PMOSFET (also commonly nMOSFET, pMOSFET, NMOS FET, PMOS FET, nMOS FET, pMOS FET). The 'metal' in the name (for transistors upto the 65 nanometer technology node) is an anachronism from early chips in which the gates were metal; They use polysilicon gates. IGFET is a related, more general term meaning insulated-gate field-effect transistor, and is almost synonymous with "MOSFET", though it can refer to FETs with a gate insulator that is not oxide. Some prefer to use "IGFET" when referring to devices with polysilicon gates, but most still call them MOSFETs. With the new generation of high-k technology that Intel and IBM have announced [1] (http://www.intel.com/technology/silicon/45nm_technology.htm) , metal gates in conjunction with the a high-k dielectric material replacing the silicon dioxide are making a comeback replacing the polysilicon. Usually the semiconductor of choice is silicon, but some chip manufacturers, most notably IBM, have begun to use a mixture of silicon and germanium (SiGe) in MOSFET channels. Unfortunately, many semiconductors with better electrical properties than silicon, such as gallium arsenide, do not form good gate oxides and thus are not suitable for MOSFETs. -

AN5252 Low-Voltage Power MOSFET Switching Behavior And

AN5252 Application note Low-voltage Power MOSFET switching behavior and performance evaluation in motor control application topologies Introduction During the last years, some applications based on electrical power conversion are gaining more and more space in the civil and industrial fields. The constant development of microprocessors and the improvement of modulation techniques, which are useful for the control of power devices, have led to a more accurate control of the converted power as well as of the power dissipation, thus increasing the efficiency of the motor control applications. Nowdays, frequency modulation techniques are used to control the torque and the speed of brushless motors in several high- and low-voltage applications and in different circuit topologies using power switches in different technologies such as MOSFETs and IGBTs. Therefore, the devices have to guarantee the best electrical efficiency and the least possible impact in terms of emissions. The aim of this application note is to provide a description of the most important parameters which are useful for choosing a low- voltage Power MOSFET device for a motor control application. Three different motor control applications and topology cases are deeply analyzed to offer to motor drive designers the guidelines required for an efficient and reliable design when using the MOSFET technology in hard-switch applications: • BLDC motor in a 3-phase inverter topology • DC motor in H-bridge configuration • DC motor in single-switch configuration AN5252 - Rev 1 - November 2018 - By C. Mistretta and F. Scrimizzi www.st.com For further information contact your local STMicroelectronics sales office. AN5252 Control techniques and brushless DC (BLDC) motors 1 Control techniques and brushless DC (BLDC) motors During the last years, servomotors have evolved from mostly brush to brushless type. -

Design, Implementation, Modeling, and Optimization of Next Generation Low-Voltage Power Mosfets

Design, Implementation, Modeling, and Optimization of Next Generation Low-Voltage Power MOSFETs by Abraham Yoo A thesis submitted in conformity with the requirements for the degree of Doctor of Philosophy Department of Materials Science and Engineering University of Toronto © Copyright by Abraham Yoo 2010 Design, Implementation, Modeling, and Optimization of Next Generation Low-Voltage Power MOSFETs Abraham Yoo Doctor of Philosophy Department of Materials Science and Engineering University of Toronto 2010 Abstract In this thesis, next generation low-voltage integrated power semiconductor devices are proposed and analyzed in terms of device structure and layout optimization techniques. Both approaches strive to minimize the power consumption of the output stage in DC-DC converters. In the first part of this thesis, we present a low-voltage CMOS power transistor layout technique, implemented in a 0.25µm, 5 metal layer standard CMOS process. The hybrid waffle (HW) layout was designed to provide an effective trade-off between the width of diagonal source/drain metal and the active device area, allowing more effective optimization between switching and conduction losses. In comparison with conventional layout schemes, the HW layout exhibited a 30% reduction in overall on-resistance with 3.6 times smaller total gate charge for CMOS devices with a current rating of 1A. Integrated DC-DC buck converters using HW output stages were found to have higher efficiencies at switching frequencies beyond multi-MHz. ii In the second part of the thesis, we present a CMOS-compatible lateral superjunction FINFET (SJ-FINFET) on a SOI platform. One drawback associated with low-voltage SJ devices is that the on-resistance is not only strongly dependent on the drift doping concentration but also on the channel resistance as well. -

Fundamentals of MOSFET and IGBT Gate Driver Circuits

Application Report SLUA618A–March 2017–Revised October 2018 Fundamentals of MOSFET and IGBT Gate Driver Circuits Laszlo Balogh ABSTRACT The main purpose of this application report is to demonstrate a systematic approach to design high performance gate drive circuits for high speed switching applications. It is an informative collection of topics offering a “one-stop-shopping” to solve the most common design challenges. Therefore, it should be of interest to power electronics engineers at all levels of experience. The most popular circuit solutions and their performance are analyzed, including the effect of parasitic components, transient and extreme operating conditions. The discussion builds from simple to more complex problems starting with an overview of MOSFET technology and switching operation. Design procedure for ground referenced and high side gate drive circuits, AC coupled and transformer isolated solutions are described in great details. A special section deals with the gate drive requirements of the MOSFETs in synchronous rectifier applications. For more information, see the Overview for MOSFET and IGBT Gate Drivers product page. Several, step-by-step numerical design examples complement the application report. This document is also available in Chinese: MOSFET 和 IGBT 栅极驱动器电路的基本原理 Contents 1 Introduction ................................................................................................................... 2 2 MOSFET Technology ...................................................................................................... -

Insulated Gate Bipolar Transistors (Igbts)

ECE442 Power Semiconductor Devices and Integrated Circuits Insulated Gate Bipolar Transistors (IGBTs) Zheng Yang (ERF 3017, email: [email protected]) Silicon Power Device Status Overview Silicon Power Rectifiers In the case of low voltage (<100V), the silicon P-i-N rectifier has been replaced by the silicon Schottky rectifier. In the case of high voltage (>100V), the silicon P-i-N rectifier continues to dominate but significant improvements are expected. Silicon Power Switches In the case of low voltage (<100V) systems, the silicon bipolar power transistor has been replaced by the silicon power MOSFET. In the case of high voltage (>100V) systems, the silicon bipolar power transistor has been replaced by the silicon IGBT. Power devices from wide-bandgap materials [cited from “H Amano et al, “The 2018 GaN power electronics roadmap”, Journal of Physics D: Applied Physics 51, 163001 (2018)] Background Pros of power MOSFET: (1) It has an excellent low on-state voltage drop due to the low resistance of the drift region (at low and modest voltages). (2) It is a voltage-controlled device and has a very high input impedance in steady-state due to its MOS gate structure. (3) It has a very fast inherent switching speed in comparison to power BJTs, due to the absence of minority carrier injection. (4) It has superior ruggedness and forward biased safe operating area (SOA) when compared to power BJTs. Cons of power MOSFET: Due to its excellent electrical characteristics, it would be desirable to utilize power MOSFET’s for high voltage power electronics applications. Unfortunately, the specific on-resistance of the drift region increases very rapidly with increasing breakdown voltage because of the need to reduce its doping concentration and increase its thickness. -

Power MOSFET Basics by Vrej Barkhordarian, International Rectifier, El Segundo, Ca

Power MOSFET Basics By Vrej Barkhordarian, International Rectifier, El Segundo, Ca. Breakdown Voltage......................................... 5 On-resistance.................................................. 6 Transconductance............................................ 6 Threshold Voltage........................................... 7 Diode Forward Voltage.................................. 7 Power Dissipation........................................... 7 Dynamic Characteristics................................ 8 Gate Charge.................................................... 10 dV/dt Capability............................................... 11 www.irf.com Power MOSFET Basics Vrej Barkhordarian, International Rectifier, El Segundo, Ca. Discrete power MOSFETs Source Field Gate Gate Drain employ semiconductor Contact Oxide Oxide Metallization Contact processing techniques that are similar to those of today's VLSI circuits, although the device geometry, voltage and current n* Drain levels are significantly different n* Source t from the design used in VLSI ox devices. The metal oxide semiconductor field effect p-Substrate transistor (MOSFET) is based on the original field-effect Channel l transistor introduced in the 70s. Figure 1 shows the device schematic, transfer (a) characteristics and device symbol for a MOSFET. The ID invention of the power MOSFET was partly driven by the limitations of bipolar power junction transistors (BJTs) which, until recently, was the device of choice in power electronics applications. 0 0 V V Although it is not possible to T GS define absolutely the operating (b) boundaries of a power device, we will loosely refer to the I power device as any device D that can switch at least 1A. D The bipolar power transistor is a current controlled device. A SB (Channel or Substrate) large base drive current as G high as one-fifth of the collector current is required to S keep the device in the ON (c) state. Figure 1. Power MOSFET (a) Schematic, (b) Transfer Characteristics, (c) Also, higher reverse base drive Device Symbol. -

Analytical Modeling of Device-Circuit Interactions for the Power Insulated Gate Bipolar Transistor (Igbt)*

ANALYTICAL MODELING OF DEVICE-CIRCUIT INTERACTIONS FOR THE POWER INSULATED GATE BIPOLAR TRANSISTOR (IGBT)* ALLEN R. HEFNER, JR. MEMBER, IEEE Semiconductor Electronics Division National Bureau of Standards Gaithersburg, MD 20899 ABSTRACT-The device-circuit interactions of the power Polyslllcon Metal IGBT MOSFET MOSFET cathode source drain Insulated Gate Bipolar Transistor (IGBT) for a series resistor- IGBT yate inductor load, both with and without a snubber, are simulated. An analytical model for the transient operation of the IGBT, Oxide previously developed, is used in conjunction with the load cir- cuit state equations for the simulations. The simulated results are compared with experimental results for all conditions. De- - 10um - 20pm -; "Bipolar base vices with a variety of base lifetimes are studied. For the fastest I 93pm , \ Epitaxial layer devices studied (base lifetime = 0.3 pa), the voltage overshoot i I of the series resistor-inductor load circuit approaches the device i I voltage rating (500 for load inductances greater than 1 pH. 1 V) t For slower devices, though, the voltage overshoot is much less PA Bipolar' emitter j and a larger inductance can therefore be switched without a Subs t r ale i I snubber circuit (e.g., 80 pH for a 7.1-ps device). In this study, IGBT anode the simulations are used to determine the conditions for which the different devices can be switched safely without a snubber Fig.1. A diagram of two of the many thousand diffused cells protection circuit. Simulations are also used to determine the of an n-channel IGBT. required values and ratings for protection circuit components when protection circuits are necessary. -

MOSFET Gate Drive Circuit Application Note

MOSFET Gate Drive Circuit Application Note MOSFET Gate Drive Circuit Description This document describes gate drive circuits for power MOSFETs. © 2017 - 2018 1 2018-07-26 Toshiba Electronic Devices & Storage Corporation MOSFET Gate Drive Circuit Application Note Table of Contents Description ............................................................................................................................................ 1 Table of Contents ................................................................................................................................. 2 1. Driving a MOSFET ........................................................................................................................... 3 1.1. Gate drive vs. base drive.................................................................................................................... 3 1.2. MOSFET characteristics ...................................................................................................................... 3 1.2.1. Gate charge ........................................................................................................................................... 4 1.2.2. Calculating MOSFET gate charge ....................................................................................................... 4 1.2.3. Gate charging mechanism ................................................................................................................... 5 1.3. Gate drive power ................................................................................................................................ -

Power MOSFET Structure and Characteristics Application Note

Power MOSFET Structure and Characteristics Application Note Power MOSFET Structure and Characteristics Description This document explains structures and characteristics of power MOSFETs. © 2017 - 20 18 1 2018-07-26 Toshiba Electronic Devices & Storage Corporation Power MOSFET Structure and Characteristics Application Note Table of Contents Description ............................................................................................................................................ 1 Table of Contents ................................................................................................................................. 2 1. Structures and Characteristics ....................................................................................................... 3 1.1. Structures of Power MOSFETs ........................................................................................................... 3 1.2. Characteristics of Power MOSFETs .................................................................................................... 4 RESTRICTIONS ON PRODUCT USE.................................................................................................... 6 © 2017 - 2018 2 2018-07-26 Toshiba Electronic Devices & Storage Corporation Power MOSFET Structure and Characteristics Application Note 1. Structures and Characteristics Since Power MOSFETs operate principally as majority-carrier devices, they are not affected by minority carriers. This is in contrast to the situation with minority-carrier devices such as bipolar -

Power MOSFET Frequently Asked Questions and Answers Rev

TN00008 Power MOSFET frequently asked questions and answers Rev. 5.0 — 23 June 2020 Technical note Document information Information Content Keywords TrenchMOS generation 3, generation 6, generation 9, avalanche, ruggedness, linear mode, reliability, thermal impedance, EMC, ESD, switching, thermal design Abstract This document provides answers to frequently asked questions regarding automotive MOSFET platforms, devices, functionality and reliability. It is also applicable to non-automotive applications. Nexperia TN00008 Power MOSFET frequently asked questions and answers 1. Introduction This technical note provides several important questions regarding the use of MOSFETs and the platforms required. Although it is focused on automotive applications, the principles can apply to industrial and consumer applications. It strives to provide clear answers to these questions and the reasoning behind the answers. This document is intended for guidance only. Any specific questions from customers should be discussed with Nexperia power MOSFET application engineers. 2. Gate 2.1. Q: Why is the VGS rating of Trench 6 automotive logic level MOSFETs limited to 10 V and can it be increased beyond 10 V? A: The VGS rating of 10 V given to Trench 6 logic level MOSFETs is driven by our <1 ppm failure rate targets and was rated to the best industry practices at the time. The ppm failure figures are not given in any data sheet nor are they part of AEC-Q101 qualification. In other words, two devices can both be qualified to AEC-Q101 and still have different ppm failure rate figures. Methods of defining, characterising and protecting these ratings have improved and there is now a possibility to operate beyond the given rating of 10 V. -

Advancing Silicon Performance Beyond the Capabilities of Discrete

ISSN: 1863-5598 ZKZ 64717 08-10 Electronics in Motion and Conversion August 2010 COVER STORY Advancing Silicon Performance Beyond the Capabilities of Discrete Power MOSFETs Combining NexFETTM MOSFETs with stacked die techniques significantly reduceds parasitic losses The drive for higher efficiency and increased power in smaller form factors is being addressed by advancements in both silicon and packaging technologies. The NexFETTM Power Block combines these two technologies to achieve higher levels of performance, and in half the space versus discrete MOSFETs. This article explains these new technolo- gies and highlights their performance advantages. By Jeff Sherman, Product Marketing Engineer, and Juan Herbsommer, Senior Member of Technical Staff, Texas Instruments End equipment users from servers to base stations are becoming more concerned about efficiency and power loss as well as their impact on annual operating costs. This means that designers must improve effi- ciency throughout the power conversion process. Traditional approach- es to improve efficiency in DC/DC synchronous buck converters include reducing conduction losses in the MOSFETs through lower RDS(ON) devices and lowering switching losses through low-frequency operation. The incremental improvements in RDS(ON) are at a point of diminishing returns and low RDS(ON) devices have large parasitic capacitances that do not facilitate the high-frequency operation required to improve power density. The NexFET Power Block is designed to leverage the NexFET power MOSFET’s significantly lower gate charge and an innovative stacked die packaging approach to achieve dramatic performance improvements. New Power Silicon The major losses that occur within a MOSFET switch in a typical syn- Figure 1: MOSFET structure comparison chronous buck converter consist of switching, conduction, body diode and gate drive losses.