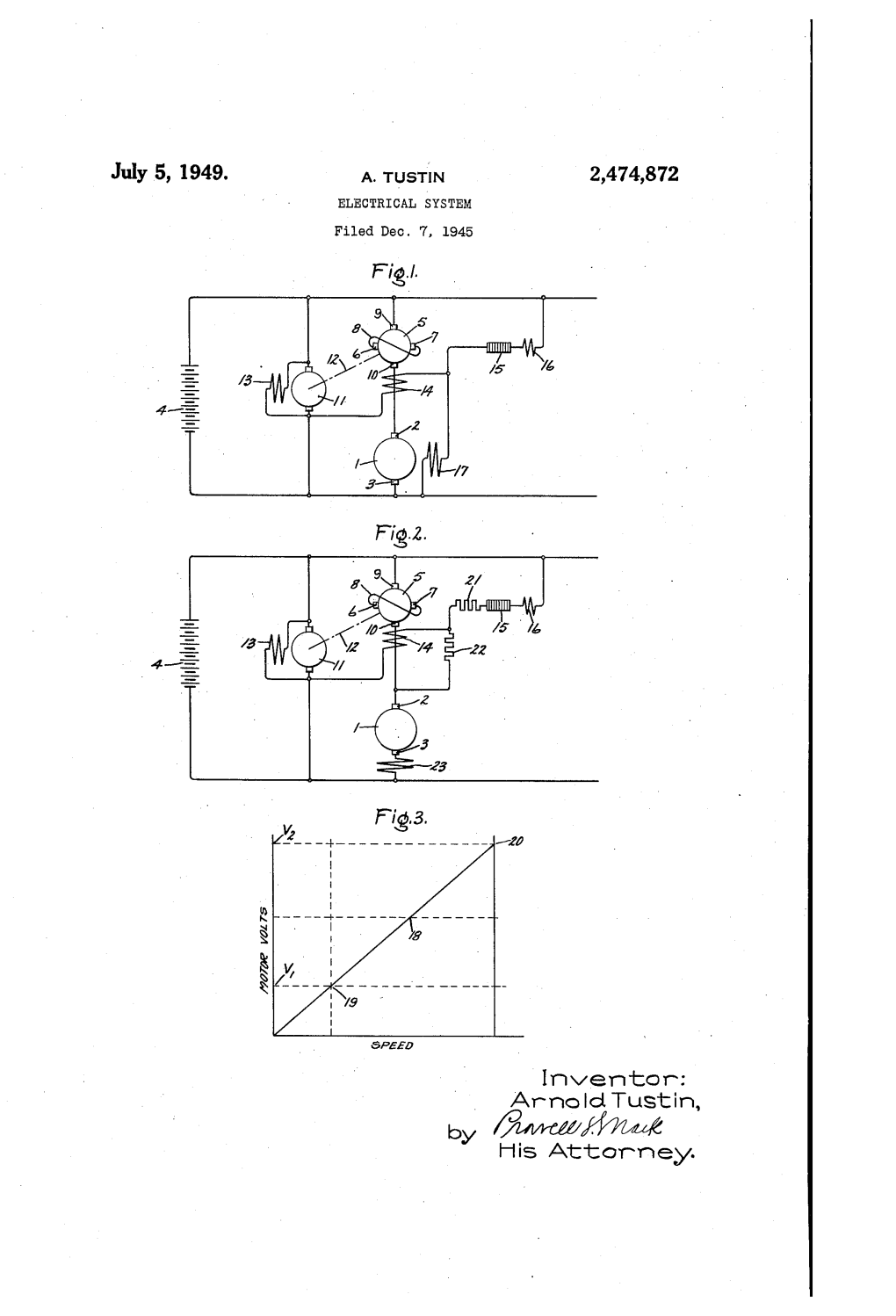

July 5, 1949. A. TUSTIN 2,474,872 ELECTRICAL SYSTEM Filed Dec

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Course Description Bachelor of Technology (Electrical Engineering)

COURSE DESCRIPTION BACHELOR OF TECHNOLOGY (ELECTRICAL ENGINEERING) COLLEGE OF TECHNOLOGY AND ENGINEERING MAHARANA PRATAP UNIVERSITY OF AGRICULTURE AND TECHNOLOGY UDAIPUR (RAJASTHAN) SECOND YEAR (SEMESTER-I) BS 211 (All Branches) MATHEMATICS – III Cr. Hrs. 3 (3 + 0) L T P Credit 3 0 0 Hours 3 0 0 COURSE OUTCOME - CO1: Understand the need of numerical method for solving mathematical equations of various engineering problems., CO2: Provide interpolation techniques which are useful in analyzing the data that is in the form of unknown functionCO3: Discuss numerical integration and differentiation and solving problems which cannot be solved by conventional methods.CO4: Discuss the need of Laplace transform to convert systems from time to frequency domains and to understand application and working of Laplace transformations. UNIT-I Interpolation: Finite differences, various difference operators and theirrelationships, factorial notation. Interpolation with equal intervals;Newton’s forward and backward interpolation formulae, Lagrange’sinterpolation formula for unequal intervals. UNIT-II Gauss forward and backward interpolation formulae, Stirling’s andBessel’s central difference interpolation formulae. Numerical Differentiation: Numerical differentiation based on Newton’sforward and backward, Gauss forward and backward interpolation formulae. UNIT-III Numerical Integration: Numerical integration by Trapezoidal, Simpson’s rule. Numerical Solutions of Ordinary Differential Equations: Picard’s method,Taylor’s series method, Euler’s method, modified -

Power Processing, Part 1. Electric Machinery Analysis

DOCONEIT MORE BD 179 391 SE 029 295,. a 'AUTHOR Hamilton, Howard B. :TITLE Power Processing, Part 1.Electic Machinery Analyiis. ) INSTITUTION Pittsburgh Onii., Pa. SPONS AGENCY National Science Foundation, Washingtcn, PUB DATE 70 GRANT NSF-GY-4138 NOTE 4913.; For related documents, see SE 029 296-298 n EDRS PRICE MF01/PC10 PusiPostage. DESCRIPTORS *College Science; Ciirriculum Develoiment; ElectricityrFlectrOmechanical lechnology: Electronics; *Fagineering.Education; Higher Education;,Instructional'Materials; *Science Courses; Science Curiiculum:.*Science Education; *Science Materials; SCientific Concepts ABSTRACT A This publication was developed as aportion of a two-semester sequence commeicing ateither the sixth cr'seventh term of,the undergraduate program inelectrical engineering at the University of Pittsburgh. The materials of thetwo courses, produced by a ional Science Foundation grant, are concernedwith power convrs systems comprising power electronicdevices, electrouthchanical energy converters, and associated,logic Configurations necessary to cause the system to behave in a prescribed fashion. The emphisis in this portionof the two course sequence (Part 1)is on electric machinery analysis. lechnigues app;icable'to electric machines under dynamicconditions are anallzed. This publication consists of sevenchapters which cW-al with: (1) basic principles: (2) elementary concept of torqueand geherated voltage; (3)tile generalized machine;(4i direct current (7) macrimes; (5) cross field machines;(6),synchronous machines; and polyphase -

Brushless DC Electric Motor

Please read: A personal appeal from Wikipedia author Dr. Sengai Podhuvan We now accept ₹ (INR) Brushless DC electric motor From Wikipedia, the free encyclopedia Jump to: navigation, search A microprocessor-controlled BLDC motor powering a micro remote-controlled airplane. This external rotor motor weighs 5 grams, consumes approximately 11 watts (15 millihorsepower) and produces thrust of more than twice the weight of the plane. Contents [hide] 1 Brushless versus Brushed motor 2 Controller implementations 3 Variations in construction 4 AC and DC power supplies 5 KM rating 6 Kv rating 7 Applications o 7.1 Transport o 7.2 Heating and ventilation o 7.3 Industrial Engineering . 7.3.1 Motion Control Systems . 7.3.2 Positioning and Actuation Systems o 7.4 Stepper motor o 7.5 Model engineering 8 See also 9 References 10 External links Brushless DC motors (BLDC motors, BL motors) also known as electronically commutated motors (ECMs, EC motors) are electric motors powered by direct-current (DC) electricity and having electronic commutation systems, rather than mechanical commutators and brushes. The current-to-torque and frequency-to-speed relationships of BLDC motors are linear. BLDC motors may be described as stepper motors, with fixed permanent magnets and possibly more poles on the rotor than the stator, or reluctance motors. The latter may be without permanent magnets, just poles that are induced on the rotor then pulled into alignment by timed stator windings. However, the term stepper motor tends to be used for motors that are designed specifically to be operated in a mode where they are frequently stopped with the rotor in a defined angular position; this page describes more general BLDC motor principles, though there is overlap. -

London Electricity Companies Had Already Supply Co

printed LONDON AREA POWER SUPPLY A Survey of London’s Electric Lighting and Powerbe Stations By M.A.C. Horne to - not Copyright M.A.C. Horne © 2012 (V3.0) London’s Power Supplies LONDON AREA POWER SUPPLY Background to break up streets and to raise money for electric lighting schemes. Ignoring a small number of experimental schemes that did not Alternatively the Board of Trade could authorise private companies to provide supplies to which the public might subscribe, the first station implement schemes and benefit from wayleave rights. They could that made electricity publicly available was the plant at the Grosvenor either do this by means of 7-year licences, with the support of the Art Gallery in New Bond Street early in 1883. The initial plant was local authority, or by means of a provisional order which required no temporary, provided from a large wooden hut next door, though a local authority consent. In either case the local authority had the right supply was soon made available to local shopkeepers. Demand soon to purchase the company concerned after 21 years (or at 7-year precipitated the building of permanent plant that was complete by intervals thereafter) and to regulate maximum prices. There was no December 1884. The boiler house was on the south side of the power to supply beyond local authority areas or to interconnect intervening passage called Bloomfield Street and was connected with systems. It is importantprinted to note that the act did not prevent the generating plant in the Gallery’s basement by means of an creation of supply companies which could generate and distribute underground passage. -

Unit I – Electric Drives and Traction Part - a 1

UNIT I – ELECTRIC DRIVES AND TRACTION PART - A 1. List the advantages and disadvantages of electric traction. (Nov – 2017/Nov - 2014) Advantages It has great passenger carrying capacity at higher speed. High starting torque. Less maintenance cost. Cheapest method of traction. Disadvantages High capital cost. Problem of supply failure. Additional equipment is required for achieving electric braking and control. 2. Define gear ratio. (Nov - 2017) Gear ratio = (Input Speed)/ (Output Speed) = (Diameter of output gear) / (Diameter of input gear) 3. What are the merits and demerits of DC system of track electrification? (May - 2017) Merits Better torque-speed characteristic. Low maintenance cost. The weight of d.c motor per H.P is less in comparison to a.c motors. Efficient regenerative braking as compared to single phase a.c series motors. De – merits The overall cost is more because of heavy cost of additional substation equipment This system is preferred for suburban services and road transport where there are frequent stops and distance is less. 4. Give the expression for total tractive effort. (Nov- 2016/May – 2014/May 2012) Total tractive effort required to run a train on track = (Tractive effort to produce acceleration + Tractive effort to overcome effect of gravity + Tractive effort to overcome train resistance) FT = Fa + Fg +Fr 5. What are the recent trends in electric traction? (Nov – 2016/Nov -2014/May - 2014) Magnetic levitation, Maglev (Or) Magnetic suspension and Pseudo - Levitation 6. What are the factors governing scheduled speed of a train? (May - 2016) Acceleration and braking retardation Maximum or Crest speed Stopping time or Duration of stop 7. -

Total No. of Printed Pages:03 SUBJECT CODE NO

Total No. of Printed Pages:03 SUBJECT CODE NO: E-19 FACULTY OF ENGINEERING AND TECHNOLOGY B.E.(EEP/EE/EEE) Examination Nov/Dec 2017 High Voltage Engineering (REVISED) [Time: Three Hours] [Max.Marks:80] Please check whether you have got the right question paper. N.B i) Question no. 1 & Question no. 6 are compulsory. ii) Attempt any two questions from remaining questions of each section. iii) Assume suitable data wherever necessary. Section A Q.1 Solve any five 10 a) What is governing equation for the electrical potential V for triangular elements in FEM? b) What is the principle of charge simulation method? c) Why there is need to control electric stress in voltage equipment? d) List out the various methods for estimation of electric field stresses. e) State the application of insulating material in power cables. f) What is difference between insulation and dielectrics? g) What is treeing and tracking? h) State applications of insulating materials. Q.2 a) Explain the procedure to control electric field intensity in HV equipment. 07 b) What is “Finite Element Method”? Give outline of this method for solving field problems. 08 Q.3 a) Describe the current growth phenomenon in a gas subjected to uniform electric fields. 07 b) Explain the experimental set-up for the measurement of pre-breakdown currents in a gas. 08 Q.4 a) Discuss the factors that influence conduction in pure liquid dielectrics and in commercial 07 liquid dielectrics. 2017 881B235DAF4A1CD31D411708CFE2CB0C881B235DAF4A1CD31D411708CFE2CB0C881B235DAF4A1CD31D411708CFE2CB0C881B235DAF4A1CD31D411708CFE2CB0C881B235DAF4A1CD31D411708CFE2CB0C881B235DAF4A1CD31D411708CFE2CB0C881B235DAF4A1CD31D411708CFE2CB0C -

The Design of Linear Servo-Mechanisms Having Prescribed Transient

THE DESIGN OF LINEAR SERVO-MECHANISMS HAVING PRESCRIBED TRANSIENT RESPONSES WITH AN EXPERIMENTAL INVESTIGATION INTO TILE PREDICTION OF TRANSIENT RESPONSE FROM FREQUENCY RESPONSE. PART I . REVIEW OF BASIC THEORY. Page No. Chapter 1. Introduction. 1 2. Transient Analysis of Linear Systems. 7 3. Frequency Analysis of Linear Systems. 25 4. Stability Criteria. 38 5. Criteria of Relative Stability. Design Procedures. 57 PART I I . THE DESIGN OF LINEAR SERVO-MECHANISMS HAVING PRESCRIBED TRANSIEN T RESPONSES. Introduction. 79 A Chapter 6. The Design of ^?(p) Transfer Functions. 80 7. Numerical Work Illustrating the Use of the (A) Design Charts. 107 6i 8. The Design of g(p) Transfer Functions. 122 9. Use of th e 7>tp) Design Charts. Comparison of Qo(p) and* . (P) Methods. 133 &l er ProQuest Number: 13838566 All rights reserved INFORMATION TO ALL USERS The quality of this reproduction is dependent upon the quality of the copy submitted. In the unlikely event that the author did not send a com plete manuscript and there are missing pages, these will be noted. Also, if material had to be removed, a note will indicate the deletion. uest ProQuest 13838566 Published by ProQuest LLC(2019). Copyright of the Dissertation is held by the Author. All rights reserved. This work is protected against unauthorized copying under Title 17, United States C ode Microform Edition © ProQuest LLC. ProQuest LLC. 789 East Eisenhower Parkway P.O. Box 1346 Ann Arbor, Ml 48106- 1346 PART I I I . EXPERIMENTAL INVESTIGATION OF TRANSIENT AND FREQUENCY RESPONSES OF METADYNE SERVO-MECHANISM. Page No. In tro d u ctio n . -

Servomechanisms

RESTRICTED A.P. 3302, PART 1 SECTION 19 CHAPTER 2 SERVOMECHANISMS ParaRraph Introduction 1 Speed Control of a D.C. Motor 6 Action of Human Operator 8 An Improved Method of Speed Control 9 Position Control Systems 14 Behaviour of a Simple Servomechanism 18 Response and Stability of Servomechanisms 20 Viscous Damping 23 Velocity Feedback Damping 26 Velocity Lag 32 Error-rate Damping 35 LJ,e of Stabilizing Networks 39 Transient Velocity Dam ping 42 Integral of Error Compensation 44 Summary of Stabilization Methods 48 Power Requirements of a Servomechanism 49 Components in a Servomechanism 52 Summary .. 55 A.L. 18 (Mar. 62) RESTRICTED RESTRICTED PART 1, SECTION 19, CHAPTER 2 SERVOMECHANISMS Introduction Only an elementary outline of the basic 1. The discovery that heat (from coal or principles involved and a general idea of oil) can be converted into mechanical energy the purpose and applications of control brought about the industrial revolution systems can be attempted in this chapter. and machines which could use this energy t~ Further information is given in Part 3 of produce useful results were quickly invented these notes. and improved. By controlling such machines, man was able to release large quantities 4. Chapter 1 has shown that d.c. remote of energy with very little expenditure of indication and a.c. synchro systems can energy on his own part. operate between shafts separated by a At first, machines were simple and a human considerable distance, but cannot supply being was quite capable of controlling in torque amplification: the torque delivered to detail the various operations that went to the load can never exceed the input torque. -

Feed Drive Design for Numerically Controlled Machine Tools

Scholars' Mine Masters Theses Student Theses and Dissertations 1971 Feed drive design for numerically controlled machine tools Subash Bhatia Follow this and additional works at: https://scholarsmine.mst.edu/masters_theses Part of the Mechanical Engineering Commons Department: Recommended Citation Bhatia, Subash, "Feed drive design for numerically controlled machine tools" (1971). Masters Theses. 5110. https://scholarsmine.mst.edu/masters_theses/5110 This thesis is brought to you by Scholars' Mine, a service of the Missouri S&T Library and Learning Resources. This work is protected by U. S. Copyright Law. Unauthorized use including reproduction for redistribution requires the permission of the copyright holder. For more information, please contact [email protected]. j/1 FEED DRIVE DESIGN FOR NUMERICALLY CONTROLLED MACHINE TOOLS BY SUBASH BHATIA, 1944 A THESIS Presented to the Faculty of the Graduate School of the UNIVERSITY OF MISSOURI - ROLLA in Partial Fulfillment of the Requirements for the Degree of MASTER OF SCIENCE IN MECHANICAL ENGINEERING 1971 T2675 161 pages Approved c.1 20294.0 ii ABSTRACT The various types of feed drive control systems used in numerical control of machine tools have been broadly classified. Further a step by step design has been pre sented for the feed drive of a numerical contouring control milling machine. The aim has been to develop a consistent strategy for tackling a variety of such problems. Conse quently stress has been laid on principles and not on design figures. iii ACKNOWLEDGEMENTS The author wishes to extend his sincere thanks and appreciation to Dr. D.A. Gyorog for the guidance, encourage ment and valuable suggestions throughout the course of this thesis. -

8.1 DC Motor

IV B. Tech I semester (JNTUH-R15) Prepared By Ms. Lekha Chandran, Assistant Professor Unit-1 ELECTRIC DRIVE ELECTRICAL ENERGY It is flexible Easilyavailable Can be converted to other forms of energy. Can be easily transported to required location Economical Mature technology Saves manual labor in industry and domestic applications UTILISATION Electrical energy is used in variousapplications: 1. Electric Drives; DC and ACmotors 2. Electric heating and welding 3. Illumination 4. Electric Traction 5. Electric Vehicles DC MOTOR • The direct current (dc) machine can be used asa motor or as agenerator. • DC Machine is most often used for amotor. • The major advantages of dc machines are theeasy speed and torqueregulation. • However, their application is limited to mills, mines and trains. As examples, trolleys and underground subway cars may use dcmotors. • In the past, automobiles were equipped withdc dynamos to charge theirbatteries. DC MOTOR • Eventoday the starter is a series dc motor • However, the recent development of power electronics has reduced the use of dc motorsand generators. • The electronically controlled ac drives aregradually replacing the dc motor drives infactories. • Nevertheless, a large number of dc motors arestill used by industry and several thousand are sold annually. CONSTRUCTI ON DC MACHINE CONSTRUCTION General arrangement of a dc machine DC MACHINES • Thestator of the dc motor has poles, which are excited by dc current to produce magnetic fields. • Inthe neutral zone, in the middle between the poles,commutating poles are placed to reduce sparking of the commutator. The commutating poles are supplied by dccurrent. • Compensating windings are mounted on the main poles. These short-circuitedwindings damp rotor oscillations. -

1. in an Open Loop Control System (A) Output Is Independent of Control Input

1. In an open loop control system (a) Output is independent of control input (b) Output is dependent on control input (c) Only system parameters have effect on the control output (d) None of the above Ans: d 2. For open control system which of the following statements is incorrect ? (a) Less expensive (b) Recalibration is not required for maintaining the required quality of the output (c) Construction is simple and maintenance easy (d) Errors are caused by disturbances Ans: b 3. A control system in which the control action is somehow dependent on the output is known as (a) Closed loop system (b) Semiclosed loop system (c) Open system (d) None of the above Ans: a 4. In closed loop control system, with positive value of feedback gain the overall gain of the system will (a) decrease (b) increase (c) be unaffected (d) any of the above Ans: b 5. Which of the following is an open loop control system ? (a) Field controlled D.C. motor (b) Ward leonard control (c) Metadyne (d) Stroboscope Ans: a 6. Which of the following statements is not necessarily correct for open control system ? (a) Input command is the sole factor responsible for providing the control action (b) Presence of non-linearities causes malfunctioning (c) Less expensive (d) Generally free from problems of non-linearities Ans: b 7. In open loop system (a) the control action depends on the size of the system (b) the control action depends on system variables (c) the control action depends on the input signal (d) the control action is independent of the output Ans: d 8 has tendency to oscillate. -

Utilization of Electrical Energy and Traction

VI Sem Electrical UTILIZATION OF ELECTRICAL ENERGY AND TRACTION NOTES PREPARED BY LECT. PARTHAVI PADHY SYLLABUS 1. ELECTROLYTIC PROCESS 1.1 Definition and Basic principle of Electro Deposition. 1.2 Important terms regarding electrolysis. 1.3 Faradays Laws of Electrolysis. 1.4 Definitions of current efficiency, Energy efficiency. 1.5 Principle of Electro Deposition. 1.6 Factors affecting the amount of Electro Deposition. 1.7 Factors governing the electro deposition. 1.8 State simple example of extraction of metals. 1.9 Application of Electrolysis. 2. ELECTRICAL HEATING 2.1. Advantages of electrical heating. 2.2. Explain mode of heat transfer and Stephen’s Law. 2.3. Discuss principle of Resistance heating. 2.3.1 Direct Resistance heating. 2.3.2 Indirect Resistance heating. 2.4. Explain working principle of direct arc furnace and indirect arc furnace. 2.5. Principle of Induction heating. 2.6. Working principle of direct core type, vertical core type and indirect core type Induction furnace. 2.7. Principle of coreless induction furnace and skin effect. 2.8. Principle of dielectric heating and its application. 2.9. Principle of Microwave heating and its application. 3. PRINCIPLES OF ARC WELDING 3.1 Explain principle of arc welding. 3.2 Discuss D. C. & A. C. arc phenomena 3.3 D.C. & A. C. arc welding plants of single and multi-operation type. 3.4 Types of arc welding. 3.5 Explain principles of resistance welding. 3.6 Descriptive study of different resistance welding methods. 4. ILLUMINATION 4 . 1 Nature of Radiation and its spectrum. 4 . 2 Terms used in Illuminations.