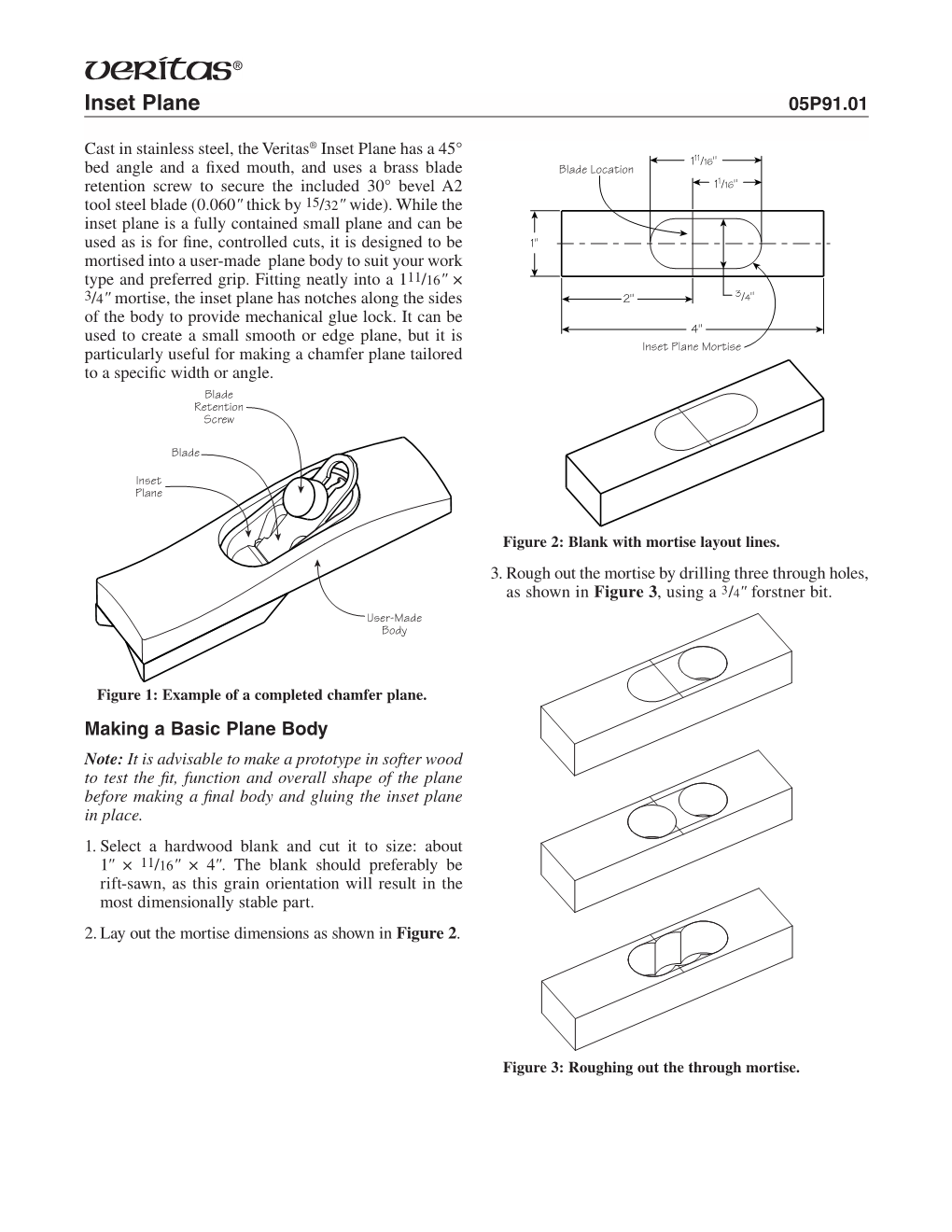

Inset Plane 05P91.01

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Chamfer Plane

Chamfer Plane Christopher Swingley Introduction These plans are for a wooden chamfer plane modelled after the chamfer plane shown in Making Traditional Wooden Planes by John M. Whelan. My plans differ slightly because I used a two piece laminated plane body instead of the single block used by Whelan. My plane iron is a bit wider than his, so my plane body is also slightly larger. Detailed instructions on plane making appear in Whelan’s book and should be consulted as a supplement to these plans. Plans The first set of plans show the body of the plane. Two pegs through the body will strengthen the connection between the halves of the body. Constructing the plane this way is much easier because we can saw and chisel the mortise. 6 3/4" 2 1/2" 2" 1 7/8" 2 7/8" 1 1/4" Left half Left half Right half Interior side Heel Mortise 2 3/4" 2 3/4" 7/8" Heel Toe 1 3/4" 3 7/8" 1 7/8" 1" 3/8" Left half 7/8" Bottom side 1 1/4" 3/8" The following diagrams show the dimensions of the stop that forms the throat in front of the iron. It rests at the front of the mortise in the body, in front of the wedge, and iron. (Insert figure here) Construction Notes *Construction begins by sawing the two halves of the plane body to size. Next, the interior surfaces need * Some images appear at http://www.frontier.iarc.uaf.edu/∼cswingle/woodworking/jigs.phtml 1 Cut List Qty Description T W L Notes 2 Plane body halves 1 1/4 2 3/4 6 3/4 Mortise cut 7/8 inches deep, bottom in- ner edge planed to 45◦. -

An Inquiry Into Worker Skill in Wood Printing Type Manufacture

Michigan Technological University Digital Commons @ Michigan Tech Dissertations, Master's Theses and Master's Dissertations, Master's Theses and Master's Reports - Open Reports 2015 WOOD TYPE ARCHAEOLOGY: AN INQUIRY INTO WORKER SKILL IN WOOD PRINTING TYPE MANUFACTURE Daniel Schneider Michigan Technological University Follow this and additional works at: https://digitalcommons.mtu.edu/etds Part of the History of Art, Architecture, and Archaeology Commons Copyright 2015 Daniel Schneider Recommended Citation Schneider, Daniel, "WOOD TYPE ARCHAEOLOGY: AN INQUIRY INTO WORKER SKILL IN WOOD PRINTING TYPE MANUFACTURE", Master's Thesis, Michigan Technological University, 2015. https://doi.org/10.37099/mtu.dc.etds/1007 Follow this and additional works at: https://digitalcommons.mtu.edu/etds Part of the History of Art, Architecture, and Archaeology Commons WOOD TYPE ARCHAEOLOGY: AN INQUIRY INTO WORKER SKILL IN WOOD PRINTING TYPE MANUFACTURE By Daniel Schneider A THESIS Submitted in partial fulfillment of the requirements for the degree of MASTER OF SCIENCE In Industrial Archaeology MICHIGAN TECHNOLOGICAL UNIVERSITY 2015 © 2015 Daniel Schneider This thesis has been approved in partial fulfillment of the requirements for the Degree of MASTER OF SCIENCE in Industrial Archaeology. Department of Social Sciences Thesis Advisor: Dr. Steven A. Walton Committee Member: Dr. Carl Blair Committee Member: Dr. Scott Marratto Department Chair: Dr. Hugh Gorman Table of Contents Index of Figures ...................................................................................... -

· Arrett Hack

· �ARRETT HACK Photographs by John.S. Sheldon The HANDPLANE Book The HANDPLANE Book GARRETT HACK Photographs by John S. Sheldon TheTauntonrn Press TauntonBOOKS & VIDEOS forfellow enthusiasts © 1999 by The Taunton Press, Inc. All rights reserved. Printed in the United States of America 10 9 8 7 6 5 4 3 2 1 The Handplane Book was originally published in hardcover © 1997 by The Taunton Press, Inc. The Taunton Press, Inc., 63 South Main Street, PO Box 5506, Newtown, CT 06470-5506 e-mail: [email protected] Distributed by Publishers Group West. Library of Congress Cataloging-in-Publication Data Hack, Garrett. The handplane book / Garrett Hack. p. cm. "A Fine woodworking book" - T.p. verso. Includes bibliographical references and index. ISBN 1-56158-155-0 hardcover ISBN 1-56158-317-0 softcover 1. Planes (Hand tools). 2. Woodwork. I. Title. TT186.H33 1997 684'.082 - dc21 97-7943 CIP About Your Safety Working wood is inherently dangerous. Using hand or power tools improperly or ignoring standard safety practices can lead to permanent injury or even death. Don't try to perform operations you learn about here (or elsewhere) unless you're certain they are safe for you. If something about an operation doesn't feel right, don't do it. Look for another way. We want you to enjoy the craft, so please keep safety foremost in your mind whenever you're in the shop. To Helen and Vinny who saw the possibilities, Ned who encouraged me, and Hope who has kept me tuned and planing true ACKNOWLEDGMENTS No one can hope to bring together a book Helen Albert, for her insights and Noel Perrin, for his insights about all like this without help. -

Tool Shed Number 117 June 2001

HED NUMBER 117 ,.i1. ' JUNE 2001 -"''·· .... ♦ ♦ ♦ A Journal of Tool Collecting published by CRAFTS of New Jersey ♦ ♦ ♦ The Belt and Suspenders Plane by Herb Kean ou ask what a belt and suspenders have to do remained: John with a plane? Well, it's a philosophy. I'm sure Veit (who was Yeveryone has heard of the man who wanted to be known for making "completely" sure that his pants would stay up. With some pretty some people that's a way oflife. Now mind you I'm not specialized tools) criticizing. We all have our "ways". But it fits a puzzle experimented with that I'm now going to describe. The puzzle does have to a double escape do with tools, so hang in there. ment, for whatever reason. Maybe it THE PUZZLE: was a special order for a user who had As I was readying planes for the CRAFTS auction, trouble with shav I noticed that one ofthem had a "round-eye" escapement ing clearance. Photo 1. Chamfer plane. Round-eye escapement left-side opening. on one side and a "straight-edge" escapement on the other side! See Photos #1 and #2. We're talking about a I put the single-iron chamfer plane, 1 3/4" wide with an integral plane away fence and stop in the profile. My first reaction was to put for another it back in the "non-ready" box, as I felt it was owner day. Hope modified. Then I looked closer. It was a crisp, homo fully, I geneously patinated JOHN VEIT that was almost would get flawless, and without the slightest sign of modification. -

THIS MONTH's MEETING AUG 22 at the TABLE TENNIS CLUB 1407 E HARRY Back to Basics, the Essentials of Furniture Making Part One

THIS MONTH’S MEETING AUG 22 AT THE TABLE TENNIS CLUB 1407 E HARRY IN THIS ISSUE 1 NEXT MEETING 1 PRESIDENT’S CORNER 2 JULY MINUTES 5 WOODWORKER’S GUILD BYLAWS 9 CLASSIFIEDS a bent lamination, and at least one veneered panel. The rest of the design is at the discretion of the This Month’s Meeting - Galen Cassidy designer. Plan on attending this meeting, as it should provide August’s Program: insight into the design process that we are rarely exposed to. Back to Basics, the Essentials of NOTE: I will outline the series programs in full in Furniture Making the September newsletter. Also, at this month’s meeting, Rickey Powell has Part one: Design graciously agreed to give a short demonstration, Whether you are starting a project from scratch or between Phillip and Bernley’s presentations, of rust from a drawing, every project starts with an idea, a removal using electrolysis. concept, or a need. That is what this first program focuses on: the design of a project. Designers President’s Corner – David Fowler Bernley Asel and Phillip Baumer will host this program with both of them designing a piece of Guild Members, furniture with one of the pieces being chosen for the Back to Basics series. Both designers were given This month, kudos goes to Mike Hutton for his identical guidelines to follow, but were also given a “everything you ever wanted to know about fair amount of latitude in the actual design of the routers” program. Mike, the members and I want project. The guidelines were as follows: the piece you to know that all that effort that you put into this needed to include; at least one frame and panel program was very much appreciated. -

Tool Shed Number 113 September 2000

1 1 HED NUMBER 113 ,..I• SEPTEMBER 2000 ~ .,,.. ..... • • • A Journal of Tool Collecting published by CRAFTS of New Jersey • • • A Visit to the Shelburne Museum by Bill McDougall had never seen a covered bridge until my visit to Vermont in April where we drove across one in the small I town of Sunderland. It was a single lane structure with a prominent sign warning that anyone driving faster than a walk would be assessed a fine of one dollar' Whenever I see a picture of a horse drawn sleigh about to enter a covered bridge 1 want to yell, "Stop! There's no snow in there." 1 saw my second covered bridge, a sturdy two-lane structure with a side footpath, at the entrance to the Shelburne Museum grounds. Essentially a preservation, the museum began its work none too soon. Had its building program not been under way in 1949 when the state decided to replace its last double-lane, covered bridge with a concrete structure, it is certain that this kind of Vermont landmark would have i disappeared entirely. The 168 foot bridge was dismantled and Bill and curator Jean Burks reassembled timber by timber at the museum. Probably One of the first books on tools that I was able to buy because they were fairly dark inside, covered bridges were when I first began collecting is Woodworking Tools at the often referred to as "kissing bridges," but that's another story. Shelburne Museum by Frank H. Wildung, published in 1957, Hank Allen and I walked across the bridge accompanied which documents the collection at that time. -

The Joiner and Cabinet Maker

The Joiner and Cabinet Maker The Joiner and Cabinet Maker His Work And its Principles “Whatever thy hand findeth to do, do it with thy might.” Ecclesiastes ix. 10. ENLARGED EDITION WITH ILLUSTRATIONS by Anon, Christopher Schwarz & Joel Moskowitz First published by Lost Art Press LLC in 2009 26 Greenbriar Ave., Fort Mitchell, KY, 41017, USA Web: http://lostartpress.com Title: The Joiner and Cabinet Maker: His Work and its Principles Authors: Anon, Christopher Schwarz and Joel Moskowitz Editor: Christopher Schwarz Copy editors: Megan Fitzpatrick, Lucy May Cover: Timothy Corbett Special thanks to Jeffrey Peachey for his chapter: “Contextualizing ‘The Joiner and Cabinet Maker’” Copyright: Part 1, all notes in Part 2, and “Epilogue” chapter are Copyright © 2009 by Joel Moskowitz. Part 3 text is Copyright © 2009 by Christopher Schwarz. ISBN: 978-0-578-03926-8 Second printing. ALL RIGHTS RESERVED No part of this book may be reproduced in any form or by any electronic or mechanical means including information storage and retrieval systems without permission in writing from the publisher; except by a reviewer, who may quote brief passages in a review. This book was printed and bound in the United States. Contents Part I: History Introduction • Page 7 • England in 1839 • Page 11 • Part II: The Original Text “The Joiner and Cabinet Maker” • Page 45• 1883 Supplement to “The Joiner and Cabinet Maker” • Page 144 • Part III: Construction Introduction • Page 155 • On the Trade • Page 159 • The Packing Box • Page 171 • The Schoolbox • Page 203 • The Chest of Drawers • Page 261 • Part IV: Further Reading Epilogue • Page 347 • Bibliography • Page 351 • Contextualizing “The Joiner and Cabinet Maker” • Page 357 • Appendix • Page 368 • Acknowledgements esearch, writing, and working in wood are never done well in a Rvacuum. -

Hans Brunner Tool Auctions April 6, 2013

Hans Brunner Tool Auctions April 6, 2013 PO Box 5238, Brassall Qld 4305 www.hansbrunnertools.gil.com.au 0421 234 645 Vol 24 featuring the collection of Dave Mills, Old Time Builder 1 1 Complete half set of 18 even Hollows & Rounds (2-18) by Marples. Also included are two sash planes numbered 1 &2 plus one of the first named OWT routers I’ve come across. No 12 R is a replacement from a different maker. G+ $ 200-400 2 3 3 Unmarked screw stem plough 2 Rare and early 8 ¾” ebony and plane, boxwood and beech with brass mortice gauge with heavy crisp edges and very good stem brass stock, adjustable from both threads. One of the outer nuts is ends i.e. front adjusts the pins, damaged. G $ 50-100 the back moves the fence. No markings but I’m pretty sure Fenton and Marsden held Reg 970 for this tool. Some minor age cracks, overall G/G + $70-140 4 4 17” beech badger plane with 2 ¼” skewed Ward cutter and dovetailed boxwood wear strip to side. Some bruising to handle and minor damage to boxing. No maker’s mark. G+ $ 60-120 Tool Sales 2013 in April, August & December - to subscribe to free catalogues please write or email. The low estimate is the reserve – I accept any amount on or over the reserve. Send in your bids anytime. Deadline is 12.00 noon on auction day. The highest offer wins. If identical bids are received on a lot the first one in is the winner with one dollar added to clear the bid. -

Sept./Oct.198

Sept./Oct.1986 , No . 60, $3.75 Chairs ® UJ11M THIS SIDE OUT N __...._ ZIllHItI Call Us Toll Free! Item Description List Sale FOR THE NAME OF YOUR LOCAL DISTRIBUTOR: In Calilornia • II You Live • II You Live LU72M010 10 x40 Gen. PurposeAT B $ 68.58 39.90 Call Toll Free: In This Area: In This Area $ 1 824-0141 -8CJO. 1-8CJO.824-8045 Call Toll Free LU73M010 10x60 Gen. PurposeAT B 79.95 44.90 (Outside NC) LU81 M0 10 10x 40 Gen. Purpo se TCG 69.30 42.90 1-800-334-4107 LU82M010 10 x 60 Gen. Purpo se TCG 86.50 47.90 LU84M01 1 10 x 50 Co mbinatio n 4 & R 74 .51 44.50 LU85M010 10x80 Fi neCutOff ATB 11 0.88 73.50 �as� LM72M010 10 x24 Rip FlatTop 64.85 44.50 PS203 7% x 24 Gen. Purpo se ATB 27.45 18.99 PS303 7% x 40 Gen. Purpose ATB 32.97 24.99 US Virgin 1 Islands- OS306 6" Dado Max. Width of Cut 716" 146.90 109.50 . - OS308 8" Dado Max. Width ofCut1716" 179.90 119.50 •• • � Puerto Rico NOTE: All Saws= and Dado have %' Bore Hawaii � ATB = Alternate Top Bevel 4&R = 4Teeth&1 Raker Tooth TCG TrlpleChlp Grlnd 218 Feld Ave., High Point, NC 27264 W®JirQ](919) 434-317 1 SALE ENDS 1570 Corporate Dr. , Suite G Costa Mesa, Cal. 92626 DECEMBER 31, 1986 (714) 751·8866 Fine __________ cIw orking September/October 1986 Editor DEPARTMENTS Paul Bertorelli Art Director 4 LeUers Roland Wolf 8 Methods of Work Associllle Editors Wired tambours; grinder misting system; featherboard variation Jim Cummins Roger Holmes 14 Questions & Answers Dick Burrows Laminating curved steps; water-repellent finish; taming Osage-orange David Sloan You could think oj a be 108 wildering variety oj jigs Events and Jixtures Jor the myr Copy Editor iad off-angle cuts in a Nancy-Lou Knapp 112 Chippendale chair, but ac Books Assistllnt Art cording to Gene Landon, Director 114 you're better off without Notes and Comment them_ He explains how to Kathleen Creston Designing for the disabled; Design Book deadline; tenon terms do the job in the article beginning on p_ 38. -

44-Year ATTORNEYS

(No.Model.) J. L.E.E. STOP CHAMFER PLANE, No. 272,274, Patented Feb. 13, 1883. WITNESSEs: INVENTOR --- Maui C.2% Y-12 44-year ATTORNEYS, UNITED STATES PATENT OFFICE. JOSEPH LEE, OF. GARNERVILLE, NEW YORK, ASSIGNOR OF ONE-TEIRD TO RICHARD FISEWICK, OF SAME PLACE. STOP CHAMFER PLANE. SPECIFICATION forming part of Letters Patent No. 272,274, dated February 18, 1888. Application filed August 12, 1882. (No model.) To all whom it may concern: . the plane. The triangular projection K has. Be it known that I, JosEPHIEE, of Gar a Wide upper edge, and the edge of the pro nerville, in the county of Rockland and State jection K is very narrow. The cutting-blade of New York, have invented a new and Im L is placed on the ridges K. K', and is pro 5 proved Stop Chamfer Plane, of which the fol. vided along one edge with a groove, M., 5s lowing is a full clear, and exact description. adapted to receive the upper edge of the ridge The object of my invention is to facilitate K on the guide A. A binding-screw, N, held the cutting of chamfers of all kinds on the on the upper end of an inclined lug, O, above edges of posts, boards, &c. the inclined ridge K, binds and holds the cut to The invention consists in a stop chamfer ting-blade L on the ridges K. K. The guide 6o plate formed of two parallel bevel-guides B is provided at its rear end with a handle, united by adjustahle cross rods, and carrying P, of the usual construction. -

Pencil Gauge PHOTOGRAPHS by THEO COOK THEO by PHOTOGRAPHS 18.2 20.0 18.2

PROJECTS & TECHNIQUES Pencil gauge PHOTOGRAPHS BY THEO COOK 18.2 20.0 18.2 6.0 19.0 M6 cheese head 20mm bolt and nut used to secure pencil in beam Half round indent on upper face 18.2 of stock to match pencil shape 18.2 70.0 250.0 4.5 Ø4.5 30.0 M6 thumbscrew tapped into 4.5mm hole with captive washer between screw end and beam 70.0 50.0 MARKING DIAGRAM First principles The pencil gauge Begin by making the stock. As every face on this component is a potential reference face take the time to make sure that every face One of the best ways to master the art of using hand tools and edge is square and flat. A hefty plane is to use them to make tools of your own. Theo Cook demonstrates and shooting board is my preferred method. If your finished dimensions are slightly less a few tricks of the trade in the making of his bog oak pencil gauge than those in the cutting list don’t fret, flat and square is more important. Having accomplished this, mark out the through hole with 45° corners with a sharp pencil on both faces of the stock. If you have chosen he pencil gauge is often technique and a selection of tools a dark wood use some masking tape to overlooked as being a useful that you can rely on. So, what CUTTING LIST make reading the layout lines easier. When Taddition to the tool kit, but better way to combine these Components size you are happy with the layout use a marking for me, it’s an essential part of my principles than to incorporate Beam: 250 x 18.2 x 18.2mm gauge to define the hole and generate cut layout and marking equipment. -

An Iconography of American Hand Tools

Tools Teach An Iconography of American Hand Tools Hand Tools in History Series Volume 6: Steel- and Toolmaking Strategies and Techniques before 1870 Volume 7: Art of the Edge Tool: The Ferrous Metallurgy of New England Shipsmiths and Toolmakers Volume 8: The Classic Period of American Toolmaking, 1827-1930 Volume 9: An Archaeology of Tools: The Tool Collections of the Davistown Museum Volume 10: Registry of Maine Toolmakers Volume 11: Handbook for Ironmongers: A Glossary of Ferrous Metallurgy Terms: A Voyage through the Labyrinth of Steel- and Toolmaking Strategies and Techniques 2000 BCE to 1950 Volume 13: Tools Teach: An Iconography of American Hand Tools Tools Teach An Iconography of American Hand Tools H. G. Brack Davistown Museum Publication Series Volume 13 © Davistown Museum 2013 ISBN 978-0-9829951-8-1 Copyright © 2013 by H. G. Brack ISBN 13: 978-0-9829951-8-1 ISBN 10: 0982995180 Davistown Museum First Edition; Second Printing Photography by Sett Balise Cover illustration by Sett Balise includes the following tools: Drawshave made by I. Pope, 913108T51 Dowel pointer, 22311T11 Inclinometer level made by Davis Level & Tool Co., 102501T1 Expansion bit patented by L. H. Gibbs, 090508T6 Socket chisel, 121805T6 Bedrock No. 2 smooth plane made by Stanley Tool Company, 100400T2 Molders’ hand tool, 102112T3 Caulking iron made by T. Laughlin Co. of Portland, ME, TCX1005 T-handle wood threading tap, 102212T2 Silversmiths’ hammer head made by Warner & Noble of Middletown, CT, 123012T3 Wire gauge made by Morse Twist Drill & Machine Co. of New Bedford MA, 10910T5 Surface gauge made by Veikko Arne Oby of Whitinsville, MA, 21201T12 No.