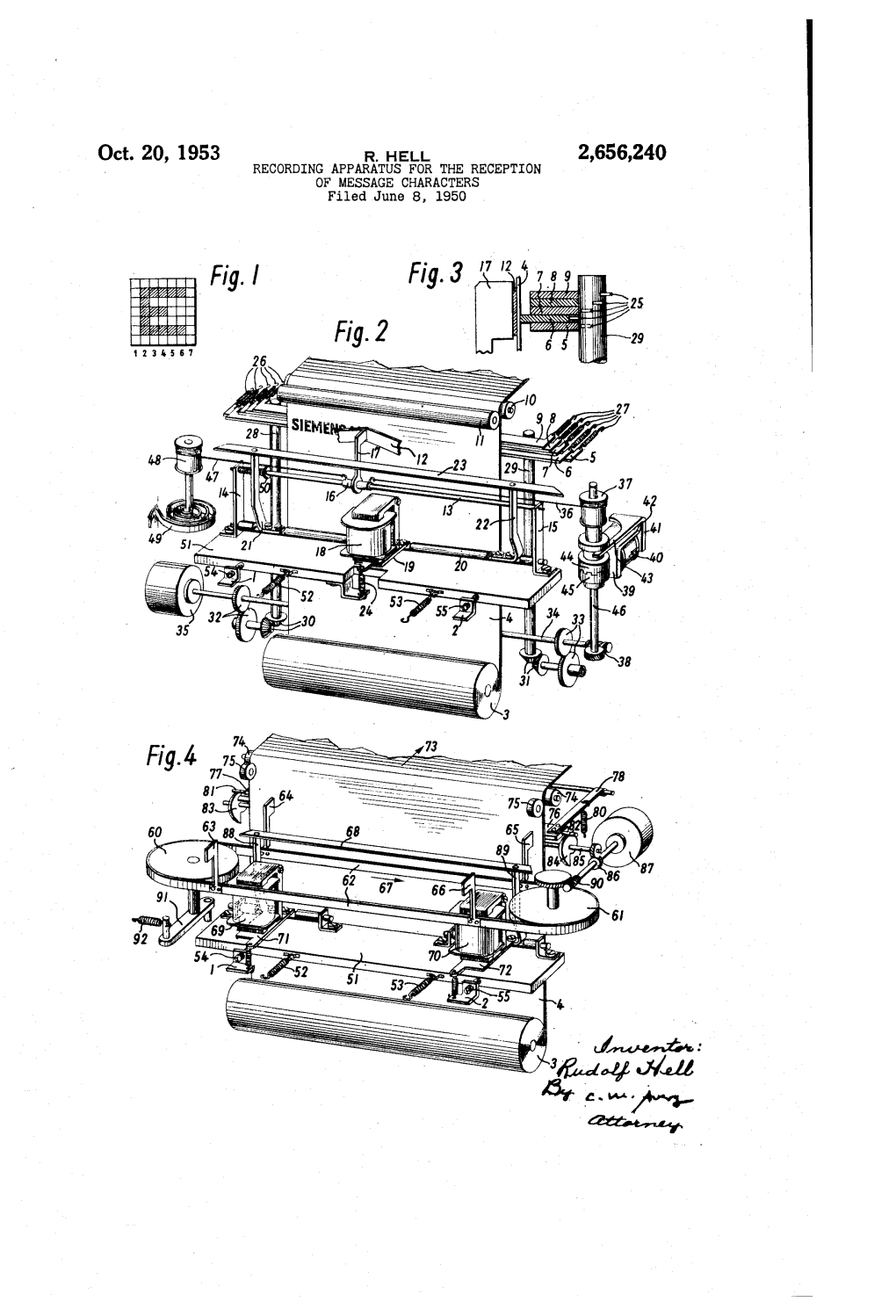

Oct. 20, 1953 R. HELL 2,656,240 RECORDING APPARATUS for the RECEPTION of MESSAGE CHARACTERS Filed June 8, 1950

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Rudolf Hell Zum 100. Geburtstag Hell

„Ich habe nie etwas gemacht nur um Geld zu verdienen. Es ging mir um den Fortschritt und die praktische Anwendung.“ Rudolf Hell Rudolf Hell zum 100. Geburtstag hell Hell Verein / www.hell-kiel.de Im Jahre 2000 konnte die Heidelberger Druckmaschinen AG ihr 150-jähriges Firmenjubiläum feiern. Das Unternehmen, das sich aus den bescheidenen Anfängen einer Schnellpressen- fabrik zum weltweit führenden Anbieter von offenen Lösungen für die Print-Media-Industrie entwickelt hat, wurde im Laufe seiner Geschichte von unterschiedlichen Persönlichkeiten geprägt: Von Dr.-Ing. e.h. Hubert H. A. Sternberg, der mit der konse- Vorwort quenten Konzentration auf die erste vollautomatische Buch- druckmaschine, den Heidelberger Tiegel, den Weg zum größten Druckmaschinenhersteller der Welt vorzeichnete. Von Hugo Brehmer, dem Erfinder der Drahtheftmaschine, der zusammen mit seinem Bruder August in Leipzig eine Buchbindereimaschinen-Fabrik gründete. Leipzig ist auch heute noch einer der Standorte unserer Sparte Druckweiterverar- beitung. Von den Brüdern Alfred und Charles Harris in den USA, die mit der Erfindung eines Anlegers die Druckgeschwindigkeit der damaligen Druckmaschinen verzehnfachen konnten. Aus diesen Anfängen entwickelte sich einer der führenden Hersteller von Rollenoffset-Maschinen, der heute innerhalb der Heidelberg-Gruppe das Solution Center Web vertritt. Von Ottmar Mergenthaler, dem Erfinder der Linotype-Setz- maschine, der die grafische Industrie veränderte, wie rund 560 Jahre zuvor Johannes Gutenberg mit seiner Erfindung der beweglichen Lettern. Und von Dr.-Ing. Rudolf Hell, dessen 100. Geburtstag wir heute feiern dürfen. Diese Festschrift zeigt den Werdegang des Menschen, Ingenieurs und genialen Erfinders Rudolf Hell und die Geschichte des von ihm gegründeten Unternehmens, das wir 1996 als Linotype- Hell AG in die Heidelberg-Familie aufnehmen konnten. -

AWAR Volume 24.Indb

THE AWA REVIEW Volume 24 2011 Published by THE ANTIQUE WIRELESS ASSOCIATION PO Box 421, Bloomfi eld, NY 14469-0421 http://www.antiquewireless.org i Devoted to research and documentation of the history of wireless communications. Antique Wireless Association P.O. Box 421 Bloomfi eld, New York 14469-0421 Founded 1952, Chartered as a non-profi t corporation by the State of New York. http://www.antiquewireless.org THE A.W.A. REVIEW EDITOR Robert P. Murray, Ph.D. Vancouver, BC, Canada ASSOCIATE EDITORS Erich Brueschke, BSEE, MD, KC9ACE David Bart, BA, MBA, KB9YPD FORMER EDITORS Robert M. Morris W2LV, (silent key) William B. Fizette, Ph.D., W2GDB Ludwell A. Sibley, KB2EVN Thomas B. Perera, Ph.D., W1TP Brian C. Belanger, Ph.D. OFFICERS OF THE ANTIQUE WIRELESS ASSOCIATION DIRECTOR: Tom Peterson, Jr. DEPUTY DIRECTOR: Robert Hobday, N2EVG SECRETARY: Dr. William Hopkins, AA2YV TREASURER: Stan Avery, WM3D AWA MUSEUM CURATOR: Bruce Roloson W2BDR 2011 by the Antique Wireless Association ISBN 0-9741994-8-6 Cover image is of Ms. Kathleen Parkin of San Rafael, California, shown as the cover-girl of the Electrical Experimenter, October 1916. She held both a commercial and an amateur license at 16 years of age. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of the copyright owner. Printed in Canada by Friesens Corporation Altona, MB ii Table of Contents Volume 24, 2011 Foreword ....................................................................... iv The History of Japanese Radio (1925 - 1945) Tadanobu Okabe .................................................................1 Henry Clifford - Telegraph Engineer and Artist Bill Burns ...................................................................... -

European Patent Bulletin 1983/51

:s>83/s: Sfotiotft©** Jbrar» 0 096 021 - 0 096 682 0iö^ctneaue ISSN 0170-9305 Europäisches European Bulletin européen Patentblatt Patent Bulletin des brevets Inhalt Contents Sommaire I Veröffentlichte Anmeldungen 2 I Published Applications 3 I Demandes publiées 3 1.1 Geordnet nach der Internationalen 1.1 Arranged in accordance with the 1.1 Classées selon la classification Patentklassifikation 8 International Patent internationale des brevets 8 1.2 Geordnet nach PCT-Veröffent- Classification 8 1.2 Classées selon les numéros de lichungsnummern 87 1.2 Arranged by PCT publication publication PCT 87 1.3 (1) Geordnet nach Veröffentlichungs- number 87 1.3(1) Classées selon les numéros de nummern 88 1-3(1) Arranged by publication publication 88 1.3 (2) Geordnet nach Anmelde- number 88 1.3 (2) Classées selon les numéros des nummern 94 1.3 (2) Arranged by application demandes 94 1.4 Geordnet nach Namen der number 94 1.4 Classées selon les noms des Anmelder 100 1.4 Arranged by name of demandeurs 100 1.5 Geordnet nach benannten applicant 100 1.5 Classées selon les Etats Vertragsstaaten 111 1.5 Arranged by designated contractants désignés 111 1.6 ( 1 ) Nach Erstellung des europäischen Contracting State 111 1.6(1) Documents découverts après Recherchenberichts ermittelte neue 1.6 (1) Documents discovered after comple- l'établissement du rapport de Schriftstücke — tion of the European search recherche européenne — 1.6 (2) Gesonderte Veröffentlichung des report — 1.6 (2) Publication séparée du rapport de europäischen Recherchen- 1.6 (2) Separate publication -

60 Years of Fraunhofer-Gesellschaft

60 YEARS OF FRAUNHOFER-GESELLSCHAFT FOREWORD Ladies and gentlemen, This ensures that government support ends up where it works most effectively – in commercially relevant projects. This mode At Fraunhofer we are used to focusing our sights on the future. of financing provided a powerful impetus to the growth of Not least because applied research is geared toward widening the Fraunhofer-Gesellschaft. The foundation or integration of the scope of opportunities for progress. We measure ourselves many application-related research institutes ultimately made in terms of market success, and therefore need to know what the Fraunhofer-Gesellschaft what it is today. customers will expect from us the day after tomorrow. Focusing on future markets has always been an essential Our future achievements will be derived from the knowledge part of our success. This principle remains unchanged, and is we have gleaned in the past. We therefore intend to make pre cisely the reason why Fraunhofer, after 60 years, is more use of our 60th anniversary as an occasion to look back and dynamic today than ever before. Particularly in the research- review the remarkable history of the Fraunhofer-Gesellschaft. intensive high-tech segment, markets are witnessing an in- At the same time we will be looking ahead, demonstrating the creasing rate of change. Nonetheless, research in the Fraunhofer kind of commitment that enables our staff to keep Fraunhofer Institutes is not only keeping up but in many cases actually forever young. setting the pace. The current technological lead held by many German companies can be attributed in no small measure to The Fraunhofer story – something you realize all too readily Fraunhofer. -

Felix HOFFMANN Herta HEUWER Hans RIEGEL 21

Herta HEUWER Hans RIEGEL Felix HOFFMANN 30. Juni 1913 in Königsberg 21. Januar 1868 in Ludwigsburg 3. April 1893 in Friesdorf neben Bonn (heute heißt die Stadt (Baden – Württemberg) (Nordrhein-Westfalen) Kaliningrad, in Russland) 3. Juli 1999 in Berlin 31. März 1945 in Bonn 8. Februar 1946 in Lausanne (Schweiz) (Land – Stadt – Hauptstadt) (Nordrhein-Westfalen) Verkäuferin im KaDeWe /Trümmerfrau Bonbonkocher Apotheker und Chemiker Freiwillige Mitarbeiterin bei der in der Firma Heinen Berliner Küchenhilfe 1922 : Goldbär (Gummibär) Firma 1897 : Aspirin 1949 : Currywurst Haribo (Hans Riegel Bonn) Melitta BENTZ Manfred VON ARDENNE Adolf RAMBOLD 20. Januar 1907 in Hamburg 31. Januar 1873 in Dresden 5. Oktober 1900 in Stuttgart (freie Hansestadt und Land) (Sachsen) (Baden – Württemberg) 26. Mai 1997 in Dresden 29. Juni 1950 in Porta Westfalica 14. Mai 1996 in Meerbusch (Sachsen) (Nordrhein-Westfalen) (Baden – Württemberg) Elektrophysiker Hausfrau Ingenieur 1933 : Fernseher 1908 : Kaffeefilter 1929 : Teebeutel Rudolf DIESEL Ottomar VON MAYENBURG Rudolf HELL 5. Dezember 1865 in Schönheide 19. Dezember 1901 in Eggmühl 18. März in Paris (Sachsen) (Bayern) (Frankreich) 24. Juli 1932 am Gut Roseneck am 11. März 2002 in Kiel 29. September 1913 im Nordsee Wörthersee (Österreich) (Schleswig-Holstein) Apotheker in Dresden (Sachsen) Ingenieur (Elektrotechnik) Ingenieur 1931 : Hellschreiber (Fax) 1907 : Zahnpasta (Chlorodont) 1890 : Dieselmotor 1963 : Scanner Gottlieb DAIMLER Reinhold BURGER Werner VON SIEMENS 13. Dezember 1916 in Lenthe 17. März 1834 in -

Dr.-Ing.Rudolf Hell

Der Jahrhundert-Ingenieur Rudolf Hell (1901-2002) hat als Erfinder, Konstrukteur und Unternehmer Boris Fuchs und Christian Onnasch wie kein Zweiter die Kommunikationstechnik des 20. Jahrhunderts geprägt. Das betrifft nicht nur das »Graphische Gewerbe«, das er durch die Ent- wicklung geeigneter elektronischer Geräte und Maschinen zur grafischen Industrie wandelte, sondern auch die Möglichkeiten, die er für jeden Dr.-Ing. Rudolf Hell Einzelnen im Alltag schuf. Ohne seine Vorarbeit in der elektronischen Repro- duktionstechnik würden heute Amateurfotografen nicht Der Jahrhundert-Ingenieur ihre Digitalfotos am PC optimieren und Autoren nicht ihre Manuskripte selbst druckreif redigieren können. In der Telekommunikation baute er bereits Kleinfax- im Spiegelbild Geräte, als ihr Massenabsatz noch nicht absehbar war, und mit der ersten Aufnahmeröhre, dem »Sondenrohr«, des Zeitgeschehens schuf er die Grundlage für das Fernsehen. Als Zeitzeuge des gesamten 20. Jahrhunderts verbindet Rudolf Hell Dr.-Ing. sich mit seiner Biografie darüber hinaus ein Stück Sein beispielhaftes Wirken Technik- und Zeitgeschichte, die in dem vorliegenden Buch ausführlich mitbehandelt wird und zum Verständ- nis der heutigen vielfältigen Mittel der Kommunikation und Telekommunikation unerlässlich ist. Die Autoren: BORIS FUCHS, Jahrgang 1933, studierte in den 1950er Jahren Maschinenbau mit dem Schwerpunkt Druck- maschinen und Druckverfahren an der Technischen Hochschule (TU) Darmstadt und war danach über 25 Jahre als Konstrukteur, Entwicklungsleiter und Vor- standsmitglied in der Druckmaschinenindustrie tätig. Ab 1984 wechselte er in das Management eines inter- nationalen Forschungsinstitutes für Zeitungs- und Medientechnik in Darmstadt, von wo er Ende 1998, nach Erreichen des 65. Lebensjahres, in den Ruhestand ging. Seitdem beschäftigt er sich als Fachjournalist ganz besonders mit technikgeschichtlichen Themen. CHRISTIAN ONNASCH, 1938 in Kiel geboren, studierte Elektrotechnik. -

Lebensdaten Und Ehrungen Von Dr. Ing. Rudolf Hell

Archiv Schierling 2001: Lebensdaten und Ehrungen von Dr. -Ing. Rudolf Hell Seite 1 von 3 Lebensdaten und Ehrungen von Dr. Ing. Rudolf Hell 1901 Am 19. Dezember wird Rudolf Hell in Eggmühl (Bayern) geboren. 1919 Studium der Elektrotechnik an der Technischen Hochschule in München 1923 Assistent bei Prof. Dr. Max Dieckmann, München (bis 1929) 1925 Erfindung der "Lichtelektrischen Bildzerlegeröhre" für das Fernsehen 1927 Vorstellung einer Fernsehsende- und empfangsstation (gemeinsam mit Prof. Dr. Dieckmann) auf der Gewerbeausstellung in München Promotion: "Direktanzeigendes Funkpeilgerät für die Luftfahrt" 1929 Gründung des eigenen Unternehmens in Neubabelsberg bei Berlin "Vorrichtung zur elektrischen Übertragung von Schriftzeichen" (Hell-Schreiber) Entstehung der Patenturkunde des Hellschreibers 1931 Entwicklung von neuartigen Morsegeräten Der Hellschreiber wird in großen Stückzahlen bei Siemens produziert. Umzug der Firma nach Berlin-Dahlem 1934 Einsatz des Hell-Schreibers in der Nachrichtenwelt Das Unternehmen wird im Zweiten Weltkrieg völlig zerstört. 1947 Neubeginn in Kiel-Dietrichsdorf 1949 Beginn der Entwicklung der Bildtelegrafie 1950 Entwicklung und Fertigung von Bild-Übertragungsgeräten für Post, Presse, Polizei, Wetterdienste 1951 Erste Versuche mit der Klischee-Graviermaschine "Klischograph" leiten eine Neuorientierung der grafischen Industrie ein. 1954 Einführung des Klischographen in Zeitungsbetrieben Entwicklung des Vario-Klischographen 1956 Hell bringt das Kleinfaxgerät KF 108 auf den Markt. 1958 Auf der Drupa 1958 wird der -

Ing. Rudolf Hell Der Jahrhundert-Ingenieur Im Spiegelbild Des Zeitgeschehens

Boris Fuchs und Christian Onnasch Dr.-Ing. Rudolf Hell Der Jahrhundert-Ingenieur im Spiegelbild des Zeitgeschehens Sein beispielhaftes Wirken 3 Hell Verein / www.hell-kiel.de Inhalt 7 Vorwort von Hermann Zapf 9 Prolog 10 1901–1907: Die Kindheit in Eggmühl 13 Kleine Geschichte der Gemeinde Eggmühl 13 Der Bahnhof Eggmühl 14 Die Bahn-Telegraphie 16 Eggmühls berühmtester Sohn 17 1907–1919: Die Schulzeit in Eger 18 Kleine Geschichte der Stadt Eger 17 Der »internationale« Bahnhof Eger 18 Die Volksschule und das Rudolphinum 19 Die Sprache in Eger war deutsch 22 1919–1929: Die Studienzeit in München 22 Die turbulente Nachkriegs- und Zwischenkriegszeit 25 Die Entstehung der Technischen Hochschule München 26 Die Münchner Schule der Telegraphie 28 Die Bild-Telegraphie 30 Dr. Dieckmanns Begeisterung für die Braun’sche Röhre 31 Unbezahlter Assistent in Dr. Dieckmanns Versuchsanstalt 33 Die Bildzerleger-Röhre für Fernseher 33 Die Frühgeschichte des Fernsehens 36 Die Würdigung durch Walter Bruch 37 Die Fortsetzung durch Manfred von Ardenne 38 Die weitere Entwicklung des Fernsehens 39 Der promovierte Ingenieur Rudolf Hell 41 Die Unternehmensgründung in Berlin 41 Das pulsierende Berlin © 2005 Edition Braus trotz Depression im Wachter Verlag GmbH, Heidelberg 46 Die harten Aufbaujahre in Berlin www.editionbraus.de 46 Der Hellschreiber als Grundstein Satz und Reproduktion: Druck: Wachter GmbH, Bönnigheim 52 Die Enigma-Story Alle Rechte am Text und Bild bei den Autoren 55 Die frühe Parallele ISBN 3-89904-163-1 zu John F. Crosfield 4 Hell Verein / www.hell-kiel.de 56 Nach 1945: 107 Diversifikation Die Wiederaufbaujahre in Kiel in verwandte Gebiete 58 Kleine Geschichte der Stadt Kiel 107 Das Matrizengerät MAT 60 Ein abermals schwieriges Beginnen 108 Patro-Geräte für die Textilindustrie 62 Fuß fassen mit ersten Produkten 109 Das Registat 62 Der Klischograph 110 Die Verschlüsselungsmaschinen brachte den Durchbruch 113 Und noch viel mehr.. -

Rudolf Hell Zum 100. Geburtstag Hell

„Ich habe nie etwas gemacht nur um Geld zu verdienen. Es ging mir um den Fortschritt und die praktische Anwendung.“ Rudolf Hell Rudolf Hell zum 100. Geburtstag hell www.hellschreiber.com Im Jahre 2000 konnte die Heidelberger Druckmaschinen AG ihr 150-jähriges Firmenjubiläum feiern. Das Unternehmen, das sich aus den bescheidenen Anfängen einer Schnellpressen- fabrik zum weltweit führenden Anbieter von offenen Lösungen für die Print-Media-Industrie entwickelt hat, wurde im Laufe seiner Geschichte von unterschiedlichen Persönlichkeiten geprägt: Von Dr.-Ing. e.h. Hubert H. A. Sternberg, der mit der konse- Vorwort quenten Konzentration auf die erste vollautomatische Buch- druckmaschine, den Heidelberger Tiegel, den Weg zum größten Druckmaschinenhersteller der Welt vorzeichnete. Von Hugo Brehmer, dem Erfinder der Drahtheftmaschine, der zusammen mit seinem Bruder August in Leipzig eine Buchbindereimaschinen-Fabrik gründete. Leipzig ist auch heute noch einer der Standorte unserer Sparte Druckweiterverar- beitung. Von den Brüdern Alfred und Charles Harris in den USA, die mit der Erfindung eines Anlegers die Druckgeschwindigkeit der damaligen Druckmaschinen verzehnfachen konnten. Aus diesen Anfängen entwickelte sich einer der führenden Hersteller von Rollenoffset-Maschinen, der heute innerhalb der Heidelberg-Gruppe das Solution Center Web vertritt. Von Ottmar Mergenthaler, dem Erfinder der Linotype-Setz- maschine, der die grafische Industrie veränderte, wie rund 560 Jahre zuvor Johannes Gutenberg mit seiner Erfindung der beweglichen Lettern. Und von Dr.-Ing. Rudolf Hell, dessen 100. Geburtstag wir heute feiern dürfen. Diese Festschrift zeigt den Werdegang des Menschen, Ingenieurs und genialen Erfinders Rudolf Hell und die Geschichte des von ihm gegründeten Unternehmens, das wir 1996 als Linotype- Hell AG in die Heidelberg-Familie aufnehmen konnten. -

The Code Is Not Coloured

The Code is not Coloured Blackboxing Colour, Light, Graphic Arts and Modernity John Henry Martin A thesis in the fulfilment of the requirement of the degree of Master of Design (Honours) undertaken at the School of Design Studies, Faculty of the College of Fine Arts, The University of New South Wales. 2012 ORIGINALITY STATEMENT ‘I hereby declare that this submission is my own work and to the best of my knowledge it contains no materials previously published or written by another person, or substantial proportions of material which have been accepted for the award of any other degree or diploma at UNSW or any other educational institution, except where due acknowledgement is made in the thesis. Any contribution made to the research by others, with whom I have worked at UNSW or elsewhere, is explicitly acknowledged in the thesis. I also declare that the intellectual content of this thesis is the product of my own work, except to the extent that assistance from others in the project's design and conception or in style, presentation and linguistic expression is acknowledged.’ Signed …………………………………………….............. Date ……………………………………………................. COPYRIGHT STATEMENT ‘I hereby grant the University of New South Wales or its agents the right to archive and to make available my thesis or dissertation in whole or part in the University libraries in all forms of media, now or here after known, subject to the provisions of the Copyright Act 1968. I retain all proprietary rights, such as patent rights. I also retain the right to use in future works (such as articles or books) all or part of this thesis or dissertation. -

Rudolf Hell – Der Zweite Gutenberg

1/3 — 01.01.09 © wenke◼net Pioniere Rudolf Hell – der zweite Gutenberg Strahlende Leistungen – und düsteres Vergessen Es gibt Erfindungen. Und es gibt Pioniertaten. Erfindungen folgen der vorgezeichneten Logik verfügbarer Technologien. Ihre Genialität liegt in der kühnen und kreativen Kombination bekannter und gegebener Elemente. Pionierleistungen aber sind Schöpfung pur: sie entstehen, ohne dass sie zwangsläufig auf etwas anderes aufsetzen müssen. Oder aber sind eine kühne Adaption, transferieren Funktionen und Ideen von einem Sach- und Fachgebiet in ein anderes. Gutenberg hat dies getan, als er aus seiner Kenntnis als Goldschmied auf die Idee ge- kommen sein soll, Druck-Lettern zu gießen und damit die Drucksei- tenherstellung in seinem Kulturkreis neu erfand (in Asien war diese Methode schon bekannt, was Gutenberg nicht wusste. Oder doch?). Ander Erfinder sind Entdecker – sie finden, indem sie buchstäblich den Schleier des Unbekannten von etwas entfernen und damit der Welt neue Ein- und Anblicke gewähren. Dr. Ing. Rudolf Hell war so einer. Ein Deutscher, dessen Leistung bis heute weit unter seinem wirklichen und wahren Wert dargestellt wird. Nebst dem Gründungs- vater des industriellen Druckens Gutenberg, dem Buchdruckmaschi- nen-Erfinder Friedrich Koenig und dem Konstrukteur der die Satz- technik revolutionierenden Linotype-Zeilensetzmaschine, Ottmar Mer- genthaler, ist Dr. Ing. Rudolf Hell ein Superheld der Druckindustrie. Vor allem, weil seine Leistungen außerhalb der Druckindustrie fast noch größer sind – und das enorm tragische Schicksal ihn dort mehr- fach scheitern ließ. Was Hell geleistet und wie die deutsche Industrie ihn ignoriert oder nicht verstanden hat, gehört zu den schwärzesten und traurigsten Kapiteln deutscher Industriegeschichte. Dr. Rudolf Hell verstarb am 11. März 2002. -

Feel Free to Download a Pdf of the Index

Title of Article Author Page Volume Year Influence of the Lens Aperture in Screen Work Max Levy 2 I 1895 Vignetting Half-Tone Blocks on Copper Henri Calmels 8 I 1895 Sensitizing Pigment papers for Rotogravure HJ Burton 16 I 1895 Swelled Gelatine A. Dawson 24 I 1895 Photo-Litho and Other Tips Joseph Lewis 39 I 1895 Filter Your Collodion WD Richmond 49 I 1895 An Illustration Note A. Horsley Hinton 56 I 1895 The Silver Bath WT Wilkinson 61 I 1895 Half-Tone (Screen) Blocks: Their Nature and Treatment in Printing Chas. H. Fisher 70 I 1895 The Electric Light Supply for Process Engravers J.R. Garratt 79 I 1895 Photo-Lithography Practically Described Gilbert Ruthven 86 I 1895 Bibliography 98 I 1895 Introductory 1 II 1896 The Correct Screen Distance in Half-Tone Negative Making The Editor 3 II 1896 The Necessity of Fine Etching in Three-Color Work Harry W. Pope 14 II 1896 Collodion Emulsion for Process Work W. B. Bolton 17 II 1896 Permanency of the Half-Tone Screens Max Levy 30 II 1896 A Process for Making Blocks for Letterpress Printing in Half-Tone E. Hamilton Frewing 32 II 1896 Three-Color Process: Its History and Adaptability to Printing Methods Martin Cohn 33 II 1896 Mercurographie, or Photogravure with Quicksilver Jos. Scholefield 35 II 1896 Some Experiences, Et Quibusdam Aliis Duncan C. Dallas 37 II 1896 Applications and Progress of Photo-Mechanical Process in France Leon Vidal 42 II 1896 Process Experiences in Ceylon S. K. Lawton 44 II 1896 The Sensitive Coating for Collotype Plates George Holzhausen and Gerald F.