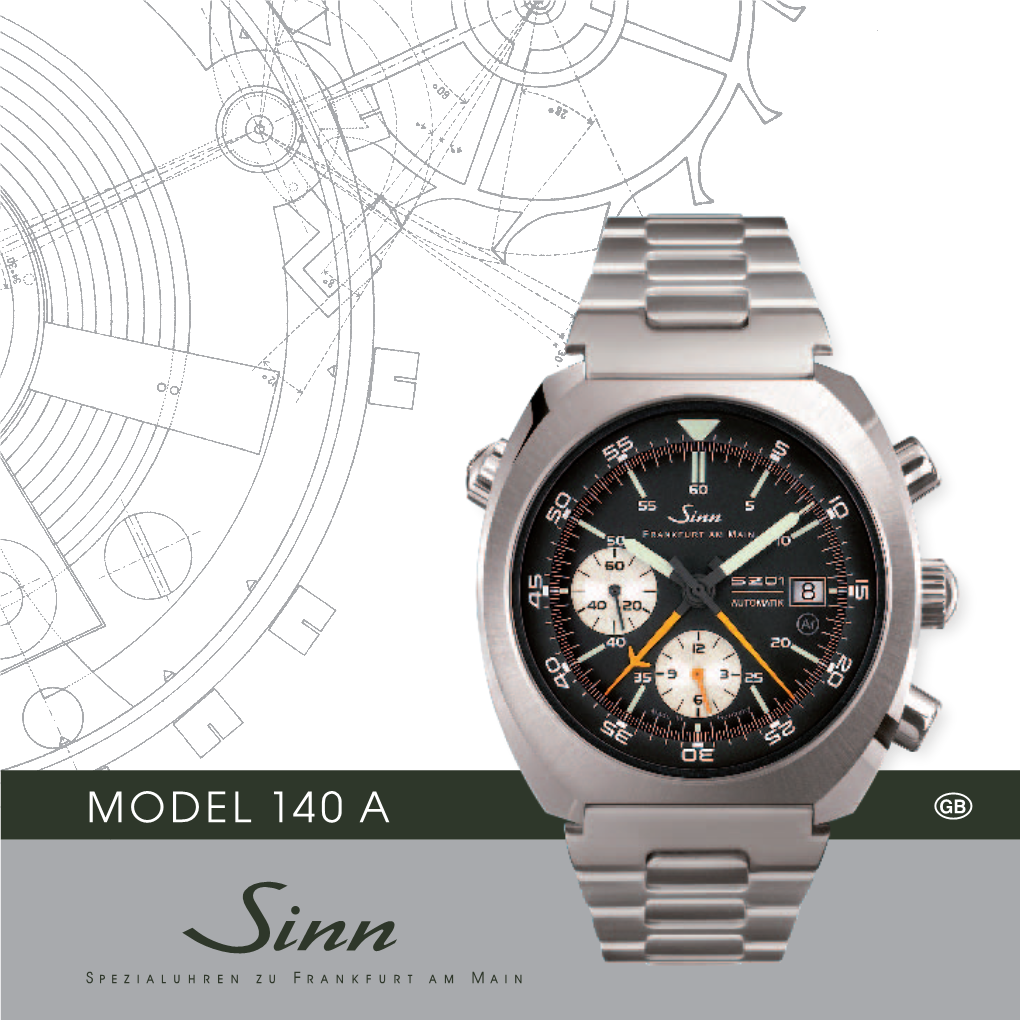

Model 140 a Contents

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Jul/Aug 2013

I NTERNATIONAL J OURNAL OF H IGH -E NERGY P HYSICS CERNCOURIER WELCOME V OLUME 5 3 N UMBER 6 J ULY /A UGUST 2 0 1 3 CERN Courier – digital edition Welcome to the digital edition of the July/August 2013 issue of CERN Courier. This “double issue” provides plenty to read during what is for many people the holiday season. The feature articles illustrate well the breadth of modern IceCube brings particle physics – from the Standard Model, which is still being tested in the analysis of data from Fermilab’s Tevatron, to the tantalizing hints of news from the deep extraterrestrial neutrinos from the IceCube Observatory at the South Pole. A connection of a different kind between space and particle physics emerges in the interview with the astronaut who started his postgraduate life at CERN, while connections between particle physics and everyday life come into focus in the application of particle detectors to the diagnosis of breast cancer. And if this is not enough, take a look at Summer Bookshelf, with its selection of suggestions for more relaxed reading. To sign up to the new issue alert, please visit: http://cerncourier.com/cws/sign-up. To subscribe to the magazine, the e-mail new-issue alert, please visit: http://cerncourier.com/cws/how-to-subscribe. ISOLDE OUTREACH TEVATRON From new magic LHC tourist trail to the rarest of gets off to a LEGACY EDITOR: CHRISTINE SUTTON, CERN elements great start Results continue DIGITAL EDITION CREATED BY JESSE KARJALAINEN/IOP PUBLISHING, UK p6 p43 to excite p17 CERNCOURIER www. -

82: a Context for International Cooperation and Competition (Part

Appendix B NASA's Approach to International Cooperation* Since the space program of United States began, the launched beyond man’s ability to repair easily.2 A National Aeronautics and Space Administration great deal of senior management attention, time and (NASA) has pursued a vigorous and successful’ pro- money is spent making sure that the last 3 to 5 per- gram of international cooperation, grounded in the cent of a project is done correctly. The importance of National Aeronautics and Space Act of 1958.** One this for international projects is that NASA managers possible reason for NASA’s success derives from a key want as much insight into them as they have into a feature of its cooperative efforts: while NASA has in- NASA-only project. This dictates a principle of “keep ternational programs, it does not fund an international it simple” in management and technical interfaces. This program. There is no “international” line item in the means that NASA prefers bilateral relations over proj- NASA budget and no money set aside especially for ects that might involve three or more countries or orga- international programs. Funding for international proj- nizations. ects must come out of the budgets of the NASA pro- The concern with technical and scientific excellence gram offices (essentially science, applications, space also contributes to NASA’s international programs in flight, and aeronautics), The Associate Administrators another fundamental way. From the very beginning of the Program Offices and their managers are rated the principal area of international space cooperation not on how many international projects they have, has been in the sciences. -

And Ba from CERN to Space

CERN Courier July/August 2013 CERN Courier July/August 2013 Interview Interview From CERN to space – and back Forty years after his PhD studies at the ISR, xenon and compare it with numerical simulations. Messerschmid’s student, Felix Huber, worked at CERN for several months but in the former astronaut Ernst Messerschmid end nothing came of the proposal. Back in Stuttgart, Messerschmid continues to teach astronau- returned to CERN to talk about his time in tics and – as in the colloquium at CERn – to spread the word on space and the imperatives for space fl ight. the value of spacefl ight for knowledge and innovation. “We fl y a mission,” he says, “and afterwards, as professors, we become ‘missionaries’ – ambassadors for science and innovation.” His “mission statement” for spacefl ight has much in common with that Ernst Messerschmid fi rst arrived at CERN as a summer student in of CERN, with three imperatives: to explore – the cultural impera- 1970, in the midst of preparations for the start up of the Intersect- tive; to understand – the scientifi c imperative; and to unify – the ing Storage Rings (ISR). The studies that he did on beam pick-ups political imperative. While the scientifi c imperative is probably in this ground-breaking particle collider formed the topic of his self-evident, the cultural imperative recognizes the human desire diploma thesis – but he was soon back at the laboratory as a fellow, Ernst Messerschmid in the European Spacelab module on which he fl ew, to learn and the need to inspire the next generation, and the politi- sharing in the excitement of seeing injection of the fi rst beams on which is now at EADS, Bremen. -

Mr. Jochen Noll University of Stuttgart, Germany, [email protected]

61st International Astronautical Congress 2010 Paper ID: 7730 SPACE EDUCATION AND OUTREACH SYMPOSIUM (E1) TO BOLDLY GO - SPACE STATION EDUCATION AND OUTREACH (5) Author: Mr. Jochen Noll University of Stuttgart, Germany, [email protected] Dr. Stefan Belz University of Stuttgart, Germany, [email protected] Mr. Manuel Schmitz Germany, [email protected] Prof. Ernst Messerschmid University of Stuttgart, Germany, [email protected] EDUCATIONAL TRAINING ON SPACECRAFT OPERATIONS IN A SOYUZ MOCK-UP SIMULATOR Abstract The Institute for Space System (IRS) at the University of Stuttgart is offering hands-on experience for students in the field of aerospace engineering with tutorial and training in a space flight simulator. In addition to the theoretical knowledge given in lectures the students can gain practical experience and develop a better understanding of spacecraft operations in a simulated space environment. Furthermore, the intrinsic motivation of students is activated by individual flight lessons in a mock-up model emulating a Soyuz-TMA spacecraft. The training comprises of theoretical lessons followed by intensive practical sessions guided by an instructor, supplemented with free training hours for each trainee. The candidates are introduced with basic manoeuvres at the beginning of the course up to complex mission scenarios toward the end of the course. The training performance of each candidate is monitored and evaluated to provide a progress feedback in a final debriefing session. The initial software, purchased from the Gagarin Cosmonaut Training Centre in 2007, was used for the training of rendezvous and docking operations be- tween the Soyuz spacecraft and the International Space Station. -

Appendix Program Managers/Acknowledgments

Flight Information Appendix Program Managers/Acknowledgments Selected Readings Acronyms Contributors’ Biographies Index Image of a Legac y—The Final Re-entry Appendix 517 Flight Information Approx. Orbiter Enterprise STS Flight No. Orbiter Crew Launch Mission Approach and Landing Test Flights and Crew Patch Name Members Date Days 1 Columbia John Young (Cdr) 4/12/1981 2 Robert Crippen (Plt) Captive-Active Flights— High-speed taxi tests that proved the Shuttle Carrier Aircraft, mated to Enterprise, could steer and brake with the Orbiter perched 2 Columbia Joe Engle (Cdr) 11/12/1981 2 on top of the airframe. These fights featured two-man crews. Richard Truly (Plt) Captive-Active Crew Test Mission Flight No. Members Date Length 1 Fred Haise (Cdr) 6/18/1977 55 min 46 s Gordon Fullerton (Plt) 2 Joseph Engle (Cdr) 6/28/1977 62 min 0 s 3 Columbia Jack Lousma (Cdr) 3/22/1982 8 Richard Truly (Plt) Gordon Fullerton (Plt) 3 Fred Haise (Cdr) 7/26/1977 59 min 53 s Gordon Fullerton (Plt) Free Flights— Flights during which Enterprise separated from the Shuttle Carrier Aircraft and landed at the hands of a two-man crew. 4 Columbia Thomas Mattingly (Cdr) 6/27/1982 7 Free Flight No. Crew Test Mission Henry Hartsfield (Plt) Members Date Length 1 Fred Haise (Cdr) 8/12/1977 5 min 21 s Gordon Fullerton (Plt) 5 Columbia Vance Brand (Cdr) 11/11/1982 5 2 Joseph Engle (Cdr) 9/13/1977 5 min 28 s Robert Overmyer (Plt) Richard Truly (Plt) William Lenoir (MS) 3 Fred Haise (Cdr) 9/23/1977 5 min 34 s Joseph Allen (MS) Gordon Fullerton (Plt) 4 Joseph Engle (Cdr) 10/12/1977 2 min 34 s Richard Truly (Plt) 5 Fred Haise (Cdr) 10/26/1977 2 min 1 s 6 Challenger Paul Weitz (Cdr) 4/4/1983 5 Gordon Fullerton (Plt) Karol Bobko (Plt) Story Musgrave (MS) Donald Peterson (MS) The Space Shuttle Numbering System The first nine Space Shuttle flights were numbered in sequence from STS -1 to STS-9. -

Newsletter 1 Fakultaet

Universität Stuttgart Fakultät Luft- und Raumfahrttechnik und Geodäsie newsletter 01 01 - 2014 news Sonderforschungsbereich geht in die zweite Runde Zum Anfang des Jahres 2014 ist der Sonderforschungsbereich Transregio 75 "Tropfendynami- sche Prozesse unter extremen Umgebungsbedingungen" in seine zweite Förderperiode gestar- tet. In diesem 2010 eingerichteten SFB arbeiten rund 60 Mitarbeiter an den Standorten Stuttgart, Darmstadt sowie dem DLR Lampoldshausen mit. Im Rahmen der Verlängerung wurden drei zusätzliche Teilprojekte, eines davon an der Universität Stuttgart, in den Forschungsverbund auf- genommen. Am Standort Stuttgart sind das VISUS (Prof. Ertl), das IAG (Prof. Munz), das IANS (Prof. Rohde), das ITT (Prof. Groß), das ITV (Prof. Kronenburg) sowie das ITLR (Prof. Weigand) beteiligt. Tropfen spielen in vielen Bereichen der Natur und der Technik eine zentrale Rolle. Beispiele aus der Natur sind Regen, Wolken oder Nebel. Im Hinblick auf technische Prozesse ist die Verdampfung von Tropfen in Kraftstoffsprays bei der Verbrennung in Kraftfahrzeugmotoren oder Flugtriebwerken zu nen- nen. Viele dieser Prozesse laufen unter extremen Umgebungsbedingungen ab, z. B. hohem Druck, extremen Temperaturen oder in starken elektrischen Feldern. Im Rahmen des Sonderforschungsbereichs versuchen die Wissenschaftler, ein vertieftes phy- sikalisches Verständnis derartiger Vorgänge zu ge- winnen. Dieses ist entscheidend für die Voraussage natürlicher Prozesse sowie die Optimierung techni- scher Systeme. Eine weitere Herausforderung des Forschungsgebietes -

Space Resources : Social Concerns / Editors, Mary Fae Mckay, David S

Frontispiece Advanced Lunar Base In this panorama of an advanced lunar base, the main habitation modules in the background to the right are shown being covered by lunar soil for radiation protection. The modules on the far right are reactors in which lunar soil is being processed to provide oxygen. Each reactor is heated by a solar mirror. The vehicle near them is collecting liquid oxygen from the reactor complex and will transport it to the launch pad in the background, where a tanker is just lifting off. The mining pits are shown just behind the foreground figure on the left. The geologists in the foreground are looking for richer ores to mine. Artist: Dennis Davidson NASA SP-509, vol. 4 Space Resources Social Concerns Editors Mary Fae McKay, David S. McKay, and Michael B. Duke Lyndon B. Johnson Space Center Houston, Texas 1992 National Aeronautics and Space Administration Scientific and Technical Information Program Washington, DC 1992 For sale by the U.S. Government Printing Office Superintendent of Documents, Mail Stop: SSOP, Washington, DC 20402-9328 ISBN 0-16-038062-6 Technical papers derived from a NASA-ASEE summer study held at the California Space Institute in 1984. Library of Congress Cataloging-in-Publication Data Space resources : social concerns / editors, Mary Fae McKay, David S. McKay, and Michael B. Duke. xii, 302 p. : ill. ; 28 cm.—(NASA SP ; 509 : vol. 4) 1. Outer space—Exploration—United States. 2. Natural resources. 3. Space industrialization—United States. I. McKay, Mary Fae. II. McKay, David S. III. Duke, Michael B. IV. United States. -

News-Archiv Weltraum Bis 2007 D1-Mission - Hintergrund 28

News-Archiv Weltraum bis 2007 D1-Mission - Hintergrund 28. Oktober 2005 Lebensläufe Reinhard Alfred Furrer (geboren 25. November 1940 in Wörgl, Österreich, gestorben am 9. September 1995 in Berlin) Reinhard Alfred Furrer Furrer studierte zunächst an der Universität Kiel und später an der Freien Universität Berlin Physik. 1969 machte er sein Diplom, 1972 erreichte er den Doktorgrad. 1974 wurde er Assistenzprofessor in Stuttgart. 1979 habilitierte er und verbrachte zwei Jahre in den USA, an der Universität sowie am Argonne National Laboratory in Chicago. 1977 bewarb sich Furrer bei der damaligen Deutschen Forschungs- und Versuchsanstalt für Luft- und Raumfahrt (DFVLR) (später: Deutsches Zentrum für Luft- und Raumfahrt, DLR), als diese einen Wissenschaftsastronauten für die erste Spacelab-Mission suchte. Bei der ersten Auswahl war er noch Ulf Merbold unterlegen, aber bei der Auswahl für die erste deutsche Spacelab-Mission 1982 wurde er dann nominiert. Am 30. Oktober 1985 startete er an Bord des Space Shuttle Challenger bei der D1-Mission als Nutzlastspezialist. Bei diesem Raumflug führte Furrer physikalische Experimente durch und untersuchte unter anderem die Auswirkungen der Schwerelosigkeit bei der Materialverarbeitung und auf den menschlichen Körper. Nach seinem Raumflug wurde er 1987 Professor und Direktor des Instituts für Weltraumwissenschaften an der Freien Universität Berlin. Furrer war begeisterter Sportpilot. Er machte seine erste Pilotenlizenz 1974 und unternahm viele Flugtouren mit einmotorigen Sportflugzeugen, beispielsweise einen Flug über das Inlandeis Grönlands oder einen Soloflug von Deutschland nach Quito (Ecuador). Furrer starb am 9. D1-Mission - Hintergrund 1 / 3 September 1995 bei einem Flugzeugabsturz während einer Flugshow auf dem Flugplatz Johannisthal (Berlin). Ernst Willi Messerschmid (geb. -

Download Chapter Two Activities

united IN space Zap to meet Welcome to the ISS! It’s time to meet your fellow Country/Region: some of the astronauts from all over the world. astronauts Greeting/s: who have been to the First astronaut: ISS. European Space Agency Time in Space: (ESA) Country/Region: Europe Awesome fact: Greeting/s: Hallo (German) or Hello (English) First astronaut: Ulf Merbold (Germany), 28 November 1983 Time in Space: Samantha Cristoforetti (Italy) had the longest single flight by a woman at 199 days, 16 hours. Hallo! Privyet! Konnichiwa! Which Awesome fact: Tim Peake was the countries have sent first British astronaut to fly with ESA. astronauts to the ISS? Can you make a country card for one of them? PRINCIPIASPACEDIARY.ORG AND LUCY HAWKING © CURVED HOUSE KIDS LTD DIARY PRINCIPIA SPACE Breaking News! Not everyone gets to go to space, so it’s important that you share your experiences with people on Earth. I’m Cindy and I help people learn more about space and science here on Earth. Can you write a news report about Tim’s first day in space? Include a picture too! A B E Earth to C D Ebiil! Principia E H Fp / qefp / Mixkbq / Bxoqe? F I Fq’p / x / ybxrqfcri / G sfbt / colj / rm / ebob. Hi, I’m Berti, Mission H Director at the European I L Qfj / Mbxhb, Space Agency. It’s my job to J keep the contact between pfdkfkd / lcc! Earth and the ISS. I’ve just K N received this message! Can L you help me decode it? M P He__ __ __ ! N O __ s / t __ i __ / P __ a n __ __ / __ __ r __ __? P S __ __ ’ __ / __ / b __ __ __ __ __ f u __ / Q Can you see R v __ __ w / f __ __ __ / __ __ / __ __ __ __. -

Spacelabspacelab

SpacelabSpacelab Achievements: principal scientific manned module for US Space Shuttle; major contributions to space sciences research and applications; first European manned space project; 22 missions Launch dates: see table Launch vehicle/site: US Space Shuttle, Kennedy Space Center, Florida Launch mass: typically 10 t (Spacelab-1 totalled 8145 kg Pressure Module and 3386 kg Pallet; including experiments totalling 1392 kg) Orbits: typically 300 km altitude, inclinations 28-57° Principal contractors: VFW-Fokker/ERNO (later MBB/ERNO; prime), Aeritalia (PM structure, Igloo, thermal control), Matra (command/data management), Dornier (IPS, ECLSS), British Aerospace (Pallet) Spacelab was an integral element of NASA’s Space Shuttle programme and provided ESA/ESRO with a unique opportunity for developing a manned space capability. The 22 missions made outstanding contributions to astronomy, life sciences, atmospheric physics, Earth observation and materials science under microgravity – advances that stemmed from this crucial European contribution. Spacelab essentially comprised two types of payload carrier: a pressurised manned laboratory module and unpressurised external pallets. Its flexibility allowed it to accommodate both multi- disciplinary experiments and complements devoted to a single scientific or applications theme. The Pressure Module (PM) hosted the experiments equipment, data processing and electrical power equipment, an environmental control system and crew control stations. The crew of up to six researchers relied on the Shuttle Orbiter for living quarters, communications and data transmissions. Europe was invited in 1969 to participate in the post-Apollo Spacelab was an programme, ultimately deciding at integral part of the the Ministerial Meeting of the Space Transportation European Space Conference in System. Shown is the Spacelab-1 Brussels on 20 December 1972 to configuration, flown in entrust ESRO with developing a 1983. -

The European Space Agency

THE EUROPEAN SPACE AGENCY UNITED SPACE IN EUROPE ESA facts and figures . Over 50 years of experience . 22 Member States . Eight sites/facilities in Europe, about 2300 staff . 5.75 billion Euro budget (2017) . Over 80 satellites designed, tested and operated in flight Slide 2 Purpose of ESA “To provide for and promote, for exclusively peaceful purposes, cooperation among European states in space research and technology and their space applications.” Article 2 of ESA Convention Slide 3 Member States ESA has 22 Member States: 20 states of the EU (AT, BE, CZ, DE, DK, EE, ES, FI, FR, IT, GR, HU, IE, LU, NL, PT, PL, RO, SE, UK) plus Norway and Switzerland. Seven other EU states have Cooperation Agreements with ESA: Bulgaria, Cyprus, Latvia, Lithuania, Malta and Slovakia. Discussions are ongoing with Croatia. Slovenia is an Associate Member. Canada takes part in some programmes under a long-standing Cooperation Agreement. Slide 4 Activities space science human spaceflight exploration ESA is one of the few space agencies in the world to combine responsibility in nearly all areas of space activity. earth observation launchers navigation * Space science is a Mandatory programme, all Member States contribute to it according to GNP. All other programmes are Optional, funded ‘a la carte’ by Participating States. operations technology telecommunications Slide 5 ESA’s locations Salmijaervi (Kiruna) Moscow Brussels ESTEC (Noordwijk) ECSAT (Harwell) EAC (Cologne) Washington Houston Maspalomas ESA HQ (Paris) ESOC (Darmstadt) Oberpfaffenhofen Santa Maria -

Part 2 Almaz, Salyut, And

Part 2 Almaz/Salyut/Mir largely concerned with assembly in 12, 1964, Chelomei called upon his Part 2 Earth orbit of a vehicle for circumlu- staff to develop a military station for Almaz, Salyut, nar flight, but also described a small two to three cosmonauts, with a station made up of independently design life of 1 to 2 years. They and Mir launched modules. Three cosmo- designed an integrated system: a nauts were to reach the station single-launch space station dubbed aboard a manned transport spacecraft Almaz (“diamond”) and a Transport called Siber (or Sever) (“north”), Logistics Spacecraft (Russian 2.1 Overview shown in figure 2-2. They would acronym TKS) for reaching it (see live in a habitation module and section 3.3). Chelomei’s three-stage Figure 2-1 is a space station family observe Earth from a “science- Proton booster would launch them tree depicting the evolutionary package” module. Korolev’s Vostok both. Almaz was to be equipped relationships described in this rocket (a converted ICBM) was with a crew capsule, radar remote- section. tapped to launch both Siber and the sensing apparatus for imaging the station modules. In 1965, Korolev Earth’s surface, cameras, two reentry 2.1.1 Early Concepts (1903, proposed a 90-ton space station to be capsules for returning data to Earth, 1962) launched by the N-1 rocket. It was and an antiaircraft cannon to defend to have had a docking module with against American attack.5 An ports for four Soyuz spacecraft.2, 3 interdepartmental commission The space station concept is very old approved the system in 1967.