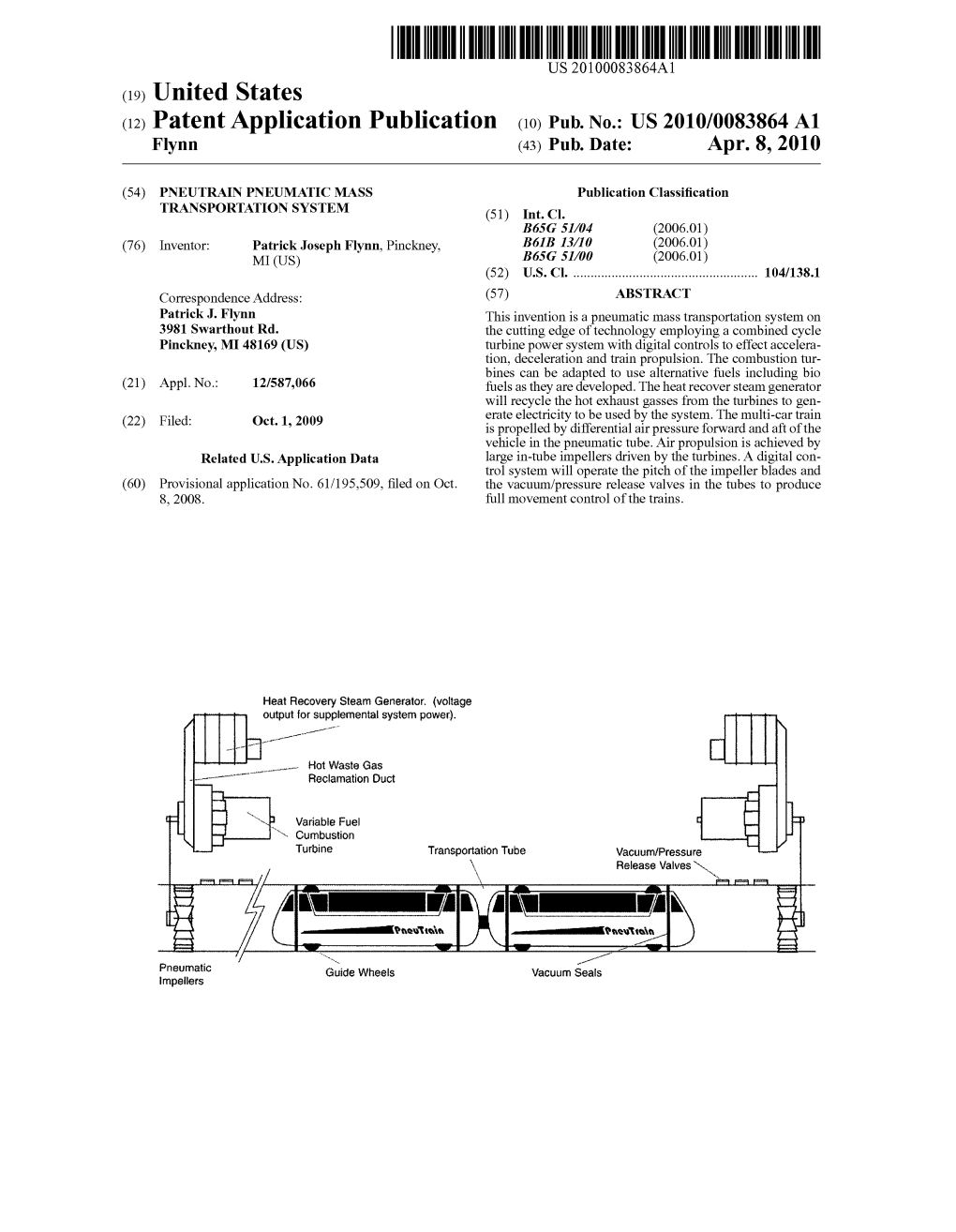

(12) Patent Application Publication (10) Pub. No.: US 2010/0083864 A1 Flynn (43) Pub

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Albuquerque Evening Citizen, 03-12-1907 Hughes & Mccreight

University of New Mexico UNM Digital Repository Albuquerque Citizen, 1891-1906 New Mexico Historical Newspapers 3-12-1907 Albuquerque Evening Citizen, 03-12-1907 Hughes & McCreight Follow this and additional works at: https://digitalrepository.unm.edu/abq_citizen_news Recommended Citation Hughes & McCreight. "Albuquerque Evening Citizen, 03-12-1907." (1907). https://digitalrepository.unm.edu/abq_citizen_news/ 3541 This Newspaper is brought to you for free and open access by the New Mexico Historical Newspapers at UNM Digital Repository. It has been accepted for inclusion in Albuquerque Citizen, 1891-1906 by an authorized administrator of UNM Digital Repository. For more information, please contact [email protected]. ilitawiiefiiw T.llirary of Congrnss ALBUQUERQUE, TUESDAY 12, 1907. Th Evanlng Cltltan, In Advs, $ pmr ysar, 70T Ol NEW MEXICO. EVENING. MAHCII Dsllvsrsd by CarrUra, M nH psr month. no more ems can now HIS FACE HIS FORTUNE F0E0 SEES FRENCH BATTLE BE INTRODUCED IN HOUSE BUT UTILE SHIP IS BE-- BUT BHULE SUSPENSION ADVANCE S Y Minority Now Has Regularly Organized 1.1 the Thaw Trial Today-- Ar Blown Up by One of Its Own guments to Oppose the Regular Or- Over Admission Torpedoes With Fatal Machine of Smith's Evidence. Effect. ganization of Republican Majority. J E DECIDES THAI IT FIFTY ARE KILLED AND MAJORITY WORKS HARD TO PERFECT GOOD LEGISLATION T TO BE ADMITTED FULLY 300 ARE INJURED Governor Did Not Appear Before the Committee on Sales of Nothing of Importance for Either Many Adjacent Ships Were Ser- He Had Been Territorial Lands as Side Developed In Testimony iously Damaged by the Requested to Do. -

Changes in Blood Gas Samples Produced by a Pneumatic Tube System J Clin Pathol: First Published As on 1 February 2002

105 ORIGINAL ARTICLE Changes in blood gas samples produced by a pneumatic tube system J Clin Pathol: first published as on 1 February 2002. Downloaded from P O Collinson, C M John, D C Gaze, L F Ferrigan, D G Cramp ............................................................................................................................. See end of article for J Clin Pathol 2002;55:105–107 authors’ affiliations ....................... Correspondence to: Dr PO Collinson, Aims: To investigate the effect of a pneumatic tube system (PTS) on the results of samples sent for blood Department of Clinical gas analysis to a central laboratory. Biochemistry, 2nd Floor, Methods: Blood gas samples were analysed immediately or sent via the PTS to the laboratory for Jenner Wing, St George’s analysis. In addition, samples sent via the PTS in a pressure sealed container were compared with those Hospital, Blackshaw Road, London SW17 0QT, UK; sent non-pressure sealed to the laboratory. poctrop@ Results: Samples sent via the PTS had significant alterations in their pO2 values, which were not seen poctrop.demon.co.uk when samples were carried by hand to the laboratory. There was no effect on pCO2 and pH values. Accepted for publication The use of a pressure sealed container abolished the alteration in pO2 values seen. 22 August 2001 Conclusions: Samples for blood gas analysis should be transported via a PTS using a pressure sealed ....................... container to avoid artefacts in the pO2. apid sample delivery systems, usually pneumatic tube Phase 2. Consecutive samples were drawn in duplicate from systems (PTS), have been installed in hospitals to reduce patients over a two week period. One sample was analysed Rdelays in delivering samples from the patient to the core immediately on the ICU by a member of the ICU staff. -

Seeds of Discovery: Chapters in the Economic History of Innovation Within NASA

Seeds of Discovery: Chapters in the Economic History of Innovation within NASA Edited by Roger D. Launius and Howard E. McCurdy 2015 MASTER FILE AS OF Friday, January 15, 2016 Draft Rev. 20151122sj Seeds of Discovery (Launius & McCurdy eds.) – ToC Link p. 1 of 306 Table of Contents Seeds of Discovery: Chapters in the Economic History of Innovation within NASA .............................. 1 Introduction: Partnerships for Innovation ................................................................................................ 7 A Characterization of Innovation ........................................................................................................... 7 The Innovation Process .......................................................................................................................... 9 The Conventional Model ....................................................................................................................... 10 Exploration without Innovation ........................................................................................................... 12 NASA Attempts to Innovate .................................................................................................................. 16 Pockets of Innovation............................................................................................................................ 20 Things to Come ...................................................................................................................................... 23 -

Launch a Rocket, Cash a Check, and Visit Another City. Thanks, Air!

August-September 2017 • Volume 6, No. 1 SY ALERT STEMTomorrow is almost here. ! Launch a rocket, cash a check, and visit another city. Thanks, air! A common example of pneumatic power can be found at your neighborhood bank. The tubes used to transport canisters Such from the drive-through station to pneumatic tube Pitsco’s Straw the office inside use pneumatic transportation systems are relatively Rocket Launcher force. The canister fits snugly in the rare today. But in the 1800s they uses pneumatic force – the tube, dividing the tube into the area were more common and used in power of compressed air – to in front of the canister and the area big cities such as London and New launch a small rocket. A weighted behind it. York to transport mail and other rod is dropped into a chamber When the air in the tube in front items from one office to another connected to the rocket. The rod of the canister is sucked out by a and even between buildings. compresses the air inside the motorized fan, a difference in air London had more than 30 miles of chamber. The rapidly pressurized pressure is created between the front pneumatic tubes beneath the city air pushes against the rocket with and back ends of the canister. The streets. You might even say that air such force that it sends it flying. air behind the canister automatically power was the first Internet. pushes the canister into the lower- (continued on page 3) pressure area in front of it until the canister arrives at its destination. -

June 23, 1981, NIH Record, Vol. XXXIII, No. 13

TheNIH Record U.S. Department June 23 National of Health 1981 Institutes and Vol. XXXIII of Human Services No. 13 Health DR. FREDRICKSON RESIGNS Three 1981 GM Foundation Citing personal reasons, Dr. Donald S. Fredrickson, NIH Director since July 1, 1975, announced his resignation Friday, June 19, Prizewinners Are NIH-Associated at a special meeting in Masur Auditorium. It Three of the four winners of the 1981 In a unique means of replication, the will be effective the 1st of July. In his re General Motors Cancer Research Founda DNA copy of the viral genetic information marks, he stated: "This July, I am complet tion awards are NIH-associated. inserts itself into the chromosomal DNA of ing my fourth 7-year term at NIH. It seems Each winner of the Kettering, Mott, and the cells infected by the virus. as exhilarating and worthwhile as in the Sloan prizes received $100,000 and a solid This chromosomal DNA is the blueprint summer of 1953, when I arrived. The last 6 gold medal from the foundation, which was that determines the inherited nature of years, however, have been spent in the re created to recognize international scientific cells and directs their function; the viral in lentless company of the administrative bur accomplishments in three basic areas of formation is thereafter included in the blue dens of the Director. It is time to shed them cancer research: diagnosis and treatment, print for every subsequent generation of for a while, lest I forget completely how to prevention, and basic scientific contribu cells. be a scientist and a physician." tions to the disease, particularly in the areas With his colleague Dr. -

NURSING LEADERSHIP and MANAGEMENT for PATIENT SAFETY and QUALITY CARE 3021 FM I-Xxx 16/01/17 3:28 PM Page Ii 3021 FM I-Xxx 16/01/17 3:28 PM Page Iii

3021_FM_i-xxx 16/01/17 3:28 PM Page i NURSING LEADERSHIP AND MANAGEMENT FOR PATIENT SAFETY AND QUALITY CARE 3021_FM_i-xxx 16/01/17 3:28 PM Page ii 3021_FM_i-xxx 16/01/17 3:28 PM Page iii NURSING LEADERSHIP AND MANAGEMENT FOR PATIENT SAFETY AND QUALITY CARE Elizabeth Murray, PhD, RN, CNE Program Director, MSN Nurse Educator Assistant Professor Florida Gulf Coast University School of Nursing Fort Myers, Florida 3021_FM_i-xxx 16/01/17 3:28 PM Page iv F. A. Davis Company 1915 Arch Street Philadelphia, PA 19103 www.fadavis.com Copyright © 2017 by F. A. Davis Company Copyright © 2017 by F. A. Davis Company. All rights reserved. This book is protected by copyright. No part of it may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without written permission from the publisher. Printed in the United States of America Last digit indicates print number: 10 9 8 7 6 5 4 3 2 1 Senior Acquisitions Editor: Susan Rhyner Developmental Editor: Amy Reeve Content Project Manager: Echo Gerhart Design and Illustration Manager: Carolyn O’Brien As new scientific information becomes available through basic and clinical research, recommended treatments and drug therapies undergo changes. The author(s) and publisher have done everything possible to make this book accurate, up to date, and in accord with accepted standards at the time of publication. The author(s), editors, and publisher are not responsible for errors or omissions or for consequences from application of the book, and make no warranty, expressed or implied, in regard to the contents of the book. -

The Hyperloop Is Here — Sort of Jack Mcguinn, Senior Editor

POWER PLAY The Hyperloop is Here — Sort of Jack McGuinn, Senior Editor It is unlikely the hyperloop will inspire Hol- lywood to start making films emulating the tried-but-true terror-on-a-train genre — a genre that includes many classics. But some- how titles like — Lady on a Hyperloop, Strangers on a Hyperloop, Murder on the Hyperloop Express, Throw Momma from the Hyperloop, The Great Hyperloop Robbery — just don’t work. And you can forget about another venerable train travel tradition — the club car — given that you will probably reach your destina- tion sooner than you can say “Jack on the rocks.” But forget all that — the hyperloop is about speed — speed to burn (pending full funding, that is). Boy Wonder Entrepreneur Extraordinaire Elon Musk Photo courtesy Hyper One. of Hyperloop One (there’s a Two and a Three else- where) says he has “verbal” approval from Washing- Those old enough and Turner Classic Movies fans are ton to build an underground hyperloop between New York perhaps somewhat aware that “pneumatic tubes (or cap- and Washington, D.C. What is normally a three-hour train sule pipelines, also known as pneumatic tube transport or trip — 75 minutes by air — the Hyperloop can complete in 29 PTT) are systems that propel cylindrical containers through minutes — at 700 mph. The route would also include Phila- networks of tubes by compressed air or by partial vacuum. delphia and Baltimore. (Musk’s involvement in the project is They are used for transporting solid objects (hyperloop ex- limited to building the tunnels; it is not yet clear which firm trapolation here: that would be passengers), as opposed to he plans to partner with to handle the pod vehicles.) conventional pipelines that transport fluids. -

!�T!!STEAM BOATS 31169 MILES

JOUHNAL OF INFORMATION, AnT, CIENCE MECHANICS, MANUFACTURES. l WEEKLY PRACTICAL S , CHEMISTRY, AND LXXXIII.-NO.ll. [$3.00 A YEAR. Vol. ] WEEKL'l. ESTABLISHED 1845. NEW YORK, SEPTEMBER 15, 1900. --------- -------------------------------------------------- ----- PNEUMATIC TUBE SUI'(. 6 STREET CARS .. t& !�t!!STEAM BOATS 31169 MILES E"-RTH . ... co "!. N e .0- 0> '" uJ � i z S! uJ 1; > uJ f- a: uJ UJ ...J "- « f- 0> '" '" 0"- en '" uJ uJ 1; ...J f- a: '" « f- z '" uJ UJ '" THE ANNUAL WEIGHT OF MAIL CARRIED IS 664,286,868 L8S. " UJ 6,576.310,000 PIECES OF MAIL, ANNUALLY, « a: TO TRANSPORT IT WOULD REQUIRE 3 3,21 4 FREIGHT CARS FORMING A TR AIN 300 MILES LONG, HAULED BY PL ACED TOGETHER, WOULD MAKE BAND :E: "- A uJ 500 LOCOMOTIVES HAVING 500,000 HORSE POWER. AND R EOU I RI NG 7 MILES OF TRACK. 7 FEET WIDE AROUND THE WORLD. > a: ...J < :x:" 0 S! 0 UJ 1; ...J f-uJ < uJ :E: "- a: e UJ e f- e r-: f- ... « :E: ",- ALL OTH ER PLAC ES. FIRST '" UJ '" 0 ,65.967,732.98 « UJ 262..239.710 lb,. ...J a: 0 0 (J)� ...J a: 0" � a: "- « 0 ...J '" ...J UJ 0 0 0 UJ z a: UJ 128.:117.992 U" 0> f- CIt "- ... ... - 0 e uJ co ...J '" a: 1 FEl TOWER" W HERE THE SECOND'CLASS MATTER IS MAILED. WEIGHT OF DIFFERENT CLASSES CARR IED __ POST�GE PAIU BY CLASSES . -'"'-----""'.�oo�rW;. - \I,\W A GRAPHICAL REPRESENTATION OF SOltE INTERESTING FEATURES OF tHE UNItED StAtES POStAL SERVICE.-lSee page 166.] fire equal to that of the more heavily armed vessels. -

Elon Musk's Idea of 'Hyperloop' Trains a Bit Too Loopy: Cameron on Transportation

Darienite News for Darien https://darienite.com Elon Musk's Idea of 'Hyperloop' Trains a Bit Too Loopy: Cameron on Transportation Author : David Gurliacci Categories : Opinion, Transportation Tagged as : Cameron on Rail Transportation 2019, Cameron on Trains 2019, Cameron on Transportation, Cameron on Transportation 2019, Elon Musk, Hyperloop Date : March 21, 2019 Is Elon Musk a brilliant innovator, or is he just smoking dope? Well, we know the answer to the second question as a viral video has shown him puffing (legal) weed on a talk show. The man is under a lot of stress, right? There’s no doubt that Musk’s privately funded ventures in space travel and electric cars are prescient, maybe even profitable someday. But his transportation vision for the Hyperloop has yet to be proven viable. Hyperloop is Musk’s 2013 vision of high-speed underground tube-travel in a near-vacuum using linear 1 / 2 Darienite News for Darien https://darienite.com induction motors akin to Maglev. The concept has already gained traction with private companies like Virgin Hyperloop One and HyperloopTT, which are looking to commercialize Musk’s idea. They’ve signed deals in South Korea, India, the United Arab Emirates, China, Indonesia and Ukraine. In the U.S., Virgin is working with state officials in Missouri and Colorado on projects, envisioning things like a 250-mile run from St. Louis to Kansas City in 28 minutes (compared to three-and-a-half hours by car). They say development costs would be 40 percent less than those for high-speed rail. Even some in Connecticut are thinking about tube travel in the Northeast. -

High Line Corridor Pneumatic Waste-Management Initiative: Pre-Implementation Planning Study

High Line Corridor Pneumatic Waste-Management Initiative: Pre-implementation Planning Study Final Report | Report Number 18-28 | January 2019 NYSERDA Department of Transportation Cover Image courtsey of ClosedLoops LLC High Line Corridor Pneumatic Waste-Management Initiative: Pre-implementation Planning Study Final Report Prepared for: New York State Energy Research and Development Authority Albany, NY Robyn Marquis, Ph.D., Project Manager Joseph D. Tario, P.E., Sr. Project Manager New York State Department of Transportation Albany, NY Mark Grainer and Robert Ancar, Project Managers Prepared by: ClosedLoops LLC New York, NY Benjamin Miller and Juliette Spertus, Co-Principal Investigators with Albert Mateu, P.E., Green Bending Christina Grace, Foodprint Group Stephen Lynch, A.I.A., Caliper Studio James Lima, James Lima Planning + Development Thomas Erickson, Rail Cents Niclas Tylli, Ph.D., P.E., MariMatic Oy Jan Allen, P.E., Impact BioEnergy NYSERDA Report 18-28 NYSERDA Contract 83177 January 2019 NYSDOT Task Assignment C-15-11 Notice This report was prepared by ClosedLoops LLC in the course of performing work contracted for and sponsored by the New York State Energy Research and Development Authority and the New York State Department of Transportation (hereafter the "Sponsors"). The opinions expressed in this report do not necessarily reflect those of the Sponsors or the State of New York, and reference to any specific product, service, process, or method does not constitute an implied or expressed recommendation or endorsement of it. Further, the Sponsors, the State of New York, and the contractor make no warranties or representations, expressed or implied, as to the fitness for particular purpose or merchantability of any product, apparatus, or service, or the usefulness, completeness, or accuracy of any processes, methods, or other information contained, described, disclosed, or referred to in this report. -

Shanghai Maglev Train General Overview and Comparative Usage of Shanghai Maglev…………

UC Santa Barbara Recent Work Title Consumer Desirability of the Proposed Hyperloop Permalink https://escholarship.org/uc/item/3w5414sm Authors Jia, Perry Zichen Razi, Kiana Wu, Nathan et al. Publication Date 2019-07-10 eScholarship.org Powered by the California Digital Library University of California Consumer Desirability of the Proposed Hyperloop Kiana Razi; Nathan Wu; Casby Wang; Marty Chen; Huizhong(Steven) Xue; Nick Lui; Perry Jia August 2018 1 Table of Contents Title page………………………………………………………………………………………… 1 Table of Contents………………………………………………………………………………. 2 - 4 Introduction of the Hyperloop………………………………………………………………... 5 Timeline………………………………………………………………………………………….. 6 - 8 Preface to the question……………………………………………………………………….. 9 Introducing the question and the reasoning behind why the question should be tackled……………………………………………………... 10 Flowchart for Determining the Economic Feasibility of the Hyperloop……………….. 11 Methodology…………………………………………………………………………………….. 12 Clarifying the Case Study Parameters Question……………………………………………………………………………………… 13 Breakdown of the question………………………………………………………………….. 13 - 14 KPI Clarification: Price……………………………………………………………………………………… 14 Travel Time………………………………………………………………………………. 14 - 15 Safety…………………………………………………………………………………….. 15 Comfort…………………………………………………………………………………... 15 Not Using Environmental Impact……………………………………………………….. 16 Setting up the theoretical Hyperloop Price of the Hyperloop………………………………………………………………………. 17 Travel Time of the Hyperloop……………………………………………………………….. 17 - 18 -

Pollution Emissions Little Or No Pollution

The New Mobilities Smart Planning for Emerging Transportation Technologies Todd Litman Victoria Transport Policy Institute Presented Smart Growth Network 24 June 2021 New Mobilities New Mobilities: Smart Planning for Emerging Transportation Technologies New Mobilities have tantalizing potential. They allow people to scoot, ride, and fly like never before. They can provide large and diverse benefits. However, they can also impose significant costs on users and communities. Decision-makers need detailed information on their impacts. Island Press 30% Discount Code: SMART Previous Transportation Dreams Previous transportation innovations seem exciting and beneficial. They are part of our collective dreams of a better future. Transportation Futures E-bikes Autonomous Cars Air Taxi Transit Improvements Mobility as a Service Pneumatic Tube Transport New Mobilities A dozen emerging transportation technologies and services 1. Active Travel and Micromobilities. Walking, bicycling, and variations, including e-bikes and e-scooters. 2. Vehicle Sharing. Convenient and affordable bicycle, scooter, and car rentals. 3. Ridehailing and Microtransit. Mobility services for individuals and small groups. 4. Electric Vehicles. Battery-powered scooters, bikes, cars, trucks, and buses. 5. Autonomous Vehicles. Vehicles that can operate without a human driver. 6. Public Transport Innovations. Innovations that improve transit travel convenience, comfort, and speed. 7. Mobility as a Service (MaaS). Navigation and transport payment apps that integrate multiple modes. 8. Telework. Telecommunications that substitutes for physical travel. 9. Tunnel Roads and Pneumatic Tube Transport. Underground roads and high-speed tube transport. 10. Aviation Innovation. Air taxis, drones, and supersonic jets. 11. Mobility Prioritization. Incentives that favor higher-value trips and more efficient modes. 12. Logistics Management.