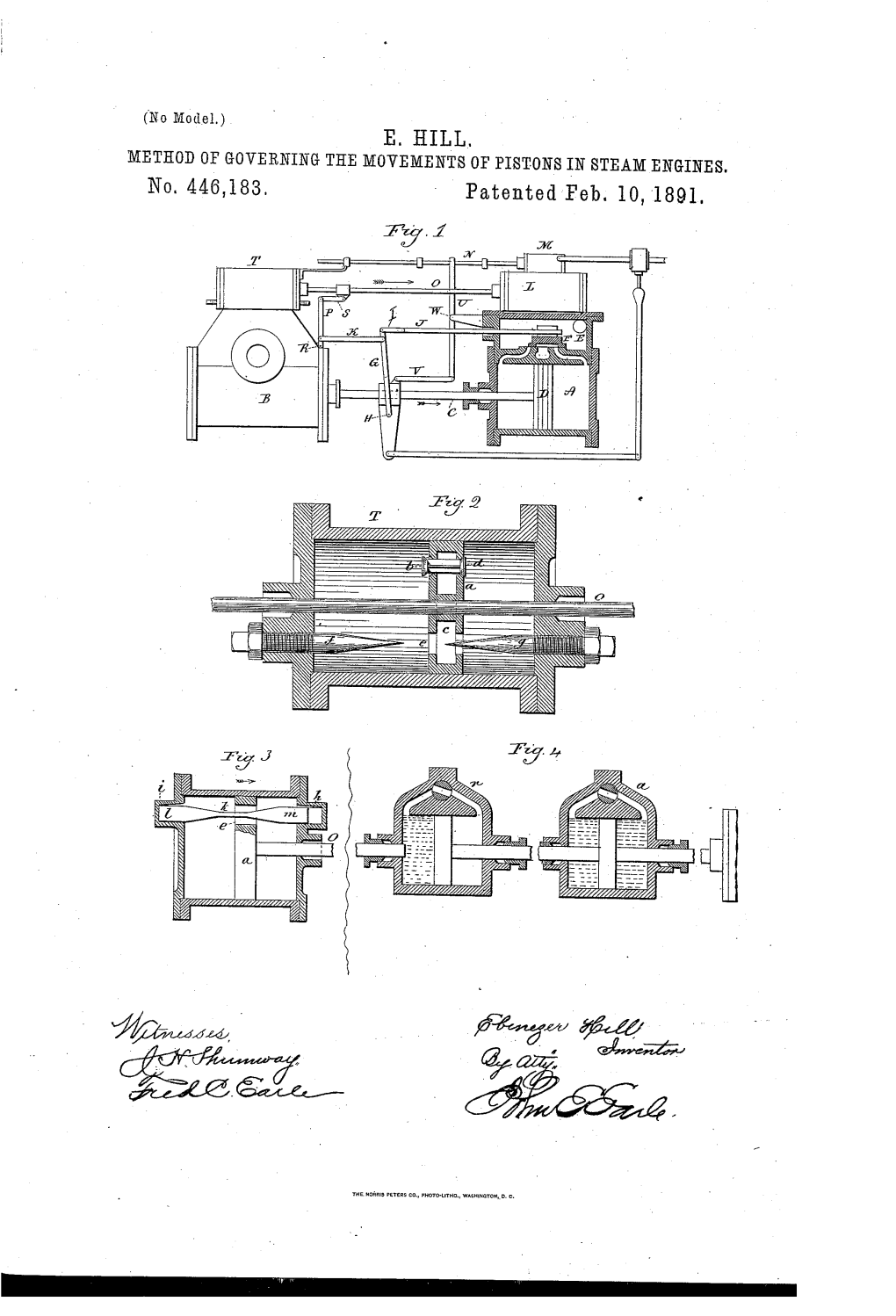

E. HILL, METHOD of GOVERNING the MOVEMENTS of PISTONS in Steamengines. No

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

21 3 Steam Engine Governor Having a Close Approximation to Perfect Action

21 3 ON A SIMPLE CONSTRUOTION OF STEAM ENGINE GOVERNOR HAVING A CLOSE APPROXIMATION TO PERFECT ACTION. BY ME. JEREMIAH HEAD, OF MIDDLESBBOUGH. The irregularity of speed tolwhich all steam engines are liable arises from two principal causes : variation in the pressure of steam supplied, and variation in the amount of resistance to be overcome. Variation of steam pressure may arise from irregular firing, overtaxed boilers, or in the case of waste-heat boilers, from several dampers happening to be closed at once, and from other similar and obvious cauaes. Variation in resistance occurs when the work to be performed is from its nature intermittent ; this variation is at its minimum in such engines as those used for pumping or blowing, and at its maximum in engines such as are attached to saw-mills, rolling mills, grindstones and shears. If an engine readily lags in speed when the resistance increases, its efficiency is lessened just when most required ; and if it “runs away” when relieved of work, or when the steam pressure is higher than ordinary, the wear and tear of the machinery connected with it is increased, and at the same time steam is wasted in doing the mischief. These considerations were all fully recognised by Watt, who sought to remedy them by his well- known steam engine governor. Although imperfect and partial in its action, this governor is sufficient for many purposes; and its extreme simplicity has caused it to remain to the present time in more extensive use than any other. It acts on a throttle-valve inserted in the steam-pipe close to the valve-chest, and partly closes the throttle-valve when the normal speed is exceeded, and opens it wider when the speed falls below the ordinary rate. -

Mmubn000001 026689529.Pdf

PDF hosted at the Radboud Repository of the Radboud University Nijmegen The following full text is a publisher's version. For additional information about this publication click this link. http://hdl.handle.net/2066/147957 Please be advised that this information was generated on 2021-09-24 and may be subject to change. OXIDATIVE CHALLENGE TO AGING HUMAN LENS LEADING TO NUCLEAR CATARACT P.M.M. van HAARD TOELICHTING Het doel van het hier beschreven onderzoek is een beter inzicht te krijgen in het ontstaan van cataract o-F staar in de ooglens van sommige ouder wordende mensen. De lens stelt de mens in staat om scherp te zien. Een voor waarde is wel dat de lens licht doorlaat. Elke verandering in de lichtdoorlaatbaarheid ten gevolge van troebel worden van de lens wordt cataract genoemd. Oit betekent niet dat onscherp zien altijd aan cataract te wijten zou zijn. De lenstroebelingen, voorkomend bij oudere mensen (90-95% van alle cataracten) worden ouderdomscataracten genoemd. Tot deze groep van cataracten behoort de kerncataract ι het is de ze vorm van cataract die ik onderzocht heb. De kerncataract is om allerlei redenen een interessant onder- zoekobject. Komen bij andere ouderdomscataracten witte troe- belingen voor in verschillende delen van de lens, bij kernca taract wcrdt alleen het normaal lichtgeel gekleurde binnenste deel van de lens - de kern - meestal rond het vijftigste jaar steeds harder, troebel en bruiner van kleur. In het ernstigste en meest gevorderde stadium blijkt de harde, zwartbruine kern van de lens even groot te zijn als de lens bij de geboorte is. -

Electrification and the Ideological Origins of Energy

A Dissertation entitled “Keep Your Dirty Lights On:” Electrification and the Ideological Origins of Energy Exceptionalism in American Society by Daniel A. French Submitted to the Graduate Faculty as partial fulfillment of the requirements for the Doctor of Philosophy Degree in History _________________________________________ Dr. Diane F. Britton, Committee Chairperson _________________________________________ Dr. Peter Linebaugh, Committee Member _________________________________________ Dr. Daryl Moorhead, Committee Member _________________________________________ Dr. Kim E. Nielsen, Committee Member _________________________________________ Dr. Patricia Komuniecki Dean College of Graduate Studies The University of Toledo December 2014 Copyright 2014, Daniel A. French This document is copyrighted material. Under copyright law, no parts of this document may be reproduced without the express permission of the author. An Abstract of “Keep Your Dirty Lights On:” Electrification and the Ideological Origins of Energy Exceptionalism in American Society by Daniel A. French Submitted to the Graduate Faculty as partial fulfillment of the requirements for the Doctor of Philosophy Degree in History The University of Toledo December 2014 Electricity has been defined by American society as a modern and clean form of energy since it came into practical use at the end of the nineteenth century, yet no comprehensive study exists which examines the roots of these definitions. This dissertation considers the social meanings of electricity as an energy technology that became adopted between the mid- nineteenth and early decades of the twentieth centuries. Arguing that both technical and cultural factors played a role, this study shows how electricity became an abstracted form of energy in the minds of Americans. As technological advancements allowed for an increasing physical distance between power generation and power consumption, the commodity of electricity became consciously detached from the steam and coal that produced it. -

The Newcomen Society

The Newcomen Society for the history of engineering and technology Welcome! This Index to volumes 1 to 32 of Transactions of the Newcomen Society is freely available as a PDF file for you to print out, if you wish. If you have found this page through the search engines, and are looking for more information on a topic, please visit our online archive (http://www.newcomen.com/archive.htm). You can perform the same search there, browse through our research papers, and then download full copies if you wish. By scrolling down this document, you will get an idea of the subjects covered in Transactions (volumes dating from 1920 to 1960 only), and on which pages specific information is to be found. The most recent volumes can be ordered (in paperback form) from the Newcomen Society Office. If you would like to find out more about the Newcomen Society, please visit our main website: http://www.newcomen.com. The Index to Transactions (Please scroll down) GENERAL INDEX Advertising puffs of early patentees, VI, 78 TRANSACTIONS, VOLS. I-XXXII Aeolipyle. Notes on the aeolipyle and the Marquis of Worcester's engine, by C.F.D. Marshall, XXIII, 133-4; of Philo of 1920-1960 Byzantium, 2*; of Hero of Alexandria, 11; 45-58* XVI, 4-5*; XXX, 15, 20 An asterisk denotes an illustrated article Aerodynamical laboratory, founding of, XXVII, 3 Aborn and Jackson, wood screw factory of, XXII, 84 Aeronautics. Notes on Sir George Cayley as a pioneer of aeronautics, paper J.E. Acceleration, Leonardo's experiments with Hodgson, 111, 69-89*; early navigable falling bodies, XXVIII, 117; trials of the balloons, 73: Cayley's work on airships, 75- G.E.R. -

Clinical Evaluation of the GENIUM AFI 5.5 Prepak in Cataract Surgery

Vincent_edit.qxp 24/9/08 12:34 Page 25 Surgery Cataracts Clinical Evaluation of the GENIUM AFI 5.5 Prepak in Cataract Surgery a report by Patrice Vincent LCA Pharmaceutical Clinical Research DOI: 10.17925/EOR.2009.02.01.25 The demand for intraocular lenses (IOLs) pre-loaded in single-use Figure 1: GENIUM AFI 5.5 Prepak Pre-loaded Intraocular Lens with Injector in Immersion Inside Its Sealed Sterile Vial sterile injectors is a logical step in the evolution of cataract surgery. The intention is not only to dispense with the surgeon or his/her assistant loading the IOL in a conventional injector, but also to directly implant the IOL inside the eye correctly and safely, reducing contact with the environment to virtually zero, and ultimately to make surgery easier and safer, preventing endophthalmitis. The obvious advantage of such a technique is the elimination of The vial itself is delivered inside a sealed pouch for double sterility protection. risks such as mistakes during IOL handling (incorrect placement inside the cartridge, accidental contamination, etc.) or even the use of an inflammation of the anterior segment, uncontrolled glaucoma and any improper injector device, resulting in a damaged lens. The latter point retinopathy that would prevent satisfactory visual acuity being obtained. demonstrates that there is a big difference between a single-use injector that has to be loaded conventionally and a truly pre-loaded The patient group ranged from 46 to 99 years of age (mean age IOL. To fulfil this demand, LCA Pharmaceutical has designed the 75.2±8.1 years) and 64% were women. -

OCTOBER Final 2020 Rumble

Badger State Region Early FordV-8 Club February 2020 THE RUMBLE SHEET A Publication of the Badger State Region Early Ford V-8 Club, Inc. Volume 49 October 2020 No events for October due to pandemic.. so how about some Halloween groaners! What do birds give out on Halloween? Tweets Why did the scarecrow get a promotion? He was outstanding in his field. What’s a skeleton’s favorite instrument? A trom-bone Why are cemeteries so popular? Everyone is dying to get in. What kind of music do mummies listen to? Wrap music What’s the best thing to put in pumpkin pie? Your teeth Why do vampires always seen sick? They’re always “coffin” Why are ghosts such bad liars? You can see right through them. Why don’t vampires have a lot of friends? Because they are a pain in the neck. What do you call a witch at the beach? A sand-witch What’s a ghost’s favorite band? The Grateful Dead What did the skeleton buy at the store? Spare ribs Why was the ghost crying? He wanted his mummy. Ok, don’t shoot me! I’ll willingly resign my position as editor. Badger State Region Early Ford V-8 Club January 2020 BOARD OF DIRECTORS - 2020 Mike Dutkiewicz - President/Historian Res: 414-529-3770 Cell: 414-510-3770 [email protected] “Mercury” Ed Suchorski - Vice President Res: 262-895-6128 [email protected] Judy Deschler - Secretary/Editor/Mailing/E-Mailings Res: 262-639-1934 Cell: 262-744-1928 [email protected] Steve Davel - Treasurer/Membership/Sales Res: 262-968-9483 Cell: 262-993-9020 [email protected] Bruce Winter- Member at Large Res: 414-422-9833 Cell: 414-520-3000 [email protected] Ryan Cross - Member at Large/Tour Coordinator/National Correspondent Cell: 414-614-8021 [email protected] Gail Leicht - Sunshine Res: 262-763-2004 [email protected] Presidents Message I hope every one read and tried to understand the Resolution from the new National Club legal advisor. -

Data for Engineering Design: Lean's Engine Reporter and Early

Les archives de l’invention, pp. 211-226. Data for engineering design: Lean’s engine reporter and early nineteenth century steam technology* Alessandro Nuvolari** One of the salient features of the Industrial Revolution was the transition from an economic system based on the exploitation of «organic»natural resources to another centered on the intensive use of inorganic minerals. In this sense, the Industrial Revolution consisted in a dramatic increase of the energy potential susceptible of effective economic utilization1. If we consider the cluster of technological innovations commonly associated with the Industrial Revolution in this perspective, the steam engine, allowing the transformation of thermal energy (heat) into kinetic energy (work), assumes paramount importance. Traditional accounts of early industrialization have, more or less explicitly, considered that a wide range of application sectors rapidly benefited from the development of steam power technologies2. This seems, however, to be generally unwarranted. When carefully examined, the diffusion of steam power appears to have been a delayed and particularly prolonged affair. The late eighteenth century and the early nineteenth century economies were still dominated by the pervasive use of animal, wind and water power3. In fact, the widespread utilization of steam power had to await a number of cumulative improvements that progressively reduced the power costs of the steam engine. A major part of the power costs associated with the * This paper draws partially on NuvolariA.,«Collective invention during the British Industrial Revolution:the case of the Cornish pumping engine»,Cambridge journal of economics, 2004, n°28.An earlier version was presented at the conference «LesArchives de l’Invention» organized at the Conservatoire national des arts et métiers – Centre d’histoire des techniques and the Centre historique des Archives nationales (Paris, 26-27 may 2003). -

The Making of Steam Power Technology

The Making of Steam Power Technology A Study of Technical Change during the British Industrial Revolution _____________________________________________________________________ Alessandro Nuvolari Eindhoven Centre for Innovation Studies (ECIS) Eindhoven University of Technology, the Netherlands CIP – DATA LIBRARY TECHNISCHE UNIVERSITEIT EINDHOVEN Nuvolari, Alessandro The making of steam power technology / by Alessandro Nuvolari. – Eindhoven: Technische Universiteit Eindhoven, 2004. – Proefschrift. – ISBN 90-386-2077-2 NUR 696 Keywords: Economical history / Industrial history / Steam engines; history Cover illustration: John Farey, vertical section of Arthur Woolf’s compound engine at Wheal Vor Mine (Cornwall), circa 1839 Cover design: Paul Verspaget Printing: Eindhoven University Press The Making of Steam Power Technology A Study of Technical Change during the British Industrial Revolution PROEFSCHRIFT ter verkrijging van de graad van doctor aan de Technische Universiteit Eindhoven, op gezag van de Rector Magnificus, prof.dr. R.A. van Santen, voor een commissie aangewezen door het College voor Promoties in het openbaar te verdedigen op donderdag 23 september 2004 om 16.00 uur door Alessandro Nuvolari geboren te Mantova, Italië Dit proefschrift is goedgekeurd door de promotoren: prof.dr. H.H.G. Verspagen en prof.dr. G.N. von Tunzelmann Copromotor: dr.ir. G.P.J. Verbong ‘You see, Tom,’ said Mr Deane, at last, throwing himself backward, ‘the world goes on at a smarter pace now than it did when I was a young fellow. Why, sir, forty years ago, when I was much such a strapping youngster as you, a man expected to pull between the shafts the best part of his life, before he got the whip in his hand. -

Arc of the Rim of a Drum Or Pulley Whose Motion It Resists

400 CHAPTER III. OF REGULATING APPARATUS. 349. Beplaliq Apparata• «,Jaued-Brake-Ply-Gove.1aer. The effect of all regulating apparatus is to control the speed of machinery. A regulating instrument may act simply by con· suming energy, so as to prevent acceleration, or produce re tardation, or stop the machine if required; it is then called & brake; or it may act by storing surplus energy at one time, and giving it out at another time, when energy is deficient: in this case it is called a fly; or it may act by adjusting the power of the prime mover to the work to be done, when it is called a gove:rnot• The use of a brake involves waste of power. A flyand a governor,. on the other hand, promote economy of power and economy ot strength. SECTION I.-Of Brakes. 350. Brakea De&aed and �laued.-The contrivances here com· prehended 11nder the general title of Brakes are those by means of which friction, whether exerted amongst solid or fluid particles, is purposely opposed to the motion of a machine, in order either to stop it, to retard it, or to employ superfluous energydurino- uniforlll motion. The use of a brake involves waste of energy, which is in itself an evil, and is not to be incurred unless it is necessary to con- venience or safety. Brakes n1av be classed as follows:- I. Block-b1:akes,in which one solid body is simply pressed against another, on ,vhich it rubs. II. Flexible brakes, which embrace the periphery of.a drum or pulley (as in Prony's Dynamometer, Article 341, page 383). -

Description of the Cornish Pumping Engine with Wrought Iron Beam and the Pit Work at Clay Cross Colliery

DESCRIPTION OF THE CORNISH PUMPING ENGINE WITH WROUGHT IRON BEAM AND THE PIT WORK AT CLAY CROSS COLLIERY. ~ BY MR. WILLIAM HOWE, OB CLAY CROSS. At the commencement of the working of the Clay Cross Colliery the upper seams of coal were drained by the Clay Cross railway tunnel ; but as the lower seams were sunk to and worked, the water could no longer run into the tunnel, and gradually increased in quantity until it became necessary first to put in pumps of small size worked by the winding engines then in use on the colliery, which were sufficient for draining the works for some years. Afterwards as the works extended fui-ther, one pump after another was added, until there were altogether six pumping stations, at two of which were independent pumping engines of 40 horse power each. The water still following to the dip of the measures, it was found that either inorc pumping power must be added in the same way that it had been increased from the commencement, by putting down more engines, or else a single large pumping engine must be erected to drain the whole of the works, which had extended to an area of several hundred acres and a depth of 420 feet. After much consideration it was determined to erect a Bingle large pumping engine on the Cornish principle, to pump the whole of the water at one point of the colliery. When this was completed it at once threw out of use seven sets of pumps and engines requiring several enginemen to look after them; and saved much expense in repairs, which had been continually necessary at one or other of the several pumping stations. -

PRESTONGRANGE Lo-Inch CORNISH ENGINE a MYTH

PRESTONGRANGE lO-inch CORNISH ENGINE A MYTH EXPLODED h u Kenneth Brown a o VI If S c F a The preserved 70-inch Cornish pumping engine at Prestongrange Colliery near E Edinburgh, now the Prestongrange Mining Museum, has always been assumed from E the inscription on the cast-iron beam to have been built by Harvey & Co. of Hayle in r 1874. The author has uncovered evidence that the engine is a little older than Robinson's famous 80-inch engine at South Crofty and enjoyed a similar working life of 101 years at four sites; moreover only the beam is of Harvey manufacture. This article is submitted in the hope that it may encourage other members to dip into the morass of literature and crumbling remains in an attempt to unravel other 'Cornish engine mysteries' which still puzzle us. My list of surviving Cornish pumping engines published in the Society's newsletter No. 31 (November 1980) was challenged by a few members on the grounds that the history given for the Prestongrange 70-inch engine is wrong. I wrote individually to each explaining how I had arrived at my conclusions concerning the engine's age and parentage, and this aroused such fascinating correspondence that I realised that the story should be made available to members generally. The various research steps were taken very much as a 'learn as you go along' process, and it is hoped that they In themselves will be of some interest, quite apart from their final outcome. This research has proved beyond any doubtthatthe enginewas built by J.E. -

James Rumsey, American Inventor by David G

James Rumsey American Inventor James Rumsey 1743-1792 Oil portrait by Benjamin West James Rumsey was the “most original and the greatest mechanical genius I have ever seen.”1 —Thomas Jefferson 1 “Jefferson to Joseph Willard, March 29, 1789, The Papers of Thomas Jefferson, 14:699.” Edwin T. Layton, Jr., "James Rumsey: Pioneer Technologist," West Virginia History, 1989. Vol. 48, p. 22. James Rumsey, American Inventor By David G. Allen 2 Introduction: Making Steam Power Work................................................... 3 James Rumsey in Virginia .......................................................................... 5 James Rumsey in England ....................................................................... 12 The First Steamboat ................................................................................. 18 James Rumsey’s Steamboat ..................................................................... 24 The Constant Inventor.............................................................................. 25 James Rumsey’s Boiler............................................................................. 28 Epilogue................................................................................................... 30 Sources.................................................................................................... 34 Timeline ................................................................................................... 36 Of Bandits and Tooth Drawers ................................................................