F. W. Wilcox. 2

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Foodservice Disposables Guide

MANUFACTURERS REPRESENTATIVES “Connecting Partnerships” FOODSERVICE DISPOSABLES ENVIRONMENTAL MATERIALS GUIDE 5th Edition 2021 NEXUS CORPORATE HEADQUARTERS 7042 Commerce Circle Suite B, Pleasanton CA 94588 | T 800.482.6088 | F 510.567.1005 www.nexus-now.com rev. 3/21 MISSION STATEMENT OF THIS PUBLICATION “Our mission, as manufacturer’s representatives, is to strive to be good stewards to the environment in our marketplaces by educating, training and informing our customers on all of the different packaging materials and substrates that are used to make a wide array of disposable foodservice products. In this publication we also seek to advise our customers on how each packaging substrate should be used in operational applications like microwaves, freezers and ovens as well as which materials can be recycled and or composted in each respective region in the Western United States.” Chris Matson President, Nexus The information provided in this guide may vary in accuracy due to the ever changing city, state and federal rules, regulations, ordinances and laws that govern recycling, landfills and commercial compost facilities. 3 FOODSERVICE DISPOSABLES ENVIRONMENTAL MATERIALS GUIDE “Connecting Partnerships” TABLE OF CONTENTS 3 MISSION STATEMENT 4 TABLE OF CONTENTS 6 INTRODUCTION 8 ENVIRONMENTAL WASTE 13 LANDFILLS 14 RECYCLABLES 17 INTERNATIONAL RECYCLING 18 PLASTICS 36 GOVERNMENT REGULATIONS 41 FOODSERVICE PACKAGING 43 CLEAN PACKAGING 46 BACTERIA 47 HACCP 49 FOODSERVICE GLOVES 55 MYTHS & FACTS 59 PAPER 65 GREEN 4 5 INTRODUCTION The world of foodservice packaging disposables can be very confusing in today’s ever changing marketplace. There are so many different packaging materials that are used in a variety of food applications made by hundreds of manufacturers. -

Wordperfect Office Document

Supervisor Bosworth offered the following resolution and moved its adoption, which resolution was declared adopted after a poll of the members of the Board: RESOLUTION NO. 234 - 2014 A RESOLUTION AUTHORIZING THE AWARD OF A BID FOR JANITORIAL PRODUCTS (TNH011-2014). WHEREAS, by Resolution No. 19-2014 adopted January 7, 2014, the Commissioner of Administrative Services (the “Commissioner”) was authorized to solicit bids for the purchase of janitorial products (the “Products”); and WHEREAS, bids for the Products were received as set forth in Exhibit A attached hereto (the “Bids”); and WHEREAS, following a review of the Bids, the Commissioner has recommended an award as set forth in Exhibit B attached hereto (the “Awards”): WHEREAS, the this Board wishes to authorize the Awards as recommended by the Commissioner. NOW, THEREFORE, BE IT RESOLVED that the Awards as recommended by the Commissioner are hereby authorized; and be it further RESOLVED that the Supervisor be and hereby is authorized and directed to execute, on behalf of the Town, any purchase agreements and related documents, a copy of which shall be on file in the Department of Administrative Service, and to take such other related action as may be necessary to effectuate the foregoing; and be it further RESOLVED that the Office of the Town Attorney be and hereby is authorized and directed to supervise the execution of the contract documents to effectuate the Award; and be it further RESOLVED that the Comptroller be, and hereby is, authorized and directed to pay the costs thereof upon receipt of a fully executed agreement and a duly certified and executed claim therefor. -

Cleveland Town Topics Volume 5, December 1889

8 'Wleeltl~ 'lRc"lew of Soclet\?, 8rt anb llterature. VOL. V., No. I. CLEVELAND, 0., DECEMBER 7, 1889. PRI\E FIVE CE;\TS. A DISTINGUISHED WURKER. MISS DEBUTANTE (enthusiasticaIM: How GRAND IT JllUST DE TO BE A MAN! MR. SOFTLY, BY THE WAY, WHAT IS YOUR VOCATION? MR. SOFTLY: OH! I AM A I'ROMINE!'iT MEMBER OF A:-i INSTITUTION ON FIFTH AVENUE. MISS DEBUTANTE: INDEED, AND WHAT DO YOU DO? MR. SOFTLY: I AW-SIT IN THE CLUB WINDOW FROM TWO TO FOUR. TOWN TOPICS. Cs(ie(jUNTNEI{~ ~ONS FU S ~eat s~I\jacl\ets.wrapsaroddoaks, shoulder capes. pelerines,moffs.etc. in choice desiglls,at moderate pricej. ~b~her 181e FIFTH AVENU~ NEW YORK SECURITY AND TRUST CO" 4G 'VALL STREET. CAI>ITAIJ, $1,000,000, SUUJ)JJUS, $;;00,000. CIlA RLES S. FA I Relll LD, President. W;\1. L. STROI G, 2d Vice-President. WII. H. APPLETV ',1st Vice-President. JOII. L. L!\MSO~, Secret:lr)'. This COOlp:tny is :tuthorizcd to art as Execulor, Trlls!l'(', Adlllinistr:ttor, Guardi:ln, Agent and Receiver. Is a legal uepository for Conrt :lnd Trllst Fllnus. Takes the ('lit ire charge of real and personal estates, collecting the rents and prolits, and :lttending- lo :III such det:lils as :In individual in like capacity could do. Receives deposits s~.iect to sight drafts, allowing intl'rest on daily balances, :lnd issues certificates of deposit IJl~aring interest. --'-------------- Fine Complexion, New ParkSorRoads TIFFANY &CO., Smooth, Soft Skin. SA~LE. UNION SQUARE, NEW YORK, Mention this :lfa,:,'a::;il/I! amI semI -1 stamps FOR • for sample of P.\CKER's TAR S(lAI'. -

Item Product Description Block 1 Janitorial Cleaners

2 5 6/7 11 Larmel Industry Corp. I. Janvey & Sons, Inc. Imperial Bag & paper WB Mason Co. Inc. P.O. Box 334 218 Front Street 255 Route 1 & 9 90 Nicon Street P.O. Box 335 Jersey City, NJ 07306 Hauppaugge, NY 11788 Oceanside, NY 11572 Hempstead, NY 11550 Thomas Schwartz Bruce Janvey Rick Kesten Daniel Orr Jr. 516-678-2780 516-489-9300 201-437-7440 888-926-2766 [email protected] [email protected] [email protected] [email protected] Item Product Description Price Price Price Price Block 1 Janitorial Cleaners 1} Janitorial Cleaning System, All components must be concentrated, in a tamper proof metered dispensing package with no hand mixing required. All Products by the Same Manufacturer Meant to be used as an integrated cleaning System and products to include: A} CLEANER, NON TOXIC , GENERAL PURPOSE , ENVIRONMENTALLY SAFE NB J-fill 2/2.5L to cs $ 44.99 NB GREEN SEAL CERTIFIED J-fill- $84.20 PRODUCT YOU ARE BIDDING : JOHNSON'S GP FORWARD (J-FILL AND RTD) OR EQ. RTD 2/1.5L to cs spartan 4740 PACKING INFORMATION: j-fill- 1:256, RTD- 1:256 4-2 liters/cs GALS: 2 PER CASE RTD- $69.70 1:128 DILUTION RATE : # gallons jfill- 1280 271 # gallons RTD-768 price per gallon jfill-0.0065 price per gallon rtd- $0.09075 0.166076367 B} BATHROOM CLEANER & SCALE REMOVER, NON TOXIC NB $ 78.38 $ 72.04 ENVIRONMENTALLY SAFE J-fill 2/2.5L to cs GREEN SEAL CERTIFIED $ 60.55 PRODUCT YOU ARE BIDDING : Johnson's Crew 44 (J-Fill and RTD) or EQ spartan 4716 BCC3314700 PACKING INFORMATION : RTD 2/1.5L to cs 4-2 liters /cs 2 L 4/CS $ 52.20 DILUTION RATIO : Not Less than 1:18 J-fill- 1:18, RTD-1:18 42395 1:64 # liters Jfill- 90, liter-$0.672 8 liters 8 2 5 6/7 11 Larmel Industry Corp. -

A Weekly Journal of Practical Information, Art

INFORMATION, ART, SCIENCE, MECHANICS, CHEMISTRY, AND MANUFACTURES. A WEEKLY JOURNAL OF PRACTICAL Vol. XXX.-No. 11. ] ['3 per Annum, [NEW SI!:RIES.j NEW YORK, MARCH 14, 1874. ADVANCE. NEW AND GIGANTIC TELESCOPE. nicest engineering skill. In brief, it may be safely asserted tbe exact form necessary. But little labor, comparatively Among the many ideas which have been elicited by the that a metallic mirror, of the large size above noted. suppos speaking, will here be required, as an approximateIN or very discussion in these columns regarding a gigantic or " million ing it. could be successfully constructed, would, from its great nearly true curve will, it is believed, be taken by the glass dollar " telescope, we bave recently had submitted to our weight but far more on account of its conse'luent flexure,be in fitting itself to the mold. The reflecting face is, lastly, examination one which seems to us quite novel, ingenious, practically useless. silvered by Dr. Draper's process, a solution of Rochelle and. although untried, not unpractical. It is a scheme for Mr. Daniel C. Chapman, of tl>is city, who is the originator salts and nitrate of silver being applied, which very quick a huge instrument, to be built on either the Gregorian or of the plan we are about to describe, suggests both a mod., ly dllposits a fine uniform metallic surface. It will be Cassegrainian system, in which the image is firstreceived on of making a mirror of light weight, and also a method of noted that the inventor thus obtains a reflector of light a large parabolic mirror located in a position diametrically supporting the same. -

Oyster Pub Cover For

GULF OYSTER INDUSTRY PROGRAM NATIONAL SEA GRANT COLLEGE PROGRAM ATMOS ND PH A ER IC IC N A A D E M C I O N I S L T A R N A O T I I T O A N N U . S E . C D R E E PA M RT OM MENT OF C This publication was produced by the Louisiana Sea Grant College Program for the National Sea Grant College Program, September 2003. Written by Elizabeth Coleman Design and cover photo by Robert Ray For more information about the oyster research projects sponsored through Sea Grant’s Gulf Oyster Industry Program and Oyster Disease Research Program, contact: National Sea Grant College Program NOAA, 1335 East -West Highway Silver Spring, Maryland 20910 Website: http://www.nsgo.seagrant.org/research/oysterdisease/index.html For additional copies of this publication, contact: Communications Office Louisiana Sea Grant College Program Louisiana State University Baton Rouge, Louisiana 70803 Telephone: (225) 578-6448 GS JOB 54665 AUGUST 2003 ACCT 167-13-5126-3110 MOHAWK 50-10 PLUS SOFT WHITE MATTE 80# COVER-100# TEXT MARKS Q=500 Contents 3 Foreword 4 An Industry Under Siege The traditional oyster industry in the Gulf of Mexico faces challenges that may destroy it. The Gulf Oyster Industry Program, a remarkable partnership among industry, science, and government, provides a practical and effective means for keeping the industry viable. 7 Controlling Disease The control of oyster pathogens – both those that kill oysters and those that cause human illness – is a priority. Because these pathogens occur naturally in the water, the greatest hope for success in fighting them lies in the laboratory and the hatchery, primarily through genetics research. -

Yashwantrao Chavan Maharashtra Open University V101:B. Sc

Yashwantrao Chavan Maharashtra Open University V101:B. Sc. (Hospitality and Tourism Studies) V102: B.Sc. (Hospitality Studies & Catering Ser- vices) HTS 103: Accomodation and Front Office Foundation -1 YASHWANTRAO CHAVAN MAHARASHTRA OPEN UNIVERSITY (43 !££§°© &≤ /¶¶©£• &§°© ) V101: B. Sc. Hospitality and Tourism Studies (2016 Pattern) V102: B. Sc. Hospitality Studies and Catering Services (2016 Pattern) Developed by Professor Dr Rajendra Vadnere Director, School of Continuing Education Yashwantrao Chavan Maharashtra Open University, Nashik UNIT 1 Accommodation Sector UNIT 2 The Guest Accommodation UNIT 3 Hotel Front Office UNIT 4 Hotel Housekeeping Semester – 1 HTS103: Accommodation & Front Office Foundation -I Theory: 4 Credits; Total Hours =60 Practical: 2 Credits, Total Hours =60 Course Contents: Unit – 1 Accommodation Sector: - Introduction, Concept, and its importance; Types & Classification of Hotels on different basis; Star Categorization, Heritage Hotels and others in India, Organisation Structure of Hotels; Origin, growth and development of Hotel Sector in India.(ITC, The Taj Group, The Oberoi Group), Foreign Hotel Chains in India – Hilton, Marriott, Hyatt Unit – 2 The Guest Accommodation: Guest Rooms, Types, Layouts, Salient Features, Description, Guest Room amenities, supplies and services, Floors, Room Name List Patterns, Guest Elevators, Floor Pantries, Guest Safety on Floors, Guest Safety Procedures during Fire, emergencies Unit – 3 Hotel Front Office : Front Office Introduction, Functions and its importance, Different -

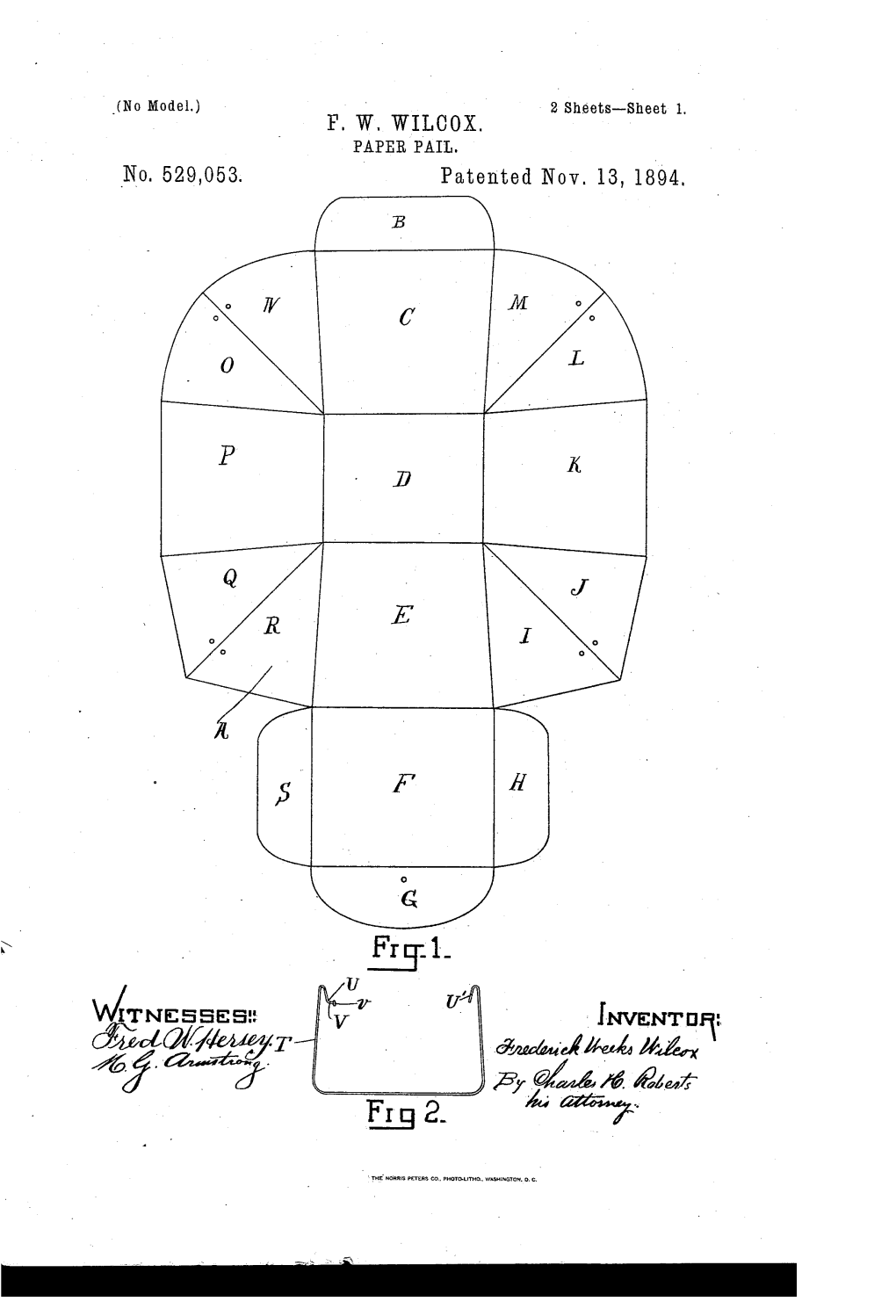

Chinese Takeout Box Emoji Proposal Submitted By: Jennifer 8

Chinese Takeout Box Emoji Proposal Submitted by: Jennifer 8. Lee, Yiying Lu, and Emojination Date: January 19, 2016 Art created by Yiying Lu. Licensed for noncommercial use: free to share and use. Abstract We propose the inclusion of the trapezoidal Chinese takeout box emoji, a highly recognized icon that carries both literal and figurative meanings. While the box itself is predominantly found in the United States and not used in greater China, it has become understood in Western cultures as a symbol of Chinese food, in addition to conveying the general concepts of takeout and delivery (Lee, 2008; Greenbaum and Rubinstein, 2012). In some cases, it has even been used to evoke the nationstate of “China” in American corporate advertising, despite the fact that the boxes themselves are not commonly found in Asia. The emoji is expected to be used frequently because it is a visual shorthand for one of one of the most popular ethnic cuisines in the world, in addition to having secondary connotations of food preparation and lifestyle. Official name: TAKEOUT BOX. Aliases: CHINESE TAKEOUT BOX, CHINESE FOOD TAKEOUT BOX, TAKEOUT CONTAINER, CHINESE TAKEOUT CONTAINER, CHINESE FOOD TAKEOUT CONTAINER, OYSTER PAIL, TAKEOUT BOX, TAKE OUT BOX. Introduction Historical Context The Chinese takeout box has a long and interesting history in the United States. The object that is now recognized as the Chinese takeout box was originally created to serve as an oyster pail around the turn of the 20th century. The first related patent was issued to the inventor Frederick Weeks Wilcox of Chicago in 1894 for a “paper pail.” A related patent was issued to 1908 to J .G. -

A Design and Build Competition for High School and Undergraduate Students

A Design and Build competition for High School and Undergraduate Students AIAA Foundation Contents 1 Preliminary Statement ................................................................................................. 1 2 Mission Scenario ......................................................................................................... 2 3 Game Design ............................................................................................................... 3 3.1 Game Overview .................................................................................................. 3 3.2 Competition Classes ............................................................................................ 3 3.3 Target Coordinates: GPS Waypoints .................................................................. 4 3.4 Target Coordinates: AR Tags ............................................................................. 4 3.5 Packages .............................................................................................................. 4 3.6 Package Delivery ................................................................................................ 5 3.7 “Successful Delivery” ......................................................................................... 5 4 Field Design ................................................................................................................ 6 4.1 Field Size ............................................................................................................ 6 4.2 Delivery -

Advertising Ephemera Trade Card Index Series I and II

Advertising Ephemera Trade Card Index Series I and II General product/ Other Formats; cards in Series Series in cards I cards Oversize Manufacturer, business or product Specific Product Names service type Ind. # Box # Total# of Location Languages Notes Joseph Breck & Sons seeds :134 18 2 2 catalog covers Price & Knickerbocker seeds :134 1 1 see also Series II Reid's Flower Seeds seeds :134 1 1 (VIA) See also Series II Rice's Seeds (Jerome B. Rice) seeds :134 1 2 (VIA) S.W. Twombley & Sons, Florists florists :134 1 1 Wm. Pierce, Florist & Seedsman seeds; florists :134 1 1 Wyman Elliot, Dealer in Seeds seeds :134 18 1 1 Humboldt Nickel & Copper Co. mining :31 Series II (VIA) only Iron Bay Manufacturing Co. foundry :31 1 1 Drake Company granite :383 Series II (VIA) only H.M. Phelps, Steam Granite Works granite :383 1 1 Auld & Conger marble :385 1 1 C.G. Gunther's Sons, Furriers fur trade :404 1 6 E. W. Boughton & Co. fur trade :404 1 1 Edward Kakas fur trade :404 Series II (VIA) only Henry Martin fur trade :404 Series II (VIA) only J.S. Barnet & Bro. skins :404 18 1 1 Joseph A. Jackson fur trade :404 1 1 folder Carter, Dinsmore & Co. Carter's Mucilage, Ink glue; ink :406 Series II (VIA) only Joshua S. Chase Chase's Liquid Glue glue :406 Series II (VIA) only Royal Cement Royal Cement glue :406 1 1 See also Series II Russia Cement Company La Page's Glue glue :406 1 1 (VIA) Tenexine Company Egyptian Tenexine glue :406 Series II (VIA) only Page 1 of 87 Advertising Ephemera Trade Card Index Series I and II General product/ Other Formats; cards in Series Series in cards I cards Oversize Manufacturer, business or product Specific Product Names service type Ind. -

Cowboy Poetry

The Fiddle Footed Cowboy C F C F C ~~~~::::;=;:~:~~~~'--./~_'--I -..fi=-'~ I~ ~ '~ - - - - ~ I~_. 1-'- - -c=. ~ - - -r- ;;;.-. ,::-. 1 He gar foot was on the rail He leaned up on the den gate His F c 07 G7 c ~ 61 . I 61 . I twirled spur TOwell with his thumb And said "I'll hit the trail. They're fight iog F c F c F - 20 when 'cr~ the pond got chore to do. But c 07 G7 c ! J rj . ~~ ~. ~- - ~ . .'- '--' =-, ~ .. =t .- 27 get the mess cleaned up Will you he wait - iog, 8_r m21ody by George W. LyonlO He leanedupon the gardengate He kicked his spur againstthe gate His foot was on the rail And slowly shook his head He twirled a spur rowell with his thumb "Don't reckon I would fancy And said "I'll hit the trail." No China doll," he said "They're fighting over 'cross the pond A rowell fell from out the spur I got a chore to do. He placed it in her hand But when we get this messcleaned up "!'llieave you this one souvenir Will you be waiting, Sue?" Whilst I'm in a foreign land:' "Boy, your twines sure tangled "Without the rowell the spur's no good, I've heard that line before Or the rowell without the spur." Just a fiddle-footed cowboy He seemdabout to mount his horse That's why you're off to war." And never looked at her. "The first good-looking gal you spy We wouldn't put dIe hobbleson When you get acrossthe sea And as he turned his head You'll start your rope a-spinning "You fiddle-footed cowboy And you'll never think of me." I'll be waiting," she said. -

31 E. Bissell Ave. Youngstown, Ohio 44505 Tel

Ho Tel. (330) 270-8000 Fax.(330) 270-8006 31 E. Bissell Ave. Youngstown, Ohio 44505 www.acmesteak.com Tel. (330) 270-8000 Fax. (330) 270-8006 Tel. (330) 270-8000 Fax.(330) 270-8006 Our History Acme Steak & Seafood was founded in 1947 in Youngstown, Ohio by three brothers: Joseph, Michael and Thomas Mike. It all began just after World War II. The three brothers had just been released from their military services in which each served four years. One day at a restaurant, they witnessed a local chef going through the laborious and seemingly icky task of making hamburger patties by hand. The final product was that each of the brothers received different sized burgers. This gave them the idea to prepare and sell the burgers in advance so as to keep the size and portions consistent and save the chef some work. And so, Acme Steak was born! Although selling frozen meat was uncommon in those days, the business eventually took off and as they say, the rest is history. Over 70 years have passed, Acme Steak and Seafood remains a localy owned family business set on providing quality products and the best service to its customers. Today, Acme Steak & Seafood is the home to a USDA Meat processing plant, a leading supplier of quality burgers, Sausage products and Custom Cut Steaks to the Youngstown and surrounding area. Today, we stock over 5000 items and counting. 31 E. Bissell Ave. Youngstown, Ohio 44505 www.acmesteak.com Tel. (330) 270-8000 Fax. (330) 270-8006 ACME SECTION PG1 ACME SECTION Pg1 OUR USDA PLANT Our state of the art USDA inspected facility insures the highest standards in meat processing and Custom Cut Steaks.