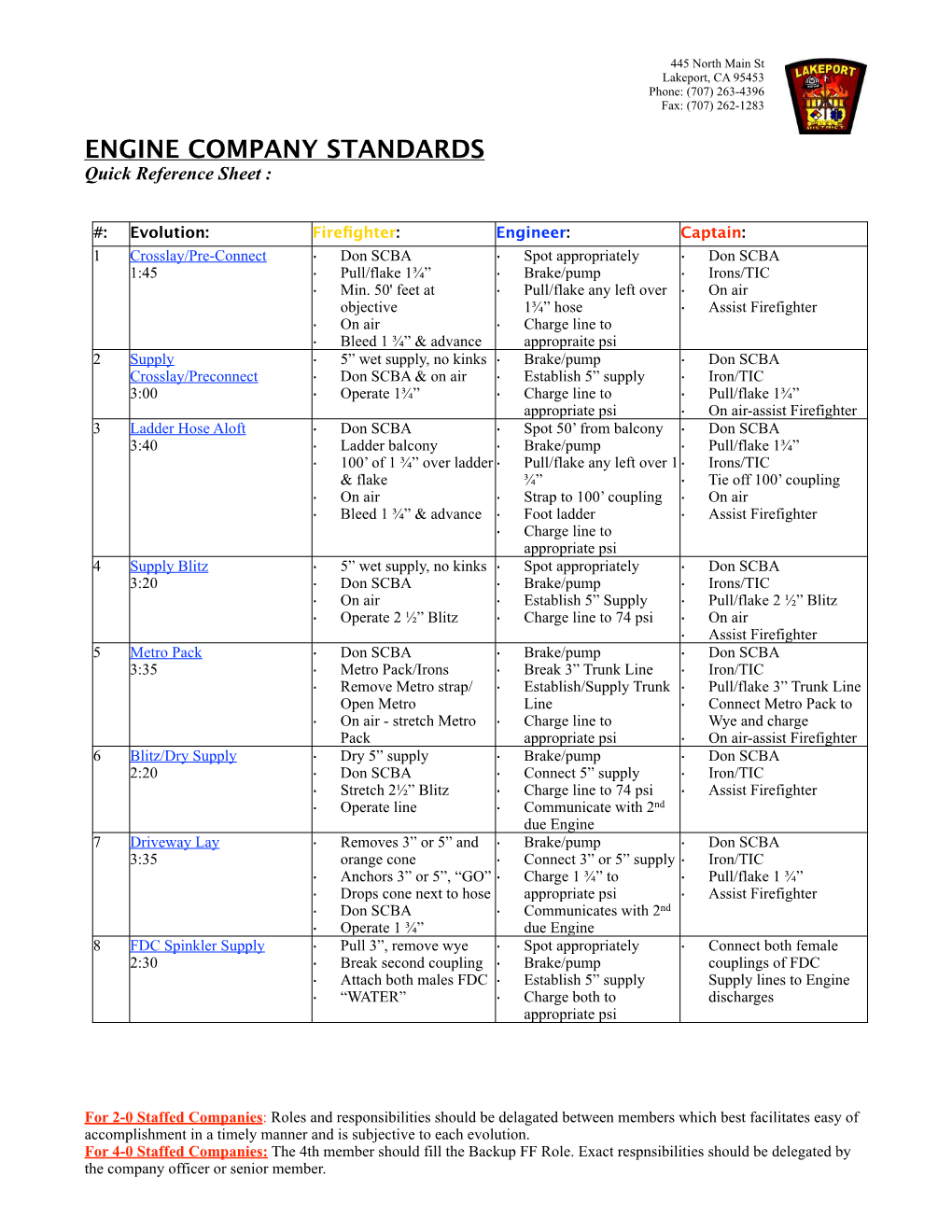

ENGINE COMPANY STANDARDS Quick Reference Sheet

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Wildland Fire Incident Management Field Guide

A publication of the National Wildfire Coordinating Group Wildland Fire Incident Management Field Guide PMS 210 April 2013 Wildland Fire Incident Management Field Guide April 2013 PMS 210 Sponsored for NWCG publication by the NWCG Operations and Workforce Development Committee. Comments regarding the content of this product should be directed to the Operations and Workforce Development Committee, contact and other information about this committee is located on the NWCG Web site at http://www.nwcg.gov. Questions and comments may also be emailed to [email protected]. This product is available electronically from the NWCG Web site at http://www.nwcg.gov. Previous editions: this product replaces PMS 410-1, Fireline Handbook, NWCG Handbook 3, March 2004. The National Wildfire Coordinating Group (NWCG) has approved the contents of this product for the guidance of its member agencies and is not responsible for the interpretation or use of this information by anyone else. NWCG’s intent is to specifically identify all copyrighted content used in NWCG products. All other NWCG information is in the public domain. Use of public domain information, including copying, is permitted. Use of NWCG information within another document is permitted, if NWCG information is accurately credited to the NWCG. The NWCG logo may not be used except on NWCG-authorized information. “National Wildfire Coordinating Group,” “NWCG,” and the NWCG logo are trademarks of the National Wildfire Coordinating Group. The use of trade, firm, or corporation names or trademarks in this product is for the information and convenience of the reader and does not constitute an endorsement by the National Wildfire Coordinating Group or its member agencies of any product or service to the exclusion of others that may be suitable. -

Engine Riding Positions Officer Heo Nozzle Ff

MILWAUKEE FIRE DEPARTMENT Operational Guidelines Approved by: Chief Mark Rohlfing 2012 FORWARD The purpose of these operational guidelines is to make clear expectations for company performance, safety, and efficiency, eliminating the potential for confusion and duplication of effort at the emergency scene. It is understood that extraordinary situations may dictate a deviation from these guidelines. Deviation can only be authorized by the officer/acting officer of an apparatus or the incident commander. Any deviation must be communicated over the incident talk group. The following guidelines are meant to clarify best operational practices for the MFD. They are not intended to be all-inclusive and are designed to be updated as necessary. They are guidelines for you to use. However, there will be no compromise on issues of safety, chain of command, correct gear usage, or turnout times (per NFPA 1710). These operating guidelines will outline tool and task responsibilities for the specific riding positions on responding units. While the title of each riding position and the assignments that follow may not always seem to be a perfect pairing, the tactical advantage of knowing where each member is supposed to be operating at a given assignment will provide for increased accountability and increased effectiveness while performing our response duties. Within the guidelines, you will see run-type specific (and in some cases, arrival order specific) tool and task assignments. On those responses listing a ‘T (or R)’ as the response unit, the Company will be uniformly listed as ‘Truck’ for continuity. The riding positions are as follows: ENGINE RIDING POSITIONS OFFICER HEO NOZZLE FF BACKUP FF TRUCK RIDING POSITIONS OFFICER HEO VENT FF FORCE FF SAFETY If you see something that you believe impacts our safety, it is your duty to report it to your superior Officer immediately. -

Firefighter I Skills Sheets Master List

NYS Basic Exterior Firefighting Operations 2016 Edition w/ HMFRO Skills Sheets by BEFO Unit [2016 Edition] TO BE COMPLETED AT HOME DEPARTMENT Skill 2-I-1 Respond on an Apparatus to an Emergency Scene- Due Unit 4 Skill 2-I-2 Operate in Established Work Area at Emergency Scene- Due Unit 4 Skill 6-I-8, 9 Filling SCBA Cylinder Due Unit 4 Skill 8-I-1 Clean and Inspect Rope Due Unit 8 Skill 10-I-1 Emergency Scene Illumination Due Unit 16 Skill 11-I-1 Hand Tool Maintenance Due Unit 19 Skill 11-I-2 Power Tool Maintenance Due Unit 19 Skill 12-I-1 Clean, Inspect, and Maintain a Ladder Due Unit 9 Optional Skill 15-I-10, 14 Loading/ Advancing a Triple-Layer Load (use if FD utilizes Load) Due Unit 14 Optional Skill 15-I-11, 14 Loading/ Advancing a Pre-Connected Minuteman Load (use if FD utilizes Load) Due Unit 14 UNIT 3 Skill 6-I-1 Donning Personal Protective Equipment Skill 6-I-6, 7 Inspection, Cleaning, and Sanitizing of SCBA Skill 6-I-10 One-person SCBA bottle change Skill 6-I-11 Two-person SCBA bottle change Unit 7 Skill 7-I-1, 2, 3 Operating Portable fire extinguishers Unit 9, 10, & 11 Skill 8-I-2 to 12 Knots Skill 8-I-13 to 18 Hoisting Tools and Equipment Skill 12-I-2 Single FF- Single Ladder- Low Shoulder Carry Skill 12-I-3 Two Firefighter – Low Shoulder Carry Skill 12-I-4 Three FF- Flat Shoulder Carry Method Skill 12-I-5 Three FF – Flat Arm Carry Skill 12-I-6 Two FF Arm’s Length on Edge Carry Method Skill 12-I-8, 17 One FF Beam Raise a Ladder, leg lock Skill 12-I-7, 9 Two FF Flat Ladder Raise, Tie a Halyard Skill 12-I-10, 16 Two FF Beam Raise, -

TFT Guide to Nozzles

CONTENTS 10 COMMON QUESTIONS ABOUT AUTOMATIC EVOLUTION OF FIRE STREAMS.......................................................2 NOZZLES EVOLUTION OF COMBINATION NOZZLES......................................3 1) How is an automatic nozzle different from a regular (conventional) UNDERSTANDING FIRE NOZZLE DESIGN ......................................5 nozzle? LIMITATIONS OF CONVENTIONAL NOZZLES.................................6 2) How does an automatic nozzle work? AUTOMATIC NOZZLES INVENTED................................................ 10 3) What pressure do we pump to automatic nozzles? BENEFITS OF AUTOMATIC NOZZLES .......................................... 13 4) How do I know how much water I am flowing? SLIDE VALVE vs. BALL VALVE ..................................................... 16 5) What is the flow from each "Click Stop" on the nozzle? TRAINING CONSIDERATIONS WITH AUTOMATICS .................... 18 6) Can I use automatics with foam and foam eductors? USING LARGER SIZE ATTACK LINES .......................................... 21 7) Why don't all automatic nozzles have spinning teeth? 8) What type of nozzle is best for “Nozzleman Flow Control?” BOOSTER TANK OPERATIONS..................................................... 22 SHAPING THE FIRE STREAM PATTERN ...................................... 23 9) Is it true that the stream from a "SOLID" bore nozzle hits harder and goes farther than the "Hollow”' stream from a fog nozzle? SMOOTH BORE vs. FOG TIP .......................................................... 24 FLUSHING DEBRIS......................................................................... -

ENGINE COMPANY OPERATIONS Second Edition

FIRE AND RESCUE DEPARTMENTS OF NORTHERN VIRGINIA FIREFIGHTING AND EMERGENCY OPERATIONS MANUAL ENGINE COMPANY OPERATIONS Second Edition Issued: November 2003 Revised: December 2013 Engine Company Operations, Second Edition Final Version, December 2013 ACKNOWLEDGEMENTS Engine Company Operations was developed through a cooperative effort of the following Northern Virginia fire departments: . City of Alexandria . Loudoun County . Arlington County . City of Manassas . City of Fairfax . Marine Corps Base Quantico . Fairfax County . Metropolitan Washington Airports . Fauquier County Authority (MWAA) . Fort Belvoir . Prince William County . Fort Myer . Stafford County The Northern Virginia Fire Operations Board managed the development of the first edition of the manual (released in November 2003) and the current second edition. The first edition content was developed by the Operations Board’s Technical Writing Group. The following members of the Firefighting and Emergency Operations Technical Writing Workgroup participated in the third edition revision of the manual in 2012 and 2013: City of Alexandria: Lieutenant Dave Bogozi, Lieutenant Matthew Craig City of Manassas: Battalion Chief Mark Nary Arlington County: Captain David Santini, Captain Nick Krechting Fairfax City: Captain Joseph Schumacher, Captain Gregory Thuot Fairfax County: Battalion Chief Tyrone Harrington, Captain David Barlow, Captain Dan Shaw, Master Technician Matthew Tamillow Fort Belvoir: Lieutenant Kevin Good Fort Myer: Assistant Chief Bruce Surette, Captain William Long Loudoun -

Examination Information Information

8/16/19 MIDDLETOWN CIVIL SERVICE COMMISSION Invites ALL Applicants for FIREFIGHTER/EMT APPLICATION INFORMATION Application Opening Date: August 16, 2019 Application Deadline: August 30, 2019 at 5:00 p.m. No application will be accepted after deadline. Application Fee: No fee is required to take the exam. How to Apply: Application packets may be obtained from the Human Resources Office located on the second floor of City Building, One Donham Plaza, Middletown, Ohio or may be downloaded from the website at http://www.cityofmiddletown.org/jobs. Please return completed application to Human Resources, City of Middletown, One Donham Plaza, Middletown, Ohio 45042, fax to 513-425-7929, or email to [email protected]. ADA Accommodation Requests: It is the policy of the City of Middletown to make all public examinations accessible to all persons, in accordance with state and/or federal laws. If you have a disability which requires accommodation in order for you to attend and/or participate in this examination, please contact us at 425-7706 or 425-7934 at least forty-eight hours prior to the time of the examination to advise us of the need for accommodation, and reasonable efforts shall be made to provide the same. EXAMINATIONEXAMINATION INFORMATION INFORMATION Examination Date and Time: ALL applicants will take a written examination on Saturday, September 7 at 9:00 a.m. Applicant check in time is between 8:15 a.m. and 8:45 a.m. No candidate will be admitted after the check in time. I.D. Requirements: Picture I.D. required at check-in. -

PASS / FAIL Firefighter II NFPA 1001, 2013 Edition Practical Skills Test JPR

CANDIDATE # Firefighter II NFPA 1001, 2013 Edition Station #: FF2-1 Practical Skills Test JPR: NFPA 1001 6.3.4 First Second Identify and Protect Evidence of Fire Cause Attempt Attempt Pass Fail Pass Fail 1 Secures the scene using barriers and/or guards Recognizes potential evidence 2 Item #1 3 Item #2 4 Item #3 Evaluator must ask: “What steps should be taken to avoid disturbing the 5 evidence you have identified?” Accept any answer that includes: Don’t touch it Keep hose lines and personnel away from it Avoid use of excessive water Don’t move it unnecessarily Evaluator states: “With the materials you have available, show me how you would 6 protect these items of evidence from being destroyed.” Covers foot prints and tire tracks (example: with cardboard boxes, traffic cones, etc.) Covers loose papers and other evidence lightly (example: with plastic sheeting) to protect against drafts and water Provides security for evidence Does not move any item of evidence 11 Describe two noteworthy observations about the scene Evaluator Name: Evaluator Signature: PASS / FAIL (Circle one) Rev 02/17 CANDIDATE # Firefighter II NFPA 1001, 2013 Edition Station #: FF2 - 1 Practical Skills Test STATION: Identify and Protect Evidence of Fire Cause Protect evidence of fire cause and origin, given a flashlight and overhaul tools, so that the OBJECTIVE: evidence is properly noted and protected from further disturbance until investigators can arrive on the scene. JPR: NFPA 1001 6.3.4 Simulated fire scene with at least 3 items of evidence, including tire tracks or footprints, EQUIPMENT: and charred, loose papers. -

ENOP Position Task Book

United States BLM FIRE AND AVIATION MANAGEMENT Department of the Interior Bureau of Land Management National Park Service TASK BOOK FOR THE POSITION OF U.S. Fish and Wildlife Service Bureau of Indian Affairs ENGINE OPERATOR (ENOP) United States Department of Agriculture U.S. Forest Service MAY 2019 Task Book Assigned To: Trainee’s Name: Home Unit/Agency: Home Unit Phone Number: Task Book Initiated By: Official’s Name: Home Unit Title: Home Unit/Agency: Home Unit Phone Number: Home Unit Address: Date Initiated: The material contained in this book accurately defines the performance expected of the position for which it was developed. This task book is approved for use as a position qualification document in accordance with the instructions contained herein. Verification/Certification of Completed Task Book for the Position of: ENGINE OPERATOR Final Evaluator’s Verification To be completed ONLY when you are recommending the trainee for certification. I verify that (trainee name) has successfully performed as a trainee by demonstrating all tasks for the position listed above and should be considered for certification in this position. All tasks are documented with appropriate initials. Final Evaluator’s Signature: Final Evaluator’s Printed Name: Home Unit Title: Home Unit/Agency: Home Unit Phone Number: Date: Agency Certification I certify that (trainee name) has met all requirements for qualification in the above position and that such qualification has been issued. Certifying Official’s Signature: Certifying Official’s Printed Name: Title: Home Unit/Agency: Home Unit Phone Number: Date: This document is posted on the NWCG website: https://www.nwcg.gov/publications/agency-taskbooks 2 BUREAU OF LAND MANAGEMENT (BLM) POSITION TASK BOOK This BLM position task book (PTBs) has been developed for the Engine Operator position. -

Occupational Safety and Health Compliance Guide for Fire

1 State of Illinois Illinois Department of Labor OCCUPATIONAL SAFETY AND HEALTH COMPLIANCE GUIDE FOR FIRE DEPARTMENTS Division of Occupational Safety and Health ILLINOIS - OSHA 2 General Disclaimer This guide was created as a resource for public sector fire departments in Illinois to achieve compliance with the minimum legal requirements for occupational safety and health contained in standards adopted by the State of Illinois. This guide cannot possibly cover every regulatory standard that may apply to fire departments but does provide a wealth of information to assist employers with providing a safe and healthful work environment. Grant Funding Declaration The 23(g) State and Local Government Plan is funded by a federal grant which constitutes fifty percent of the overall budget. Fifty percent is financed by State funds. Clarification on Fire Department and Fire District Illinois OSHA understands the similarities and differences between a municipal fire department and a fire protection district, however, for the purposes of simplicity the term “fire department” will be used in this guide to reference both types of fire protection organizations. External Links There are several resources and websites that are hyperlinked in this document. Most links are not administered by the Illinois Department of Labor. Links that no longer function can be reported to [email protected]. ILLINOIS - OSHA 3 Table of Contents Introduction . 4 Interacting with Illinois OSHA Enforcement . 7 The Inspection Process . 10 Fire Department Training Requirements . 15 Sample Annual Training Plan . 28 Training – Frequently Asked Questions . 31 Injury and Illness Reporting and Recordkeeping . 34 Compliance . 39 Fire Department Health and Safety Program (non-mandatory). -

25 Pointers for Your Engine Company by JEFF SHUPE

Continuing Education Course 25 Pointers for Your Engine Company BY JEFF SHUPE Program supported through an educational grant provided by: TRAINING THE FIRE SERVICE FOR 134 YEARS To earn continuing education credits, you must successfully complete the course examination. The cost for this CE exam is $25.00. For group rates, call (973) 251-5055. 25 Pointers for your engine company Educational Objectives On completion of this course, students will: ● Describe the limits of various hoseline sizes and the appropri- ● Gain an understanding of the importance of apparatus posi- ate size for specific fires using the acronym “ADULTS” tioning in terms of hoseline stretching ● Describe proper nozzle operating techniques ● Gain an understanding of the importance of proper hoseline pressure and flow B Y J E F F S H U P E building. it is a narrow street, and cars line both sides. the officer in charge of the first-due engine radios, “We have a 1 onsider this scenario: it is a midday summer working fire in a large 2 ⁄2-story frame. Well involved!” 1 afternoon, and a large 2 ⁄2-story, wood-frame structure the two firefighters in the company start to stretch the C is on fire. it is a double-decker style two-family dwell- initial attack hose. the older, senior firefighter knows the situ- ing that has been vacant for a short time. Fire is coming out of ation and “has been there” many times before. he starts to lay all windows and doors on both floors and the attic.t he smoke out the 2½-inch attack line. -

Operations Safety – Lost/Trapped Firefighter Policy # 13-0320.2 Issued 03/20/2013

HR/LF OPERATIONS SAFETY – LOST/TRAPPED FIREFIGHTER POLICY # 13-0320.2 ISSUED 03/20/2013 Subject: Lost/Trapped Firefighter-Self-Survival actions. Purpose: This policy outlines self-survival procedures for firefighters who are lost or trapped. Scope: This policy applies to all New Salem Fire Department personnel. The nature of firefighting places the firefighter at risk of becoming lost or trapped. The toxic environment provides only a narrow window of survivability. Survival depends on a mix of predictable self-survival actions by the lost firefighter and the Incident Commander. All crews entering the hazard zone must have a portable radio and personal rescue tools Minimum crew size is two and crews must stay intact 1 Crews must have an assignment and work under the supervision of a Division/Group Supervisor Crews must follow air management guidelines The following are basic guidelines for firefighters to follow if they become lost or trapped. Call for help immediately Firefighters who find themselves lost/trapped must immediately use “MAYDAY” to announce their situation while they continue to attempt to find a way out. Firefighters shall not delay notification of distress. Notifications must occur as soon as the firefighter THINKS he or she is in trouble. The acronym LIPS is used to provide information that will assist in rescuing the firefighter: L- Location - Advise command of your location I- Identification - Give your Name & Department P- Problem - Low on air, lost, trapped, entangled etc. S- Survival - Start self rescue and survival skills (ACTIVATE PASS) Other radio channel If a lost firefighter cannot contact dispatch, or other units on the assigned radio channel, the firefighter should go to another channel to attempt contact and declare an emergency. -

Home & Land Owners

HOME & LAND OWNERS URBAN | WILDLAND INTERFACE FIRE PROTECTION EQUIPMENT LNCURTIS.COM WATER FLOW IMPORTANT: Fighting fires should be performed by trained fire fighters only. PREPARATION PREVENTION DEFENSIBLE SPACE CALL 911 Intermountain Division Serving Colorado, Southern Idaho, Montana, Eastern Nevada, Utah and Wyoming 1635 Gramercy Road Salt Lake City, UT 84104 phone: 800-426-0509 fax: 801-487-1278 [email protected] Northwest Division Serving Alaska, Northern Idaho, Oregon and Washington 6507 South 208th Street Kent, WA 98032 phone: 800-426-6633 fax: 253-236-2997 [email protected] Pacific Division Serving California, Hawaii and Nevada 1800 Peralta Street Oakland, CA 94607 phone: 800-443-3556 fax: 510-839-5325 [email protected] Southwest Division Serving Arizona and New Mexico 4647 South 33rd Street Phoenix, AZ 85040 phone: 877-453-3911 fax: 602-453-3910 [email protected] facebook.com/ToolsForHeroes @ToolsForHeroes Tools for Heroes® courtesy https://www.nfpa.org/Public-Education/Fire-causes-and-risks/Wildfire/Preparing-homes-for-wildfire HOME & LAND OWNERS URBAN | WILDLAND INTERFACE FIRE PROTECTION EQUIPMENT PREPARATION PREVENTION DEFENSIBLE SPACE CALL 911 Informative resources for urban wildland interface readiness programs: U.S FOREST SERVICE https://www.fs.usda.gov/rmrs/ living-fire-how-social-scientists-are- photo courtesy Colorado State Forest Service helping-wildland-urban-interface- communities-reduce-wildfire NATIONAL FIRE The collection of product herein is designed to help the home and PROTECTION ASSOCIATION land