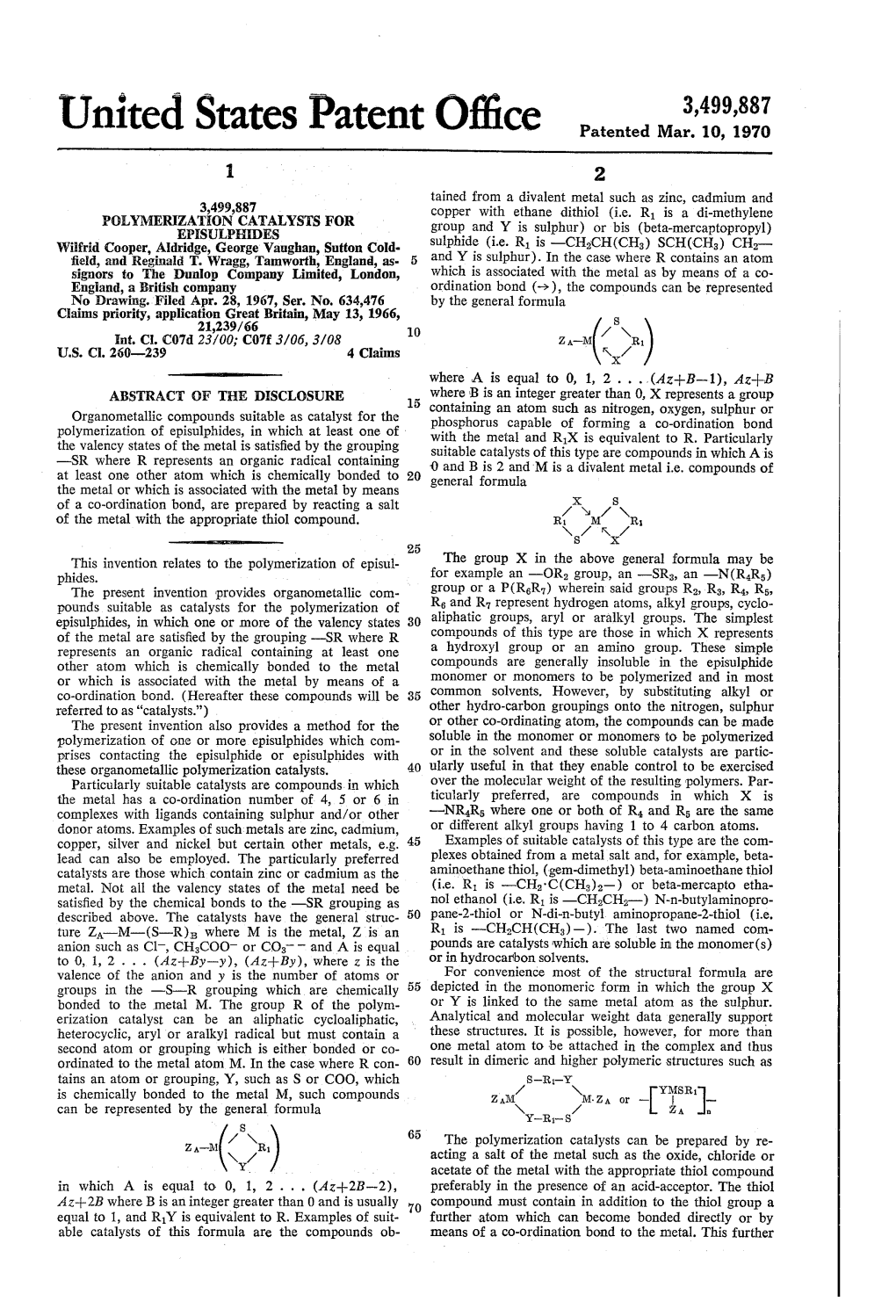

United States Patent Office Patented Mar

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Electronic Supplementary Material (ESI) for Chemcomm. This Journal Is © the Royal Society of Chemistry 2016

Electronic Supplementary Material (ESI) for ChemComm. This journal is © The Royal Society of Chemistry 2016 Colloidal Atomic Layer Deposition Growth of PbS/CdS Core/Shell Quantum Dots Michel Nasilowski,a Lea Nienhaus,a Sophie N. Bertram,a Moungi. G. Bawendia,* Department of Chemistry, Massachusetts Institute of Technology, Cambridge, Massachusetts 02139, USA. *e-mail: [email protected] Supplementary Information Experimental methods Chemicals: Sulfur (Aldrich, 99.998%), oleylamine (OLA, Aldrich, technical grade 70%), lead chloride (PbCl2, Alfa-Aesar, 99.999%), hexanes (Omnisolv, 98.5%), formamide (FA, Sigma-Aldrich, >99%), ammonium sulfide ((NH4)2S, Strem, 40-44% aqueous solution), cadmium acetate dihydrate (Cd(Ac)2, Sigma-Aldrich 98%), cadmium oxide (CdO, Alfa-Aesar, 99.998%), oleic acid (OA, Alfa-Aesar, technical grade 90%) and tetracholorethylene (Alfa-Aesar, 99%) were used without further purification. Cd(OA)2: 1.28 g of cadmium oxide in 20 mL of oleic acid was heated at 160°C for 1 hour under nitrogen until colorless. The solution was then degassed under vacuum at 70°C for 30 min. Synthesis of PbS QDs: The synthesis of PbS QDs was adapted from a previously reported procedure.1,2 0.080g of sulfur in 7.5 mL OLA was heated at 120°C for 20 min under nitrogen bubbling and stirring. 0.83g of PbCl2 in 15 mL OLA was degassed for 30 minutes at room temperature, then under nitrogen, the temperature was increased to 120°C (with a vacuum pull at 110°C for ~5min). Once the temperature was stable at 120°C, 2.5mL of the sulfur solution was swiftly injected into the lead solution. -

Oiv-Ma-As313-21.Pdf

COMPENDIUM OF INTERNATIONAL ANALYSIS OF METHODS - OIV Metatartaric acid Method OIV-MA-AS313-21 Type IV method Determination of the presence of metatartaric acid (Resolution Oeno 10/2007) 1. Introduction Metatartaric acid added to the wine to avoid tartaric precipitation is traditionally proportioned by the difference between the total tartaric acid following hot hydrolysis of metatartaric acid and natural tartaric acid preceding hydrolysis. However, taking into account the precision of the determination of tartaric acid, traces of metatartaric acid are not detectable by this method, and the additive, which is not accepted in certain countries, must therefore be characterised using a more specific method. 2. Scope Wines likely to contain traces of metatartaric acid. 3. Principle In relatively acid mediums, metatartaric acid forms an insoluble precipitate with cadmium acetate; it is the only one of all the elements present in must and wine to give such a precipitate . Note: Tartaric acid is also precipitated with cadmium acetate, but only in the presence of an alcohol content greater than 25% vol. The precipitate redissolves in water, unlike the precipitate obtained with metatartaric acid. The cadmium precipitate of metatartaric acid breaks down by heating with sodium hydroxide and releases tartaric acid. The latter produces a specific orange colour with ammonium metavanadate. 4. Reagents 4.1 Cadmium acetate solution at 5 p.100 4.1.1 Dihydrated cadmium acetate at 98% 4.1.2 Pure acetic acid 4.1.3 Distilled or demineralized water OIV-MA-AS313-21 : R2007 1 COMPENDIUM OF INTERNATIONAL ANALYSIS OF METHODS - OIV Metatartaric acid 4.1.4 Cadmium acetate solution: dissolve 5 g of cadmium acetate (4.1.1) in 99 mL of water (4.1.3) add 1 mL of pure acetic acid (4.1.2) 4.2 Sodium hydroxide 1M 4.3 Sulfuric acid 1M 4.4 Solution of ammonium metavanadate 2% w/v 4.4.1 Ammonium metavanadate 4.4.2 Trihydrated sodium acetate at 99% 4.4.3 Sodium acetate solution at 27 p. -

Qt4gj5w6d6 Nosplash 07E474c

This is an open access article published under a Creative Commons Attribution (CC-BY) License, which permits unrestricted use, distribution and reproduction in any medium, provided the author and source are cited. Article Cite This: ACS Omega 2019, 4, 5486−5495 http://pubs.acs.org/journal/acsodf Mechanochemical Synthesis, Accelerated Aging, and Thermodynamic Stability of the Organic Mineral Paceite and Its Cadmium Analogue ‡ † ‡ † § ‡ § Shaodi Li, , Igor Huskic,́, Novendra Novendra, Hatem M. Titi, Alexandra Navrotsky,*, ‡ and Tomislav Frisčič*́, ‡ Department of Chemistry, McGill University, 801 Sherbrooke St. W., H3A 0B8 Montreal, Canada § Peter A. Rock Thermochemistry Laboratory and NEAT ORU, University of California Davis, One Shields Avenue, Davis, California 95616, United States *S Supporting Information ABSTRACT: We demonstrate the use of ball milling mechanochemistry for rapid, simple, and materials-efficient · synthesis of the organic mineral paceite CaCu(OAc)4 6H2O (where OAc− is the acetate ion), composed of coordination polymer chains containing alternating Ca2+ and Cu2+ ions, as · well as its cadmium-based analogue CaCd(OAc)4 6H2O. While the synthesis of paceite in aqueous solutions requires a high excess of the copper precursor, mechanochemistry permits the use of stoichiometric amounts of reagents, as well as the use of poorly soluble and readily accessible calcium carbonate or hydroxide reactants. As established by thermochemical measurements, enthalpies of formation of both synthetic paceite and its cadmium analogue relevant to the mechanochemical reactions are highly exothermic. Reactions can also be conducted using accelerated aging, a synthetic technique that mimics geological processes of mineral weathering. Accelerated aging reactivity involving copper(II) acetate monohydrate (hoganite) and calcium carbonate (calcite) provides a potential explanation of how complex organic minerals like paceite could form in a geological environment. -

Synthesis and Characterization of Surface-Capped, Size-Quantized Cds Clusters

1322 J. Am. Chem. SOC.1990, I12, 1322-1 326 Synthesis and Characterization of Surface-Capped, Size-Quantized CdS Clusters. Chemical Control of Cluster Size Norman Henon,**+Ying Wang,+ and Hellmut Eckert* Contribution No. 4743 from E.I. du Pont de Nemouts & Company, Central Research and Development Department, P.O.Box 80328, Wilmington, Delaware 19880-0328, and Department of Chemistry, University of California at Santa Barbara, Santa Barbara, California 93106. Received May 8, I989 Abstract: Clusters of CdS in the quantum confinement regime C5O-A diameter are prepared in a rational technique whereby the cluster size and its distribution are controlled by chemical means. Competitive reaction chemistry between CdS core cluster growth and surface capping by thiophenolateleads to clusters whose core is essentially sphalerite CdS but whose reactive surface has been passivated by covalently attached phenyl groups. Adjustment of the sulfide to thiophenol ratio during synthesis takes advantage of the competitive reaction rates of these species with Cd ions to control the eventual cluster size. The clusters remain soluble in several organic solvents but may be isolated as stable powders and subsequently redissolved. The Cd "'NMR data for this series of capped clusters confirm the presence of sphalerite CdS as the cluster core and the increasing percentage of Cd involved in this core as the S/SPh ratio increases. Optical properties demonstrate well-behaved absorption edge and emission band shifts with development of exciton features as the clusters grow. Colloidal semiconductor species are currently under intense combustion (C + H) and atomic absorption were performed by Galbraith investigation as examples of nonmolecular materials that dem- Co., Knoxville, TN. -

Chemical Names and CAS Numbers Final

Chemical Abstract Chemical Formula Chemical Name Service (CAS) Number C3H8O 1‐propanol C4H7BrO2 2‐bromobutyric acid 80‐58‐0 GeH3COOH 2‐germaacetic acid C4H10 2‐methylpropane 75‐28‐5 C3H8O 2‐propanol 67‐63‐0 C6H10O3 4‐acetylbutyric acid 448671 C4H7BrO2 4‐bromobutyric acid 2623‐87‐2 CH3CHO acetaldehyde CH3CONH2 acetamide C8H9NO2 acetaminophen 103‐90‐2 − C2H3O2 acetate ion − CH3COO acetate ion C2H4O2 acetic acid 64‐19‐7 CH3COOH acetic acid (CH3)2CO acetone CH3COCl acetyl chloride C2H2 acetylene 74‐86‐2 HCCH acetylene C9H8O4 acetylsalicylic acid 50‐78‐2 H2C(CH)CN acrylonitrile C3H7NO2 Ala C3H7NO2 alanine 56‐41‐7 NaAlSi3O3 albite AlSb aluminium antimonide 25152‐52‐7 AlAs aluminium arsenide 22831‐42‐1 AlBO2 aluminium borate 61279‐70‐7 AlBO aluminium boron oxide 12041‐48‐4 AlBr3 aluminium bromide 7727‐15‐3 AlBr3•6H2O aluminium bromide hexahydrate 2149397 AlCl4Cs aluminium caesium tetrachloride 17992‐03‐9 AlCl3 aluminium chloride (anhydrous) 7446‐70‐0 AlCl3•6H2O aluminium chloride hexahydrate 7784‐13‐6 AlClO aluminium chloride oxide 13596‐11‐7 AlB2 aluminium diboride 12041‐50‐8 AlF2 aluminium difluoride 13569‐23‐8 AlF2O aluminium difluoride oxide 38344‐66‐0 AlB12 aluminium dodecaboride 12041‐54‐2 Al2F6 aluminium fluoride 17949‐86‐9 AlF3 aluminium fluoride 7784‐18‐1 Al(CHO2)3 aluminium formate 7360‐53‐4 1 of 75 Chemical Abstract Chemical Formula Chemical Name Service (CAS) Number Al(OH)3 aluminium hydroxide 21645‐51‐2 Al2I6 aluminium iodide 18898‐35‐6 AlI3 aluminium iodide 7784‐23‐8 AlBr aluminium monobromide 22359‐97‐3 AlCl aluminium monochloride -

Cumulative Cross Index to Iarc Monographs

PERSONAL HABITS AND INDOOR COMBUSTIONS volume 100 e A review of humAn cArcinogens This publication represents the views and expert opinions of an IARC Working Group on the Evaluation of Carcinogenic Risks to Humans, which met in Lyon, 29 September-6 October 2009 LYON, FRANCE - 2012 iArc monogrAphs on the evAluAtion of cArcinogenic risks to humAns CUMULATIVE CROSS INDEX TO IARC MONOGRAPHS The volume, page and year of publication are given. References to corrigenda are given in parentheses. A A-α-C .............................................................40, 245 (1986); Suppl. 7, 56 (1987) Acenaphthene ........................................................................92, 35 (2010) Acepyrene ............................................................................92, 35 (2010) Acetaldehyde ........................36, 101 (1985) (corr. 42, 263); Suppl. 7, 77 (1987); 71, 319 (1999) Acetaldehyde associated with the consumption of alcoholic beverages ..............100E, 377 (2012) Acetaldehyde formylmethylhydrazone (see Gyromitrin) Acetamide .................................... 7, 197 (1974); Suppl. 7, 56, 389 (1987); 71, 1211 (1999) Acetaminophen (see Paracetamol) Aciclovir ..............................................................................76, 47 (2000) Acid mists (see Sulfuric acid and other strong inorganic acids, occupational exposures to mists and vapours from) Acridine orange ...................................................16, 145 (1978); Suppl. 7, 56 (1987) Acriflavinium chloride ..............................................13, -

Electroless Deposition of Cdte on Stainless Steel 304 Substrates By

Electroless Deposition of CdTe on Stainless Steel 304 Substrates By James Francis Malika Submitted in Partial Fulfillment of the Requirements for the Degree of Master of Science in the Chemistry Program YOUNGSTOWN STATE UNIVERSITY May 2021 Electroless Deposition of CdTe on Stainless Steel 304 Substrates James Francis Malika I hereby release this thesis to the public. I understand that this thesis will be made available from the Ohio LINK ETD Center and the Maag Library Circulation Desk for public access. I also authorize the University or other individuals to make copies of this thesis as needed for scholarly research. Signature: James Francis Malika, Student Date Approvals: Dr. Clovis A. Linkous, Thesis Advisor Date Dr. Timothy R. Wagner, Committee Member Date Dr. Christopher Arnsten, Committee Member Date Dr. Salvatore A. Sanders, Dean of Graduate Studies Date ABSTRACT The semiconductor cadmium telluride (CdTe) has become the leading material for thin- film photovoltaic applications. Among the many techniques for preparing these thin films, electroless deposition, commonly known as chemical bath deposition, deserves special focus since it has been shown to be a pollution-free, low-temperature and inexpensive method. In this project, CdTe thin films were deposited on stainless steel 304 by the electroless deposition method using cadmium acetate and tellurium oxide dissolved in pH 12.5 NH3(aq). The deposition was based on the gradual release of 2+ 2- cadmium ions (Cd ) and the gradual addition of tellurium as TeO3 and their subsequent reduction in a hot aqueous alkaline chemical bath at 70 oC. This was attained by adding a complexing agent such as ammonia and a chemical reducing agent. -

Structural and Optoelectronic Properties of Nanocrystalline Cdte Thin Films Synthesized by Using SILAR Technique

JOURNAL OF NANO- AND ELECTRONIC PHYSICS ЖУРНАЛ НАНО- ТА ЕЛЕКТРОННОЇ ФІЗИКИ Vol. 9 No 5, 05028(4pp) (2017) Том 9 № 5, 05028(4cc) (2017) Structural and Optoelectronic Properties of Nanocrystalline CdTe Thin Films Synthesized by Using SILAR Technique Swapna Samanta1, D.B. Salunke2, S.R. Gosavi3,*, R.S. Patil4 1 Department of Physics, H.P.T. Arts & R.Y.K. Science College, Nasik-5 2 Department of Physics, KVPS, Kisan Arts, Commerce and Science College, Parola, Dist-Jalgaon 425111, (M. S.), India 3 Material Research Laboratory, Department of Physics, C. H. C. Arts, S. G. P. Commerce, and B. B. J. P. Science College, Taloda, Dist. Nandurbar-425413, (M. S.), India 4 Department of Physics, P. S. G. V. P. Mandal’s Arts, Commerce and Science College, Shahada, Dist. Nandurbar. (M. S.), India (Received 28 April 2017; revised manuscript received 06 June 2017; published online 16 October 2017) Nanocrystalline CdTe thin films were deposited on amorphous glass substrate using successive ionic layer adsorption and reaction (SILAR) technique. The films are characterized using XRD, FESEM, optical absorption techniques and electrical resistivity measurement. The XRD pattern revealed that nanocrystal- line CdTe thin films has mixed phase of hexagonal and cubic crystal structure. The calculated crystallite size from the XRD measurement was found to be in the range of 9-12 nm. FESEM image showed uniform deposition of the material over entire glass substrate and film consists of interconnected spherical grains of nanometer size. Compositional analysis showed that the nanocrystalline CdTe thin film becomes cadmium deficient and tellurium richer. The optical absorption studies show that the films have a direct band gap of 1.51 eV. -

Nomenclature Practice Sheet

Nomenclature Key C2WS6K By: Dr. Robert Belford 1) aluminum nitride AlN 24) diboron hexafluoride B2F6 2) aluminum carbonate Al2(CO3)3 25) tin (IV) fluoride SnF4 3) aluminum bicarbonate Al(HCO3)3 26) tin (II) fluoride SnF2 4) nitrogen dioxide NO2 27) tin (IV) sulfide SnS2 5) zinc sulfate ZnSO4 28) tin (II) sulfide SnS 6) zinc sulfide ZnS 29) nitrogen trichloride NCl3 7) zinc phosphate Zn3(PO4)2 30) manganese (II) sulfide MnS 8) carbon tetrachloride CCl4 31) manganese (II) sulfate MnSO4 9) sodium hydroxide NaOH 32) manganese (II) phosphate 10) barium hydroxide Ba(OH)2 Mn3(PO4)2 11) titanium (II) cyanide Ti(CN)2 33) manganese (II) nitrate Mn(NO3)2 12) cadmium iodide CdI2 34) vanadium (V) oxide V2O5 13) cadmium acetate Cd(CH3CO2)2 35) molybdenum (VI) sulfide MoS3 14) cadmium bromide CdBr2 36) silver phosphide Ag3P 15) cadmium nitrate Cd(NO3)2 37) mercury (II) oxide HgO 16) cadmium sulfide CdS 38) chromium (III) bromide CrBr3 17) phosphorus pentachloride PCl5 39) chromium (III) nitrate Cr(NO3)3 18) iron (II) sulfide FeS 40) sulfur dichloride SCl2 19) iron (II) sulfate FeSO4 41) magnesium sulfide MgS 20) iron (III) sulfate Fe2(SO4)3 42) magnesium sulfate MgSO4 21) iron (III) nitrate Fe(NO3)3 43) cobalt (III) carbonate Co2(CO3)3 22) magnesium nitride Mg3N2 44) cobalt (III) phosphide CoP 23) magnesium nitrate Mg(NO3)2 Write formulas from the following names: 1) Ni(NO3)3 nickel (III) nitrate 2) NiCl3 nickel (III) chloride Nomenclature Key C2WS6K By: Dr. Robert Belford 3) Mn(OH)2 manganese (II) hydroxide 28) Al(CN)3 aluminum cyanide 4) Hg(CN)2 mercury -

Recognition of Heavy Metal Ions by Using E-5-((5-Isopropyl-3,8-Dimethylazulen-1-Yl) Dyazenyl)-1H-Tetrazole Modified Electrodes

S S symmetry Article Recognition of Heavy Metal Ions by Using E-5-((5-Isopropyl-3,8-Dimethylazulen-1-yl) Dyazenyl)-1H-Tetrazole Modified Electrodes Adina-Maria Păun, Ovidiu-Teodor Matica, Veronica Anăstăsoaie, Laura-Bianca Enache, Elena Diacu * and Eleonora-Mihaela Ungureanu Faculty of Applied Chemistry and Materials Science, University “Politehnica” of Bucharest, Gheorghe Polizu 1-7, Sector 1, 011061 Bucharest, Romania; [email protected] (A.-M.P.); [email protected] (O.-T.M.); [email protected] (V.A.); [email protected] (L.-B.E.); [email protected] (E.-M.U.) * Correspondence: [email protected]; Tel.: +40-722366378 Abstract: Chemically modified electrodes (CMEs) based on polymeric films of E-5-((5-isopropyl- 3,8-dimethylazulen-1-yl) diazenyl)-1H-tetrazole (L) deposited on the surface of the glassy carbon electrode have been used for the recognition of heavy metal (Me) ions. The electrochemical study of L was done by three methods: differential pulse voltammetry (DPV), cyclic voltammetry (CV), and rotating disk electrode voltammetry (RDE). The CV, DPV, and RDE studies for L were per- formed at different concentrations in 0.1 M tetrabutylammonium perchlorate solutions in acetonitrile. The polymeric films were formed by successive cycling or by controlled potential electrolysis (CPE). Citation: P˘aun,A.-M.; Matica, O.-T.; The film formation was proven by recording the CV curves of the CMEs in ferrocene solution. An˘ast˘asoaie,V.; Enache, L.-B.; Diacu, The CMEs prepared at different charges or potentials were used for detection of heavy metal ions. E.; Ungureanu, E.-M. Recognition of Synthetic samples of heavy metal ions (Cd(II), Pb(II), Cu(II), Hg(II)) of concentrations between 10−8 Heavy Metal Ions by Using E-5-((5- and 10−4 M were analyzed. -

Influence of Cationic Precursors on Cds Quantum-Dot-Sensitized Solar

Article pubs.acs.org/JPCC Influence of Cationic Precursors on CdS Quantum-Dot-Sensitized Solar Cell Prepared by Successive Ionic Layer Adsorption and Reaction † ‡ † † † ‡ † Ru Zhou, , Qifeng Zhang, Jianjun Tian, Daniel Myers, Min Yin,*, and Guozhong Cao*, † Department of Materials Science and Engineering, University of Washington, Seattle, Washington 98195, United States ‡ Department of Physics, University of Science and Technology of China, Hefei 230026, China *S Supporting Information ABSTRACT: Successive ionic layer adsorption and reaction (SILAR) is the most extensively used method for the direct and simultaneous synthesis and deposition of quantum dots (QDs) onto porous oxide films for quantum-dot-sensitized solar cell (QDSC) applications. In this work, the noticeable influences of the cationic precursors on the deposition of CdS QDs and the QDSC performance have been studied. A careful comparison of two cationic precursors, cadmium nitrate and cadmium acetate, for the preparation of CdS QDSCs by the SILAR method showed that, compared to the commonly used cadmium nitrate, cadmium acetate provided a significantly higher deposition rate of fi ffi CdS QDs on TiO2 lms. A solar cell power conversion e ciency of 2.15% was achieved for a CdS QDSC employing cadmium acetate as the cationic precursor, much higher than the value of 1.44% obtained for the cell prepared using cadmium nitrate for the same number of SILAR cycles. Control experiments in which the recipes of the cationic precursor solutions were changed revealed a dramatic effect of the cationic precursor pH on the deposition rate fi of CdS QDs on the TiO2 lm. In addition, an appreciable anomalous red shift, which became more pronounced with increasing fi amount of QDs, was observed in both the optical absorption and photocurrent spectra of CdS-sensitized TiO2 lms. -

Hazardous Substances

HAZARDOUS SUBSTANCES 1. Acetaldehyde 74. Carbaryl 145. Formaldehyde 2. Acetic acid 75. Carbofuran 146. Formic acid 3. Acetic anhydride 76. Carbon disulfide 147. Fumaric acid 4. Acetone cyanohydrin 77. Carbon tetrachloride 148. Furfural 5. Acetyl bromide 78. Chlordane 149. Guthion 6. Acetyl chloride 79. Chlorine 150. Heptachlor 7. Acrolein 80. Chlorobenzene 151. Hexachlorocyclopentadiene 8. Acrylonitrile 81. Chloroform 152. Hydrochloric acid 9. Adipic acid 82. Chloropyrifos 153. Hydrofluoric acid 10. Aldrin 83. Chlorosulfonic acid 154. Hydrogen cyanide 11. Allyl alcohol 84. Chromic acetate 155. Hydrogen sulfide 12. Allyl chloride 85. Chromic acid 156. Isoprene 13. Aluminum sulfate 86. Chromic sulfate 157. Isopropanolamine 14. Ammonia 87. Chromous chloride dodecylbenzenesulfonate 15. Ammonium acetate 88. Cobaltous bromide 158. Kelthane 16. Ammonium benzoate 89. Cobaltous formate 159. Kepone 17. Ammonium bicarbonate 90. Cobaltous sulfamate 160. Lead acetate 18. Ammonium bichromate 91. Coumaphos 161. Lead arsenate 19. Ammonium bifluoride 92. Cresol 162. Lead chloride 20. Ammonium bisulfite 93. Crotonaldehyde 163. Lead fluoborate 21. Ammonium carbamate 94. Cupric acetate 164. Lead flourite 22. Ammonium carbonate 95. Cupric acetoarsenite 165. Lead iodide 23. Ammonium chloride 96. Cupric chloride 166. Lead nitrate 24. Ammonium chromate 97. Cupric nitrate 167. Lead stearate 25. Ammonium citrate 98. Cupric oxalate 168. Lead sulfate 26. Ammonium fluoroborate 99. Cupric sulfate 169. Lead sulfide 27. Ammonium fluoride 100. Cupric sulfate ammoniated 170. Lead thiocyanate 28. Ammonium hydroxide 101. Cupric tartrate 171. Lindane 29. Ammonium oxalate 102. Cyanogen chloride 172. Lithium chromate 30. Ammonium silicofluoride 103. Cyclohexane 173. Malathion 31. Ammonium sulfamate 104. 2,4-D acid (2,4- Dichlorophenoxyacetic 174. Maleic acid 32. Ammonium sulfide acid) 175.