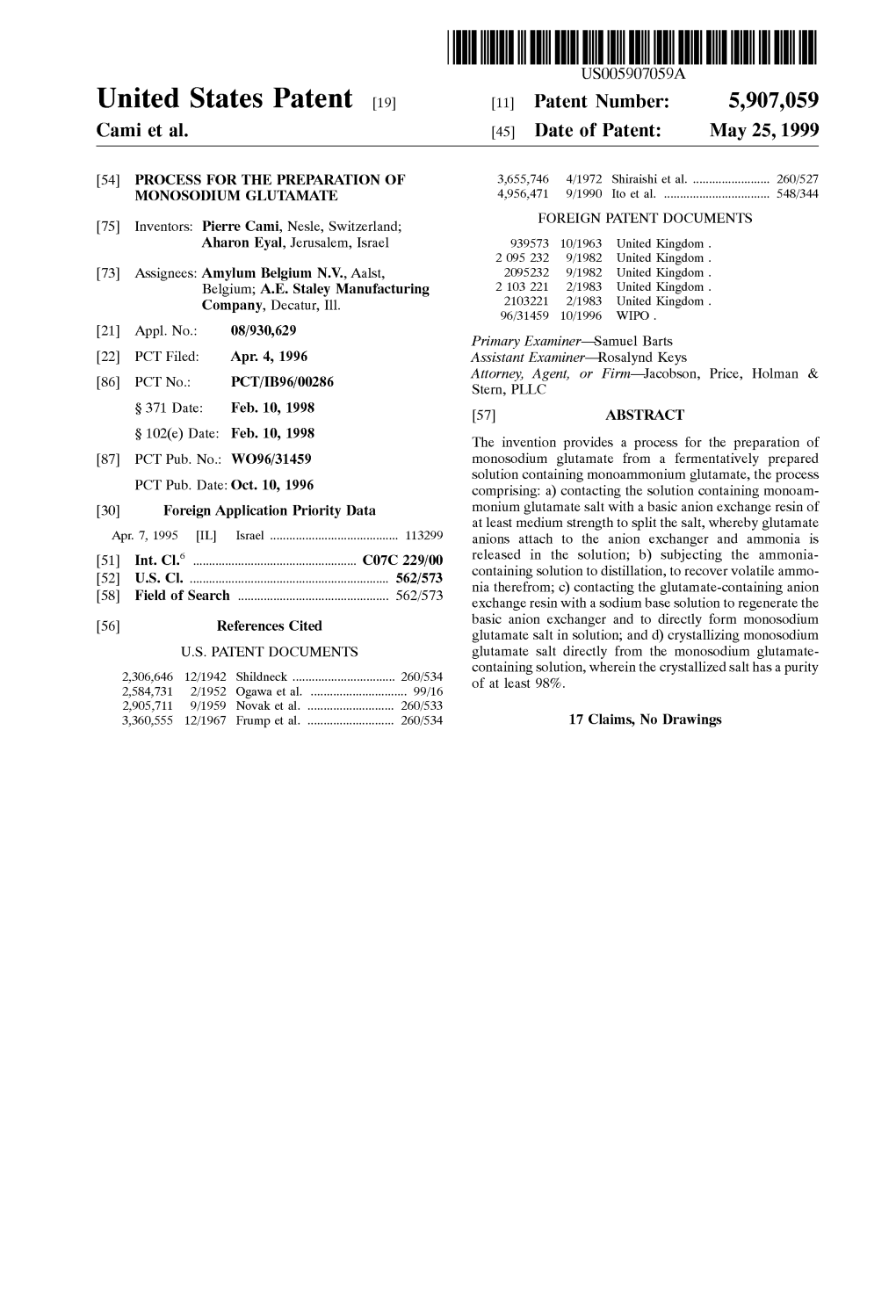

United States Patent (19) 11 Patent Number: 5,907,059 Cami Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

477 Subpart B—Multiple Purpose GRAS Food Substances

Food and Drug Administration, HHS § 182.1131 Casein. (c) Limitations, restrictions, or expla- Cellulose acetate. nation. This substance is generally rec- Cornstarch. ognized as safe when used as a salt sub- Diatomaceous earth filler. Ethyl cellulose. stitute in accordance with good manu- Ethyl vanillin. facturing practice. Glycerin. Oleic acid. § 182.1057 Hydrochloric acid. Potassium sorbate. (a) Product. Hydrochloric acid. Silicon dioxides. Sodium aluminate. (b) [Reserved] Sodium chloride. (c) Limitations, restrictions, or expla- Sodium hexametaphosphate. nation. This substance is generally rec- Sodium hydrosulfite. ognized as safe when used as a buffer Sodium phosphoaluminate. and neutralizing agent in accordance Sodium silicate. with good manufacturing practice. Sodium sorbate. Sodium tripolyphosphate. § 182.1073 Phosphoric acid. Sorbitol. Soy protein, isolated. (a) Product. Phosphoric acid. Starch, acid modified. (b) Conditions of use. This substance Starch, pregelatinized. is generally recognized as safe when Starch, unmodified. used in accordance with good manufac- Talc. Vanillin. turing practice. Zinc hydrosulfite. Zinc sulfate. § 182.1087 Sodium acid pyrophosphate. [42 FR 14640, Mar. 15, 1977] (a) Product. Sodium acid pyrophosphate. EDITORIAL NOTE: For additional FEDERAL (b) Conditions of use. This substance REGISTER citations affecting § 182.90, see the List of CFR Sections Affected, which appears is generally recognized as safe when in the Finding Aids section of the printed used in accordance with good manufac- volume and on GPO Access. turing practice. § 182.99 Adjuvants for pesticide chemi- § 182.1125 Aluminum sulfate. cals. (a) Product. Aluminum sulfate. Adjuvants, identified and used in ac- (b) Conditions of use. This substance cordance with 40 CFR 180.1001 (c) and is generally recognized as safe when (d), which are added to pesticide use di- used in accordance with good manufac- lutions by a grower or applicator prior turing practice. -

1 Abietic Acid R Abrasive Silica for Polishing DR Acenaphthene M (LC

1 abietic acid R abrasive silica for polishing DR acenaphthene M (LC) acenaphthene quinone R acenaphthylene R acetal (see 1,1-diethoxyethane) acetaldehyde M (FC) acetaldehyde-d (CH3CDO) R acetaldehyde dimethyl acetal CH acetaldoxime R acetamide M (LC) acetamidinium chloride R acetamidoacrylic acid 2- NB acetamidobenzaldehyde p- R acetamidobenzenesulfonyl chloride 4- R acetamidodeoxythioglucopyranose triacetate 2- -2- -1- -β-D- 3,4,6- AB acetamidomethylthiazole 2- -4- PB acetanilide M (LC) acetazolamide R acetdimethylamide see dimethylacetamide, N,N- acethydrazide R acetic acid M (solv) acetic anhydride M (FC) acetmethylamide see methylacetamide, N- acetoacetamide R acetoacetanilide R acetoacetic acid, lithium salt R acetobromoglucose -α-D- NB acetohydroxamic acid R acetoin R acetol (hydroxyacetone) R acetonaphthalide (α)R acetone M (solv) acetone ,A.R. M (solv) acetone-d6 RM acetone cyanohydrin R acetonedicarboxylic acid ,dimethyl ester R acetonedicarboxylic acid -1,3- R acetone dimethyl acetal see dimethoxypropane 2,2- acetonitrile M (solv) acetonitrile-d3 RM acetonylacetone see hexanedione 2,5- acetonylbenzylhydroxycoumarin (3-(α- -4- R acetophenone M (LC) acetophenone oxime R acetophenone trimethylsilyl enol ether see phenyltrimethylsilyl... acetoxyacetone (oxopropyl acetate 2-) R acetoxybenzoic acid 4- DS acetoxynaphthoic acid 6- -2- R 2 acetylacetaldehyde dimethylacetal R acetylacetone (pentanedione -2,4-) M (C) acetylbenzonitrile p- R acetylbiphenyl 4- see phenylacetophenone, p- acetyl bromide M (FC) acetylbromothiophene 2- -5- -

Concord Food Co-Op Unacceptable Ingredients for Food

Concord Food Co-op Unacceptable Ingredients for Food (as of April 15, 2021) 2,4,5-trihydroxybutyrophenone (THBP) benzoyl peroxide acesulfame-K benzyl alcohol acetoin (synthetic) beta-cyclodextrin acetone peroxides BHA (butylated hydroxyanisole) acetylated esters of mono- and diglycerides BHT (butylated hydroxytoluene) activated charcoal bleached flour advantame bromated flour aluminum ammonium sulfate brominated vegetable oil aluminum potassium sulfate burnt alum aluminum starch octenylsuccinate butylparaben aluminum sulfate caffeine (extended release) ammonium alum calcium benzoate ammonium chloride calcium bromate ammonium saccharin calcium disodium EDTA ammonium sulfate calcium peroxide apricot kernel/extract calcium propionate artificial sweeteners calcium saccharin aspartame calcium sorbate azo dyes calcium stearoyl-2-lactylate azodicarbonamide canthaxanthin bacillus subtilis DE111 caprocaprylobehenin bacteriophage preparation carmine bentonite CBD/cannabidiol benzoates certified colors benzoic acid charcoal powder benzophenone Citrus Red No. 2 Page 1 of 4 cochineal foie gras DATEM gardenia blue diacetyl (synthetic) GMP dimethyl Silicone gold/gold leaf dimethylpolysiloxane heptylparaben dioctyl sodium sulfosuccinate (DSS) hexa-, hepta- and octa-esters of sucrose disodium 5'-ribonucleotides high-fructose corn syrup/HFCS disodium calcium EDTA hjijiki disodium dihydrogen EDTA hydrogenated oils disodium EDTA inosine monophosphate disodium guanylate insect Flour disodium inosinate iron oxide dodecyl gallate kava/kava kava EDTA lactic acid esters of monoglycerides erythrosine lactylated esters of mono- and diglycerides ethoxyquin ma huang ethyl acrylate (synthetic) methyl silicon ethyl vanillin (synthetic) methylparaben ethylene glycol microparticularized whey protein derived fat substitute ethylene oxide monoammonium glutamate eugenyl methyl ether (synthetic) monopotassium glutamate FD&C Blue No. 1 monosodium glutamate FD&C Blue No. 2 myrcene (synthetic) FD&C Colors natamycin (okay in cheese-rind wax) FD&C Green No. -

Contents / Iii

FCC 11 Contents / iii Contents 1 I; ~ith ~er PREFACE v i I PEOPLE xi NEW AND CHANGED..................................................................................................................................................... xiii GENERAL PROVISIONS AND REQUIREMENTS APPLYING TO SPECIFICATIONS, TESTS, AND ASSAYS OF THE FOOD CHEMICALS CODEX .. MONOGRAPHS.................................................................................................................................................................. 9 should IDENTITY STANDARDS.............................................................................................................................................. 1269 GENERAL TESTS AND ASSAyS................................................................................................................................... 1275 Appendix I: Apparatus for Tests and Assays.............................................................................................................. 1279 Appendix II: Physical Tests and Determinations........................................................................................................ 1282 A. Chromatography......................... 1282 B. Physicochemical Properties......................................................................................................................... 1290 C. Others............................. 1302 Appendix III: Chemical Tests and Determinations.................................................................................................... -

Your Essentials Sensitivity Results Are Here

Your Essentials Sensitivity results are here Garfield Legros Redemption code: EAIKBNUDXG Report Date: Apr 27 2021 Garfield Legros Back to contents 2 EAIKBNUDXG Dear Garfield Legros, We are delighted to present you with your test results report! Your results have been created by our state of the art bioresonance testing machine and our technician Julie. Your results Your results are divided into sections by the We believe that in providing you with your type of items tested. Within each section test results and relevant information in each you’ll find an overview page, this is to ensure section, your results can form the beginning your results are as clear and concise as of a journey, enabling you to make positive possible and your attention is drawn to the changes to your daily diet and environment. information that is of greatest value to you. In doing so we want you to be able to take You can see the full list of items tested in the steps towards eating a diet, which is nutritious detailed analysis page. Your results report is and enjoyable and living a life, which is designed to provide the utmost clarity on your healthful and happy. results and the actions we would recommend. If you have any further questions please do not hesitate to get in touch with us. Sincerely, Check My Body Health Team Complementary Alternative Medicine (CAMS) Our food sensitivity tests are carried out using bioresonance therapy and is categorised under Complementary and Alternative Medicines (CAMs) which covers a wide range of therapies that fall outside mainstream medicine. -

Your Solution Starts Here Dear Test Test, We Are Delighted to Present Your Test Results!

Your Solution Starts Here Dear Test Test, We are delighted to present your test results! Your Results Your results are divided into sections by the We believe that in providing you with your type of items tested. Within each section test results and relevant information in each you'll nd an overview page, this is to section, your results can form the beginning ensure your results are as clear and concise of a journey, enabling you to make positive as possible and your attention is drawn to changes to your daily diet and environment. the information that is of greatest value to you. You can see the full list of items tested In doing so we want you to be able to take in the detailed analysis page. steps towards eating a diet, which is nutritious and enjoyable and living a life, Your results report is designed to provide which is healthful and happy. the utmost clarity on your results and the actions we would recommend. If you have any further questions please do not hesitate to get in touch with us. Healthy regards, The US Food Intolerance Team [email protected] - www.usfoodintolerance.com 2 (65) Table of Contents Your Results Explained page 4 Food Sensitivities Analysis page 8 Non-food Sensitivities Analysis page 17 Hormonal Balance Analysis page 22 Gut Biome Analysis page 27 Digestive Health and Metabolism Analysis page 32 Metal Sensitivities Analysis page 37 Minerals and Nutrients Analysis page 42 Vitamins Analysis page 46 Additives Analysis page 50 What Can You Do Next? page 57 Simple Advice - A 23 Days Plan page 59 E-Numbers Explained page 60 Metal Potential Sources page 64 Contact page 65 3 (65) Your Results Explained A sensitivity test is not an allergy test It is important to reiterate that this test is NOT for allergy. -

FCC 10, Second Supplement the Following Index Is for Convenience and Informational Use Only and Shall Not Be Used for Interpretive Purposes

Index to FCC 10, Second Supplement The following Index is for convenience and informational use only and shall not be used for interpretive purposes. In addition to effective articles, this Index may also include items recently omitted from the FCC in the indicated Book or Supplement. The monographs and general tests and assay listed in this Index may reference other general test and assay specifications. The articles listed in this Index are not intended to be autonomous standards and should only be interpreted in the context of the entire FCC publication. For the most current version of the FCC please see the FCC Online. Second Supplement, FCC 10 Index / Allura Red AC / I-1 Index Titles of monographs are shown in the boldface type. A 2-Acetylpyrrole, 21 Alcohol, 90%, 1625 2-Acetyl Thiazole, 18 Alcohol, Absolute, 1624 Abbreviations, 7, 3779, 3827 Acetyl Valeryl, 608 Alcohol, Aldehyde-Free, 1625 Absolute Alcohol (Reagent), 5, 3777, Acetyl Value, 1510 Alcohol C-6, 626 3825 Achilleic Acid, 25 Alcohol C-8, 933 Acacia, 602 Acid (Reagent), 5, 3777, 3825 Alcohol C-9, 922 ªAccuracyº, Defined, 1641 Acid-Hydrolyzed Milk Protein, 22 Alcohol C-10, 390 Acesulfame K, 9 Acid-Hydrolyzed Proteins, 22 Alcohol C-11, 1328 Acesulfame Potassium, 9 Acid Calcium Phosphate, 240 Alcohol C-12, 738 Acetal, 10 Acid Hydrolysates of Proteins, 22 Alcohol C-16, 614 Acetaldehyde, 11 Acidic Sodium Aluminum Phosphate, Alcohol Content of Ethyl Oxyhydrate Acetaldehyde Diethyl Acetal, 10 1148 Flavor Chemicals (Other than Acetaldehyde Test Paper, 1636 Acidified Sodium Chlorite -

Index to FCC 11 the Following Index Is for Convenience and Informational Use Only and Shall Not Be Used for Interpretive Purposes

Index to FCC 11 The following Index is for convenience and informational use only and shall not be used for interpretive purposes. In addition to effective articles, this Index may also include items recently omitted from the FCC in the indicated Book or Supplement. The monographs and general tests and assay listed in this Index may reference other general test and assay specifications. The articles listed in this Index are not intended to be autonomous standards and should only be interpreted in the context of the entire FCC publication. For the most current version of the FCC please see the FCC Online. FCC 11 Index / Allyl Butanoate / I-1 Index Index Titles of monographs are shown in the boldface type. A 2-Acetyl Thiazole, 18 Alcohol C-8, 863 Acetyl Valeryl, 562 Alcohol C-9, 854 Abbreviations, 6 Acetyl Value, 1400 Alcohol C-10, 362 Absolute Alcohol (Reagent), 5 Achilleic Acid, 24 Alcohol C-11, 1231 Acacia, 556 Acid (Reagent), 5 Alcohol C-12, 681 ªAccuracyº, Defined, 1538 Acid-Hydrolyzed Milk Protein, 22 Alcohol C-16, 569 Acesulfame K, 9 Acid-Hydrolyzed Proteins, 22 Alcohol Content of Ethyl Oxyhydrate Acesulfame Potassium, 9 Acid Calcium Phosphate, 219 Flavor Chemicals (Other than Acetal, 10 Acid Hydrolysates of Proteins, 22 Essential Oils), 1437 Acetaldehyde, 10 Acidic Sodium Aluminum Phosphate, Alcohol, Diluted, 1524 Acetaldehyde Diethyl Acetal, 10 1065 Alcoholic Potassium Hydroxide TS, Acetaldehyde Test Paper, 1535 Acidified Sodium Chlorite 1524 Acetals (Essential Oils and Flavors), Solutions, 23 Alcoholometric Table, 1644 1395 Acidity -

This Is a List of Unsafe, Unhealthy And/Or Potentially Toxic Ingredients in Food and Products You Should Avoid

This is a list of unsafe, unhealthy and/or potentially toxic ingredients in food and products you should avoid. Adapted from Whole Foods Market’s Unacceptable Ingredients for Food and Earth Fare’s Boot List. Be sure to check the Environmental Working Group’s website as well. • 2,4,5-trihydroxybutyrophenone (THBP) • acesulfame-potassium (acesulfame-K) • acetoin (synthetic) • acetone peroxides • acetylated esters of mono and diglycerides • activated charcoal • advantame • aluminum ammonium sulfate • aluminum potassium sulfate • aluminum starch octenylsuccinate • aluminum sulfate • ammonium alum • ammonium chloride • ammonium saccharin • ammonium sulfate • apricot kernel/extract • artificial colors • artificial fats • artificial flavors • artificial preservatives • artificial sweeteners • aspartame • azo dyes • azodicarbonamide • bacillus subtilis DE111 • bacteriophage preparation • bentonite • benzoates in food • benzoic acid • benzophenone • benzoyl peroxide • benzyl alcohol • beta-cyclodextrin • BHA (butylated hydroxyanisole) • BHT (butylated hydroxytoluene) • bleached flour • bromated flour • brominated vegetable oil (BVO) • BST (bovine somatotropin) • burnt alum • butane glycol • butylparaben • caffeine, extended release • calcium benzoate • calcium bromate • calcium disodium EDTA • calcium peroxide • calcium propionate • calcium saccharin • calcium sorbate • calcium stearoyl-2-lactylate • canthaxanthin • caprenin • caprocaprylobehenin • carmine (cochineal) • certified colors • charcoal powder • Citrus Red No. 2 • cochineal • cotton -

B COMMISSION REGULATION (EU) No 231/2012 of 9 March

02012R0231 — EN — 23.10.2019 — 021.001 — 1 This text is meant purely as a documentation tool and has no legal effect. The Union's institutions do not assume any liability for its contents. The authentic versions of the relevant acts, including their preambles, are those published in the Official Journal of the European Union and available in EUR-Lex. Those official texts are directly accessible through the links embedded in this document ►B COMMISSION REGULATION (EU) No 231/2012 of 9 March 2012 laying down specifications for food additives listed in Annexes II and III to Regulation (EC) No 1333/2008 of the European Parliament and of the Council (Text with EEA relevance) (OJ L 83, 22.3.2012, p. 1) Amended by: Official Journal No page date ►M1 Commission Regulation (EU) No 1050/2012 of 8 November 2012 L 310 45 9.11.2012 ►M2 Commission Regulation (EU) No 25/2013 of 16 January 2013 L 13 1 17.1.2013 ►M3 Commission Regulation (EU) No 497/2013 of 29 May 2013 L 143 20 30.5.2013 ►M4 Commission Regulation (EU) No 724/2013 of 26 July 2013 L 202 11 27.7.2013 ►M5 Commission Regulation (EU) No 739/2013 of 30 July 2013 L 204 35 31.7.2013 ►M6 Commission Regulation (EU) No 816/2013 of 28 August 2013 L 230 1 29.8.2013 ►M7 Commission Regulation (EU) No 817/2013 of 28 August 2013 L 230 7 29.8.2013 ►M8 Commission Regulation (EU) No 1274/2013 of 6 December 2013 L 328 79 7.12.2013 ►M9 Commission Regulation (EU) No 264/2014 of 14 March 2014 L 76 22 15.3.2014 ►M10 Commission Regulation (EU) No 298/2014 of 21 March 2014 L 89 36 25.3.2014 ►M11 Commission Regulation -

B COMMISSION REGULATION (EU) No 231/2012 of 9 March

2012R0231 — EN — 29.11.2012 — 001.001 — 1 This document is meant purely as a documentation tool and the institutions do not assume any liability for its contents ►B COMMISSION REGULATION (EU) No 231/2012 of 9 March 2012 laying down specifications for food additives listed in Annexes II and III to Regulation (EC) No 1333/2008 of the European Parliament and of the Council (Text with EEA relevance) (OJ L 83, 22.3.2012, p. 1) Amended by: Official Journal No page date ►M1 Commission Regulation (EU) No 1050/2012 of 8 November 2012 L 310 45 9.11.2012 2012R0231 — EN — 29.11.2012 — 001.001 — 2 ▼B COMMISSION REGULATION (EU) No 231/2012 of 9 March 2012 laying down specifications for food additives listed in Annexes II and III to Regulation (EC) No 1333/2008 of the European Parliament and of the Council (Text with EEA relevance) THE EUROPEAN COMMISSION, Having regard to the Treaty on the Functioning of the European Union, Having regard to Regulation (EC) No 1333/2008 of the European Parliament and of the Council of 16 December 2008 on food additives (1 ), and in particular Articles 14 and 30(4) thereof, and Regu lation (EC) No 1331/2008 of the European Parliament and of the Council of 16 December 2008 establishing a common authorisation procedure for food additives, food enzymes and food flavourings (2 ), and in particular Article 7(5) thereof, Whereas: (1) Specifications relating to origin, purity criteria and any other necessary information should be adopted for food additives listed in the Union lists in Annex II and III to Regulation (EC) No 1333/2008. -

Technical Report

Ammonia Extract Crops 1 2 Identification of Petitioned Substance 3 4 Chemical Names: 19 Trade Names: 5 Ammonia 20 N/A 6 Nitrogen trihydride 21 7 Azane CAS Numbers: 8 Ammonium 7664-41-7 (ammonia) 9 Ammonium ion 14798-03-9 (ammonium) 10 Ammonium cation 11 Azanium Other Codes: 12 EC No. 231-635-3 (ammonia) 13 Other Names: ICSC No. 0414 (ammonia) 14 Ammonia extract RTECS No. BO0875000 (ammonia) 15 Novel ammonia UNII No. 5138Q19F1X (ammonia) 16 Novel ammonia fertilizer UNII No. 54S68520I4 (ammonium) 17 Captured ammonia 18 Anhydrous ammonia 22 23 Summary of Petitioned Use 24 25 A petition, submitted by True Organic Products Inc. to the National Organic Standards Board (NOSB) on 26 February 14, 2020, seeks to add ammonia extract to the National List of Allowed and Prohibited Substances 27 under Title 7 of the Code of Federal Regulations Section 205.602 (7 CFR 205.602). The petition describes ammonia + 28 extract as ammonia (NH3) and/or ammonium (NH4 ) compounds captured, extracted, and/or concentrated from 29 chemical, environmental, or biological processes (USDA 2020). This petition seeks to prohibit the use of ammonia 30 and ammonium compounds, whether they are formed through synthetic or non-synthetic methods. 31 32 Most commercially available ammonia and ammonium compounds are formed through the synthetic 33 Haber-Bosch process, making ammonia fertilizers and other agricultural products prohibited from use in organic 34 agriculture, unless specifically allowed under 7 CFR 205.601. Though new production methods have been 35 developed for the production and/or isolation of ammonia and ammonium compounds from environmental and 36 biological sources, the petition seeks to prohibit the use of these potential non-synthetic ammonia and 37 ammonium sources along with the already prohibited synthetic sources.