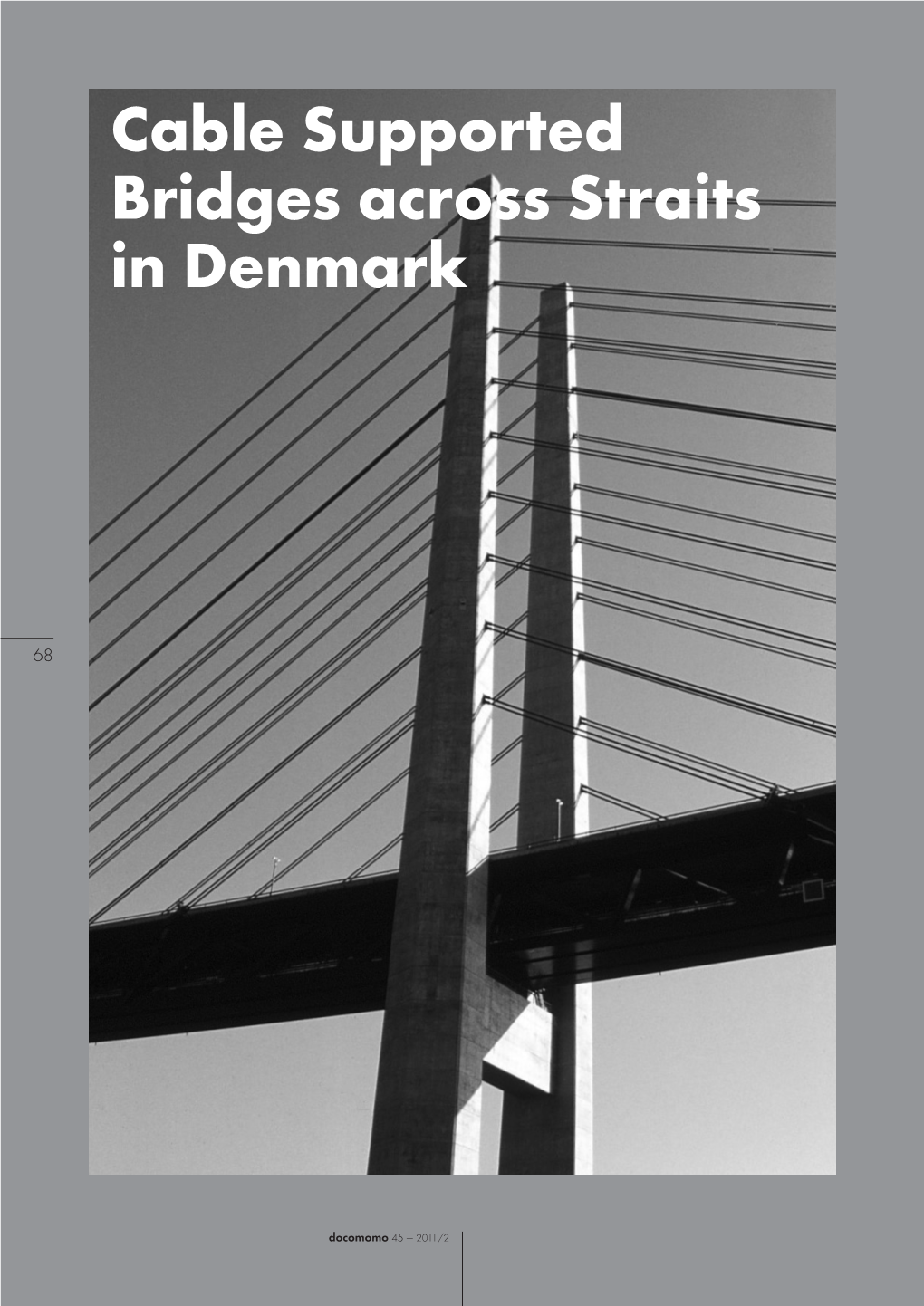

Cable Supported Bridges Across Straits in Denmark

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Coastal Living in Denmark

To change the color of the coloured box, right-click here and select Format Background, change the color as shown in the picture on the right. Coastal living in Denmark © Daniel Overbeck - VisitNordsjælland To change the color of the coloured box, right-click here and select Format Background, change the color as shown in the picture on the right. The land of endless beaches In Denmark, we look for a touch of magic in the ordinary, and we know that travel is more than ticking sights off a list. It’s about finding wonder in the things you see and the places you go. One of the wonders that we at VisitDenmark are particularly proud of is our nature. Denmark has wonderful beaches open to everyone, and nowhere in the nation are you ever more than 50km from the coast. s. 2 © Jill Christina Hansen To change the color of the coloured box, right-click here and select Format Background, change the color as shown in the picture on the right. Denmark and its regions Geography Travel distances Aalborg • The smallest of the Scandinavian • Copenhagen to Odense: Bornholm countries Under 2 hours by car • The southernmost of the • Odense to Aarhus: Under 2 Scandinavian countries hours by car • Only has a physical border with • Aarhus to Aalborg: Under 2 Germany hours by car • Denmark’s regions are: North, Mid, Jutland West and South Jutland, Funen, Aarhus Zealand, and North Zealand and Copenhagen Billund Facts Copenhagen • Video Introduction • Denmark’s currency is the Danish Kroner Odense • Tipping is not required Zealand • Most Danes speak fluent English Funen • Denmark is of the happiest countries in the world and Copenhagen is one of the world’s most liveable cities • Denmark is home of ‘Hygge’, New Nordic Cuisine, and LEGO® • Denmark is easily combined with other Nordic countries • Denmark is a safe country • Denmark is perfect for all types of travelers (family, romantic, nature, bicyclist dream, history/Vikings/Royalty) • Denmark has a population of 5.7 million people s. -

Shore Excursions Featuring Top Attractions Credible, Close, Cruiseable

Cruise Fredericia presents SHORE EXCURSIONS FEATURING TOP ATTRACTIONS CREDIBLE, CLOSE, CRUISEABLE Royal Jelling 45 MIN. City of Fredericia 5 MIN. A UNESCO SITE In the A historic town UNESCO of it all ! ® LEGOLAND 45 MIN. The original LEGOLAND® Tirpitz 80 MIN. A World War II Bunker Museum LEGO® House A museum and Hans Christian Andersen’s experience center childhood home in Odense 45 MIN. 50 MIN. 1 HOUR Historic Christiansfeld Ribe: the oldest COPENHAGEN and the Moravian Brethren FREDERICIA city in Denmark - the Church 35 MIN. authentic, living A UNESCO SITE Viking experience 75 MIN. UNESCO The Wadden Sea 75 MIN. Egeskov Castle 60 MIN. A UNESCO SITE Finest renaissance architecture and gardens UNESCO A BROAD SELECTION OF ATTRACTIONS - FOR EVERYONE Fredericia is a Scandinavian cruise destination situated in the heart of Denmark. Whether you are into historic and authentic attractions, culture sites or activities for the entire family, Fredericia is the perfect destination. Fredericia is surrounded by world famous tourist attractions and within a 1-hour drive you can reach three UNESCO sites, the childhood home of the world famous author Hans Christian Andersen, the original LEGOLAND® and many other sites. CITY OF FREDERICIA HISTORY AND AUTHENTICITY THE MOST WELL-PRESERVED RAMPARTS IN NORTHERN EUROPE Fredericia was established as a fortress town in 1650. On the landside, the town was laid out in circular form with nine large moated bastions. On the waterfront, the town had a somewhat weaker fortification line together with a citadel as its last defense. Fredericia was planned as a fortress town and the streets within the ramparts are all regular and entirely perpendicular. -

Invitation to the 15Th Congress of IABSE

Invitation to the 15th congress of IABSE Autor(en): Gimsing, Niels J. Objekttyp: Article Zeitschrift: IABSE congress report = Rapport du congrès AIPC = IVBH Kongressbericht Band (Jahr): 14 (1992) PDF erstellt am: 30.09.2021 Persistenter Link: http://doi.org/10.5169/seals-13936 Nutzungsbedingungen Die ETH-Bibliothek ist Anbieterin der digitalisierten Zeitschriften. Sie besitzt keine Urheberrechte an den Inhalten der Zeitschriften. Die Rechte liegen in der Regel bei den Herausgebern. Die auf der Plattform e-periodica veröffentlichten Dokumente stehen für nicht-kommerzielle Zwecke in Lehre und Forschung sowie für die private Nutzung frei zur Verfügung. Einzelne Dateien oder Ausdrucke aus diesem Angebot können zusammen mit diesen Nutzungsbedingungen und den korrekten Herkunftsbezeichnungen weitergegeben werden. Das Veröffentlichen von Bildern in Print- und Online-Publikationen ist nur mit vorheriger Genehmigung der Rechteinhaber erlaubt. Die systematische Speicherung von Teilen des elektronischen Angebots auf anderen Servern bedarf ebenfalls des schriftlichen Einverständnisses der Rechteinhaber. Haftungsausschluss Alle Angaben erfolgen ohne Gewähr für Vollständigkeit oder Richtigkeit. Es wird keine Haftung übernommen für Schäden durch die Verwendung von Informationen aus diesem Online-Angebot oder durch das Fehlen von Informationen. Dies gilt auch für Inhalte Dritter, die über dieses Angebot zugänglich sind. Ein Dienst der ETH-Bibliothek ETH Zürich, Rämistrasse 101, 8092 Zürich, Schweiz, www.library.ethz.ch http://www.e-periodica.ch 373 Invitation to the 15th Congress of IABSE Extract from the Invitation Adress by the chairman of the Danish National Group of IABSE, Professor Niels J Gimsing at the closing session of the IABSE Congress in New Delhi: The very successful 14th Congress of the IABSE has come to an end, so it is time to look ahead to 1996 when the next of the large IABSE Congresses will be held. -

44259 - Materie 16/08/04 7:27 Side I

A Windfall for the Magnates. The Development of Woodland Ownership in Denmark c. 1150-1830 Fritzbøger, Bo Publication date: 2004 Document version Publisher's PDF, also known as Version of record Citation for published version (APA): Fritzbøger, B. (2004). A Windfall for the Magnates. The Development of Woodland Ownership in Denmark c. 1150-1830. Syddansk Universitetsforlag. Download date: 29. Sep. 2021 44259 - Materie 16/08/04 7:27 Side i “A Windfall for the magnates” 44259 - Materie 16/08/04 7:27 Side ii Denne afhandling er af Det Humanistiske Fakultet ved Københavns Universitet antaget til offentligt at forsvares for den filosofiske doktorgrad. København, den 16. september 2003 John Kuhlmann Madsen Dekan Forsvaret finder sted fredag den 29. oktober 2004 i auditorium 23-0-50, Njalsgade 126, bygning 23, kl. 13.00 44259 - Materie 16/08/04 7:27 Side iii “A Windfall for the magnates” The Development of Woodland Ownership in Denmark c. 1150-1830 by Bo Fritzbøger University Press of Southern Denmark 2004 44259 - Materie 16/08/04 7:27 Side iv © The author and University Press of Southern Denmark 2004 University of Southern Denmark Studies in History and Social Sciences vol. 282 Printed by Special-Trykkeriet Viborg a-s ISBN 87-7838-936-4 Cover design: Cover illustration: Published with support from: Forskningsstyrelsen, Danish Research Agency The University of Copenhagen University Press of Southern Denmark Campusvej 55 DK-5230 Odense M Phone: +45 6615 7999 Fax: +45 6615 8126 [email protected] www.universitypress.dk Distribution in the United States and Canada: International Specialized Book Services 5804 NE Hassalo Street Portland, OR 97213-3644 USA Phone: +1-800-944-6190 www.isbs.com 44259 - Materie 16/08/04 7:27 Side v Contents Preface . -

The 1935 Little Belt Bridge, Denmark: Maintenance Experiments

The 1935 Little Belt Bridge, Denmark: maintenance experiments Autor(en): Christensen, Knud V. Objekttyp: Article Zeitschrift: IABSE reports = Rapports AIPC = IVBH Berichte Band (Jahr): 73/1/73/2 (1995) PDF erstellt am: 25.09.2021 Persistenter Link: http://doi.org/10.5169/seals-55220 Nutzungsbedingungen Die ETH-Bibliothek ist Anbieterin der digitalisierten Zeitschriften. Sie besitzt keine Urheberrechte an den Inhalten der Zeitschriften. Die Rechte liegen in der Regel bei den Herausgebern. Die auf der Plattform e-periodica veröffentlichten Dokumente stehen für nicht-kommerzielle Zwecke in Lehre und Forschung sowie für die private Nutzung frei zur Verfügung. Einzelne Dateien oder Ausdrucke aus diesem Angebot können zusammen mit diesen Nutzungsbedingungen und den korrekten Herkunftsbezeichnungen weitergegeben werden. Das Veröffentlichen von Bildern in Print- und Online-Publikationen ist nur mit vorheriger Genehmigung der Rechteinhaber erlaubt. Die systematische Speicherung von Teilen des elektronischen Angebots auf anderen Servern bedarf ebenfalls des schriftlichen Einverständnisses der Rechteinhaber. Haftungsausschluss Alle Angaben erfolgen ohne Gewähr für Vollständigkeit oder Richtigkeit. Es wird keine Haftung übernommen für Schäden durch die Verwendung von Informationen aus diesem Online-Angebot oder durch das Fehlen von Informationen. Dies gilt auch für Inhalte Dritter, die über dieses Angebot zugänglich sind. Ein Dienst der ETH-Bibliothek ETH Zürich, Rämistrasse 101, 8092 Zürich, Schweiz, www.library.ethz.ch http://www.e-periodica.ch 437 The 1935 Little Belt Bridge, Denmark: Maintenance Experiments Expériences de maintenance sur le pont de Little Belt au Danemark Unterhaltsexperimente an der Kleinen-Belt-Brücke, Dänemark Knud V. CHRISTENSEN K.V. Christensen, born in 1947, Civil and Structural Eng. received his degree at the DSB radgivning Engineering Academy in Aalborg, Denmark. -

Looking for Paradise. Finding Fyn

LOOKING FOR PARADISE. FINDING FYN. FYN AND THE ARCHIPELAGO The Little Belt YOUR ROUTE Bridge MIDDELFART E2 0 TO FYN HI GH WAY Find further information on the island Fyn and the surrounding islands of the archipelago on visitfyn.com ASSENS FACTS ABOUT FYN AND Like us on Facebook. THE ARCHIPELAGO /visitfyn Number of inhabitants: 488.384 Overall area: 3.489 km2 Number of islands: Over 90 islands, 25 that are inhabited Coastal route: 1.130 km Signposted bike routes: 1.000 km Fishing spots: 117 (seatrout.dk) Harbours: 37 Castles and mansions: 123 Biggest town: Odense – 197.513 inhabitants Geographic position: 96 km away from Legoland Billund, about 1 h drive DENMARK 138 km distance to Copenhagen, about 1:15 h drive 298 km distance to Hamburg, about 3 h drive Travel time: Attractive for families as well as for couples during all seasons. Annually about 1 million visitors FYN FLENSBURG BOGENSE KERTEMINDE E2 0 H ODENSE IGH WAY FYN NYBORG The Great Belt Bridge ASSENS H I G H W A Y LOCAL TOURIST INFORMATION FAABORG VisitAssens Visit Faaborg visitassensinfo.com visitfaaborg.com VisitKerteminde Langeland Tourist Office SVENDBORG visitkerteminde.com my-langeland.com Ferry Als - Bøjden VisitLillebaelt VisitNordfyn visitlillebaelt.com visitnordfyn.com VisitNyborg VisitSvendborg visitnyborg.com visitsvendborg.com RUDKØBING VisitOdense Ærø Tourist Office ÆRØ visitodense.com visitaeroe.com ÆRØSKØBING LANGELAND LIKE A DREAM COME TRUE - THE ISLAND FYN Endless beaches and a semingly limitless number of cultural or jump aboard a ferryboat to take a trip to the many islands experiences: on Fyn, tranquility and relaxation goes hand in around Fyn. -

07 Master Shorex.Qxd:SE7 Baltic

Shore Excursions 2007 scandinavia & russia se-7 Contents The Benefits of Booking With Us 2 Make Your Reservations Online 3 Frequently Asked Questions 4 The Medallion Collection/The Signature Collection 6 How to Choose Your Tours 9 Shore Excursion Prices 10 How to Book More Than One Tour in Each Port 10 Århus, Denmark 11 Copenhagen, Denmark 14 Gdansk, Poland 15 Gothenburg, Sweden 17 Hamburg, Germany 20 Helsinki, Finland 26 Kalmar, Sweden 31 Lübeck, Germany 33 Oslo, Norway 37 Riga, Latvia 42 Rønne, Bornholm, Denmark 44 Stockholm, Sweden 46 St. Petersburg, Russia 52 Tallinn, Estonia 63 Visby, Gotland, Sweden 68 Warnemünde, Germany 70 Ystad, Sweden 80 General Information 81 Some images supplied by Shutterstock 1 The Benefits of Booking Make Your Reservations With Us Online When you book your shore excursions with Holland America Now you can easily choose your tour times, book your Line, you can count on our Signature of Excellence® to tours and receive confirmation of your shore excursion consistently offer a superior experience ashore: reservations 24 hours a day. Visit us online at quality www.hollandamerica.com Clean and comfortable transportation equipment; we engage professional independent tour operators dedicated to Book online now, up until 10 days before sailing. Make your customer satisfaction. payment online via our secure website, and receive confirmation safety as well as your approximate tour departure times. You can also download the shore excursions, view tour prices, find answers to Tour operators have contractually agreed to comply with local frequently asked questions and read general information. government requirements and to carry liability insurance in amounts consistent with local standards to address personal Remember, online shore excursion reservations are processed injury and property damage claims. -

Experience It on Funen! Zu Erleben Auf Fünen! 2020 1 DK: SMUK OPLEVELSE I 60 METERS HØJDE! Midt I Danmark Venter Der En Helt Særlig Oplevelse

Experience it on Funen! Zu erleben auf Fünen! 2020 1 DK: SMUK OPLEVELSE I 60 METERS HØJDE! Midt i Danmark venter der en helt særlig oplevelse. Her kan du nemlig komme op og gå på den gamle Lillebæltsbro – 60 meter over havets overflade! Glæd dig til at mærke suset, opleve den friske luft, den fantastiske udsigt og de spændende fortællinger fra din guide. Turen tager 2 timer inkl. sikkerhedsinstruktion og omklædning. UK: UDSIGT TIL NOGET SÆRLIGT! FANTASTIC EXPERIENCE AT 60 METRES! THE PROSPECT OF SOMETHING SPECIAL / In the middle of Denmark a special experience awaits you. You AUSSICHT AUF ETWAS BESONDERES can access and walk on the Old Little Belt Bridge – 60 metres above sea level! Feel the fresh air and the wind on your face, take in the amazing view and listen to your guide’s exciting stories The tour takes 2 hours incl. safety instructions and change of clothes. DE: TOLLES ERLEBNIS IN 60 METERN HÖHE! Im Herzen von Dänemark erwartet Sie ein ganz besonderes Erlebnis. Laufen Sie ganz oben die alte Brücke über den leinen Belt entlang – 60 Meter über dem Meer! Spüren Sie den Wind, genießen Sie die frische Luft und die antastische Aussicht und lauschen Sie den spannenden eschichten Ihres Guides. Die Tour dauert 2 Stunden inkl. Sicherheitsanweisungen und Umkleiden. unik oplevelse GÅ PÅ EN BRO I 60 METERS HØJDE unik oplevelse / UNique experience / ein enmaliges erlebnis TAKE A WALK ON A BRIDGE 60 METERS HIGH FINDES KUN 3 andre steder / GEHEN SIE AUF EINER BRÜCKE IN 60 METER HÖHE i verden / can only be found in three other places in the world -

Odense Adelige Jomfrukloster Havde Found Their Way to the Archives

198 Th e Arcade Room Who lived in the so-called Arcade Room, 206, is not redecorated before moving in. Th e conservators known before the end of the 1780’s, but the room’s estimate that the painted wooden walls were lined appearance has changed completely several times with canvas and wallpaper between 1780 and 1800, – none of the other rooms on the fi rst fl oor have so it may have been Miss de Leth who had the room had such diff erent styles within the course of a few decorated – perhaps aft er 45 years at the dilapidated decades. Sanderumgaard she needed to see something fresh In 1785, the 38-year old Johanne de Leth of and modern. Sanderumgaard Manor became a conventual. She Johanne de Leth lived here until 1808 when she came from a family of 14 siblings, and of the eight became Prioress and moved down to the ground daughters, one was dead and three had long been fl oor. She died at the age of 77 in 1825 and was buried married. Her father had died a few years before, and in St. Knud’s Church. Th e church register states that she now lived at the manor together with her mother the bells were rung – this was not otherwise done and two unmarried sisters in their thirties. Th is for Prioresses or ladies, no doubt because of the was not the present Sanderumgaard, whose main bell-ringer’s fee. building dates from the 1870’s. Johan von Bülow, One of Miss de Leth’s unmarried sisters entered who bought the manor aft er the mother’s death in Vemmetoft e Secular Convent for Noblewomen, but, 1792, described it in his diary as a modest and very even so, lived for a while with a sister and brother- dilapidated house in one storey, with small leaded in-law in Kerteminde. -

Baltic Cruise and Denmark Trip August 9 to August 30, 2010

BALTIC CRUISE AND DENMARK TRIP AUGUST 9 TO AUGUST 30, 2010 And so we begin the second great journey in this, our fourth year of blissful retirement from useful labor, by traveling to Stockholm, boarding a cruise ship that will sail the Baltic for ten days and take us to relatively exotic ports, and visiting Copenhagen before driving around the rest of Denmark. Our only concerns before leaving the U. S. of A. are: (1) Will the Icelandic volcano (Eyjafjallajökull by name) erupt again, thus interfering with our overseas flight? (2) Will the brutal heat wave* that has enervated much of _____________________________________________________________________________ *It has been an unusually hot summer in Eastern Europe. Moscow has been ringed by forest fires and St. Petersburg, one of our destinations, has seen temperatures over 100°F. In fact, a Houston native, if you can believe it, having taken the identical Regent Seven Seas Voyager itinerary that we'll be following, but from July 8 to 18, reported on Cruise Critic how beastly hot she found the various museums and churches in St. Pete, none of which had the benefit of modern air-conditioning. _______________________________________________________________________________ this part of Europe break by the time we get there? And (3) Will my sciatica* be well-enough behaved that we can enjoy ourselves? _____________________________________________________________________________ *Readers of my New Zealand journal (http://web.utk.edu/~rmagid/NewZealand2010.pdf) will recall that the sciatica that began in October, 2009, was but a mild nuisance during our travels earlier this year. This summer, however, the pain in both of m y legs increased to the point that I had an MRI done in early July, visited a neurosurgery practice on July 27, and was advised to get a cortisone shot directly to the area of the spine where the bulging discs were impinging on the sciatic nerve. -

Fyn Island-Denmark Incentive

Fyn Island, Denmark Incentive Sweden Group Incentive Location Fyn and Copenhagen, Program Includes Denmark ▪ Transfer from Copenhagen airport ▪ Lunch at Storms Pakhus Season ▪ Fairytale City tour through Odense April - October ▪ Welcome dinner at Virgo Rigborg ▪ South Funen Island hopping by Rib boat Maximum Capacity ▪ Picnic lunch at the beach 200 pax ▪ Gala dinner at Denmark’s railway museum ▪ À la carte activities Duration ▪ Transfer back to Copenhagen or airport 2 nights Denmark The Fairytale island of Funen Denmark Funen This is Funen (Fyn), only 1½ hours’ drive from Copenhagen, the Fairy tale island of Denmark. The island offers several activities, charming castles, beautiful nature, small local micro producers and the footprints of Hans Christian Andersen. Funen also hosts a lot of small craftsmen because of the inspiring nature. You find designer hats, ceramics and sculptures. The local chefs also find inspiration for their cooking and you will discover many local delicacies like cheese, honey and beer. Many farm shops sell their products to our groups. The island is ideally explored in self-drive vintage cars and a vintage theme dinner can be arranged at one of the castles. The South Funen archipelago can be reached by boat or a chartered schooner and great walks or bicycle programs can be arranged with local guides. Denmark Proposed Agenda Day 1 Denmark Agenda Day 1 10:00 Transfer from Copenhagen airport to Funen Island 12:00 Arrive at Odense and check in at Hotel 12:45 Lunch at Storms Pakhus 13:45 Fairytale City Tour Odense 18:00 Welcome dinner at Virgo Rigborg 22:00 Transfer back to Hotel Denmark Lunch Denmark Storms Pakhus Odense has a new, atmospheric food market of international format in Storms Pakhus' raw industrial warehouse at the harbor. -

Counter-Memorial Submitted by the Government of the Kingdom of Denmark

iNTERNATIONAL COURT OF JUSTICE PASSAGE THROUGH THE GREAT BELT (FINLAND v. DENMARK) COUNTER-MEMORIAL SUBMITTED BY THE GOVERNMENT OF THE KINGDOM OF DENMARK VOLUME 1 MAY 1992 VOLUME 1 TABLE OF CONTENTS Page INTRODUCTION ........................... 3 PART 1. THE FACTS .......................... 11 CHAPTER 1. THE GEOGRAPHY OF DENMARK AND THE DANISH STRAITS ..... 13 CHAPTER II . THE DANISH PLANS FOR A FIXED LINK ACROSS THE GREAT BELT . 16 A . The Early Plans ....................... 16 1 . Introduction .......................... 16 2 . The Proposals made in the 1930s ........... 16 B . The Preparatory Work 1948 . 1972 ......... 17 I . The Great Belt Bridge Commission ......... 17 2 . The 1961 Act ......................... 19 3 . The Working Committee ................. 20 4 . The Technical Committee ................ 22 C . The Initial Project ..................... 23 I . The 1973 Act on the Constmction of a Bridge across the Great Belt ............. 23 2 . Siatshroen Store Bcelt ................... 24 3 . The Circular Note of 12 May 1977 ......... 26 4 . The Progress of the Initial Project .......... 28 Page 5 . Debates in the Danish Parliament on the Great Belt Project 1977 . 1978 .......... 29 D . The Postponement ..................... 31 I . The Decision to Postpone the Project .......................... 31 2 . Reactions from other States ............... 32 3 . Debates in the Danish Parliament on the Great Belt Project 1978 . 1985 and New Investigations ................. : . 33 E . The Present Project .................... 37 1. The 1986 Political