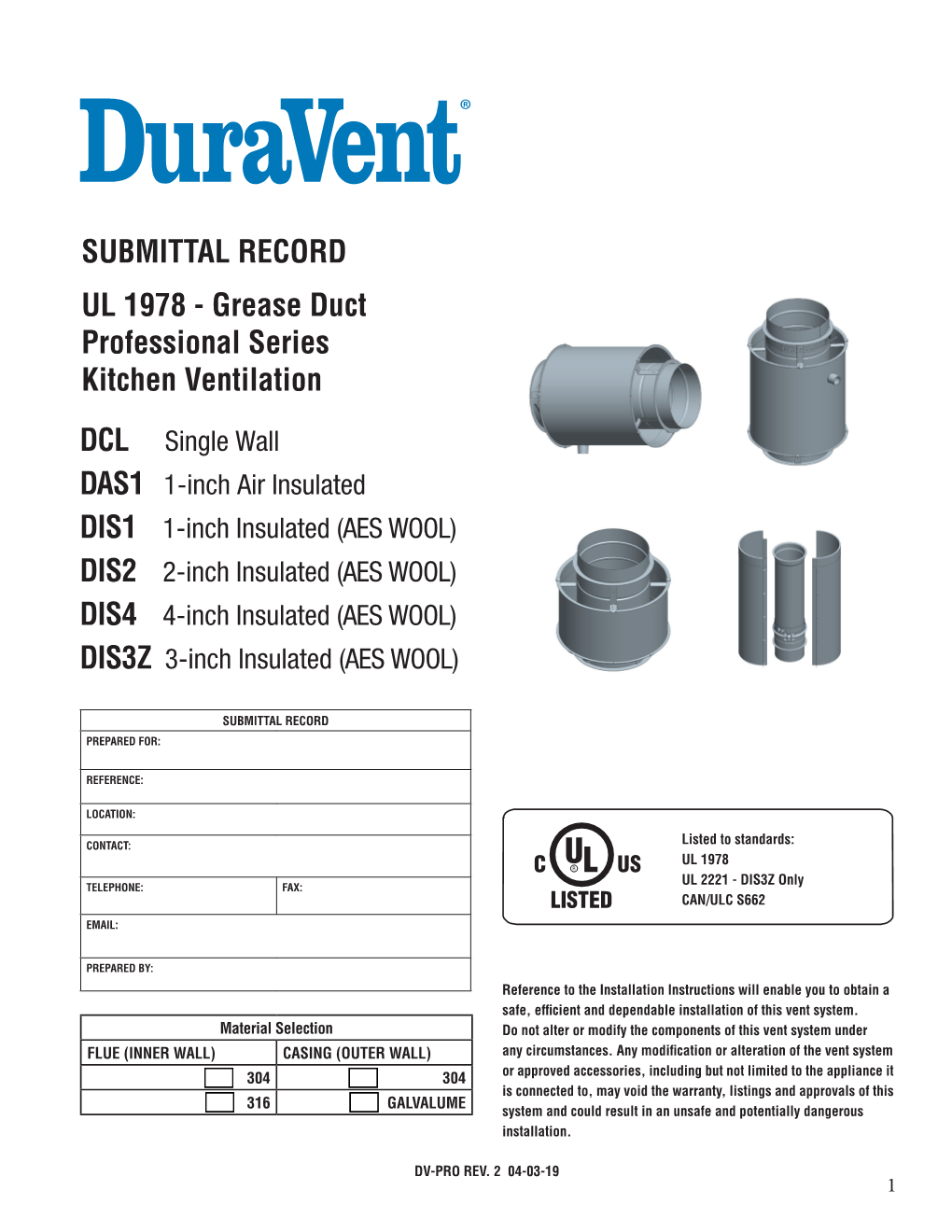

UL 1978 - Grease Duct Professional Series Kitchen Ventilation

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Common Duct Insulation Materials Supplement F

Supplement F Common Duct Insulation Materials The Washington State Energy Code (WSEC) Hotline has received questions about different types and thicknesses of duct insulation. There appears to be some confusion about Table 5-11 of the WSEC which lists the minimum densities, out-of-packages thickness and R-values for different types of duct insulation. Table F-1 shows what the R-values are for varying thicknesses and types of duct insulation in a better layout than Table 5-11. This table also lists the ASTM and UL. Table F-1 R-Values for Common Duct Insulation Materials Installed R-Value1 Typical Material meeting or exceeding the given R-value2 (h.°F sq.ft.)/Btu 1/2-inch Mineral fiber duct liner per ASTM C 1071, Type I 1.9 1-inch Mineral fiber duct wrap per ASTM C 1290 1-inch Mineral fiber duct liner per ASTM C 1071, Types I & II 1-inch Mineral fiber board per ASTM C 612, Types I & IB 3.5 1-inch Mineral fiber duct board per UL 181 1-1/2-inch Mineral fiber duct wrap per ASTM C 1290 1-inch Insulated flex duct per UL 181 1-1/2-inch Mineral fiber duct liner per ASTM C 1071 1-1/2-inch Mineral fiber duct board per UL 181 1-1/2-inch Mineral fiber board per ASTM C 612, Types IA & IB 6.0 2-inch, 2 lb/cu.ft. Mineral fiber duct wrap per ASTM C 1290 2-1/2-inch, .6 to 1 lb/cu.ft. Mineral fiber duct wrap per ASTM C 1290 2-1/2-inch Insulated flex duct per UL 181 2-inch Mineral fiber duct liner per ASTM C 1071, Types I & II 2-inch Mineral fiber Duct board per UL 181 8.0 2-inch Mineral fiber board per ASTM C 612, Types 612, Types I! & IB 3-inch 3/4 lb/cu.ft. -

Commercial Kitchen Ventilation Testing Requirements

COMMERCIAL KITCHEN VENTILATION TESTING REQUIREMENTS CALL FIRE MARSHAL/FIRE SUB CODE OFFICIAL AT 908-454-6121 EXT 360 TO SCHEDULE ACCEPTANCE TESTING IMC 506.3.2.5 GREASE DUCT TEST Prior to the use or concealment of any portion of grease duct system, a leakage test shall be performed in the presence of the Fire Inspector. Ducts shall be considered to be concealed where installed in shafts or covered by coatings or wraps that prevent the ductwork from being visually inspected on ALL sides. The permit holder shall be responsible to provide the necessary equipment and perform the grease duct leakage test. A light test or approved equivalent test method shall be performed to determine that all welded and brazed joints are liquid tight. A light test shall be performed by passing a lamp having a power rating of not less than 100 watts (or 1500 lumens for energy efficient bulb types) through the entire section of duct work to be tested. The lamp shall be open so as to emit light equally in all directions perpendicular to the duct walls. At test shall be performed for the entire duct system, including the hood-to-duct connection. The ductwork shall be permitted to be testing in sections, provided that every joint is tested. IMC 507.16 PERFORMANCE TEST A performance test shall be conducted upon completion and before final approval of installation of a ventilation system serving commercial cooking appliances. The test shall verify the rate of exhaust airflow required by Section 507.13, makeup airflow required by Section 508, and proper operation as specified in this chapter the permit holder shall furnish the necessary test equipment and devices required to perform the tests. -

Whole-House Duct Mount Hepa Air Cleaner

MODEL DA-HEPADM400-VS WHOLE-HOUSE DUCT MOUNT HEPA AIR CLEANER Description The DIRECT AIR Whole House Duct Mount HEPA Cabinet Construction Features Air Cleaner has been designed to remove atmospheric and household dust, coal dust, One piece wrap, steel cabinet has powder-coat insecticide dust, mites, pollen, mold spores, fungi, paint finish to provide rigid installation and durabil- bacteria, viruses, pet dander, cooking smoke and ity. grease, tobacco smoke particles, and more down Pre-punched openings at back of unit and mount- to 0.3 micron (1/84,000 of an inch) with 99.97% ing template are provided for easier duct mount efficiency on the first pass of air. installation; no external ducting required. It’s ideal for homes that have tight space condi- Pre-punched openings at top and bottom of unit tions in their furnace/air conditioning rooms. This facilitate collar mount installation. unit is compact and can be installed directly on the return air vent. It can also be mounted directly to Media Replacement Filters the furnace and collar mounted to the return air duct to save space. PART REPLACE Ideal for homes with allergy, asthma or respiratory NUMBER DESCRIPTION EVERY sufferers, smokers, pets, cooking odors and musti- ness. DMH4-0400 HEPA Media Filter 2-3 years Helps protect and prolong the operating efficiency of the heating and cooling equipment. DMH4-0855 Prefilter, MERV 11 3-6 months Standard Features DMH4-0810 Carbon Prefilter 3-6 months Highly Efficient MERV 11 Prefilter removes lint and hair before they enter HEPA filter. Activated Carbon Prefilter removes odors to ex- tend the life of the HEPA filter. -

Model Ipic Series 4G Grease Duct

INSTALLATION AND WALMART MAINTENANCE APPLICATION INSTRUCTIONS 637N MODEL IPIC 7N71 SERIES 4G GREASE DUCT IT IS OF THE UTMOST IMPORTANCE THAT THIS DUCT BE INSTALLED ONLY IN ACCORDANCE WITH THESE INSTRUCTIONS. IMPORTANT: DO NOT INSTALL GREASE DUCT WITHOUT FIRST READING THESE INSTRUCTIONS VERY CAREFULLY. COMBUSTIBLE MATERIAL: Material made of or surfaced with wood, compressed paper, plant fibers, plastic or other material that will ignite and burn, whether flame proofed or not, or whether plastered or unplastered. Metal-Fab’s series 4G Grease Duct System has been fully tested, listed and classified by Underwriters Laboratories, Inc. and Underwriters Laboratories of Canada. Metal-Fab’s Series 4G Grease Duct Systems have been evaluated and accepted by BOCA, SBCCI, and ICBO as an alternative to a two hour fire rated shaft enclosure when installed in accordance with these installation instructions. Grease Duct installed in accordance with these Installation Instructions meet the requirements of NFPA96. These instructions contain complete information on details concerning dimensions, installation, clearance to combustibles, use of noncombustible enclosures, and Firestops. For any additional information, refer to the parts catalog. METAL-FAB INC., • P.O. BOX 1138, WICHITA, KANSAS 67201 • (316) 943-2351 GENERAL INFORMATION LISTINGS: Metal-Fab IPIC Series 4G Grease Duct Systems (6” thru 36” diameter) are classified by Underwriters Laboratories, Inc. (UL File No. R15388) in accordance with SBCCI acceptance criteria for Grease Duct Enclosure Systems (January 1, 1998). The IPIC Series 4G Grease Ducts for use in Grease Duct Assembly No. G-1 is Classified as an alternate to 3 hr. fire resistive rated shaft enclosure system with a minimum zero clearance to combustibles. -

Significant Changes to the March 2017 International Mechanical Code

Significant Changes to the March 2017 International Mechanical Code State of Connecticut Department of Administrative Services Division of Construction Services Office of Education and Data Management Office of Education and Data Management Spring 2017 Career Development Series Significant Changes to the International Mechanical Code Presented by John Tye Office of the State Building Inspector, DAS “2012” International Mechanical Code Update The following presentation contains “significant” code changes which took place in the International Mechanical Code from 2003 through 2012. Office of Education 2 and Data Management Office of Education and Data Management 1 Significant Changes to the March 2017 International Mechanical Code IMC update 2012 Many code changes have taken place in the IMC since 2003. This seminar will only be able to identify a small number of these changes. Confusion still exists between proper code use such as the IRC versus the IMC for fuel gas installations. The IMC does not address gas or gas related equipment. Office of Education 3 and Data Management IMC update (continued) The IRC uses both its Chapter 24(based on the IFGC) and the 2012 NFPA 54 document for gas piping and equipment installations. The Ct. supplement to the IRC includes the NFPA 54 document. Section 101.4.1 (Add) As I stated in the previous slide the IMC references the International Fuel Gas Code (IFGC) (member of the ICC family of codes). The State of Connecticut did not adopt the IFCG and instead references the NFPA 54 document, currently the 2012 edition for gas piping and equipment installations. Office of Education 4 and Data Management Office of Education and Data Management 2 Significant Changes to the March 2017 International Mechanical Code IMC update (continued) Any reference to the IFGC in either the IMC or IRC shall be considered a reference to NFPA 54, NFPA 2, and NFPA 58. -

Duct Fire Protection Products

23 07 00/THE Duct Fire Protection Products BuyLine 8880 Thermal Ceramics, a global manufacturer of high temperature insulation prod- ucts, has provided engineered solutions for heat containment problems for over 75 years, and was the first to develop flexible fire resistive duct enclosures, mar- keted under the brandname of FireMaster®, for commercial kitchen grease and air ventilation ducts. Unlike imitation wraps in today’s market, Thermal Ceramics has the widest range of duct enclosure products that are performance-tested beyond minimum laboratory listings or code requirements. This assures fire con- tainment, from the typical to the most complex duct designs, without theorizing. Thermal Ceramics innovative duct products are high temperature (2000°F) fire rated solutions that do not age, become brittle, or shrink during in-service opera- tions, like lower temperature mineral wool wraps. The duct products in the FireMaster line are resistant to mold growth in test conditions of 75-95% relative humidity (ASTM D6329). With zero flame and smoke ratings on the blanket, and only a 5 flame spread and 10 smoke rating on the foil encapsulation, Thermal Ceramics duct products do not add toxic emissions to fire conditions. With a vast number of field installations worldwide and over 20 years of successful fire con- tainment in real-world fires, the duct products in the FireMaster line have proven their worth. Typical Applications • Commercial Kitchen Grease Ducts • Air Ventilation Ducts • Chemical Exhaust Ducts • Stair Pressurization Ducts • Hazardous Exhaust Ducts • Trash and linen chutes Duct Fire Protection Products 2000°F Rigid Flexible External 2 Hr Internal 2000°F Commercial Kitchen Shaft Alternative Installation ASTM E119 & Grease Duct Fire Grease Duct Method E814 Performance Containment Air Ventilation Duct Systems Installation Experience Complies with • Wynn Hotel, Las Vegas, NV - Grease duct • Baylor University Bio-Science College, Waco, Texas - Chemical exhaust duct • M.D. -

Guideline on Through Penetration Firestopping

GUIDELINE ON THROUGH-PENETRATION FIRESTOPPING SECOND EDITION – AUGUST 2007 SHEET METAL AND AIR CONDITIONING CONTRACTORS’ NATIONAL ASSOCIATION, INC. 4201 Lafayette Center Drive Chantilly, VA 20151-1209 www.smacna.org GUIDELINE ON THROUGH-PENETRATION FIRESTOPPING Copyright © SMACNA 2007 All Rights Reserved by SHEET METAL AND AIR CONDITIONING CONTRACTORS’ NATIONAL ASSOCIATION, INC. 4201 Lafayette Center Drive Chantilly, VA 20151-1209 Printed in the U.S.A. FIRST EDITION – NOVEMBER 1996 SECOND EDITION – AUGUST 2007 Except as allowed in the Notice to Users and in certain licensing contracts, no part of this book may be reproduced, stored in a retrievable system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of the publisher. FOREWORD This technical guide was prepared in response to increasing concerns over the requirements for through-penetration firestopping as mandated by codes, specified by system designers, and required by code officials and/or other authorities having jurisdiction. The language in the model codes, the definitions used, and the expectations of local code authorities varies widely among the model codes and has caused confusion in the building construction industry. Contractors are often forced to bear the brunt of inadequate or confusing specifications, misunderstandings of code requirements, and lack of adequate plan review prior to construction. This guide contains descriptions, illustrations, definitions, recommendations on industry practices, designations of responsibility, references to other documents and guidance on plan and specification requirements. It is intended to be a generic educational tool for use by all parties to the construction process. Firestopping Guideline • Second Edition iii FIRE AND SMOKE CONTROL COMMITTEE Phillip E. -

Grease Duct Enclosures Fire and Smoke Dampers in Grease Ducts

506.3.11 CHANGE TYPE: Modification CHANGE SUMMARY: The code specifically prohibits the installation of Grease Duct Enclosures fire and smoke dampers in grease ducts. 2015 CODE: 506.3.11 Grease Duct Enclosures. A commercial kitchen grease duct serving a Type I hood that penetrates a ceiling, wall, floor or any concealed spaces shall be enclosed from the point of penetration to the outlet terminal. In-line exhaust fans not located outdoors shall be enclosed as required for grease ducts. A duct shall penetrate exterior walls only at locations where unprotected openings are permitted by the International Building Code. The duct enclosure shall serve a single grease duct and shall not contain other ducts, piping or wiring systems. Duct enclosures shall be either a shaft enclosure in accordance with Section 506.3.11.1, a field-ap- plied enclosure assembly in accordance with 506.3.11.2 or a factory-built enclosure assembly in accordance with Section 506.3.11.3. Duct enclosures shall have a fire-resistance rating of not less than that of the assembly pen- etrated and not less than 1 hour. Fire dampers and smoke dampers shall not be installed in grease ducts. Duct enclosures shall be as prescribed by Section 506.3.11.1, 506.3.11.2 or 506.3.11.3. 506.3.11.4 Duct enclosure not required. This excerpt is taken from Exception: A duct enclosure shall not be required for a grease duct Significant Changes to the that penetrates only a non-fire-resistance-rated roof/ceiling assembly. International Plumbing/ CHANGE SIGNIFICANCE: It has long been understood that fire and smoke dampers are not compatible with grease ducts, and the duct en- Mechanical/ closure requirements clearly account for the lack of such dampers where Fuel Gas the ducts penetrate walls, floors and ceilings. -

Duct Liner Insulation

Duct Liner Insulation Product Performance for Lining HVAC Ducts ABOUT K-FLEX USA K-FLEX USA IS A LEADING MANUFACTURER In April 2012, K-FLEX USA was awarded of closed cell flexible elastomeric foam with ISO 9001:2008 certification by FM insulation products for mechanical Approvals. The independent certification piping, air handling units and vessels. demonstrates the company’s commitment to quality. Designed for ease of installation and reliable performance, K-FLEX® products K-FLEX products have proven performance provide excellent thermal and acoustical in the Plumbing, HVAC/R, Commercial/ performance, including inherent Industrial, Marine, Oil & Gas, Acoustic resistance to moisture intrusion. and OEM Markets. Youngsville, NC Headquarters K-FLEX USA prides itself on being As a member of the IK Insulation Group, responsive to the market, providing K-Flex USA delivers state-of-the-art levels dependable service to customers of technical knowledge and customer throughout North America, bringing an support to the global mechanical innovative approach to product offerings, insulation market. and having products that are 3rd party tested and certified. ISO 9001 CERTIFIED COMPANY HISTORY 2001 Nomaco Insulation and 1989 L’Isolante K-FLEX joined to 2004 1965 L’Isolante K-FLEX was formed. form Nomaco K-FLEX (NKF). NKF acquired RBX’s mechanical insulation Rubatex was formed. business. 1975 1999 2002 2008 Halstead was formed and INSUL-TUBE® Rubatex acquired NKF entered into a Sales & L’Isolante K-FLEX and became a well-known product brand. Halstead -

Kitchen Hood Test Data Form

CITY OF HENDERSON Department of Building & Fire Safety KITCHEN HOOD TEST DATA Date Permit No. Street Address * * * * * * * * * * * * * * General Contractor Phone Sub-Contractor Phone Address License # HOOD LOCATION PLAN SHEET NO. TESTING EQUIPMENT TYPE TYPE OF HOOD: Type I LIST ALL EQUIPMENT UNDER HOOD: ACTUAL HOOD SIZE: ft x ft = sq. ft. (Hood Width) (Hood Length) (Hood Area) REQUIRED QUANTITY OF AIR: (See UMC 2003 for appropriate formula) Ft x ft x = CFM (Hood Width) (Hood Length) (Formula) (Hood Exhaust) ACTUAL QUANTITY OF AIR AS MEASURED: CFM (Actual Volume) ACTUAL TOTAL FILTER AREA: sq. ft. (Filter Area) ACTUAL FILTER AIR FLOW RATE PER SQ. FT. OF FILTER AREA: CFM - sq. ft. = FPM (Actual Volume) (Filter Area) (Each Filter) LISTED FILTER AIRFLOW RATE: = FPM per filter (As Shown on Filter) ACTUAL DUCT SIZE: Rectangular Duct Ft x ft = sq. ft. (Front Width) (Side Length) (Duct Size) Round Duct .79 x ft = sq. ft. (Duct Diameter) (Duct Size) ACTUAL GREASE DUCT AIR VELOCITY: CFM - sq. ft. = FPM (Actual Volume) (Duct Size) (Duct Velocity) REQUIRED DUCT SYSTEM AIR VELOCITY FOR SHOP MADE HOODS: 1500 FPM (minimum) 2500 FPM (maximum) MANUFACTURERS STATED VELOCITY FOR LISTED HOODS: (Minimum) (Maximum) MAKEUP AIR SOURCE AND SIZE: (Size of source in total CFM) THE EXHAUST AND MAKEUP AIR SYSTEMS SHALL BE CONNECTED BY AN ELECTRICAL INTERLOCK SWITCH. 2000 Southern Nevada Uniform Mechanical Code Amendments - 509.11 ( Performance Test) Upon completion and before final approval of the installation of ventilation system serving commercial food heat-processing equipment, a performance test, shall be performed to verify the rate of airflow and proper operation as specified in this chapter. -

VOC Duct and Rough Service Sensor Air Quality Sensors Rev

D10 VOC Duct and Rough Service Sensor Air Quality Sensors Rev. 12/19/16 Features & Options l Corresponds to ASHRAE’s CO2-Based DCV Algorithm l Duct Aspiration Tube or Rough Service Ventilated BAPI-Box l 0 to 5 VDC or 0 to 10 VDC Output Humans respirate Volatile Organic Compounds (VOCs) as well as CO2. The BAPI sensor measures these VOCs and indicates when a space is occupied just as well as a CO2 sensor. The advantage of the VOC sensor is that it measures air contaminants from other sources besides respiration, such as building materials, cleaners, perfumes and furniture and carpet VOC Duct Sensor off-gassing. Using this sensor for Demand Controlled Ventilation then is a way of achieving true indoor air quality, rather than just CO2 dilution. A further benefit is that it requires no additional work on your part. That’s because the sensor converts the VOC reading to a CO2 equivalent level. This lets you use ASHRAE’s CO2- based VRP schedule to ventilate. (More information on the CO2 equivalent output is available on our website or in the Application Notes at the end of this section.) The Duct Sensor samples duct air using an aspiration tube, while the Rough Service unit features a ventilated BAPI-Box and is ideal for areas such as outdoor air plenums, equipment rooms, green houses and warehouses. The VOC level is indicated as “Good, Fair or Poor” by three discrete green, yellow and red LED’s on the front of the unit. If the output reaches 2,000 PPM, the red LED VOC Rough Service Sensor will begin to flash because it has hit its maximum output. -

To the NADCA Standard ACR

Joe, the title of the document should read “Air Systems Cleaning Specialists” and also at the bottom of each page it reads Air Cleaning System Specialists. Air Systems Cleaning Specialist To the NADCA Standard ACR Copyright © 2013 NADCA, All Rights Reserved ii | NADCA AIR SYSTEMS CLEANING SPECIALIST TABLE OF CONTENTS NADCA Air Systems Cleaning Specialist MODULE 1 Overview of Heating Ventilating and Air-Conditioning (HVAC) Systems Cleaning ..................1 History of Heating Ventilating and Air-Conditioning (HVAC) Systems Cleaning ................1 Factors Affecting the HVAC (Duct) Cleaning Industries Growth ............................................2 What is HVAC Contamination Composed Of? ..........................................................................3 The National Air Duct Cleaners Association (NADCA) ...........................................................4 MODULE 2 HVAC Systems Overview ....................................................................................................................7 Principles of Heating Ventilation and Air Conditioning Systems ............................................7 Types of HVAC Systems...............................................................................................................27 Basic Components of HVAC Systems ........................................................................................31 MODULE 3 Protecting Health & Safety of Occupants and Building .................................................................45 Preliminary Recommendations