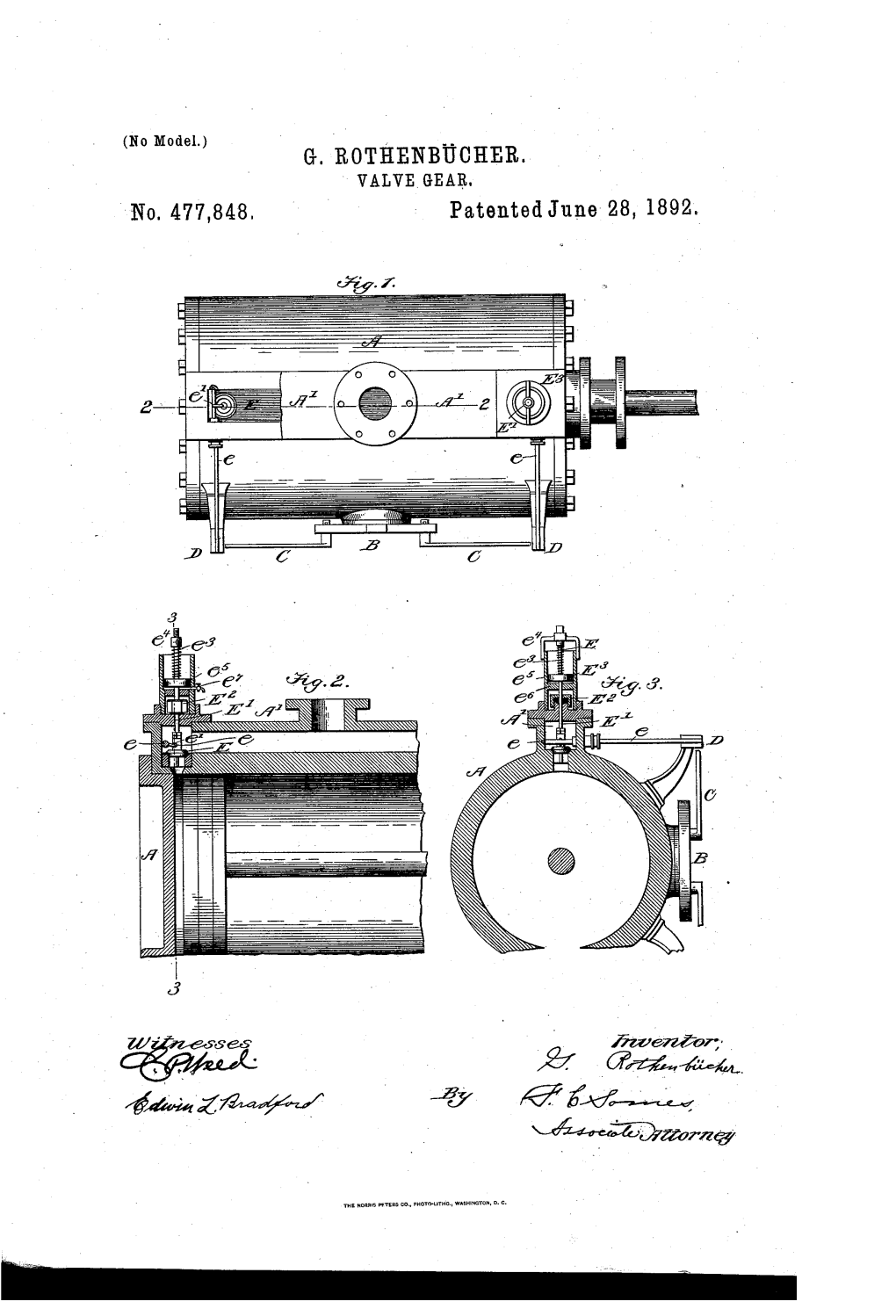

No. 477,848, Patented June 28, 1892

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Steam As a General Purpose Technology: a Growth Accounting Perspective

Working Paper No. 75/03 Steam as a General Purpose Technology: A Growth Accounting Perspective Nicholas Crafts © Nicholas Crafts Department of Economic History London School of Economics May 2003 Department of Economic History London School of Economics Houghton Street London, WC2A 2AE Tel: +44 (0)20 7955 6399 Fax: +44 (0)20 7955 7730 1. Introduction* In recent years there has been an upsurge of interest among growth economists in General Purpose Technologies (GPTs). A GPT can be defined as "a technology that initially has much scope for improvement and evntually comes to be widely used, to have many uses, and to have many Hicksian and technological complementarities" (Lipsey et al., 1998a, p. 43). Electricity, steam and information and communications technologies (ICT) are generally regarded as being among the most important examples. An interesting aspect of the occasional arrival of new GPTs that dominate macroeconomic outcomes is that they imply that the growth process may be subject to episodes of sharp acceleration and deceleration. The initial impact of a GPT on overall productivity growth is typically minimal and the realization of its eventual potential may take several decades such that the largest growth effects are quite long- delayed, as with electricity in the early twentieth century (David, 1991). Subsequently, as the scope of the technology is finally exhausted, its impact on growth will fade away. If, at that point, a new GPT is yet to be discovered or only in its infancy, a growth slowdown might be observed. A good example of this is taken by the GPT literature to be the hiatus between steam and electricity in the later nineteenth century (Lipsey et al., 1998b), echoing the famous hypothesis first advanced by Phelps-Brown and Handfield-Jones, 1952) to explain the climacteric in British economic growth. -

Aquidneck Island's Reluctant Revolutionaries, 16'\8- I 660

Rhode Island History Pubhshed by Th e Rhod e bland Hrstoncal Society, 110 Benevolent St reet, Volume 44, Number I 1985 Providence, Rhode Island, 0 1~, and February prmted by a grant from th e Stale of Rhode Island and Providence Plamauons Contents Issued Ouanerl y at Providence, Rhode Island, ~bruary, May, Au~m , and Freedom of Religion in Rhode Island : November. Secoed class poet age paId al Prcvrdence, Rhode Island Aquidneck Island's Reluctant Revolutionaries, 16'\8- I 660 Kafl Encson , presIdent S HEI LA L. S KEMP Alden M. Anderson, VIet presIdent Mrs Edwin G FI!I.chel, vtce preudenr M . Rachtl Cunha, seatrory From Watt to Allen to Corliss: Stephen Wllhams. treasurer Arnold Friedman, Q.u ur<lnt secretary One Hundred Years of Letting Off Steam n u ow\ O f THl ~n TY 19 Catl Bndenbaugh C H AR LES H O F f M A N N AND TESS HOFFMANN Sydney V James Am cmeree f . Dowrun,; Richard K Showman Book Reviews 28 I'UIIU CAT!O~ S COM!I4lTT l l Leonard I. Levm, chairmen Henry L. P. Beckwith, II. loc i Cohen NOl1lUn flerlOlJ: Raben Allen Greene Pamtla Kennedy Alan Simpson William McKenzIe Woodward STAff Glenn Warren LaFamasie, ed itor (on leave ] Ionathan Srsk, vUlI1ng edltot Maureen Taylo r, tncusre I'drlOt Leonard I. Levin, copy editor [can LeGwin , designer Barbara M. Passman, ednonat Q8.lislant The Rhode Island Hrsto rrcal Socrerv assumes no respcnsrbihrv for the opinions 01 ccntnbutors . Cl l9 8 j by The Rhode Island Hrstcncal Society Thi s late nmeteensh-centurv illustration presents a romanticized image of Anne Hutchinson 's mal during the AntJnomian controversy. -

Age of Steam" Reconsidered

A Service of Leibniz-Informationszentrum econstor Wirtschaft Leibniz Information Centre Make Your Publications Visible. zbw for Economics Castaldi, Carolina; Nuvolari, Alessandro Working Paper Technological revolution and economic growth: The "age of steam" reconsidered LEM Working Paper Series, No. 2004/11 Provided in Cooperation with: Laboratory of Economics and Management (LEM), Sant'Anna School of Advanced Studies Suggested Citation: Castaldi, Carolina; Nuvolari, Alessandro (2004) : Technological revolution and economic growth: The "age of steam" reconsidered, LEM Working Paper Series, No. 2004/11, Scuola Superiore Sant'Anna, Laboratory of Economics and Management (LEM), Pisa This Version is available at: http://hdl.handle.net/10419/89286 Standard-Nutzungsbedingungen: Terms of use: Die Dokumente auf EconStor dürfen zu eigenen wissenschaftlichen Documents in EconStor may be saved and copied for your Zwecken und zum Privatgebrauch gespeichert und kopiert werden. personal and scholarly purposes. Sie dürfen die Dokumente nicht für öffentliche oder kommerzielle You are not to copy documents for public or commercial Zwecke vervielfältigen, öffentlich ausstellen, öffentlich zugänglich purposes, to exhibit the documents publicly, to make them machen, vertreiben oder anderweitig nutzen. publicly available on the internet, or to distribute or otherwise use the documents in public. Sofern die Verfasser die Dokumente unter Open-Content-Lizenzen (insbesondere CC-Lizenzen) zur Verfügung gestellt haben sollten, If the documents have been made available under an Open gelten abweichend von diesen Nutzungsbedingungen die in der dort Content Licence (especially Creative Commons Licences), you genannten Lizenz gewährten Nutzungsrechte. may exercise further usage rights as specified in the indicated licence. www.econstor.eu Laboratory of Economics and Management Sant’Anna School of Advanced Studies Piazza Martiri della Libertà, 33 - 56127 PISA (Italy) Tel. -

Civil Engineering

I UNIVERSITY OF 'ILLINOIS CONVOCATION lt _ , ' ! ' I . THE WATT CENTENARY : AND THE I /• COLLEGE OF ENGINEERING. · OPEN· HOUSE , ' · f ~L. 0 ' ' ., . 't MARCH 23, 1920 lnscription on the monument to James Watt m Westminister Abbey, London NOT TO PERPETDATE A NAME WHICH MUST ENDURE WHILE THE PEACEFUL ARTS FLOURISH, · BUT TO SHEW THAT MANKIND HAVE LEARNT TO HONOUR THOSE WHO BEST DESERVE THEIR GRATITUDE, THE KING HIS MINISTERS, AND MANY OF THE NOBLES AND COMMONERS OF THE REALM RAISED THIS MONUMENT TO JAMES WATT WHO DIRECTING THE FORCE OF AN ORIGINAL GENIUS EARLY EXERCISED IN PHILOSOPHIC RESEARCH TO THE IMPROVEMENT OF THE STEAM-ENGINE, ENLARGED THE RESGURCES OF HIS COUNTRY INCREASED THE POWER OF MAN, AND ROSE TO AN El\1INENT PLACE AMONG THE MOST ILLUSTRIOUS FOLLOWERS OF SCIENCE AND THE REAL BENEFACTORS OF THE WORLD BORN AT GREENOCK MDCCXXXVI DIED AT HEATHFIELD IN STAFFORDSHIRE MDCCCXIX WATT CENTENARY CONVOCATION under the auspices of the COLLEGE OF ENGINEERING INTRODUCTORY REMARKS by CHARLES RUSS RICHARDS Dean of the College of Engineering ADDRESS: JAMES WATT, HIS LIFE AND ITS INFLUENCE UPON THE INDUSTRIAL DEVELOPMENT OF THE WORLD by LESTER PAIGE BRECKENRIDGE, PH.B., M.A., DR.ENG'G Professor of Mechanical Engineering, University of Illinois, 1893-1909; Professor of Mechanical Engineering, Sheffield Scientific School, Yale University, 1909- PROGRAM OF THE OPEN HOUSE OF THE COLLEGE OF ENGINEERING The College of Engineering provides instruction in twelve four year curriculums in the following branches of engineering. Archi tecture Mining Engineering -

A Catechism of the Steam Engine by John Bourne</H1>

A Catechism of the Steam Engine by John Bourne A Catechism of the Steam Engine by John Bourne Produced by Robert Connal and PG Distributed Proofreaders from images generously provided by the Digital & Multimedia Center, Michigan State University Libraries. A CATECHISM OF THE STEAM ENGINE IN ITS VARIOUS APPLICATIONS TO MINES, MILLS, STEAM NAVIGATION, RAILWAYS, AND AGRICULTURE. WITH PRACTICAL INSTRUCTIONS FOR THE MANUFACTURE AND MANAGEMENT OF ENGINES OF EVERY CLASS. BY page 1 / 559 JOHN BOURNE, C.E. _NEW AND REVISED EDITION._ [Transcriber's Note: Inconsistencies in chapter headings and numbering of paragraphs and illustrations have been retained in this edition.] PREFACE TO THE FOURTH EDITION. For some years past a new edition of this work has been called for, but I was unwilling to allow a new edition to go forth with all the original faults of the work upon its head, and I have been too much engaged in the practical construction of steam ships and steam engines to find time for the thorough revision which I knew the work required. At length, however, I have sufficiently disengaged myself from these onerous pursuits to accomplish this necessary revision; and I now offer the work to the public, with the confidence that it will be found better deserving of the favorable acceptation and high praise it has already received. There are very few errors, either of fact or of inference, in the early editions, which I have had to correct; but there are many omissions which I have had to supply, and faults of arrangement and classification which I have had to rectify. -

PRESIDENT, SECRETARY, I'~

~ .-:/t, r'j; ~assaehusetts Institute of Te, , . ) -~ S~ JUN |~3~ REPORTS f OF THE . , . ~ k PRESIDENT, SECRETARY, i'~ AND r ~ ~ "r [~ DEPARTMENTS.~ ':- ~!! [ 1871-72. ~ ,:rI~,~:~ . _ '-;2 ~-. / l BOSTON: PRESS OF A. A. K;INGMAN. 1872. i "7-1"11 MASSACHUSETTS STITUTE OF TECHNOLOGY. PRESIDENT'S REPORT. To the CorToration qf the Institute. G~NTLE~Z~.~":--Your attention is respectfully invited to the accompanying reports, as carefully prepared statements of the condition of the depar~tments to which they relate, and leaving but little to be said in addition. Since tile report of the department of Mining a~.t Metallurgy was put in type, Mr. Samuel Bachelder, of Cambridge, has presentedto the Institute his very ingenious dynamometer, which accurately weighs all the power transmitted through it. This will enable the department to keep an exact record of all the power used in the mining and metallurgcial laboratory in run- ning all or any of the machines in use. We have also received a Blake crusher, size 3 rF by 5", and a 12 inch Whelpley and Storer dry pulverizer. The new smelting and blast furnace~ have been fully designed by Pros Ordway~ and their construc- tion begun. Our thanks are due to H. J. Booth & Co., of the Union Iron Works, San Francisco, California, for a very large and generous reduction in the price of the machinery furnished by them; and it is but justice to I. M. Scott, Esq, of that fil~n, who designed and built the five-stamp battery now in our laboratory, expressly for the Institute, to say that it is complete in all its parts, and gives entire satisfaction. -

Guide to the Evolution of the Corliss Steam Engine Album

Guide to the Evolution of the Corliss Steam Engine Album NMAH.AC.1016 Alison Oswald 2018 Archives Center, National Museum of American History P.O. Box 37012 Suite 1100, MRC 601 Washington, D.C. 20013-7012 [email protected] http://americanhistory.si.edu/archives Table of Contents Collection Overview ........................................................................................................ 1 Administrative Information .............................................................................................. 1 Arrangement..................................................................................................................... 2 Scope and Contents note................................................................................................ 2 Biographical/Historical note.............................................................................................. 2 Names and Subjects ...................................................................................................... 2 Container Listing ............................................................................................................. 3 Evolution of the Corliss Steam Engine Album NMAH.AC.1016 Collection Overview Repository: Archives Center, National Museum of American History Title: Evolution of the Corliss Steam Engine Album Identifier: NMAH.AC.1016 Date: 1930. Extent: 0.3 Cubic feet (1 box) Creator: Franklin Machine Company Providence, Rhode Island Corliss, George H. (George Henry), 1817-1888 Language: English Summary: Collection -

Bulletin 173 Plate 1 Smithsonian Institution United States National Museum

U. S. NATIONAL MUSEUM BULLETIN 173 PLATE 1 SMITHSONIAN INSTITUTION UNITED STATES NATIONAL MUSEUM Bulletin 173 CATALOG OF THE MECHANICAL COLLECTIONS OF THE DIVISION OF ENGINEERING UNITED STATES NATIONAL MUSEUM BY FRANK A. TAYLOR UNITED STATES GOVERNMENT PRINTING OFFICE WASHINGTON : 1939 For lale by the Superintendent of Documents, Washington, D. C. Price 50 cents ADVERTISEMENT Tlie scientific publications of the National Museum include two series, known, respectively, as Proceedings and Bulletin. The Proceedings series, begun in 1878, is intended primarily as a medium for the publication of original papers, based on the collec- tions of the National Museum, that set forth newly acquired facts in biology, anthropology, and geology, with descriptions of new forms and revisions of limited groups. Copies of each paper, in pamphlet form, are distributed as published to libraries and scientific organi- zations and to specialists and others interested in the different sub- jects. The dates at which these separate papers are published are recorded in the table of contents of each of the volumes. Tlie series of Bulletins, the first of which was issued in 1875, contains separate publications comprising monographs of large zoological groups and other general systematic treatises (occasionally in several volumes), faunal works, reports of expeditions, catalogs of type specimens and special collections, and other material of simi- lar nature. The majority of the volumes are octavo in size, but a quarto size has been adopted in a few instances in which large plates were regarded as indispensable. In the Bulletin series appear vol- umes under the heading Contrihutions from the United States Na- tional Eerharium, in octavo form, published by the National Museum since 1902, which contain papers relating to the botanical collections of the Museum. -

Steam Engine Collection

STEAM ENGINE COLLECTION The New England Museum of Wireless And Steam Frenchtown Road ~ East Greenwich, R.I. International Mechanical Engineering Heritage Collection Designated September 12, 1992 The American Society of Mechanical Engineers INTRODUCTION It has been said that an operating steam engine is ‘visual music’. The New England Museum of Wireless and Steam provides the steam engine enthusiast, the mechanical engineer and the public at large with an opportunity to experience the ‘music’ when the engines are in steam. At the same time they can appreciate the engineering skills of those who designed the engines. The New England Museum of Wireless and Steam is unusual among museums in its focus on one aspect of mechanical engineering history, namely, the history of the steam engine. It is especially rich in engines manufactured in Rhode Island, a state which has had an influence on the history of the steam engine in the United States out of all proportion to its size and population. Many of the great names in the design and manufacture of steam engines received their training in Rhode Island, most particularly in the shops of the Corliss Steam Engine Co. in Providence. George H. Corliss, an important contributor to steam engine technology, founded his company in Providence in 1846. Engines that used his patent valve gear were built in large numbers by the Corliss company, and by others, both in the United States and abroad, either under license or in various modified forms once the Corliss patent expired in 1870. The New England Museum of Wireless and Steam is particularly fortunate in preserving an example of a Corliss engine built by the Corliss Steam Engine Company. -

Engines Exposed Engines Exposed Exhibit Map There Are More Than 60 on View, but Here Matt Anderson, Curator of Check out More Autos with Their Hoods Popped

Take it forward.® 1926 Rolls-Royce 1963 Buick Riviera 1965 Goldenrod New Phantom Limousine Into Autos? Keep pace with the latest content, collections and expert insights for collectors, gearheads, race fans and restorers. Cruise into thehenryford.org/onwheels 1933 Willys Drag Racer or subscribe to OnWheels at thehenryford.org/enews. We’ve popped the hoods on the incredible stories of grit and imagi- nation that drive us forward. Dozens of our most fascinating mod- els share the inside story of this evolving technology. Discover the Mark Your Calendar For thinking behind our most advanced cars that started over a century ago. Dive into the surprising and daring history of the automobile on These Popular Car Shows a deeper level. Daily Programming Saturday Programming Exploring Automotive Innovations Make Something: Saturdays Join us for a 20-minute conversation about January 14-February 26 10:00-3:00 our world-class car collection. Topics Museum Gallery Plaza (near Your Place change daily and may include everything in Time) from the basics to a deep dive on one or January two cars. Check on-site signage for today’s offerings. We’ll bring in 2017 by highlighting the Mon.-Fri. 11:30, 12:30 and 3:00 best projects of 2016. Tinker with flight, Sat.-Sun. 10:30, 12:30 and 3:00 learn to solder with a simple LED badge*, Meet outside Drive-In Theater. make a tinkering journal and build a bot.* Great Father’s Day Outing! 67th Annual February Curator Close-Up Explore the evolution of vehicle power Motor Muster Old Car Festival sources including electrical generation, Greenfield Village • June 17-18, 2017 Greenfield Village • Sept. -

Landmarks in Mechanical Engineering

Page iii Landmarks in Mechanical Engineering ASME International History and Heritage Page iv Copyright © by Purdue Research Foundation. All rights reserved. 01 00 99 98 97 5 4 3 2 1 The paper used in this book meets the minimum requirements of American National Standard for Information Sciences– Permanence of Paper for Printed Library Materials, ANSI Z39.481992. Printed in the United States of America Design by inari Cover photo credits Front: Icing Research Tunnel, NASA Lewis Research Center; top inset, Saturn V rocket; bottom inset, WymanGordon 50,000ton hydraulic forging press (Courtesy Jet Lowe, Library of Congress Collections Back: top, Kaplan turbine; middle, Thomas Edison and his phonograph; bottom, "Big Brutus" mine shovel Unless otherwise indicated, all photographs and illustrations were provided from the ASME landmarks archive. Library of Congress Cataloginginpublication Data Landmarks in mechanical engineering/ASME International history and Heritage. p. cm Includes bibliographical references and index. ISBN I557530939 (cloth:alk. paper).— ISBN I557530947 (pbk. : alk. paper) 1. Mechanical engineering—United States—History 2. Mechanical engineering—History. 1. American Society of Mechanical Engineers. History and Heritage Committee. TJ23.L35 1996 621'.0973—dc20 9631573 CIP Page v CONTENTS Preface xiii Acknowledgments xvii Pumping Introduction 1 Newcomen Memorial Engine 3 Fairmount Waterworks 5 Chesapeake & Delaware Canal Scoop Wheel and Steam Engines 8 Holly System of Fire Protection and Water Supply 10 Archimedean Screw Pump 11 Chapin Mine Pumping Engine 12 LeavittRiedler Pumping Engine 14 Sidebar: Erasmus D.Leavitt, Jr. 16 Chestnut Street Pumping Engine 17 Specification: Chestnut Street Pumping Engine 18 A. -

Thirty Chronicles

Thirty Chronicles The Collected Newsletters of the Herreshoff Marine Museum Numbers 1 to 30 (1979 - 2001) Scans by the Herreshoff Marine Museum and Maynard Bray Data Processing by Claas van der Linde Copyright © Herreshoff Marine Museum, Bristol, R.I. 2007 Contents No. 1 Spring 1979 Sprite Returns Home To Bristol [by Carlton J. Pinheiro] Thomas P. Brightman Obituary S Class Anniversary [by Halsey C. Herreshoff] NC-4 (aircraft) Anniversary [by Carlton J. Pinheiro] Old Jock Davidson Falls Overboard [by Clarence DeWolf Herreshoff] Museum Report – Spring 1979 [by Halsey C. Herreshoff] No. 2 Fall 1979 S Class Anniversary Race [by Halsey C. Herreshoff] Who Built The Yachts? [by Alice DeWolf Pardee] Recollections of the Herreshoffs [by Irving M. Johnson] 12 ½ Footer Donated [by Carlton J. Pinheiro] The “240” trip in 1906 [by A. Griswold Herreshoff] Mr. J.B., Though Blind, Directs His Chauffeur [by Clarence DeWolf Herreshoff] Columbia’s Topmast Returns [by Halsey C. Herreshoff] Railway Restored [by Nathanael G. Herreshoff III] No. 3 Spring 1980 Herreshoff Catamarans – Amaryllis [by Carlton J. Pinheiro] Enterprise Fiftieth Anniversary [by Nathanael G. Herreshoff III] Belisarius and Charles B. Rockwell [by Eleanor Rockwell Edelstein] N.G.H. Stops Vibration [by Clarence DeWolf Herreshoff] Recollections of Herreshoff Mfg. Co. [by Professor Evers Burtner] The Tender Nathanael [by Waldo Howland] Indian Donated [by George E. Lockwood] Memories of Captain Nat [by Pattie Munroe Catlow] No. 4 Fall 1980 Freedom Visits The Museum Colors Fly From Columbia’s Topmast Marjorie (Van Wickle Steam Yacht) [by Alice DeWolf Pardee] Captain Nat Ignores A Bit Of Horseplay [by Clarence DeWolf Herreshoff] J.