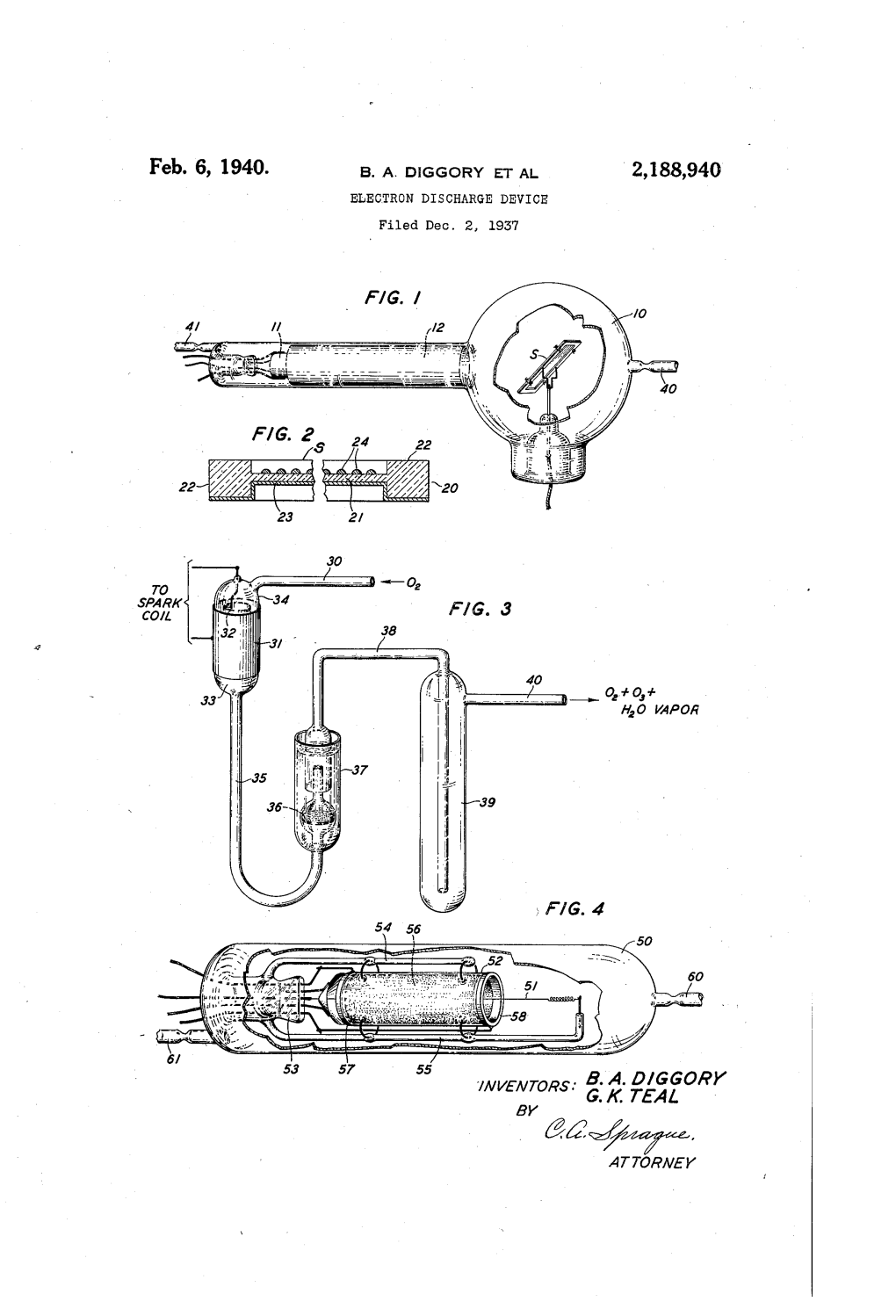

Feb- 6, 1940- B. A. DIGGORY ET AL ' 2,138,940 H20 Mpon

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

UNITED STATES PATENT OFFICE PRODUCTION of VANILLIC ACID (SILVER, Oxide PROCESS) Irwin A

Patented Apr. 15, 1947 2,419,158 UNITED STATES PATENT OFFICE PRODUCTION OF VANILLIC ACID (SILVER, oxIDE PROCESS) Irwin A. Pearl, Appleton, Wis., assignor, by mesne assignments, to Sulphite Products Corporation, - Appleton, Wis., a corporation of Wisconsin No Drawing. Application January 12, 1944, Seria No. 517,985 8 Claims. (C. 260-521) 2 The present invention relates to the production About 300 parts of vanillic acid melting at 210 of vanillic and closely related acids, and to an 211 is obtained. - a improved process for producing acids derived by Ortho vanillin and syringaldehyde react in the oxidation from vanillin, Ortho-vanillin, and same way as the vanillin in Example I, with syringaldehyde. similarly high yields of completely transformed Most aldehydes may be transformed to the material. corresponding acids by common oxidizing agents If the treatment with solid sodium hydroxide or in the Cannizzaro reaction, but vanillin, Ortho warms the solution materially above 50° C., the vanillin, and Syringaldehyde are exceptions and vaniliin reacts as fast as it is added and the have been reported as not amenable to either temperature rises, but full completion of the reaction. Ordinary oxidizing agents either (1) action is assured by slight further heating. I have no action on the compound or (2) act as have secured good results with final temperatures dehydrogenating agents, and yield the dehydro of 75° to 85, but higher temperatures are dicompound or (3) cause complete decomposition. innocuous. The Cannizzaro reaction is conveniently written 5 However, if the materials are admixed at tem as follows: peratures materially below 50° C., it is first neces NaOH sary to warm them, and at about 50° C. -

Silver As a Drinking-Water Disinfectant

Silver as a drinking-water disinfectant Silver as a drinking-water disinfectant Alternative drinking-water disinfectants: silver ISBN 978-92-4-151369-2 © World Health Organization 2018 Some rights reserved. This work is available under the Creative Commons Attribution- NonCommercial-ShareAlike 3.0 IGO licence (CC BY-NC-SA 3.0 IGO; https://creativecommons.org/licenses/by-nc-sa/3.0/igo). Under the terms of this licence, you may copy, redistribute and adapt the work for non-commercial purposes, provided the work is appropriately cited, as indicated below. In any use of this work, there should be no suggestion that WHO endorses any specific organization, products or services. The use of the WHO logo is not permitted. If you adapt the work, then you must license your work under the same or equivalent Creative Commons licence. If you create a translation of this work, you should add the following disclaimer along with the suggested citation: “This translation was not created by the World Health Organization (WHO). WHO is not responsible for the content or accuracy of this translation. The original English edition shall be the binding and authentic edition”. Any mediation relating to disputes arising under the licence shall be conducted in accordance with the mediation rules of the World Intellectual Property Organization. Suggested citation. Alternative drinking-water disinfectants: bromine, iodine and silver. Geneva: World Health Organization; 2018. Licence: CC BY-NC-SA 3.0 IGO. Cataloguing-in-Publication (CIP) data. CIP data are available at http://apps.who.int/iris. Sales, rights and licensing. To purchase WHO publications, see http://apps.who.int/bookorders. -

Controlled Growth of Silver Oxide Nanoparticles on the Surface of Citrate Anion Intercalated Layered Double Hydroxide

nanomaterials Article Controlled Growth of Silver Oxide Nanoparticles on the Surface of Citrate Anion Intercalated Layered Double Hydroxide Do-Gak Jeung 1, Minseop Lee 2, Seung-Min Paek 2,* and Jae-Min Oh 1,* 1 Department of Energy and Materials Engineering, Dongguk University-Seoul, Seoul 04620, Korea; [email protected] 2 Department of Chemistry, Kyungpook National University, Daegu 41566, Korea; [email protected] * Correspondence: [email protected] (S.-M.P.); [email protected] (J.-M.O.) Abstract: Silver oxide nanoparticles with controlled particle size were successfully obtained utilizing citrate-intercalated layered double hydroxide (LDH) as a substrate and Ag+ as a precursor. The lattice of LDH was partially dissolved during the reaction by Ag+. The released hydroxyl and citrate acted as a reactant in crystal growth and a size controlling capping agent, respectively. X-ray diffraction, X-ray photoelectron spectroscopy, and microscopic measurements clearly showed the development of nano-sized silver oxide particles on the LDH surface. The particle size, homogeneity and purity of silver oxide were influenced by the stoichiometric ratio of Ag/Al. At the lowest silver ratio, the particle size was the smallest, while the chemical purity was the highest. X-ray photoelectron spectroscopy and UV-vis spectroscopy results suggested that the high Ag/Al ratio tended to produce silver oxide with a complex silver environment. The small particle size and homogeneous distribution of silver oxide showed advantages in antibacterial efficacy compared with bulk silver oxide. LDH Citation: Jeung, D.-G.; Lee, M.; Paek, with an appropriate ratio could be utilized as a substrate to grow silver oxide nanoparticles with S.-M.; Oh, J.-M. -

Silver Oxide Battery SIZES: All Sizes EMERGENCY HOTLINE: 800-424-9300 (24 Hr, Chemtrec) EDITION DATE: 08/11/2014

Spectrum Brands, Inc. Rayovac Division 3001 Deming Way Middleton, WI 53562-1431 Phone: (608) 275-3340 Fax: (608) 275-4577 http://www.rayovac.com SAFETY DATA SHEET The Safety Data Sheet is supplied as a service to you. For other related information, please visit: http://www.rayovac.com 1. IDENTIFICATION PRODUCT NAME: Silver Oxide Battery SIZES: All sizes EMERGENCY HOTLINE: 800-424-9300 (24 hr, Chemtrec) EDITION DATE: 08/11/2014 2. HAZARD IDENTIFICATION We would like to inform our customers that these batteries are exempt articles and are not subject to the 29 CFR 1910.1200 OSHA requirements, Canadian WHMIS requirements or GHS requirements. Emergency Overview OSHA Hazards-not applicable Target Organs-not applicable GHS Classification-not applicable GHS Label Elements, including precautionary Statement-not applicable Pictogram-not applicable Signal words-not applicable Hazard statements-not applicable Precautionary statements-not applicable 3. COMPOSITION/INFORMATION ON INGREDIENTS INGREDIENT NAME CAS # % TLV*/**TWA Silver Oxide 20667-12-3 <0.5 .01 mg/m3 (TWA) Steel 7439-89-6 37-41 --- Zinc 7440-66-6 30-40 5.0 mg/m3 (ZnO as Fume) Potassium Hydroxide 1310-58-3 1-3 Solution Not Listed Graphite 7782-42-5 <0.25 15 mppcf (TWA) Mercury 7439-97-6 <0.9** 1 mg/10 m3 (Ceiling) Manganese Dioxide 1313-13-9 <2.5 C5.0 mg/ m3 (Mn, TWA) Water, paper, plastic, other --- Balance --- *Source: OSHA 29 CFR 1910.1000 Table Z-1, 2 or 3 11-01-2012 ** All Silver Oxide cells contain less than 25 mg/cell of mercury NA = Not Applicable Safety Data Sheet Information (800) 237-7000 Page 1 of 4 4. -

Page 1 of 4 Silver Oxide Batteries January 2016

Page 1 of 4 Silver Oxide Batteries January 2016 PRODUCT SAFETY DATA SHEET PRODUCT NAME: Energizer Battery Type No.: Volts: 1.5 /cell TRADE NAMES: Energizer, Hearwell, Overtime Approximate Weight: CHEMICAL SYSTEM: Silver Oxide-Zinc Designed for Recharge: No Energizer has prepared copyrighted Product Safety Datasheets to provide information on the different Eveready/Energizer battery systems. Batteries are articles as defined under the GHS and exempt from GHS classification criteria (Section 1.3.2.1.1 of the GHS). The information and recommendations set forth herein are made in good faith, for information only, and are believed to be accurate as of the date of preparation. However, ENERGIZER BATTERY MANUFACTURING, INC. MAKES NO WARRANTY, EITHER EXPRESS OR IMPLIED, WITH RESPECT TO THIS INFORMATION AND DISCLAIMS ALL LIABILITY FROM REFERENCE ON IT. SECTION 1 - MANUFACTURER INFORMATION Energizer Battery Manufacturing, Inc. Telephone Number for Information: 25225 Detroit Rd. 800-383-7323 (USA / CANADA) Westlake, OH 44145 Date Prepared: January 2016 SECTION 2 – HAZARDS IDENTIFICATION GHS classification: N/A Signal Word: N/A Hazard Classification: N/A Under normal conditions of use, the battery is hermetically sealed. Ingestion: Swallowing a battery can be harmful. Contents of an open battery can cause serious chemical burns of mouth, esophagus, and gastrointestinal tract. Inhalation: Contents of an open battery can cause respiratory irritation. Skin Contact: Contents of an open battery can cause skin irritation and/or chemical burns. Eye Contact: Contents of an open battery can cause severe irritation and chemical burns. SECTION 3 - INGREDIENTS IMPORTANT NOTE: The battery should not be opened or burned. Exposure to the ingredients contained within or their combustion products could be harmful. -

Printed Textile-Based Ag2o–Zn Battery for Body Conformal Wearable Sensors

sensors Communication Printed Textile-Based Ag2O–Zn Battery for Body Conformal Wearable Sensors Akash Kota * , Ashish Gogia, Amy T. Neidhard-Doll and Vamsy P. Chodavarapu Department of Electrical and Computer Engineering, University of Dayton, Dayton, OH 45469, USA; [email protected] (A.G.); [email protected] (A.T.N.-D.); [email protected] (V.P.C.) * Correspondence: [email protected] Abstract: Wearable electronics are playing an important role in the health care industry. Wearable sensors are either directly attached to the body surface or embedded into worn garments. Textile- based batteries can help towards development of body conformal wearable sensors. In this letter, we demonstrate a 2D planar textile-based primary Ag2O–Zn battery fabricated using the stencil printing method. A synthetic polyester woven fabric is used as the textile substrate and polyethylene oxide material is used as the separator. The demonstrated battery achieves an areal capacity of 0.6 mAh/cm2 with an active electrode area of 0.5 cm × 1 cm. Keywords: sensor power; textile battery; stencil printing; zinc-silver oxide; battery characteristics 1. Introduction The rapid development of wearable devices is fueled by the interest from the general population for real-time health and wellness monitoring [1,2]. Various human health and Citation: Kota, A.; Gogia, A.; wellness indicators including body temperature, peripheral capillary oxygen saturation Neidhard-Doll, A.T.; Chodavarapu, (SpO2) level, electrocardiogram, calories burned, exercise outcomes, and walking steps V.P. Printed Textile-Based Ag2O–Zn can be monitored non-invasively in real time by wearable devices. Wearable devices also Battery for Body Conformal Wearable play an important role in the development of smart bandages for wound healing applica- Sensors. -

Silver Oxide Battery �IL�ER O�IDE BATTERY

Primary Battery SRSilver Oxide Battery SILVER OXIDE BATTERY Safety Instructions Improper handling of the battery could lead to distortion, leakage*, overheating, or explosion, causing bodily injury or equipment trouble. Especially touch with liquid leaked out of battery could cause injury like a loss of eyesight. Please observe the following instructions to prevent S accidents. (* Leakage is defined as the unintentional escape of a liquid from a battery.) R Warnings — Handling Caution — Handling/Storage í Never swallow. í Never reverse the positive and negative terminals when Always keep the battery out of the reach of infants and young mounting. children to prevent it from being swallowed. If it is swallowed, Improper mounting of the battery may lead to short-circuiting, consult a physician immediately. charging or forced-discharging. This may cause distortion, leakage, overheating, or explosion. í Never allow liquid leaking from the battery to get in your body. The battery contains strong alkaline liquid, which is deleterious í Never short-circuit the battery while installing into equipment. material. If it does come in contact with your eyes, flush them Please be careful when installing the battery not to short-circuit it immediately with plenty of water and consult a physician, because with metal portions of the equipment. the alkaline liquid could cause becoming blind. Likewise, If the liquid gets in your mouth, rinse immediately with plenty of water and í Never weld the terminal or wire to the body of the battery consult a physician. The alkaline liquid could also cause the skin directly. irritation and/or chemical burns. If the liquid adheres to the skin or The heat of welding or soldering may cause distortion, leakage, clothes, immediately flush it with plenty of water. -

Vanillic Acid [I

A Publication of Reliable Methods for the Preparation of Organic Compounds Working with Hazardous Chemicals The procedures in Organic Syntheses are intended for use only by persons with proper training in experimental organic chemistry. All hazardous materials should be handled using the standard procedures for work with chemicals described in references such as "Prudent Practices in the Laboratory" (The National Academies Press, Washington, D.C., 2011; the full text can be accessed free of charge at http://www.nap.edu/catalog.php?record_id=12654). All chemical waste should be disposed of in accordance with local regulations. For general guidelines for the management of chemical waste, see Chapter 8 of Prudent Practices. In some articles in Organic Syntheses, chemical-specific hazards are highlighted in red “Caution Notes” within a procedure. It is important to recognize that the absence of a caution note does not imply that no significant hazards are associated with the chemicals involved in that procedure. Prior to performing a reaction, a thorough risk assessment should be carried out that includes a review of the potential hazards associated with each chemical and experimental operation on the scale that is planned for the procedure. Guidelines for carrying out a risk assessment and for analyzing the hazards associated with chemicals can be found in Chapter 4 of Prudent Practices. The procedures described in Organic Syntheses are provided as published and are conducted at one's own risk. Organic Syntheses, Inc., its Editors, and its Board of Directors do not warrant or guarantee the safety of individuals using these procedures and hereby disclaim any liability for any injuries or damages claimed to have resulted from or related in any way to the procedures herein. -

Chemical Names and CAS Numbers Final

Chemical Abstract Chemical Formula Chemical Name Service (CAS) Number C3H8O 1‐propanol C4H7BrO2 2‐bromobutyric acid 80‐58‐0 GeH3COOH 2‐germaacetic acid C4H10 2‐methylpropane 75‐28‐5 C3H8O 2‐propanol 67‐63‐0 C6H10O3 4‐acetylbutyric acid 448671 C4H7BrO2 4‐bromobutyric acid 2623‐87‐2 CH3CHO acetaldehyde CH3CONH2 acetamide C8H9NO2 acetaminophen 103‐90‐2 − C2H3O2 acetate ion − CH3COO acetate ion C2H4O2 acetic acid 64‐19‐7 CH3COOH acetic acid (CH3)2CO acetone CH3COCl acetyl chloride C2H2 acetylene 74‐86‐2 HCCH acetylene C9H8O4 acetylsalicylic acid 50‐78‐2 H2C(CH)CN acrylonitrile C3H7NO2 Ala C3H7NO2 alanine 56‐41‐7 NaAlSi3O3 albite AlSb aluminium antimonide 25152‐52‐7 AlAs aluminium arsenide 22831‐42‐1 AlBO2 aluminium borate 61279‐70‐7 AlBO aluminium boron oxide 12041‐48‐4 AlBr3 aluminium bromide 7727‐15‐3 AlBr3•6H2O aluminium bromide hexahydrate 2149397 AlCl4Cs aluminium caesium tetrachloride 17992‐03‐9 AlCl3 aluminium chloride (anhydrous) 7446‐70‐0 AlCl3•6H2O aluminium chloride hexahydrate 7784‐13‐6 AlClO aluminium chloride oxide 13596‐11‐7 AlB2 aluminium diboride 12041‐50‐8 AlF2 aluminium difluoride 13569‐23‐8 AlF2O aluminium difluoride oxide 38344‐66‐0 AlB12 aluminium dodecaboride 12041‐54‐2 Al2F6 aluminium fluoride 17949‐86‐9 AlF3 aluminium fluoride 7784‐18‐1 Al(CHO2)3 aluminium formate 7360‐53‐4 1 of 75 Chemical Abstract Chemical Formula Chemical Name Service (CAS) Number Al(OH)3 aluminium hydroxide 21645‐51‐2 Al2I6 aluminium iodide 18898‐35‐6 AlI3 aluminium iodide 7784‐23‐8 AlBr aluminium monobromide 22359‐97‐3 AlCl aluminium monochloride -

Synthesis of Vanadium Oxide Nanostructures for Functional Applications Haitao Fu

Synthesis of Vanadium Oxide Nanostructures for Functional Applications By Haitao Fu A thesis submitted in fulfillment of the requirements for the degree of Doctor of Philosophy School of Materials Science and Engineering Faculty of Science The University of New South Wales August 2013 ORIGINALITY STATEMENT ‘I hereby declare that this submission is my own work and to the best of my knowledge it contains no materials previously published or written by another person, or substantial proportions of material which have been accepted for the award of any other degree or diploma at UNSW or any other educational institution, except where due acknowledgement is made in the thesis. Any contribution made to the research by others, with whom I have worked at UNSW or elsewhere, is explicitly acknowledged in the thesis. I also declare that the intellectual content of this thesis is the product of my own work, except to the extent that assistance from others in the project's design and conception or in style, presentation and linguistic expression is acknowledged.’ Signed ……………………………………………...... Date …………………………………………….............. i List of Publications Peer-Reviewed Journals 1. Fu, H.; Yang, X.; Jiang, X.; Yu, A., Bimetallic Ag–Au Nanowires: Synthesis, Growth Mechanism, and Catalytic Properties. Langmuir 2013, 29, (23), 7134-7142. 2. Fu, H.; Yang, X.; Yu, A.; Jiang, X., Rapid synthesis and growth of silver nanowires induced by vanadium trioxide particles. Particuology 2013, 11, (4), 428-440. 3. Su, D.; Fu, H.; Jiang, X.; Wang, G., ZnO nanocrystals with a high percentage of exposed reactive facets for enhanced gas sensing performance. Sensors and Actuators B: Chemical, 2013, 186, (0), 286-292. -

Research Article Structural and Optical Properties of Chemical Bath Deposited Silver Oxide Thin Films: Role of Deposition Time

Hindawi Publishing Corporation Advances in Materials Science and Engineering Volume 2013, Article ID 450820, 8 pages http://dx.doi.org/10.1155/2013/450820 Research Article Structural and Optical Properties of Chemical Bath Deposited Silver Oxide Thin Films: Role of Deposition Time A. C. Nwanya,1 P. E. Ugwuoke,1 B. A. Ezekoye,2 R. U. Osuji,2 andF.I.Ezema2 1 National Centre for Energy Research and Development, University of Nigeria, Nsukka 41001, Nigeria 2 Department of Physics and Astronomy, University of Nigeria, Nsukka 41001, Nigeria Correspondence should be addressed to A. C. Nwanya; [email protected] Received 3 December 2012; Revised 21 March 2013; Accepted 22 March 2013 Academic Editor: Zhimin Liu Copyright © 2013 A. C. Nwanya et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. ∘ Silver oxide thin films were deposited on glass substrates at a temperature of50 C by chemical bath deposition technique under different deposition times using pure AgNO3 precursor and triethanolamine as the complexing agent. The chemical analysis based on EDX technique shows the presence of Ag and O at the appropriate energy levels. The morphological features obtained from SEM showed that the AgO structures varied as the deposition time changes. The X-ray diffraction showed the peaks ofAg2Oand AgO in the structure. The direct band gap and the refractive index increased as the deposition time increased and was in the range of 1.64–1.95 eV and 1.02–2.07, respectively. -

Impact of Structure and Defect Modification on Vanadium Oxide For

Impact of Structure and Defect Modification on Vanadium Oxide for Alkali-ion Battery Electrodes Evan Uchaker A dissertation submitted in partial fulfillment of the requirements for the degree of Doctor of Philosophy University of Washington 2015 Reading Committee: Professor Guozhong Cao, Chair Professor Lucien N. Brush Professor Jihui Yang Program Authorized to Offer Degree: Materials Science and Engineering c Copyright by Evan Uchaker, 2015. All rights reserved. University of Washington Abstract Impact of structure and defect modification on vanadium oxide for alkali-ion battery electrodes Evan Uchaker Chair of the Supervisory Committee: Professor Guozhong Cao Materials Science and Engineering The proliferation of portable electronics and electric vehicles paired with the updating of an antiquated grid system has driven the rapid progression of improved technologies related to energy distribution and storage. However, energy storage materials and devices have come to be viewed as a crux impeding advanced device development. Alkali-ion, namely lithium and sodium, batteries are a robust technology that has seen gains in performance based on materials chemistry over the past several decades. Despite years of intensive research ac- companied with significant progress, the cathode remains a limiting factor towards improved battery performance because of its low capacity and exasperated degradation over long term cycling; the cathode is also one of the most expensive material components of the overall cell. Thus, research concerning new cathode material development and the improvement of already well-established cathode materials should be a top priority. Within this context, vanadium oxide is an ideally suited model material showcasing how structural or chemical alterations can have tremendous impact on device performance.