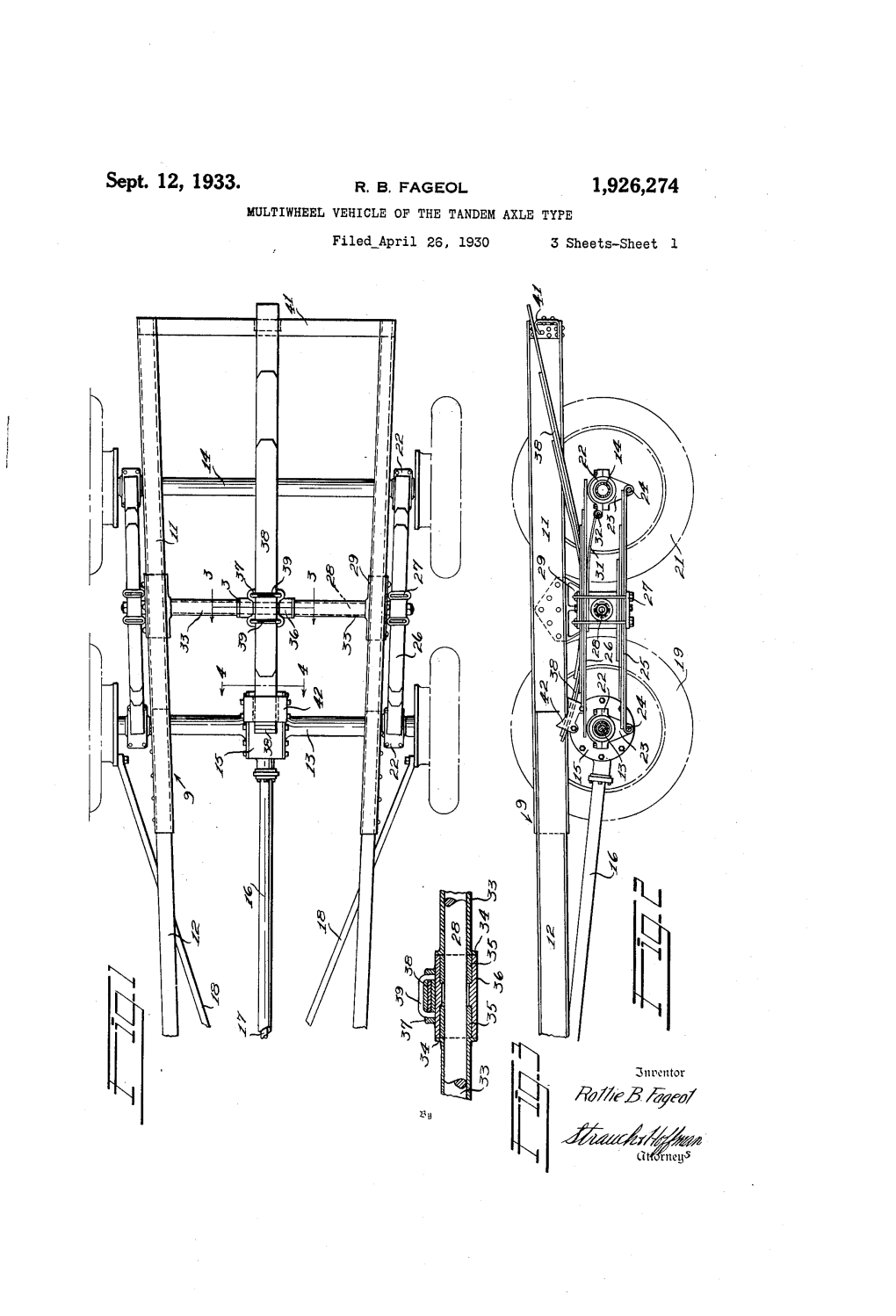

Sept 12, 1933- R. B. FAGEOL 1,926,274 MULTIWHEEL VEHICLE 0F the TANDEM AXLE TYPE Filed April 26, 1930 3 Sheets-Sheet L

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

US2716461.Pdf

Aug. 30, 1955 E. s. MaCPHERSON 2,716,461 RESILIENT MOUNTING OF‘ MOTOR VEHICLE DRIVE urms Filed Nov. 6, 1951 3 Sheets-Sheet 2 47 ' 48 I l . 69 ~ 6 ,. I’|| _ 64 _ 72 6.9 a ~ 55' 7/ Q 7 . -> 7/ 67 ' ~ 7 _ 9 7 '66 _ .5 . 62 65 7a .- - ._ > 76 _~_| _~ _ _ T.-_.——_ ' | | n 76 f \ | ,F/ 6. 7 E. s. MAcPHERSON - INVENTOR. A TTORNEVS Aug. 30, 1955 E, s. MaCPHERSON _ 2,716,461 RESILIENT MOUNTING OF MOTOR VEHICLE DRIVE UNITS Filed Nov. 6, 1951 3 Sheets-Sheet s 74 E..S.MACPHER$0N INVENTOR. $202K MI, A TTORNEVS‘ 2,716,461 United States Patent 0 cc Patented Aug. 30, 1955 1 2 Figure 2 is a side-elevational view of the construction shown in Figure l. ' ' 2,716,461 Figure 3 is an enlarged horizontal cross-sectional view RESILIENT MOUNTING or MOTOR VEHICLE through the differential unit, taken on the line 3-3 of 5 ' DRIVE UNITS Figure 2. Figure 4 is an enlarged vertical transverse. cross-sec Earle S. MacPherson, Huntington Woods, Mich., assignor tional view, partly in elevation, taken on the line 4+—-4 to Ford Motor Company, Dearborn, Mich., a corpo ration of Delaware of Figure l. ' Figure 5 is an enlarged horizontal cross-sectional view Application November 6, 1951, Serial N 0. 255,008 taken on the line 5—5 of Figure 2'. I Figure 6 is a diagrammatic sketch illustrating the power 2 Claims. (Cl. 180-64) train of the present invention and the'forces therein. -

Sau1301 Automotive Chassis

SCHOOL OF MECHANICAL ENGINEERING DEPARTMENT OF AUTOMOBILE ENGINEERING SAU1301 AUTOMOTIVE CHASSIS 1 UNIT I - INTRODUCTION 2 Unit-1 1. Introduction: ➢ The power developed inside the engine cylinder is ultimately transmitted to the driving wheels so that the motor vehicle can move on the road. This mechanism is called power transmission. ➢ It consists of clutch, gearbox, universal joint, propeller shaft, final drive, and axle shaft. General arrangement of power transmission system (or) front engine rear wheel drive: ➢ Fig (1) shows that layout of the front engine rear wheel drive. 3 ➢ Power is produced i n s i d e the engine cylinder transmitted to flywheel through crankshaft. ➢ Clutch is conduct with flywheel to engage and disengage drive from the engine to gearbox. ➢ Gearbox consists of s set of gears to change the speed. ➢ The power is transmitted from the gearbox to the propeller shaft through the universal joint and then to the differential through another universal joint. ➢ Finally, the power is transmitted to the rear wheels through the rear axles. Front engine front wheel drives: Fig (2): shows that layout of the front engine front wheel drive. ➢ In this drive the clutch, gear box, differential is arranged in a common housing. ➢ In this arrangement there is no need of separate long propeller shaft for transmitting power to the rear wheels. ➢ Because the engine power is transmitted only for front wheels alone. ➢ Rear axle is dead axles, when front wheels are rolling with power and rear wheels are freely move in the direction of front wheels. 4 Rear Engine rear wheel drive: Fig (3): shows that layout of the rear engine front wheel drive. -

Automobile Engineering

A Course Material on Automobile Engineering By Mr. T.Manokaran ME,MBA ASSISTANT PROFESSOR DEPARTMENT OF MECHANICAL ENGINEERING SASURIE COLLEGE OF ENGINEERING VIJAYAMANGALAM – 638 056 Author Page At first I like to submit my sincere thanks to GOD, PARENTS and FRIENDS who have helped and encouraged me to prepare this entire course material for the subject of Automobile Engineering. Automobile Engineering is a vast field encompassing different types of vehicles used for transportation of people and materials. It is very difficult to cover all the aspects of automobile engineering in single notes, because vehicles are being refined and improved day by day. However an attempt is made in this course material to give the maximum possible details of fundamentals of the automobile vehicles. It is always challenging to decide whether historical notes should come before or after the description and interpretation of the state of the art. Arguing for the second alternative is the fact that readers should already have understood the motivations that drive a design decision. We begin this chapter with basis of automobile, and through by the transmissions and steering systems, going on later to describe wheels, tires and braking & suspension systems. This emphasis is solely due to the larger impact that suspensions and steering systems have on vehicle architecture and its consequent evolution; steering systems will be described together with suspensions because these two systems are indissoluble from the point of view of designers. Knowing is not enough, We must apply. Willing is not enough, We must do. ALL the BEST T.Manokaran ME,MBA Assistant Professor Department of Mech.Engg. -

Suspension Systems and Components 2 of 42 Objectives

Suspension systems and components 2 of 42 Objectives • To provide good ride and handling performance – – vertical compliance providing chassis isolation – ensuring that the wheels follow the road profile – very little tire load fluctuation • To ensure that steering control is maintained during maneuvering – – wheels to be maintained in the proper position wrt road surface • To ensure that the vehicle responds favorably to control forces produced by the tires during – longitudinal braking – accelerating forces, – lateral cornering forces and – braking and accelerating torques – this requires the suspension geometry to be designed to resist squat, dive and roll of the vehicle body • To provide isolation from high frequency vibration from tire excitation – requires appropriate isolation in the suspension joints – Prevent transmission of ‘road noise’ to the vehicle body 3 of 42 Vehicle Axis system • Un-sprung mass • Right-hand orthogonal axis system fixed in a vehicle • x-axis is substantially horizontal, points forward, and is in the longitudinal plane of symmetry. • y-axis points to driver's right and • z-axis points downward. • Rotations: – A yaw rotation about z-axis. SAE vehicle axes – A pitch rotation about y-axis. – A roll rotation about x-axis Figure from Gillespie,1992 4 of 42 Tire Terminology - basic • Camber angle – angle between the wheel plane and the vertical – taken to be positive when the wheel leans outwards from the vehicle • Swivel pin (kingpin) inclination – angle between the swivel pin axis and the vertical • Swivel pin (kingpin) offset – distance between the centre of the tire contact patch and – intersection of the swivel pin axis and the ground plane Figure from Smith,2002 5 of 42 Tire Terminology - basic • Castor angle – inclination of the swivel pin axis projected into the fore–aft plane through the wheel centre – positive in the direction shown. -

2006 Dodge Ram 2500/3500 Box-Off

DODGE RAM 2500/3500 BOX-OFF 2006SPECIFICATIONS All dimensions are in inches (millimeters) unless otherwise noted. All dimensions measured at curb weight with standard tires and wheels. GENERAL INFORMATION Body Styles _______________________________________________________Regular cab and Quad Cab™ Assembly Plants __________________________________________ Saltillo, Mexico and St. Louis, Missouri EPA Vehicle Class ___________________________________________________________ Standard Pickup ENGINE: 5.7-LITER HEMI® MAGNUM V-8 Availability _________________________________________________________________________ Std.(a) Type and Description _____________________________________ Eight-cylinder, 90° V-type, liquid-cooled Displacement _______________________________________________________ 343 cu. in. (5654 cu. cm) Bore x Stroke ________________________________________________________3.92 x 3.58 (99.5 x 90.9) Valve System _________ Pushrod-operated overhead valves, 16 valves, hydraulic lifters with roller followers Fuel Injection _______________________________________ Sequential, multi-port, electronic, returnless Construction _________________________Deep-skirt cast-iron block with cross-bolted main bearing caps, aluminum alloy heads with hemispherical combustion chambers Compression Ratio ____________________________________________________________________ 9.6:1 Power (SAE net) _______________________ 345 bhp (257 kW) @ 5,400 rpm, (58.4 bhp/L), 2500 series(b) 330 bhp (246 kW) @ 4,800 rpm, (55.9 bhp/L), 3500 series Torque (SAE net) __________________________ -

Unit-Iii Transmission System

UNIT-III TRANSMISSION SYSTEM TRANSMISSION SYSTEM Chief function of the device is to receive power at one torque and angular velocity and to deliver it at another torque and the corresponding angular velocity. LAYOUT OF AUTOMOBILE POWER TRANSMISSION SYSTEM REQUIREMENTS OF TRANSMISSION SYSTEM 1. To provide for disconnecting the engine from the driving wheels. 2. When the engine is running, to enable the connection to the driving wheels to be made smoothly and without shock. 3. To enable the leverage between the engine and driving wheels to be varied. 4. It must reduce the drive-line speed from that of the engine to that of the driving wheels in a ratio of somewhere between about 3:1 and 10:1 or more, according to the relative size of engine and weight of vehicle. 5. Turn the drive, if necessary, through 90° or perhaps otherwise re-align it. 6. Enable the driving wheels to rotate at different speeds. 7. Provide for relative movement between the engine and driving wheels. CLUTCH The clutch is housed between the engine and transmission where it provides a mechanical coupling between the engine's flywheel and the transmission input shaft. The clutch is operated by a linkage that extends from the passenger compartment to the clutch housing. The purpose of the clutch is to disconnect the engine from the driven wheels when a vehicle is changing gears or being started from rest. Disengaging the clutch separates the flywheel, the clutch plate and the pressure plate from each other. The flywheel is bolted to the end of the crankshaft and rotates with it. -

Shake Down Driveline Vibration

Shake Down Driveline Vibration This is the front driveshaft and differential of a 2007 S550 w221 S-Class. This car had a vibration that the owner kept ignoring until the front universal joint finally gave out altogether causing extensive drivetrain damage. 4 Mercedes-Benz StarTuned Shake Down Driveline Vibration Next to squeaks and rattles, vibration can be one While tracking down of the most difficult vehicle complaints to diagnose. the source of bad vibes Driveline vibration that only presents itself at a certain speed or under a given load is a formidable may not make you a foe because of the inability to reproduce the condition in a normal shop setting. There are many lot of money, it sure factors that can upset driveline balance and even can make you a hero the most seasoned technician can struggle with tracking down this type of problem. Often time- to your customers. consuming and not a significant source of revenue, driveline vibration diagnosis can be made less stressful by exploring the subject until you reach a full understanding of the dynamics involved so that your next encounter with this situation will work out smoothly. Pleasing the customer is the main benefit you’ll get from this, and that’s paramount to your reputation. Straight talk When dealing with driveline components, things are not always straightforward; getting and keeping parts to work in harmony is a balancing act. Luckily for us independent service providers, Mercedes-Benz has done an exceptional job engineering and building a remarkable, mostly problem-free driveline. That said, the driveline is not maintenance-free -- there are components that need to be inspected for damage during routine maintenance and replaced when they have reached the end of their service life. -

Sept. 12, 1933. R

Sept. 12, 1933. R. E3, FAGEOL 1,926,274 MULTIWHEEL VEHICLE OF THE TANDEM AXLE TYPE Filed April 26 1930 35 Sheets-Sheet lil :===C) ?zzzzZzZZZZZZZZZZZZZZZZºzzarararazzzzzzzz? t Sept. 12, 1933. R. B. FAGEOL 1,926,274 MULTIWHEEL VEHICLE OF THE TANDEM AXLE TYPE Filed April 26, 1930 3. Sheets-Sheet 2 LLSLLL0SAAAAALLLAASLLLLSLLLLLL ? Stettor A22A /l???/ rtcly Sept. 12, 1933. R. B. FAGEOL 1,926,274 MULTIWHEEL VEHICLE OF THE TANDEM AXLE TYPE Filed April 26, 1930 3. Sheets-Sheet 3 ?): Stpettor criteus Patented Sept. 12, 1933 1926,274 UNITED STATES PATENT OFFICE 1926,274 MIUL IWH IEEL VEHIC LE OF IHE ANDEM AX,E TYPE Rollie B. Fageol, Los Angeles, Calif., assignor, by mesne assignments, to Automotive Engineer ing Corporation, a corporation of Delaware Application April 26, 1930. Serial No. 447,542 11 Claims. (Cl. 180——22) This invention relates to suspension arrange multiwheel spring suspension embodying rela ments for multiwheel Venicles. The invention tively light springs in combination with an addi is particularly concerned with tandem axle com tional set of springs which assists said light binations wherein one of the axles is dead and Springs Only to support relatively heavy loads or S the other is a drive axle. to resist relatively great road shocks. 60 When multiwheel vehicles, of the type having Another object lies in the provision of means a single drive axle, are driven in substantially un directly associated with a drive axle for increas loaded condition over uneven wet roads, or over ing the traction of the driven wheels under cer soft or slippery ground, it often becomes difficult tain conditions of operation of the vehicle. -

1151Au214 Automotive Chassis 3 0 2 4

L T P C 1151AU214 AUTOMOTIVE CHASSIS 3 0 2 4 1. Preamble This course provides an introduction to the various types of chassis, frames, front axle, universal joint, propeller shaft, torque tube drive, final drives, suspension, brakes and steering. 2. Pre-requisite 1151AU101 Engineering Mechanics 3. Links to other courses Automotive Transmission Engine Design and Development 4. Course Educational Objectives Students undergoing this course are expected to To understand different types of chassis. To gain knowledge about different types of steering geometry and types of front axle. To educate the students regarding the ergonomics of an automobile. Educate about modern drive line and braking systems. 5. Course Outcomes Upon the successful completion of the course, learners will be able to Level of learning CO Course Outcomes domain (Based on Nos. revised Bloom’s) List out the types of chassis layouts, frames and materials used for C01 heavy duty, light duty, three wheeler and two-wheeler construction and K3, S2 examine their specification with standards. Illustrate and verify the concepts, construction, material related to front C02 axle and steering system for a typical heavy duty, light duty, three and K2, S2 two wheeled vehicles. List and verify the concepts, construction and material used for clutch, C03 gearbox, rear axle, differential, multiaxle and propeller shaft by K2, S2 inspecting the heavy and light duty vehicles. Consolidate the concepts, types, construction and operation of different C04 suspension systems for heavy duty, light duty, three wheeler and two- K2, S2 wheeled vehicles. Classify and inspect the different braking system used in heavy duty, C05 light duty, three wheeler and two-wheeled vehicles on the basis of K3, S2 theory, construction and application. -

Rear Axle Operation the Differential

Rear Axle Operation Below is an overview of rear axle operation The Differential The differential is the thing that works both drive axles at the same time, but lets them rotate at different speeds so that the car can make turns. When a car makes a turn, the outer wheel has to turn faster than the inner wheel, due to the difference in the length of the paths they take. The differential is located between the two wheels, and is attached to each wheel by a half-shaft rotated through a bevel gear. Four- wheel drive cars have a separate differential for each pair of wheels. A grooved, or splined, axle side gear is positioned on the splined end of each axle. The side gears are driven by "spider" gears, which are little gears mounted on a shaft attached to the differential case. As it is supported by the differential case, the side gear can turn inside the case. The differential case can be turned, revolving around the axle gears. The differential pinion (a pinion is a small gear that either drives a larger gear or is driven by one) shaft turns the ring gear, which is fastened to the differential case. The propeller shaft (drive shaft) connects the transmission output shaft to the differential pinion shaft. The turning differential case is mounted on two large bearing holders. These bearings are called carrier bearings. The propeller shaft rotates the ring gear pinion, and the pinion turns the ring gear. The ring gear then turns the differential case and pinion shaft, but the axle side gears will not turn. -

Year Mech. Motor Vehicle Trade Theory

Multiple Choice Practice Questions/Answer for ONLINE/OMR AITT-2020 2nd Year Mech. Motor Vehicle Trade Theory HEAVY VEHICLES 1. Generally heavy vehicles are considered as above gross vehicle weight rating (GVWR) capacity of (A)1500 Kg, (B) 3000 Kg, (C)- 4500 Kg, (D)-6000 Kg 2. Which of these falls under Heavy passenger vehicles category based on its capacity? (A) Trucks, (B) Buses, (C) Cars, (D) Motorcycles. 3. Which of these falls under Heavy commercial vehicles category based on its capacity? (A) Trucks, (B) Buses, (C) Cars, (D) Motorcycles. 4. A delivery van falls under the category of which type of vehicle. (A)Heavy passenger vehicle (B) light passenger vehicle (C) heavy goods vehicle (D) light goods vehicle 5. A truck also often called as A) Trailer B) Lorry C)Van D) Carriage 6. A compartment from which the driver of a heavy earthmoving machinery operates is called A) Cage B) Cab C) Cart D) Core 7. Modern truck are mostly powered by ………Engines A) Petrol B) CNG C) Diesel D) LPG 8. A truck used as liquefied petroleum gas container is termed as A) Rigid Truck B) Haulage Truck C) Trailer Truck D) Tipper 9. The heavy vehicle factory (HVF) is located at Avadi in A) Mumbai B) Kolkata C) Hyderabad D) Chennai 10. Vehicle without body is called ……… A) Wheel, B) Axle C) Frame D) Chassis 11. Which of the following is called power plant of a vehicle? A) Axle B) Chassis C) Wheel D) Engine 12. Which of the following Diesel engines are used in heavy motor vehicle? A) TC Engines B) TCAC Engines C) CRDI Engines D) All of these 13. -

Digital Notes

DIGITAL NOTES Automobile Engineering R15A0333 B.Tech IV Year I Semester DEPARTMENT OF MECHANICAL ENGINEERING MALLA REDDY COLLEGE OF ENGINEERING & TECHNOLOGY (An Autonomous Institution – UGC, Govt.of India) Recognizes under 2(f) and 12(B) of UGC ACT 1956 (Affiliated to JNTUH, Hyderabad, Approved by AICTE –Accredited by NBA & NAAC-“A” Grade-ISO 9001:2015 Certified) Department Of Mechanical Engineering,MRCET. MALLA REDDY COLLEGE OF ENGINEERING & TECHNOLOGY COURSE OBJECTIVES: The objective of this subject is to provide knowledge about various systems involved in automobile engine. Able to learn about different components of IC Engines. Different automobile engine systems line diagrams. UNIT – I Introduction : Components of four wheeler automobile – chassis and body – power unit –power transmission – rear wheel drive, front wheel drive, 4 wheel drive – types of automobile engines, engine construction, turbo charging and super charging – engine lubrication, splash and pressure lubrication systems, oil filters, oil pumps – crank case ventilation – engine service, reboring, decarbonisation, Nitriding of crank shaft. Fuel System: S.I. Engine: Fuel supply systems, Mechanical and electrical fuel pump – filters – carburettor – types – air filters – petrol injection. C.I. Engines: Requirements of diesel injection systems, types of injection systems, fuel pump, nozzle, spray formation, injection timing, testing of fuel pumps. UNIT – II Cooling System : Cooling Requirements, Air Cooling, Liquid Cooling, Thermo, water and Forced Circulation System – Radiators – Types – Cooling Fan - water pump, thermostat, evaporating cooling – pressure sealed cooling – antifreeze solutions. Ignition System: Function of an ignition system, battery ignition system, constructional features of storage, battery, auto transformer, contact breaker points, condenser and spark plug – Magneto coil ignition system, electronic ignition system using contact breaker, electronic ignition using contact triggers – spark advance and retard mechanism.