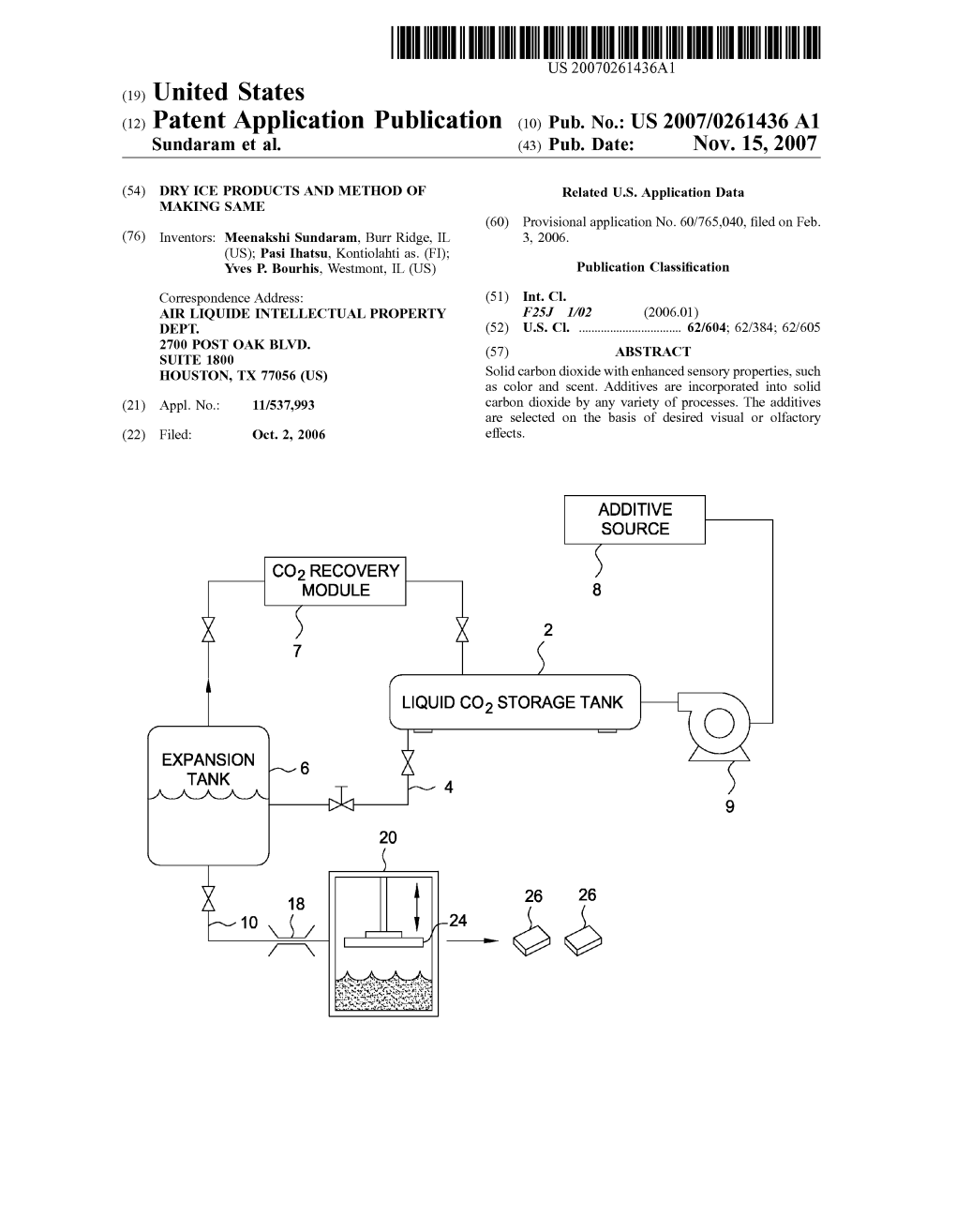

(12) Patent Application Publication (10) Pub. No.: US 2007/0261436A1 Sundaram Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Expanding the Modular Ester Fermentative Pathways for Combinatorial Biosynthesis of Esters from Volatile Organic Acids

ARTICLE Expanding the Modular Ester Fermentative Pathways for Combinatorial Biosynthesis of Esters From Volatile Organic Acids Donovan S. Layton,1,2 Cong T. Trinh1,2,3 1 Department of Chemical and Biomolecular Engineering, University of Tennessee, Knoxville, Tennessee 2 BioEnergy Science Center (BESC), Oak Ridge National Laboratory, Oak Ridge, Tennessee 3 Bredesen Center for Interdisciplinary Research and Graduate Education, University of Tennessee, Knoxville, Tennessee; telephone: þ865-974-8121; fax: 865-974-7076; e-mail: [email protected] Biotechnol. Bioeng. 2016;113: 1764–1776. ABSTRACT: Volatile organic acids are byproducts of fermentative ß 2016 Wiley Periodicals, Inc. metabolism, for example, anaerobic digestion of lignocellulosic KEYWORDS: modular chassis cell; carboxylate; ester; acyl acetate; biomass or organic wastes, and are often times undesired inhibiting acyl acylate; ester fermentative pathway cell growth and reducing directed formation of the desired products. Here, we devised a general framework for upgrading these volatile organic acids to high-value esters that can be used as flavors, fragrances, solvents, and biofuels. This framework employs the acid-to-ester modules, consisting of an AAT (alcohol Introduction acyltransferase) plus ACT (acyl CoA transferase) submodule and an alcohol submodule, for co-fermentation of sugars and organic Harnessing renewable or waste feedstocks (e.g., switchgrass, corn acids to acyl CoAs and alcohols to form a combinatorial library of stover, agricultural residue, or municipal solid waste) -

Biocatalytic Synthesis of Flavor Ester “Pentyl Valerate” Using Candida Rugosa Lipase Immobilized in Microemulsion Based Organogels: Effect of Parameters and Reusability

Hindawi Publishing Corporation BioMed Research International Volume 2014, Article ID 353845, 14 pages http://dx.doi.org/10.1155/2014/353845 Research Article Biocatalytic Synthesis of Flavor Ester ‘‘Pentyl Valerate’’ Using Candida rugosa Lipase Immobilized in Microemulsion Based Organogels: Effect of Parameters and Reusability Tripti Raghavendra,1 Nilam Panchal,1 Jyoti Divecha,2 Amita Shah,1 and Datta Madamwar1 1 BRD School of Biosciences, Sardar Patel Maidan, Sardar Patel University, Satellite Campus, Vadtal Road, P.O. Box 39, Vallabh Vidyanagar, Gujarat 388120, India 2 Department of Statistics, Sardar Patel University, Vallabh Vidyanagar, Gujarat 388120, India Correspondence should be addressed to Datta Madamwar; datta [email protected] Received 28 February 2014; Revised 5 May 2014; Accepted 19 May 2014; Published 1 July 2014 Academic Editor: Yunjun Yan Copyright © 2014 Tripti Raghavendra et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. Pentyl valerate was synthesized biocatalytically using Candida rugosa lipase (CRL) immobilized in microemulsion based organogels ∘ (MBGs). The optimum conditions were found to be pH 7.0, temperature of 37 C, ratio of concentration of water to surfactant (Wo) of 60, and the surfactant sodium bis-2-(ethylhexyl)sulfosuccinate (AOT) for MBG preparation. Although kinetic studies revealed that the enzyme in free form had high affinity towards substrates ( = 23.2 mM for pentanol and 76.92 mM for valeric acid) whereas, after immobilization, the values increased considerably (74.07 mM for pentanol and 83.3 mM for valeric acid) resulting in a slower reaction rate, the maximum conversion was much higher in case of immobilized enzyme (∼99%) as compared to free enzyme (∼19%). -

Articles Is an Important Step for the For- Mation and Transformation of Atmospheric Particles

Atmos. Chem. Phys., 15, 5585–5598, 2015 www.atmos-chem-phys.net/15/5585/2015/ doi:10.5194/acp-15-5585-2015 © Author(s) 2015. CC Attribution 3.0 License. Compilation and evaluation of gas phase diffusion coefficients of reactive trace gases in the atmosphere: Volume 2. Diffusivities of organic compounds, pressure-normalised mean free paths, and average Knudsen numbers for gas uptake calculations M. J. Tang1, M. Shiraiwa2, U. Pöschl2, R. A. Cox1, and M. Kalberer1 1Department of Chemistry, University of Cambridge, Cambridge CB2 1EW, UK 2Multiphase Chemistry Department, Max Planck Institute for Chemistry, 55128, Mainz, Germany Correspondence to: M. J. Tang ([email protected]) and M. Kalberer ([email protected]) Received: 26 January 2015 – Published in Atmos. Chem. Phys. Discuss.: 25 February 2015 Revised: 24 April 2015 – Accepted: 3 May 2015 – Published: 21 May 2015 Abstract. Diffusion of organic vapours to the surface of 1 Introduction aerosol or cloud particles is an important step for the for- mation and transformation of atmospheric particles. So far, Organic aerosols are ubiquitous in the atmosphere and can however, a database of gas phase diffusion coefficients for or- account for a dominant fraction of submicron aerosol par- ganic compounds of atmospheric interest has not been avail- ticles (Jimenez et al., 2009). Organic aerosols affect climate able. In this work we have compiled and evaluated gas phase by scattering and adsorbing solar and terrestrial radiation and diffusivities (pressure-independent diffusion coefficients) of serving as cloud condensation nuclei and ice nuclei (Kanaki- organic compounds reported by previous experimental stud- dou et al., 2005; Hallquist et al., 2009). -

Microbial Synthesis of a Branched-Chain Ester Platform from Organic Waste Carboxylates

Metabolic Engineering Communications 3 (2016) 245–251 Contents lists available at ScienceDirect Metabolic Engineering Communications journal homepage: www.elsevier.com/locate/mec Microbial synthesis of a branched-chain ester platform from organic waste carboxylates Donovan S. Layton a,c, Cong T. Trinh a,b,c,n a Department of Chemical and Biomolecular Engineering, The University of Tennessee, Knoxville, The United States of America b Bredesen Center for Interdisciplinary Research and Graduate Education, The University of Tennessee, Knoxville, The United States of America c Bioenergy Science Center (BESC), Oak Ridge National Laboratory, Oak Ridge, The United States of America article info abstract Article history: Processing of lignocellulosic biomass or organic wastes produces a plethora of chemicals such as short, Received 6 June 2016 linear carboxylic acids, known as carboxylates, derived from anaerobic digestion. While these carbox- Received in revised form ylates have low values and are inhibitory to microbes during fermentation, they can be biologically 15 July 2016 upgraded to high-value products. In this study, we expanded our general framework for biological up- Accepted 5 August 2016 grading of carboxylates to branched-chain esters by using three highly active alcohol acyltransferases Available online 6 August 2016 (AATs) for alcohol and acyl CoA condensation and modulating the alcohol moiety from ethanol to iso- Keywords: butanol in the modular chassis cell. With this framework, we demonstrated the production of an ester Carboxylate platform library comprised of 16 out of all 18 potential esters, including acetate, propionate, butanoate, pen- Ester platform tanoate, and hexanoate esters, from the 5 linear, saturated C -C carboxylic acids. -

ENGLISH POSITIVE LIST MATERIAL (ENG).Pdf

Attachment of Decree Number: SK15/Dir/LPPOM MUI/XI/19 HALAL POSITIVE LIST OF MATERIALS Halal Positive List of Materials consists of non critical materials, in terms of their halalness status, commonly used in prosessing industries. This material list was made based on the assessment of LPPOM MUI refer to the literature, abundance in nature, and consideration of commercially production scales. Companies that using materials listed in Halal Positive List of Materials will get advantages as follows: 1. In selection process of new materials, materials listed in Halal Positive List of Materials already get material approval from LPPOM MUI automatically prior to use. 2. In process of incoming material checking, materials listed in Halal Positive List of Materials does not require the suitability checking of the material name, manufacture's name and country of origin. 3. In product registration process, materials listed in Halal Positive List of Materials does not require supporting document. If the materials use trade name which is different with material name, the material specification document is still required. During the audit process, the auditor may check the supporting documents of material when necessary. Halal Positive List of Materials is given in the following table: Prohibited for Foods (BPOM CAS Chemical Name Regulation) Foods Cosmetics 673-84-7 2,6-Dimethyl-2,4,6-octatriene 91-57-6 2-Methylnaphthalene 1576-78-9 [(E)-hept-3-enyl] acetate 72214-23-4 7-acetoxy-3,7-dimethyl-octa-1,3- diene Page 3 of 192 2216-45-7 (4-methylphenyl)methyl -

X International Conference “Mechanisms of Catalytic Reactions”

Boreskov Institute of Catalysis SB RAS, Novosibirsk, Russia Zelinsky Institute of Organic Chemistry RAS, Moscow, Russia Lomonosov Moscow State University, Moscow, Russia 2016 X International Conference “Mechanisms of Catalytic Reactions” Svetlogorsk, Kaliningrad Region, Russia October 2 - 6, 2016 ABSTRACTS Novosibirsk-2016 Boreskov Institute of Catalysis SB RAS, Novosibirsk, Russia Zelinsky Institute of Organic Chemistry RAS, Moscow, Russia Lomonosov Moscow State University, Moscow, Russia X International Conference “Mechanisms of Catalytic Reactions” Svetlogorsk, Kaliningrad Region, Russia October 2 - 6, 2016 ABSTRACTS Novosibirsk-2016 УДК 544.47+66.09 ББК Г544 M45 Mechanisms of Catalytic Reactions. X International Conference (MCR-X). (October 2 - 6, 2016, Svetlogorsk, Kaliningrad Region, Russia) [Electronic resourse]: Book of abstracts / Boreskov Institute of Catalysis SB RAS ed.: prof. V.I. Bukhtiyarov, - Novosibirsk: BIC, 2016. p.328, – 1 electronic optical disc (CD-R). ISBN 978-5-906376-15-2 В надзаг.: Boreskov Institute of Catalysis SB RAS, Novosibirsk, Russia Zelinsky Institute of Organic Chemistry RAS, Moscow, Russia Lomonosov Moscow State University, Moscow, Russia Topics of book: – First-principles approach, theory and simulation in catalysis; – Advanced methods for studies of mechanisms of catalyzed reactions; – In-situ and operando studies of model and real catalysts; – Kinetics and reaction intermediates of catalyzed processes; – From mechanistic studies to design of advanced catalyst systems. The Conference is accompanied -

Nicolet Vapor Phase

Nicolet Vapor Phase Library Listing – 8,654 spectra This library is one the most comprehensive collections of vapor phase FT-IR spectra. It is an invaluable tool for scientist involved in investigations on gas phase materials. The Nicolet Vapor Phase Library contains 8654 FT-IR spectra of compounds measured in gas phase. Most spectra were acquired by the Sigma-Aldrich Co. using product samples. Additional spectra were collected by Hannover University, University of Wurzburg and Thermo Fisher Scientific applications scientists. Spectra were collected using sampling techniques including heated or room temperature gas cell or a heated light-pipe connected to the outlet of a gas chromatograph. Nicolet Vapor Phase Index Compound Name Index Compound Name 8402 ((1- 5457 (-)-8-Phenylmenthol; (-)-(1R,2S,5R)-5- Ethoxycyclopropyl)oxy)trimethylsilane Methyl-2-(2-phenyl-2-propyl)cyc 4408 (+)-1,3-Diphenylbutane 1095 (-)-Carveol, mixture of isomers; p- 4861 (+)-1-Bromo-2,4-diphenylbutane Mentha-6,8-dien-2-ol 2406 (+)-3-(Heptafluorobutyryl)camphor 3628 (-)-Diisopropyl D-tartrate 2405 (+)-3-(Trifluoroacetyl)camphor 1427 (-)-Limonene oxide, cis + trans; (-)-1,2- 281 (+)-3R-Isolimonene, trans-; (1R,4R)- Epoxy-4-isopropenyl-1-methyl (+)-p-Mentha-2,8-diene 1084 (-)-Menthol; [1R-(1a,2b,5a)]-(-)-2- 289 (+)-Camphene; 2,2-Dimethyl-3- Isopropyl-5-methylcyclohexanol methylenebicyclo[2.2.1]heptane 2750 (-)-Menthoxyacetic acid 3627 (+)-Diisopropyl L-tartrate 1096 (-)-Myrtanol, cis-; (1S,2R)-6,6- 2398 (+)-Fenchone; (+)-1,3,3- Dimethylbicyclo[3.1.1]heptane-2-metha -

Calculation of the Isobaric Heat Capacities of the Liquid and Solid Phase of Organic Compounds at and Around 298.15 K Based on Their “True” Molecular Volume

molecules Article Calculation of the Isobaric Heat Capacities of the Liquid and Solid Phase of Organic Compounds at and around 298.15 K Based on Their “True” Molecular Volume Rudolf Naef Department of Chemistry, University of Basel, 4003 Basel, Switzerland; [email protected]; Tel.: +41-61-9119273 Received: 28 March 2019; Accepted: 20 April 2019; Published: 24 April 2019 Abstract: A universally applicable method for the prediction of the isobaric heat capacities of the liquid and solid phase of molecules at 298.15 K is presented, derived from their “true” volume. The molecules’ “true” volume in A3 is calculated on the basis of their geometry-optimized structure and the Van-der-Waals radii of their constituting atoms by means of a fast numerical algorithm. Good linear correlations of the “true” volume of a large number of compounds encompassing all classes and sizes with their experimental liquid and solid heat capacities over a large range have been found, although noticeably distorted by intermolecular hydrogen-bond effects. To account for these effects, the total amount of 1303 compounds with known experimental liquid heat capacities has been subdivided into three subsets consisting of 1102 hydroxy-group-free compounds, 164 monoalcohols/monoacids, and 36 polyalcohols/polyacids. The standard deviations for Cp(liq,298) were 20.7 J/mol/K for the OH-free compunds, 22.91 J/mol/K for the monoalcohols/monoacids and 16.03 J/mol/K for the polyols/polyacids. Analogously, 797 compounds with known solid heat capacities have been separated into a subset of 555 OH-free compounds, 123 monoalcohols/monoacids and 119 polyols/polyacids. -

(12) United States Patent (10) Patent No.: US 9,301.910 B2 Yontz (45) Date of Patent: Apr

US0093 0191 OB2 (12) United States Patent (10) Patent No.: US 9,301.910 B2 Yontz (45) Date of Patent: Apr. 5, 2016 (54) FRAGRANT FORMULATIONS, METHODS OF C09D 7/1233 (2013.01); A61 K 2800/49 MANUFACTURE THEREOF AND ARTICLES (2013.01); C08K 5/156 (2013.01) COMPRISING THE SAME (58) Field of Classification Search None (75) Inventor: Dorie J. Yontz, Bloomington, MN (US) See application file for complete search history. (73) Assignee: GFBiochemicals Limited (MT) (56) References Cited (*) Notice: Subject to any disclaimer, the term of this U.S. PATENT DOCUMENTS patent is extended or adjusted under 35 U.S.C. 154(b) by 0 days. 1934,309 A 1 1/1933 Hoover 2,008,720 A 7/1935 Lawson (21) Appl. No.: 13/104,706 2,260,261 A 10/1941 Morey et al. 2,556,135 A 6, 1951 Croxall et al. 1-1. 2,654,723 A 10, 1953 Greene (22) Filed: May 10, 2011 2.985,536 A 5, 1961 Stein et al. O O 3,201.420 A 8, 1965 Fuzesi et al. (65) Prior Publication Data 3,658,789 A 4, 1972 Fried 3,855,248 A 12, 1974 Lannert et al. US 2011/0274.643 A1 Nov. 10, 2011 4,460,767 A 7/1984 Matsumura et al. 4,737,426 A 4, 1988 Roth Related U.S. Application Data 4,792,411 A 12/1988 Walsh 4,806,448 A 2/1989 Roth (60) Provisional application No. 61/332,982, filed on May 5,705,087 A 1/1998 Mushrush et al. -

GC-MS) Techniques and Selected Ion Flow Tube Mass Spectrometry (SIFT-MS) Assessment of Volatiles Produced from Nitric Oxide Producing Smart Dressings

The detection of trace volatiles from complex matrices using gas chromatography mass spectrometry (GC-MS) techniques and selected ion flow tube mass spectrometry (SIFT-MS) assessment of volatiles produced from nitric oxide producing smart dressings Oliver John Gould A thesis submitted in partial fulfilment of the requirements of the University of the West of England, Bristol for the degree of Doctor of Philosophy Faculty of Health and Applied Sciences, University of the West of England, Bristol 2019 Copyright declaration This copy has been supplied on the understanding that it is copyright material and that no quotation from the thesis may be published without proper acknowledgment. i Acknowledgements I would like to thank my supervisors Professor Norman Ratcliffe, and Associate Professor Ben de Lacy Costello for all their help, guidance, and support over the course of this work, and for their co-authorship on the published versions of chapters 2 and 3. I would also like to thank Dr Hugh Munro and Edixomed Ltd for financial support and scientific guidance with chapter 4. I would like to thank my co-authors on the publication of chapter 2 Tom Wieczorek, Professor Raj Persad. Also thank you to my co-authors on the publication of chapter 3, Amy Smart, Dr Angus Macmaster, and Dr Karen Ransley; and express my appreciation to Givaudan for funding the work undertaken in chapter 3. Thank you also to my colleagues and fellow post graduate research students at the University of the West of England for always being on hand for discussion and generation of ideas. A special mention to Dr Peter Jones who has been mentoring me on mass spectrometry for a number of years. -

Rhenium Trioxide, Rhenium Heptoxide and Rehnium Trichloride As Hydrogenation Catalysts

Brigham Young University BYU ScholarsArchive Theses and Dissertations 1958-07-21 Rhenium trioxide, rhenium heptoxide and rehnium trichloride as hydrogenation catalysts William J. Bartley Brigham Young University - Provo Follow this and additional works at: https://scholarsarchive.byu.edu/etd BYU ScholarsArchive Citation Bartley, William J., "Rhenium trioxide, rhenium heptoxide and rehnium trichloride as hydrogenation catalysts" (1958). Theses and Dissertations. 8161. https://scholarsarchive.byu.edu/etd/8161 This Thesis is brought to you for free and open access by BYU ScholarsArchive. It has been accepted for inclusion in Theses and Dissertations by an authorized administrator of BYU ScholarsArchive. For more information, please contact [email protected], [email protected]. (QJ> I ,_t;z .1537 {1~ c~z- RHENIUMTRIOXIDE, RHENIUMHEPTOXIDE AND RHENIUMTRICHLORIDE AS HYDROGENATIONCATALYSTS A Thesis Submitted to the Department of Chemistry Brigham Young University Provo, Utah In Partial Fulfillment Of the Requirements for the Degree of Master of Science by William J. Bartley August, 1958 This thesis by William J. Bartley is accepted in its present form by the Department of Chemistry of the Brigham Young University as satisfying the thesis requirements for the degree of Master of Science. ii ACKNOWLEDGEMENTAND DEDICATION 'fhe author wishes to express his sincere appreciation and thanks to all who have assisted in any way toward the com- pletion of this work. Special thanks is extended to Dr. H. Smith Broadbent, who gave freely of his kind assistance and excellent advice. To my parents, Mr. and Mrs. Wm. Bartley, goes my grati- tude and appreciation for their undeviating support. My love and devotion go to my wonderful wife, Earlene, for her patience and encouragement. -

합성향료 Synthetic Flavoring Substances 정 <식약처 고시 제2021

<식약처 고시 제2021-00호, 2021.6.00.> [시행일 2022.7.1.] ※ 합성향료를 삭제하고, 천연향료와 통합하여 향료로 신설 합성향료 Synthetic Flavoring Substances 정 의 식품에 착향의 목적으로 사용할 수 있는 합성향료는 아래와 같다. 다만, 이 품목에는 아래의 향료를 화학적 변화를 주지 않는 방법으로 2종 이상 단순 혼합한 것이 포함되며, 품질보존, 희석, 용해, 분산 등을 위하여 물, 주정, 프로필렌글리콜, 트리아세틴, 글리세린, 덱스트린, 전분, 변성전분, 아라비아검, 이산화규소를 첨가할 수 있다. 순 번 일 반 명 이 명 Ethylidine diethyl acetal; acetaldehyde diethyl acetal; diethyl acetal; A001 Acetal 1,1-Diethoxyethane; Ethylidine diethyl ether; 1,1-Diethoxyethane A002 Acetaldehyde Acetic aldehyde; Ethanal; Ethyl aldehyde Acetaldehyde butyl phenethyl 2-Butoxy-2-phenylethoxy-ethane; A003 acetal 1-Butoxy-1-(2-phenylethoxy)ethane Acetaldehyde diisoamyl Butane, 1,1'-[ethylidenebis(oxy)]bis[3-methyl]-, A004 acetal 3-Methyl-1-[1-(3-methyl-butoxy)-ethoxy]-butane Ethyl cis-3-hexenyl acetal; cis-1-(ethoxyethoxy)-3-hexene; Acetaldehyde ethyl A005 1-Ethoxy-1-(cis-3-hexenyloxy)ethane, Leaf acetal; Leaf cis-3-hexenyl acetal alcohol ethyl acetal; Acetaldehyde ethyl (z)-3-hexenyl acetal; - 1 - 1-Ethoxy-1-(3-hexenyloxy)ethane; Acetaldehyde ethyl 3-hexenyl acetal Benzene, 2-(1-propoxyethoxy)ethyl; Acetal R; pepital; Acetaldehyde phenethyl 1-Phenethoxy-1-propexy-ethane; A006 propyl acetal Propyl phenethyl acetal; 2-(1-Propoxyethoxy)ethyl]benzene Acetic acid amide; Acetimidic acid; Ethanamide; A007 Acetamide Ethanamidic acid; Methanecarboxamide Methyl 4-methoxyphenyl ketone; 4-Acetylanisole; p-Acetyl anisole; A008 Acetanisole p-Methoxy-acetophenone; Navatone; 1-(4-Methoxyphenyl)ethanone; 4-Methoxyacetophenone Acetyl methyl carbinol; 2,3-Butanolone; Dimethylketol;