A Review on Blisk Technology

Total Page:16

File Type:pdf, Size:1020Kb

Load more

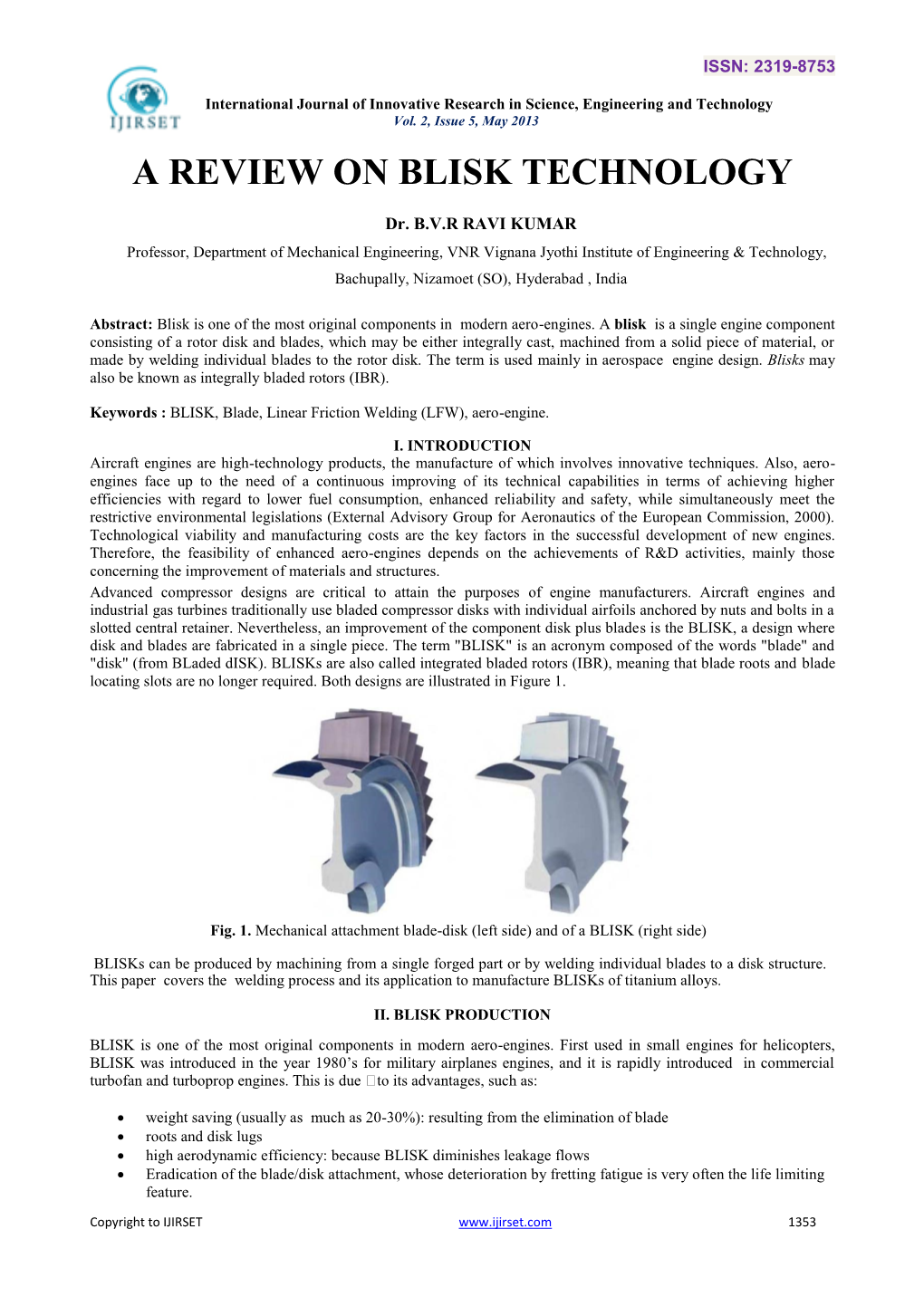

Recommended publications

-

Aerospace Engine Data

AEROSPACE ENGINE DATA Data for some concrete aerospace engines and their craft ................................................................................. 1 Data on rocket-engine types and comparison with large turbofans ................................................................... 1 Data on some large airliner engines ................................................................................................................... 2 Data on other aircraft engines and manufacturers .......................................................................................... 3 In this Appendix common to Aircraft propulsion and Space propulsion, data for thrust, weight, and specific fuel consumption, are presented for some different types of engines (Table 1), with some values of specific impulse and exit speed (Table 2), a plot of Mach number and specific impulse characteristic of different engine types (Fig. 1), and detailed characteristics of some modern turbofan engines, used in large airplanes (Table 3). DATA FOR SOME CONCRETE AEROSPACE ENGINES AND THEIR CRAFT Table 1. Thrust to weight ratio (F/W), for engines and their crafts, at take-off*, specific fuel consumption (TSFC), and initial and final mass of craft (intermediate values appear in [kN] when forces, and in tonnes [t] when masses). Engine Engine TSFC Whole craft Whole craft Whole craft mass, type thrust/weight (g/s)/kN type thrust/weight mini/mfin Trent 900 350/63=5.5 15.5 A380 4×350/5600=0.25 560/330=1.8 cruise 90/63=1.4 cruise 4×90/5000=0.1 CFM56-5A 110/23=4.8 16 -

Propulsione Aeronautica 2020/2021 Francesco Barato

PROPULSIONE AERONAUTICA 2020/2021 FRANCESCO BARATO MATERIALE DI SUPPORTO FONDAMENTI DI PROPULSIONE AERONAUTICA Thrust 푇 = (푚̇ 푎 + 푚̇ 푓)푉푒 − 푚̇ 푎푉0 + (푝푒 − 푝푎)퐴푒 푇 ≈ 푚̇ 푎(푉푒 − 푉0) + (푝푒 − 푝푎)퐴푒 1 PROPULSIONE AERONAUTICA 2020/2021 FRANCESCO BARATO Ramjet P-270 Moskit (left), BrahMos (right) Turboramjet Pratt & Whitney J-58 turbo(ram)jet 2 PROPULSIONE AERONAUTICA 2020/2021 FRANCESCO BARATO Scramjet 3 PROPULSIONE AERONAUTICA 2020/2021 FRANCESCO BARATO Specific impulse 푇 푉푒 푇 푚̇ 푝 푉푒 − 푉0 퐼푠푝 = = [푠] 푟표푐푘푒푡푠 퐼푠푝 = = [푠] 푎푟 푏푟푒푎푡ℎ푛푔 푚̇ 푝푔0 푔0 푚̇ 푓푔0 푚̇ 푓 푔0 4 PROPULSIONE AERONAUTICA 2020/2021 FRANCESCO BARATO Propulsive efficiency Overall efficiency Overall efficiency with Mach number 5 PROPULSIONE AERONAUTICA 2020/2021 FRANCESCO BARATO Engine bypass ratios Bypass Engine Name Major applications ratio turbojet early jet aircraft, Concorde 0.0 SNECMA M88 Rafale 0.30 GE F404 F/A-18, T-50, F-117 0.34 PW F100 F-16, F-15 0.36 Eurojet EJ200 Typhoon 0.4 Klimov RD-33 MiG-29, Il-102 0.49 Saturn AL-31 Su-27, Su-30, J-10 0.59 Kuznetsov NK-144A Tu-144 0.6 PW JT8D DC-9, MD-80, 727, 737 Original 0.96 Soloviev D-20P Tu-124 1.0 Kuznetsov NK-321 Tu-160 1.4 GE Honda HF120 HondaJet 2.9 RR Tay Gulfstream IV, F70, F100 3.1 GE CF6-50 A300, DC-10-30,Lockheed C-5M Super Galaxy 4.26 PowerJet SaM146 SSJ 100 4.43 RR RB211-22B TriStar 4.8 PW PW4000-94 A300, A310, Boeing 767, Boeing 747-400 4.85 Progress D-436 Yak-42, Be-200, An-148 4.91 GE CF6-80C2 A300-600, Boeing 747-400, MD-11, A310 4.97-5.31 RR Trent 700 A330 5.0 PW JT9D Boeing 747, Boeing 767, A310, DC-10 5.0 6 PROPULSIONE -

SP's Aviation August 2010

SP’s AN SP GUIDE PUBLICATION A-BASED BUYER ONLY) BUYER A-BASED I News Flies. We Gather Intelligence. Every Month. From India. RS. 75.00 (IND RS. Aviationwww.spsaviation.net AUGUST • 2010 IAF to get more AWACS Military Aero Engines Interviews with Lockheed Martin’s Ralph Heath & Boeing’s Chris Chadwick FARNBOROUGH AIRSHOW 2010 Iconic RNI NUMBER: DELENG/2008/24199 PAGE 24 SHOW Answering the call with confidence. It’s in our power.™ Pratt & Whitney builds and supports the most advanced military engines in the world, including the F117 engine for the C-17 Globemaster III airlifter. In fact, 27 armed services across the globe employ 11,000 of our engines to deliver when it really counts. Learn more at www.pw.utc.com. Military Engines SP’s AN SP GUIDE PUBLICATION TABLE of CONTENTS News Flies. We Gather Intelligence. Every Month. From India. AviationIssue 8 • 2010 CEOSPEAK 28 Ralph Heath ‘We are the only provider of the fifth generation aircraft to the world’ OEM 30 Interview ‘We focus on the market through the eyes of our customers’ INTERVIEW 32 OEM ‘Reliability and maintainability: A400M, manufactured by Airbus Military, during an impressive two outstanding benefits’ flying display at the Farnborough Airshow 2010. T he aircraft 24 was rechristened – Grizzly HALL OF famE 34 Lawrence Hargrave FIRST Lead Story REGULAR DEpaRTMENTS 8 Transformer 5 A Word from Editor ICONIC SHOW TECH WATCH Farnborough, the biggest air 6 NewsWithViews show of the year, witnessed 9 – Phantom Eye several new aircraft, new - Laser System to track – At an Advantage players and new orders. -

The Market for Aviation Turbofan Engines

The Market for Aviation Turbofan Engines Product Code #F640 A Special Focused Market Segment Analysis by: Aviation Gas Turbine Forecast Analysis 1 The Market for Aviation Turbofan Engines 2010-2019 Table of Contents Executive Summary .................................................................................................................................................2 Introduction................................................................................................................................................................2 Trends..........................................................................................................................................................................3 Market Focus .............................................................................................................................................................3 Competitive Environment.......................................................................................................................................4 Figure 1 - The Market for Aviation Turbofan Engines Unit Production 2010 - 2019 (Bar Graph) .................................................................................6 Figure 2 - The Market for Aviation Turbofan Engines Value of Production 2010 - 2019 (Bar Graph)...........................................................................6 Manufacturers Review.............................................................................................................................................7 -

Testing Down to the Last Detail

1/2010 Testing down to the last detail MTU Aero Engines Holding AG Customers + PartnersTechnology + Science MTU Global Dachauer Straße 665 80995 Munich • Germany Tel. +49 89 1489-0 Fax +49 89 1489-5500 Power for the Jumbo Jet Hardfaced tips for top MTU support for the [email protected] www.mtu.de and the Dreamliner efficiency “flying gas station” Contents Editorial Cover Story Dear Readers: Testing down to the last detail 4 – 7 Finally, yes finally, the bird is on the wing. However, the program highlights something Late last year, the new A400M military trans- else too—something we have witnessed re- Customers + Partners port aircraft successfully completed its long- peatedly in the past. Almost all the major Power for the Jumbo Jet and 8 – 11 awaited, eagerly anticipated maiden flight commercial and military aircraft programs the Dreamliner above the Spanish city of Seville. The relief that have ever been initiated in Europe and A boost for the MRJ 12 – 15 Testing down to the last detail was palpable throughout the industry; delays the United States have been subject to to the project had been creating too much delays, some of them massive. In this respect, Four TP400-D6 engines lift Europe’s new military transport, the A400M, up into turbulence all round. Now, the ongoing flight the A400M is no exception. As things stand the air—now almost an everyday occurrence at Seville airport. Since the maiden Technology + Science test program is demonstrating the superior at present, in pure economic terms, MTU flight in December 2009, flight testing has been in full swing. -

V16 GE-1015 Jane's Aero Engine March 2000.Pdf

MITLibraries RUSH DOCUMENT SERVICES Massachusetts Institute of Technology SHIP TO: Weil, Gotshal & Mang,;JJ-J:. Room 14-0551 1300 Eye Street NW I II It: 77 Massachusetts A venue Suite 900 Pg/Date Cambridge, MA 02139-4307 USA Washington, DC 20005 Tel 617-253-2800 Fax 617-253-1690 Attn: Carrie Port [email protected] http://libraries.mit.edu/docs Phone: (202) 682-7273 Email: [email protected] Invoice No. 22436 Invoice Date 27-Feb-2015 BILL TO: Weil, Gotshal & Manges LLP 1300 Eye Street NW Suite 900 Washington, DC 20005 CC Transaction ID: 1400000860379 Order Reference: 47890.0284-1655 Article No. of Pages Format Cost Journal Title: Jane's aero-engines. 8 Electronic/PDF Standard $20.00 Issue: 7 Date: March 2000 Author: Editor: Bill Gunston. Article Title: article discussing the PW8000 from Pratt and Whitney Page Range: article+ cover+ copyright+ TOC +title fJ-"\. ~ Call Number: b TL701.J36 Subtotal $20.00 Shipping and Handling: $0.00 Payments to Date: $20.00 Total: $0.00 11Allt ***US Copyright Notice*** The copyright law of the United States (Title 17, United States Code) governs the making of reproductions of copyrighted material. Under certain conditions specified in the law, libraries are authorized to furnish a reproduction. One of these specified conditions is that the reproduction is not to be "used for any purpose other than private study, scholarship, or research." If a user makes a request for, or later uses, a reproduction for purposes in excess of "fair use," that user may be liable for copyright infringement. This Institution reserves the right to refuse to accept a copying order if, in its judgment, fulfillment of the order would involve violation of Copyright Law. -

The Revista Aérea Collection

The Revista Aérea Collection Dan Hagedorn and Pedro Turina 2008 National Air and Space Museum Archives 14390 Air & Space Museum Parkway Chantilly, VA 20151 [email protected] https://airandspace.si.edu/archives Table of Contents Collection Overview ........................................................................................................ 1 Administrative Information .............................................................................................. 1 Historical Note.................................................................................................................. 2 Arrangement..................................................................................................................... 2 Scope and Content Note................................................................................................. 2 Names and Subjects ...................................................................................................... 3 Container Listing ............................................................................................................. 4 Series A: Aircraft...................................................................................................... 4 Series B: Propulsion............................................................................................. 218 Series C: Biography............................................................................................. 262 Series D: Organizations...................................................................................... -

Aerothermodynamic Cycle Analysis of a Dual-Spool, Separate-Exhaust

Michigan Technological University Digital Commons @ Michigan Tech Dissertations, Master's Theses and Master's Dissertations, Master's Theses and Master's Reports - Open Reports 2006 Aerothermodynamic cycle analysis of a dual-spool, separate- exhaust turbofan engine with an interstage turbine burner Ka Heng Liew Michigan Technological University Follow this and additional works at: https://digitalcommons.mtu.edu/etds Part of the Mechanical Engineering Commons Copyright 2006 Ka Heng Liew Recommended Citation Liew, Ka Heng, "Aerothermodynamic cycle analysis of a dual-spool, separate-exhaust turbofan engine with an interstage turbine burner", Dissertation, Michigan Technological University, 2006. https://doi.org/10.37099/mtu.dc.etds/382 Follow this and additional works at: https://digitalcommons.mtu.edu/etds Part of the Mechanical Engineering Commons AEROTHERMODYNAMIC CYCLE ANALYSIS OF A DUAL-SPOOL, SEPARATE-EXHAUST TURBOFAN ENGINE WITH AN INTERSTAGE TURBINE BURNER By KA HENG LIEW A DISSERTATION Submitted in partial fulfillment of the requirements for the degree of DOCTOR OF PHILOSOPHY (Mechanical Engineering-Engineering Mechanics) MICHIGAN TECHNOLOGICAL UNIVERSITY 2006 This dissertation, “Aerothermodynamic Cycle Analysis of a Dual- spool, Separate-exhaust Turbofan Engine with an Interstage Tur- bine Burner”, is hereby approved in partial fulfillment of the re- quirements for the degree of DOCTOR OF PHILOSOPHY in the field of Mechanical Engineering-Engineering Mechanics. DEPARTMENT of Mechanical Engineering-Engineering Mechanics Dissertation Advisor: Dr. Song-Lin Yang Department Chair: Dr. William W. Predebon Date: AEROTHERMODYNAMIC CYCLE ANALYSIS OF A DUAL-SPOOL, SEPARATE-EXHAUST TURBOFAN ENGINE WITH AN INTERSTAGE TURBINE BURNER Ka Heng Liew Department of Mechanical Engineering-Engineering Mechanics Michigan Technological University Abstract This study focuses on a specific engine, i.e., a dual-spool, separate-flow turbofan engine with an Interstage Turbine Burner (ITB). -

India Invites Aerospace Majors for Partnerships, Outsourcing

www.indiastrategic.in AERO INDIA 2011 February 09–13, Bangalore SHOW DAILY #2 India invites aerospace majors MRCA decision likely by September for partnerships, outsourcing By Gulshan Luthra it transparent and effi cient, the minister angalore. India should select told a select gathering of national and Bthe Medium Multi Role Combat international delegations that the scope Aircraft (MMRCA) by mid-2011, or of the offset policy guidelines has been latest by September. expanded to civil aerospace, internal Releasing the Aero India special security and training to include eligible edition of India Strategic defence products and services to enable global magazine (www.indiastrategic.in) fi rms bagging orders to discharge their on the opening day of the Aero obligations. “We hope the revised defence production India 2011 here, Chief of Air Staff of the Indian Air Force, Air Chief angalore. India has invited leading policy and procurement policy will provide Binternational aerospace fi rms to partner better opportunities to foreign original Marshal P V Naik, said that the with its strong defence organisations, state- equipment manufacturers (OEMs) and progress of the evaluation process run enterprises and the emerging private help build indigenous capabilities to was going on satisfactorily and sector for the all-round development of its undertake outsourcing of products and that he expected the decision by aerospace industry. services for the global aerospace and the middle of this year, or latest by “We are open to joint ventures, civil aviation industry,” Antony pointed Contd. on pg 3 long-term partnerships and licence out. (IANS) production under transfer of technology ■ with leading international aerospace companies to make our aerospace sector strong, competitive and self-reliant,” Defence Minister A.K. -

ACP 34 Volume 2 Air Ll.Pmd

Uncontrolled Copy Not Subject To Amendment air cadet publication ACP 34 aircraft operation volume 2 - airmanship Il Revision 1.02 Uncontrolled Copy Not Subject To Amendment Amendment List Date Amended by Incorporated No Date 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 i Revision 1.02 Uncontrolled Copy Not Subject To Amendment ACP 34 AIRCRAFT OPERATION CONTENTS Volume 1 .................. Airmanship l Volume 2................. Airmanship ll Volume 3 .................. Aircraft Handling Volume 4.................. Operational Flying Volume 2 Airmanship ll Chapter 1 ................. Air Traffice Control. Chapter 2 ................. Rules of the Air. Chapter 3 ................. Aircraft Knowledge. Instructors’ Guide ISSUED 2005 ii Revision 1.02 Uncontrolled Copy Not Subject To Amendment iii Revision 1.02 Uncontrolled Copy Not Subject To Amendment AIR TRAFFIC CONTROL CHAPTER 1 AIR TRAFFIC CONTROL Introduction ATC, ATCC & ATCRU 1. At Royal Air Force airfields all movements of aircraft, both on the ground and in the air, are monitored and controlled by a vital service known as Air Traffic Control (ATC). The ATC controllers and supporting staff operate from the “control tower”, and they communicate with the aircrew by radio telephony (RT). In the tower will be aerodrome controllers for aircraft on the ground and in the circuit, and approach controllers for aircraft that are outside the circuit, but within the airfield’s area of responsibility. Other controllers, responsible for the safety of aircraft flying between airfields, may be located in Air Traffic Control Centres (ATCCs) or Air Traffic Control Radar Units (ATCRUs) neither of which need be situated on airfields. The Control Tower Recognise a Control 2. -

Ef Tecguide 2013A Layout 1 18.11.13 13:55 Seite 1

0002-2594-13-pri Ef TecGuide 2013a_Layout 1 18.11.13 13:55 Seite 1 Eurofighter Jagdflugzeug GmbH Am Söldnermoos 17 85399 Hallbergmoos Germany Telephone +49 811 80 0 Fax +49 811 80 1557 E-mail [email protected] www.eurofighter.com Issue 01-2013 Technical Guide Effective Proven Trusted 0002-2594-13-pri Ef TecGuide 2013a_Layout 1 18.11.13 13:55 Seite 3 3 CONTENTS 1 INTRODUCTION 05 2 GENERAL CHARACTERISTICS 09 Dimensions|Mass|Design Characteristics| Performance Characteristics| Materials| Performance 3 OPERATIONAL CAPABILITIES 15 Multi-Role and Swing-Role|Air Superiority| Beyond Visual Range (BVR)|Within Visual Range (WVR)| One Aircraft Any Mission| Unmatched Capability|Fleet Effectiveness| Continuous Enhancements 4 AVIONICS AND SENSORS 27 Sensor Fusion|Individual Sensors| Navigation Features|Cockpit 5 MAIN AIRCRAFT SYSTEMS 39 The Engine| Flight Control System| Utilities Control System|Other Systems 6 INTEGRATED LOGISTICS SUPPORT 47 Key Aspects 7 FACTS & FIGURES 51 8 ORGANISATION AND STRUCTURE 53 9 GLOSSARY 55 0002-2594-13-pri Ef TecGuide 2013a_Layout 1 18.11.13 13:55 Seite 4 4 5 1 1 INTRODUCTION Eurofighter Typhoon is a highly agile Air Superiority and Air-to-Surface, multi-role/swing-role weapon system. 1 INTRODUCTION In full operation with six nations – Germany, Italy, Spain, the United Kingdom, Austria and the Kingdom of Saudi Arabia – Eurofighter Typhoon is the most capable modern combat aircraft available on the global market. Austria became the first export customer in 2003. Deliveries to the Kingdom of Saudi Arabia started in 2009. A new contract with the Sultanate of Oman as the third export customer was signed in December 2012. -

Aviation Week & Space Technology Student Edition

Stratolaunch’s Open Rotor Revival M&A in the Hypersonic Reset at GE-Safran Age of COVID-19 $14.95 OCTOBER 26-NOVEMBER 8, 2020 ISS TURNS 20 RICH MEDIA EXCLUSIVE Digital Edition Copyright Notice The content contained in this digital edition (“Digital Material”), as well as its selection and arrangement, is owned by Informa. and its affiliated companies, licensors, and suppliers, and is protected by their respective copyright, trademark and other proprietary rights. Upon payment of the subscription price, if applicable, you are hereby authorized to view, download, copy, and print Digital Material solely for your own personal, non-commercial use, provided that by doing any of the foregoing, you acknowledge that (i) you do not and will not acquire any ownership rights of any kind in the Digital Material or any portion thereof, (ii) you must preserve all copyright and other proprietary notices included in any downloaded Digital Material, and (iii) you must comply in all respects with the use restrictions set forth below and in the Informa Privacy Policy and the Informa Terms of Use (the “Use Restrictions”), each of which is hereby incorporated by reference. Any use not in accordance with, and any failure to comply fully with, the Use Restrictions is expressly prohibited by law, and may result in severe civil and criminal penalties. Violators will be prosecuted to the maximum possible extent. You may not modify, publish, license, transmit (including by way of email, facsimile or other electronic means), transfer, sell, reproduce (including by copying or posting on any network computer), create derivative works from, display, store, or in any way exploit, broadcast, disseminate or distribute, in any format or media of any kind, any of the Digital Material, in whole or in part, without the express prior written consent of Informa.