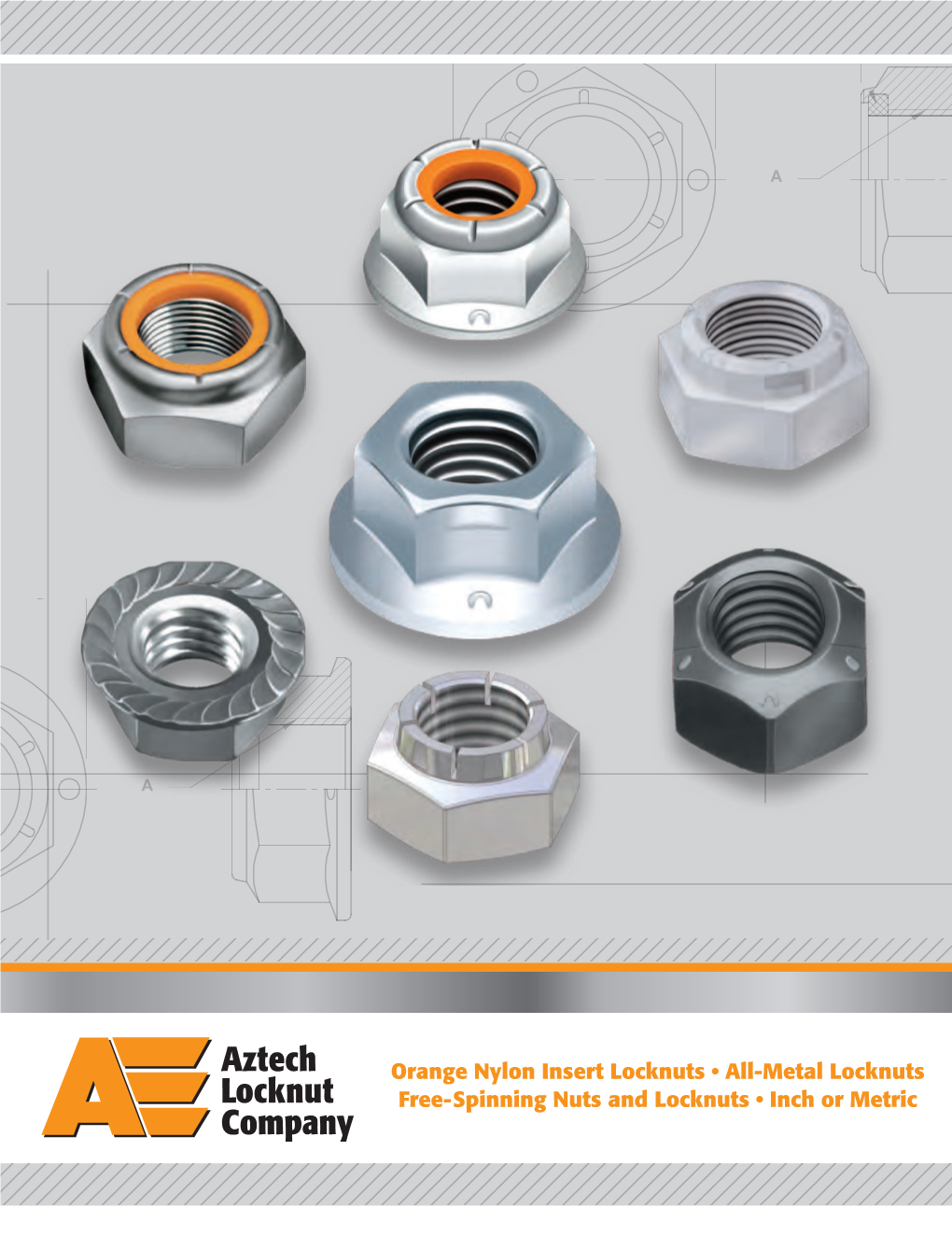

Orange Nylon Insert Locknuts • All-Metal Locknuts Free-Spinning

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

LIO-360-B1G6 Engine Maintenance Manual Lycoming Part Number: MM-LIO-360-B1G6

Engine Maintenance Manual (Principal Manual) LIO-360-B1G6 Engine September 2017 Part No. MM-LIO-360-B1G6 © 2017 Avco Corporation. All Rights Reserved. LIO-360-B1G6 Engine Maintenance Manual Lycoming Part Number: MM-LIO-360-B1G6 Contact Us: Mailing Address: Lycoming Engines 652 Oliver Street Williamsport, PA 17701 USA Phone: U.S. and Canada Toll Free: +1 (800) 258-3279 Factory Direct: +1 (570) 323-6181 Technical Support Hotline • +1 (877) 839-7878 (Toll Free) • +1 (570) 327-7222 Lycoming’s regular business hours are Monday through Friday from 8:00AM through 5:00PM Eastern Time (-5 GMT). Visit us Online: www.Lycoming.com LIO-360-B1G6 Engine Maintenance Manual RECORD OF REVISIONS Revision Revised Revision Date By Revision Description Original Original Release of Maintenance Manual - Part No. MM-LIO-360-B1G6 © 2017 Avco Corporation. All Rights Reserved Record of Revisions September 2017 Page i LIO-360-B1G6 Engine Maintenance Manual This page intentionally left blank. Record of Revisions © 2017 Avco Corporation. All Rights Reserved Page ii September 2017 LIO-360-B1G6 Engine Maintenance Manual SERVICE DOCUMENT LIST NOTICE: The following is a list of service documents referenced in or incorporated into the information in this manual. Always refer to the latest revision of any service document (including any supplements) for changes or additional information. Number Incorporation Subject Date S.B. 201 09/17 Inspection of Crankshaft Flange S.B. 240 09/17 Mandatory Parts Replacement at Overhaul and During Repair or Maintenance S.B. 342 09/17 Fuel Line (Stainless Steel Tube Assy.) and Support Clamp Inspection and Installation S.B. -

PDF Product List

STRUCTURAL BOLTS MACHINE BOLTS NUTS A325 Screw Only, A193 B7 Heavy Hex Head Bolt Acorn (Cap) Nut Domestic & Import A307A Breakaway Bolt Allen Nut A325 Bolt with Nut A307B Heavy Head Bolt Cap (Acorn) Nut A325 Type 3 Bolt, Domestic F1554 Hex Machine Bolt Castle Nut A325 Interference Body Bolt (Grades 36, 55, & 105) Coupling Nut Canadian A325 Bolt w/DH Nut, Square Head Machine Bolt Coupling Nut, Reducer Hot Dip Galvanized Coupling Nut, Heavy Duty A490 Screw Only, BOLTS & SCREWS Hex Nut Domestic & Import Carriage Bolt Hex Nut, Left Hand TC A325 Assembly, Countersunk Bolt Hex Nut, Heavy Grade 4 Domestic& Import Counterbore Screw, 12 Point Hex Nut, Heavy, Grade 7 TC A490 Assembly, Elevator Bolt Hvy Double Recess Guardrail Nut Domestic & Import Flange Bolt Jack Nut Flat Head Bolt, Slotted Jam Nut STRUCTURAL NUTS Guardrail Bolt Jam Nut, Left Hand A194 2H Nut, Domestic Hanger Bolt Flange Nut A194 2H Nut, Import Lag Screw High Nut A563 Grade DH Heavy Nut, Lag Screw, 1-Way Truss Head Knurled Nut Domestic Lag Screw, Indented HWH Machine Screw Nut, Hex A563 DH Type 3 Nut Full Thread Machine Screw Nut, Small Pattern ANCO Heavy Hex Locknut Lag Screw, Square Head Machine Screw Nut, Square ANCO Finished Locknut Penta Head Bolt Palnut ANCO 2H Heavy Locknut Place Bolt Panel Nut ANCO A325 Locknut Plow Bolt, Grade 2 Slotted Nut Plow Bolt, Grade 5 Slotted Nut, Heavy STRUCTURAL WASHERS Plow Bolt, Grade 8 Square Nut F436 Hardened Washer Shaker Screen Bolt, Grade 5 Square Nut, Heavy Domestic & Import Shackle Bolt Tee Nut F436 Type 3 Washer Security Bolt Wing -

Fastener Identification Guide • 4.13 KM • Printed in the USA

HEAD STYLES Hex Cap Screw Bugle Hex cap screws feature a washer face on the Button Washer bearing surface, a chamfered point, and tighter body tolerances than hex bolts. Pan Binding Undercut Hex Bolt Similar to hex cap screw, hex bolts do not require a washer face or a pointed end and have a greater tolerance range in the body. Round Head Fillister Socket Head Cap Screw Socket heads feature an internal hexagonal drive DRIVES socket and close tolerances for precision assembly. Flat 82° Cross Recess Button Head Socket Cap Screw Type I FASTENER (Phillips) Button heads feature a dome shaped head, though Flat 100° this feature reduces the tensile capacity. Cross Recess Flat Head Socket Cap Screw Type IA Flat heads feature an 82° countersunk head for Flat Undercut (Pozidriv®) IDENTIFICATION flush connections. Like the button heads, this feature reduces the tensile capacity. Cross Recess Type II (Frearson) Low Head Socket Cap Screw Indented Hex Low heads are similar to standard socket heads, but with a shorter head for applications where clearance Cross Recess Square GUIDE is an issue. This head configuration also reduces the Combo strength capacity. Indented Hex Washer (Quadrex®) NUTS Carriage Bolt A round head bolt with a square neck under the Slotted head. These must be tightened with a nut. Serrated Hex Finished Hex Nuts: Hex Coupling Nuts: Washer Hexagonal shaped nuts with internal screw Designed to join two externally threaded Plow Bolt threads. Finished hex nuts are one of the most objects, usually threaded rod, together. Combination Similar to a carriage bolt, these have a flat head common nuts used. -

Maclean ESNA's Catalog

611 COUNTRY CLUB ROAD POCAHONTAS, ARKANSAS 72445 SALES: 1-(800)-331-6469 FAX: 1-(870)-892-8938 WWW.MACLEANFOGGCS.COM 1 The ESNA® story began in 1927, when a young engineer named Carl Arthur Swanstrom came to this country from Sweden. He brought with him a license to manufacture and sell a unique new self-locking fastener. The Inventor called the new fastener an “Elastic Stop® nut” because the nut remained “stopped” anywhere along the bolt threads. A non-damaging insert, fitted into the top of the nut, gripped the bolt threads firmly, holding the nut in position without seating against the work or using secondary locking devices. The only problem with the new nut was the inability to mass-produce them. The next few years were spent perfecting an automatic assembly machine to insert the locking device into the top of the nut. Swanstrom perfected the machine in the early 1930s and only four years later the Elastic Stop® Nut Corporation of America was founded. A threaded fastener, able to positively resist the loosening effect of vibration, had long been sought by manufacturers of every type of equipment. The Elastic Stop® nut proved to be the answer — totally reliable, able to reduce maintenance costs and prevent equipment failure. The outstanding performance of the Elastic Stop® nut was further substantiated in 1943 when the Air Force tested and issued the first approval letter to use ESNA® fasteners on military aircraft, both fuselage and engines. During WWII billions of Elastic Stop® nuts were produced for every branch of the armed services. -

Bus and Coach Rear Drive Axles Revised 06-16

Maintenance Manual 23A Bus and Coach Rear Drive Axles Revised 06-16 59000 Series 61000 Series 71000 and 79000 Series RC-26-700 Series Service Notes About This Manual How to Obtain Additional Maintenance, This manual provides maintenance and service information for the Service and Product Information Meritor 59000, 61000, 71000, 79000, RC-23-160 and Visit Literature on Demand at meritor.com to access and order RC-26-700 Series bus and coach rear drive and center axles and T additional information. Series parking brake. Contact the Meritor OnTrac™ Customer Call Center at Before You Begin 866-668-7221 (United States and Canada); 001-800-889-1834 (Mexico); or email [email protected]. 1. Read and understand all instructions and procedures before you begin to service components. If Tools and Supplies are Specified in 2. Read and observe all Warning and Caution hazard alert This Manual messages in this publication. They provide information that can Contact Meritor’s Commercial Vehicle Aftermarket at help prevent serious personal injury, damage to components, 888-725-9355. or both. 3. Follow your company’s maintenance and service, installation, Kiene Diesel Accessories, Inc., 325 S. Fairbanks Street, Addison, IL 60101. Call the company’s customer service center at and diagnostics guidelines. 800-264-5950, or visit their website at kienediesel.com. 4. Use special tools when required to help avoid serious personal injury and damage to components. SPX/OTC Service Solutions, 655 Eisenhower Drive, Owatonna, MN 55060. Call the company’s customer service center at Hazard Alert Messages and Torque 800-533-6128, or visit their website at otctools.com. -

ABS Fastener Catalog

ABS FASTENERS OFFERS A COMPLETE LINE OF COMMERCIAL STANDARDS AND SPECIALS. We are your premier source for commercial grade fasteners, nuts, bolts, screws, and hard- ware. For more than 60 years, ABS has set the standard for quality, value-added services, and superior customer service. From our seven ABS warehouses strategically located across the USA and Mexico stocking several million in inventory, we are uniquely poised to serve your fastener and hardware needs for manufacturing and assembly. 4 ...........Anchors 20 .........Custom Fasteners & Hardware 5 ...........Bits 21 .........Value Added Services 6-7 ........Bolts 22 .........Quick Fastener Reference 8-9 ........Nuts 23 .........Heads, Threads, and Drive Styles 10 .........Washers 24 .........Thread Pitch Guide 11 .........Socket Products 25 .........Material Reference 12 .........Machine Screws 26 .........Plating Reference 13 .........Wood Screws 27 .........Painting Services 14 .........Construction Screws 28 .........Staple Reference 15 .........Self Drilling Screws 29 .........Nail Reference 16-17 ...Sheet Metal Screws 30 .........Hardware Off ering 18 .........Nails & Rivets 29 .........ABS Locations & Contact Info 19 .........Pins & Miscellaneous Items © 2017 American Bolt & Screw. All Rights Reserved. Reproducing or copying any part of this catalog without permission is unlawful under the United States Copyright Act. Violaters are subject to full prosecution under federal law. We hold industry together... You are not anchored to other suppliers! We have the anchors you need for light or heavy jobs. Conical Plastic Anchors E-Z Anchors Toggle Bolts Light-duty wall anchor used with a sheet metal or wood Pre-drills own hole in gympsum wallboard.Replaces A machine screw and toggle wing anchoring system screw in drywall,concrete or hollow brick. -

EML2322L Fastener Reference Guide

EML2322L Fastener Reference Guide Introduction Common Fastener Head, Nut, and Washer Types Fasteners are connective hardware that can easily Fastener Name Tighten With be installed and removed with common hand tools. Bolts, screws, nuts, and rivets are typical examples flat head slotted head of fasteners. The difference between a bolt, screw, (slotted) screwdriver and a stud is determined by its use. pan head Phillips head (Phillips) screwdriver wrench, socket hex head wrench button Allen/hex head cap wrench screw Allen/hex set screw Bolts are headed fasteners with external threads wrench that meet an exacting, uniform thread specification such that they can accept a standardized nut. In the Allen/hex socket head most general sense, screws are headed, externally- wrench threaded fasteners that can cut their own internal threads when installed. In mechanical and aero- shoulder Allen/hex space design applications (which are what we care screw wrench about as design engineers), screws are identical to wrench, socket bolts, but do not require nuts, as they instead screw stud wrench into threaded holes previously created in work- pieces. Studs are externally threaded headless fasteners with which one end usually mates with a rivet rivet gun threated component and the other end typically wrench, socket mates with a standardized nut. hex nut wrench Purpose wrench, socket Nyloc nut wrench The ONLY purpose of fasteners is to clamp parts together. Standard fasteners are NOT intended to serrated wrench, socket be used to for positioning or pivoting; that is the flange nut wrench function of dowel pins, locating shoulders, and flat washer - piloting diameters. -

Fastener Design Manual

. _- NASA 'Reference Publication 1228 March 1990 Fastener Design Manual Richard T. Barrett . , :. ? . ,' - ' ' - "'".'-*'" _,'" ' "l ......... ' " • ' ¢ ",;L, NASA Reference Publication 1228 1990 Fastener Design Manual Richard T. Barrett Lewis Research Center Cleveland, Ohio National Aeronautics and Space Administration Office of Management Scientific and Technical Information Division ERRATA NASA Reference Publication 1228 Fastener Design Manual Richard T. Barrett March 1990 The manual describes various platings that may be used for corrosion control including cadmium and zinc plating. It does not mention outgassing problems caused by the relatively high vapor pressure of these metals. The fastener manual was intended primarily for aeronautical applica- tions, where outgassing is typically not a concern. Issued June 17, 2008 Summary ........... ..... ............. ..... ..... ..... ................................ ..... ....... ....... ............. 1 Introduction ... .................. .......... ..... ..... ..... ..... ..... .......... ............ ..... ....... ............... 1 General Design Information Fastener Materials .... ........ ..... ..... ..... ..... ...................... .......... ............ ............ ..... .. 1 Platings and Coatings ... ..... ..... .......... ..... ..... ..... ..... ................. ..... ............ .............. 1 Thread Lubricants ... ....................... ...................... .......... ................. ....... ..... ..... .... 4 Corrosion ........ ..... .................. ..... .... -

UNITED's Nuts! Acorn, Lock - Spherical Flange Coupling, Lock and Flange Nuts GET MORE for LESS at UNITED! ACORN NUTS See Section G for Stainless

Nuts: Acorn-Coupling- UNITED's Nuts! Acorn, Lock - Spherical Flange Coupling, Lock and Flange Nuts GET MORE FOR LESS AT UNITED! ACORN NUTS See Section G for Stainless. Closed end ACORN NUT A B C protects stud UDB-925000 1/4-20 1/2 1/2 threads from UDB-925005 5/16-18 5/8 9/16 damage. Heat UDB-925010 3/8 – 16 3/4 11/16 treated black UDB-925015 1/2-13 15/16 7/8 B oxide finish. UDB-925020 5/8-11 1-3/16 1-1/16 UDB-925025 3/4 – 10 1-3/8 1-1/4 C12L15 STEEL — HEAT TREATED WITH BLACK OXIDE FINISH. UDB-925030 7/8 – 9 1-7/16 1-7/16 KNURLED LOCK NUTS See Section G for Stainless. Quick thread 1018 STEEL — HEAT TREATED — BLACK OXIDE locking on jigs STEEL STAINLESS A THD B O. D. C STEP D E F DIA PART NO. PART NO. I. D. SIZE DIA DIA WIDTH LIP +.005 and fixtures. 1/4 -.000 detents permit UDB-925110 UDB-925110S 1/4 – 20 1-1/8 1" 7/16 1/16 .250 additional UDB-925115 UDB-925115S 3/8 – 16 1-1/8 1" 7/16 1/16 .250 tightening with UDB-925120 UDB-925120S 1/2 – 13 1-1/8 1" 7/16 1/16 .250 1/4" pin. UDB-925125 UDB-925125S 5/8 – 11 1-3/8 1" 7/16 1/16 .250 COUPLING NUTS Makes unlimited COUPLING NUT A B C stud length UDB-925050 3/8 – 16 1 11/16 combinations UDB-925055 1/2-13 1-1/4 7/8 available. -

Body Shop Fasteners

BSF-712 QUALITY BODY PRODUCTS SHOP FASTENERS QUALITY PRODUCTS PRODUIT DE QUALITE INTERIOR EXTERIOR INTERIEUR EXTERIEUR ATTACHES A CARROSSERIE H. Paulin & Co., a division of The Hillman Group Canada ULC Toronto, Canada M1L 4N3 www.hpaulin.com www.hpaulin.com INDEX Name Page Name Page BOLTS GM........................................................................ 30-32 Misc. Bolts ................................................................. 20 Interior Retainers. Imported Brands Body Bolts (Inch & Metric).................................... 17-20 BMW..................................................................... 34 Bumper Bar Bolts (Inch & Metric)....................... 15-17 Honda.................................................................. 34-35 Hyundai.............................................................. 36 KIA........................................................................ 36 Lexus.................................................................... 36 BUSHINGS Mazda.................................................................. 36-37 Door Hinge Bushings............................................. 75 Mersedes-Benz................................................. 37 Mitsubishi.......................................................... 37 CLIPS Nissan.................................................................. 38 ‘T’ Bolt Clis (Inch)...................................................... 21 Toyota.................................................................. 39 Moulding Clips & Retainers................................. -

Fasteners & Bolts

Parts for Trucks, Trailers & Buses ® 11 FASTENERS Proven, reliable and always innovative. TRP® offers reliable aftermarket products that are designed and tested to exceed customers’ expectations regardless of the vehicle make, model or age. BOLTS • Clips • GROMMETS • inserts • nuts • sCrews • washers Tested. Reliable. Guaranteed. TABLE OF CONTENTS Fasteners FASTENERS Fastener Guide ..............................11-4 Choosing the right Bolts ......................................11-6 replacement part or service for your vehicle—whether you own Clips .....................................11-39 one, or a fleet—is one of the Collars ....................................11-44 most important decisions you can make for your business. Cotter ....................................11-45 ® And, with tested TRP parts Fastener Assortment for HWU10000 ............11-48 it’s an easy decision. Fastener Assortment for HWU11301 ............11-50 Regardless of the make Grommets .................................11-53 you drive, TRP® quality replacement parts are Huck Bolts .................................11-54 engineered to fit your truck, Huck Collars ...............................11-56 trailer or bus. Choose the parts that give you the best Huck Fastener Tools .........................11-57 value for your business. Check Inserts ....................................11-59 them out at an approved TRP® retailer near you. Kits ......................................11-66 Nuts .....................................11-67 Pins ......................................11-86 The cross reference information in this catalog is based upon data provided by several industry sources and our partners. While every attempt is made to ensure the information presented is accurate, we bear no liability due to incorrect or incomplete information. Product Availability Due to export restrictions and market ® demands, not all products are TRP North America always available in every location. 750 Houser Way N. Check for availability in your area with your local TRP® Distributor. -

Screw Products Bits Teks

FASTENER LINE CARD Structural Bolt Nuts/Structural Bolt/ Screw Products A325 Screw Only* A194 2H Domestic Hex Screw Grade 2, Course/ Fine A490 Screw Only A194 2H Import Hex A307 Grade A, Course A325 Bolt With Nut A325 Domestic Hex C/S Grade 5, Course/ Fine A325 Type 3 Bolt Domestic A325 Import Hex C/S Grade 8, Course/ Fine Canadian A325 Bolt W/DH Nut--HDG A563 Gr.DH Heavy* Carriage Bolt A325 Interference Body Bolt A325 Type 3 Grade 5 Shaker Screen A490 Screw Only* Anco Heavy Hex Locknut Lag Screw A325 & A490 Tension Control (TC)* Anco Finished Locknut One Way Lag Screw (Truss) A325 & A490 TC Assembly-Domestic Anco 2H Heavy Locknut Square Head Lag Screw Anco A325 Locknut Indented HWH Lag Full Thrd Washers/Structural Allen Nut Hanger Bolt USS Flat/Cut Castle A307 Grade B Heavy Hex Head Bolt A325/A490 (F436) Hardened* Coupling L9 Hex Screw A325 Type 3 Reducer Coupling A307a Breakaway Bolt A325 Square Beveled Acorn/Cap Plow Bolts --- Grade 2/5/8 Clipped* Finished Hex Slotted Flat Head Bolt A325 & A490 Direct Tension Indicator L9 Finished Hex Nut Square Head Machine Bolt Square Plate Heavy Hex Elevator Bolt Square Malleable Beveled Finished Jam Step Bolt Round Malleable Iron Heavy Jam Tap Bolt Beveled Washer Aluminum Left Hand A193 B7 Heavy Hex Head Bolt Belleville Heavy Left Hand Taper Bolt Hillside Washers Guardrail (Heavy Double Recess) Penta Head Bolt Ogee Pattern Grade 4--- Heavy Place Bolt Torque Washer Grade 7--- Heavy Shackle Bolt USS Hard F436 Flatwasher Jack T-Head Bolt SAE Left Hand Jam Oval Neck Track Bolt W/Square Nut Fender Flange