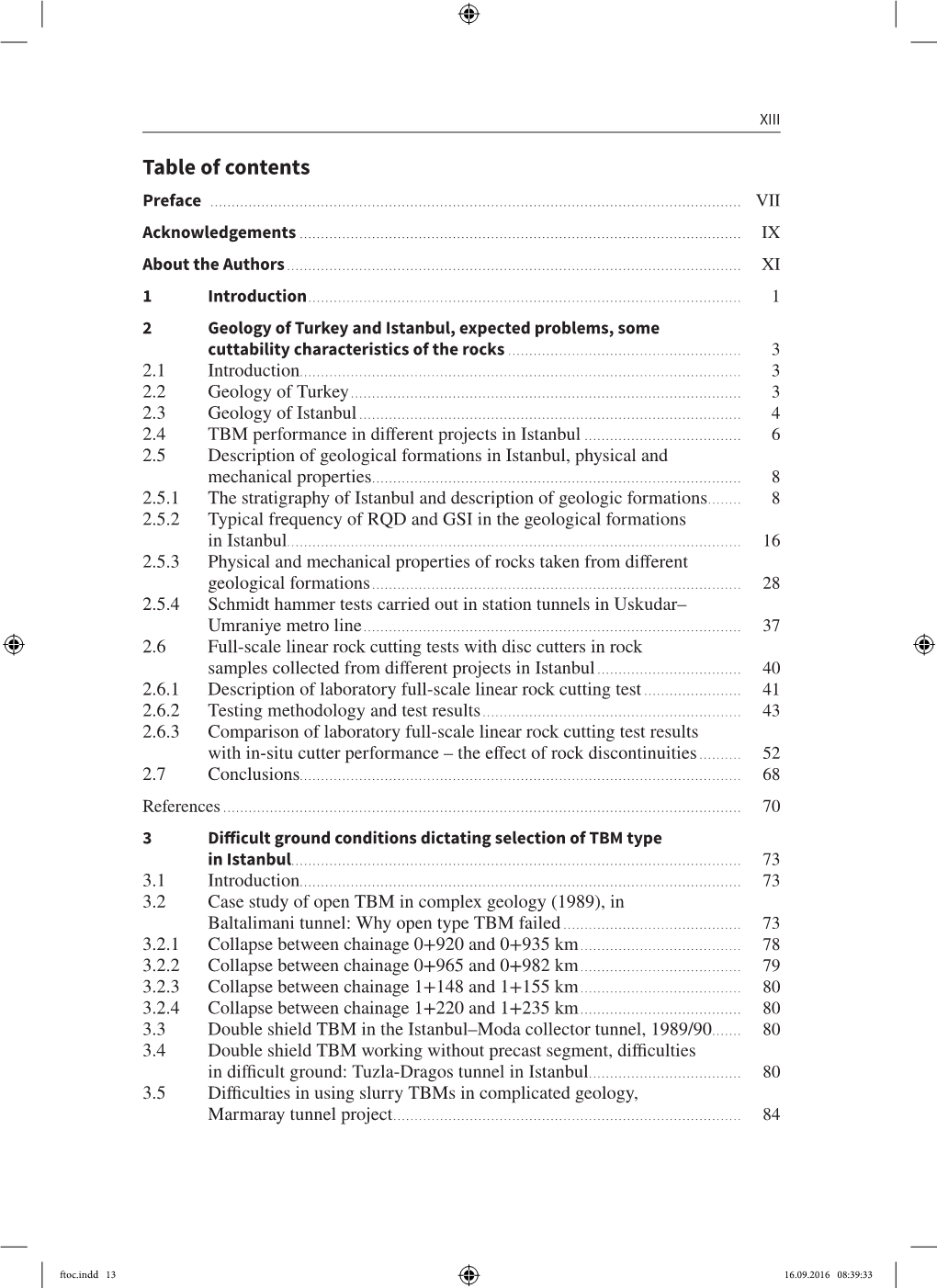

Table of Contents

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Virtual PPP Week 2020 02 November 2020, 11.00 the Head of Free

Tarih: 2 November 2020 Virtual PPP Week 2020 02 November 2020, 11.00 The Head of Free Zones, Overseas Investment and Services from Ministry of Trade Mr. Murat Nesimoğlu, Chairman of İstanbul PPPCOE Dr. Eyüp Vural Aydın, Vice-President to the International Sustainable Resilience Center (ISRC) Mr. David Baxter, Chairman of OECD Infrastructure Forum Thomas Barret, Dear Participants, Thank you. Firstly, I wish healthy days for all of us. I think we realized the importance of being healthy more than ever being effected by Covid-19 and lately by the earthquake we had recently. My condolences and also wishes for soon recovery for all effected ones. I’m glad to meet with you one year later even if it’s virtual, for the fifth time. And, I would like to greet you all, on behalf of the Foreign Economic Relations Board of Turkey (DEİK), at the Virtual PPP Week. Tarih: 2 November 2020 It’s my honor to welcome our panelists and participants from 60 countries including significant decision-makers in both the public and private sectors today. Thanks to our Trade Ministry, Islamic Development Bank, World Bank, our PPP Committee and Istanbul PPPCoE and all organizations for their supports to make this event possible. Each of you offers a unique and telling perspective that we appreciate very much, and all of us at DEIK are so thankful that this video technology has brought us all together to discuss these extremely important matters. We’ll bring together virtually the contracting, technical consultancy, law and project consultancy sectors with the country representatives participating in our program to share our experiences in the model of PPP to potential markets, for 5 days. -

Arcadius 8; (Column

index INDEX 319 Arcadius 8; (column of) 184 Balat 213–14 Archaeological Museum 93ff Baldwin, Count of Flanders 15 Argonauts, myth of 259, 263, 276 Balıklı Kilisesi 197–98 Major references, in cases where many are listed, are given in bold. Numbers in italics Armenian, Armenians 25, 189, 192, Balkapanı Han 132 are picture references. 193, 241–42, 258, 278; (Cemetery) Baltalimanı 258 268; (Patriarchate) 192 Balyan family of architects 34, 161, 193; Arnavutköy 255 (burial place of) 268 A Alexander, emperor 67 Arsenal (see Tersane) Balyan, Karabet 34, 247 Abdülaziz, sultan 23, 72, 215, 251; Alexander the Great 7; (sculptures of) 96 Ashkenazi Synagogue 228 Balyan, Kirkor 34, 234 (burial place of) 117 Alexander Sarcophagus 94, 95 Astronomer, office of 42 Balyan, Nikoğos 34, 246, 247, 249, Abdülhamit I, sultan 23, 118; (burial Alexius I, emperor 13, 282 At Meydanı (see Hippodrome) 252, 255, 274, 275 place of) 43 Alexius II, emperor 14 Atatürk 24, 42, 146, 237, 248; Balyan, Sarkis 34, 83, 247, 258, 272, Abdülhamit II, sultan 23, 251, 252, Alexius III, emperor 14 (Cultural Centre) 242; (Museum) 243; 267 278; (burial place of) 117 Alexius IV, emperor 15 (statue of) 103 Bank, Ottoman 227 Abdülmecit I, sultan 71, 93, 161, 164, Alexius V, emperor 15 Atik Ali Pasha 171; (mosque of) 119 Barbarossa, pirate and admiral 152, 247; (burial place of) 162 Ali Pasha of Çorlu, külliye of 119–20 Atik Mustafa Paşa Camii 216 250, 250; (burial place of) 250; Abdülmecit II, last caliph 24 Ali Sufi, calligrapher 157, 158 Atik Sinan, architect 130, 155, 212; (ensign -

Yedikule Cer Katalog Ing

EVERYONE IS BORN INTO THIS WORLD TO LEAVE A LEGACY FOR THE FUTURE… SOME LEAVE QUOTES THAT WILL CHANGE THE WORLD. SOME LEAVE AN IDEA THAT WILL SHAPE THE FUTURE. SOME LEAVE A WORK OF ART THAT WILL SURVIVE FOR GENERATIONS. A GIFT TO THE FUTURE TO THE FUTURE Proud to have created an unparalleled living space which will revive the history that once witnessed a deep-rooted culture and leave it for the future as an invaluable legacy, we present this project, which has been designed like a work of art with each and every detail, to the world, Istanbul and coming generations… IN THE MIDST OF HISTORY The images used here are for promotional purposes and Ege Yapı A.Ş – Yedikule Gayrimenkul Yatırım A.Ş. Joint Venture reserves the right to make changes on condition that such changes are approved by Emlak Konut GYO A.Ş. AS GLORIOUS AS THE GOLDEN AGES GOLDEN GATE From Hagia Sophia to the Blue Mosque, Basilica Cistern to the Topkapı Palace… The Historical Peninsula, full of splendid palaces, mosques, churches and fountains, runs along the city walls rising with the glory of great empires and opens up to the world as a beauty reflecting the spirit of time and a magnificent world heritage… Yedikule, a district named after the seven towers of Istanbul’s city walls surrounding the Historical Peninsula and also one of the open-air museums of Istanbul, is one of the most glorious examples of the opulent life on the CITYHistorical Peninsula. OF Yedikule is considered as an open-air museum with its old EMPIRESGreek houses, fortress, city walls, gasworks and impressive historical fabric and preserves its value as a unique historical beauty… TOPKAPI PALACE GRAND BAZAAR HAGIA SOPHIA BASILICA CISTERN Time travel of the Ottoman railway lines starts in the 19th century and continues until the 21st century on the Historical Peninsula, a home to the world’s cultural heritage. -

Exports: the Heart of Nep

How to Export to 2018 Turkey This report includes all the information related to trade basics and detailed data regarding export from Brazil to Turkey. This report is for information purposes only and Tumer Eng. will not be liable to any direct, indirect, incidental, special, consequential or exemplary damages, including but not limited to, damages for loss of profits, goodwill, use, data, or other intangible losses. Ver:1.0 2018 1 Contents 1 Why Turkey.................................................................................................................................... 12 1.1 General Information .............................................................................................................. 12 1.2 Geography ............................................................................................................................. 13 1.2.1 Distances ....................................................................................................................... 18 1.2.2 Climate of Turkey .......................................................................................................... 19 1.2.2.1 Air temperature changes until now .......................................................................... 20 1.2.2.2 Precipitation changes until now ................................................................................ 21 1.2.2.3 Air temperature changes in the 21st century ........................................................... 21 1.2.2.4 Precipitation changes in the 21st century ................................................................ -

L-G-0008366837-0017086142.Pdf

Nuh Bilgin Hanifi Copur Cemal Balci TBM Excavation in Difficult Ground Conditions TBM Excavation in Difficult Ground Conditions Case Studies from Turkey Nuh Bilgin Hanifi Copur Cemal Balci Prof. Dr. Nuh Bilgin Prof. Dr. Hanifi Copur Prof. Dr. Cemal Balci Istanbul Technical University Faculty of Mines, Mining Engineering Department 34469 Maslak/Istanbul Turkey Cover: Methane Explosion in the Pressure Chamber of a Tunnel Boring Machine Photo: Bilgin/Copur Library of Congress Card No.: applied for British Library Cataloguing-in-Publication Data A catalogue record for this book is available from the British Library. Bibliographic information published by the Deutsche Nationalbibliothek The Deutsche Nationalbibliothek lists this publication in the Deutsche Nationalbibliografie; detailed bibliographic data are available on the Internet at <http://dnb.d-nb.de>. © 2016 Wilhelm Ernst & Sohn, Verlag für Architektur und technische Wissenschaften GmbH & Co. KG, Rotherstraße 21, 10245 Berlin, Germany All rights reserved (including those of translation into other languages). No part of this book may be reproduced in any form – by photoprinting, microfilm, or any other means – nor transmitted or translated into a machine language without written permission from the publishers. Registered names, trademarks, etc. used in this book, even when not specifically marked as such, are not to be considered unprotected by law. Coverdesign: Sonja Frank, Berlin Production Management: pp030 – Produktionsbüro Heike Praetor, Berlin Typesetting: Reemers Publishing Services -

Public Private Partnership Projects: Eurasia Tunnel

5th Global Business Research Congress (GBRC - 2019), Vol.9-p.253-256 Sari, Gungor PUBLIC PRIVATE PARTNERSHIP PROJECTS: EURASIA TUNNEL DOI: 10.17261/Pressacademia.2019.1100 PAP- V.9-2019(47)-p.253-256 Askin Kaan Kaptan1, Suat Teker2 1 Işık University, Institute of Social Sciences, Istanbul, Turkey. [email protected], ORCID: 0000-0002-6473-9985 2 Işık University, Maslak Campus, Istanbul, Turkey. [email protected], ORCID: 0000-0002-7981-3121 To cite this document Kaptan, A.K., Teker, S., (2019). Public private partnership projects: Eurasia Tunnel. PressAcademia Procedia (PAP), V.9, p.253-256 Permenant link to this document: http://doi.org/10.17261/Pressacademia.2019.1100 Copyright: Published by PressAcademia and limited licenced re-use rights only. ABSTRACT Purpose- Governments perform and observe various services and investments via various methodologies in several sectors such as transportation, health, education for the prosperity of the citizens. Public-Private-Partnership (PPP) model is a commonly applied method by Turkish Government recently due to financing and operational advantages. The main purpose of the study is to understand the fundamentals of a PPP Project and compare international examples and principles with a case analysis of the Eurasia Tunnel. Methodology- PPP fundamentals and the application process are defined in the study with exploratory research methodology. According to the recommended structures, process cycle and process applications, comparative case study methodology is used to determine the similarities between theoretical knowledge and practice. Findings- As a result of the comparison study the similarities and detailed information are provided about the case study. Also, the additional benefits of the project mentioned in the case study is determined. -

Marmaray Tunnel Under the Sea: Public Safety, Cellular and GSMR Coverage in the Marmaray Tunnel

Cobham Wireless Case Study Marmaray tunnel Under the sea: public safety, cellular and GSMR Coverage in the Marmaray Tunnel Overview The project involved providing public safety, cellular and GSM-R connectivity for the Marmaray underground tunnel, a 13.6km long section of the Marmaray rail project. The tunnel connects Europe to Asia via an undersea tunnel crossing the Bosphorus strait. It is of significant strategic importance to Turkey, so a solution was required which would deliver reliable connectivity to the rail operator, the emergency services and commuters. Challenge Undersea tunnels are a challenging environment to provide coverage. Users of the network should The Challenge also not experience loss of communication while The Marmaray tunnel is a 13.6km long undersea tunnel, with three underground entering or exiting the tunnel, which provides an stations along the route. The tunnel connects Europe to Asia via the Bosphorus strait. additional challenge. A solution was required that would be capable of providing consistent and The project required providing public safety services and critical communications to the reliable public safety, cellular and GSM-R emergency services (police, fire service and ambulance service). connectivity throughout the tunnel. With such a critical project, it was also important Cellular connectivity was also required to connect rail passengers using three Turkish that the deployment was completed in time for operator networks, and GSM-R connectivity needed to be provided for the rail operator. the official opening of the tunnel. Therefore, a system was needed that could accommodate multiple radio technologies such as TETRA, UHF and VHF analogue (later migrated to VHF APCO), GSM, UMTS and The Tech GSM-R. -

A Milestone Project: Istanbul Strait Road Tube Crossing

TURKISH PPP EXPERIENCE And A Milestone Project: Istanbul Strait Road Tube Crossing Emre AYKAR President – CICA (Confederation of International Contractors’ Association), Vice President – TCA (Turkish Contractors’ Association) Partner, Member of the Board – Yapı Merkezi September 2, 2015 – Kuwait City Turkish PPP Experience Contents 1. A General Outlook to Turkish PPP Experience with Reference to Major Ongoing PPP Projects 2. Presentation of Istanbul Strait Road Tube Crossing (The Eurasia Tunnel) Project 3. Final Remarks September 2, 2015 – Kuwait City Main Idea of the Presentation How to transform a desirable project on a government wish list to an attractive investment opportunity for potential private sector partner? September 2, 2015 – Kuwait City A General Outlook to Turkish PPP Experience with Reference to Major Ongoing PPP Projects September 2, 2015 – Kuwait City A General Outlook to Turkish PPP Experience Macroeconomic Outlook of Turkey in 2014 Population 76,9 Mil. Annual Pop. Growth 1,3% GDP USD 800 Bil. GDP Growth Rate 2,9% GDP Per Capita USD 10.404 Unemployment Rate 9,48% Inflation Rate 8,17% Exports USD 157,6 Bil. Imports USD 242,2 Bil. Current Account (% of GDP) -5,7% Public Debt (% of GDP) 33,1% Foreign Direct Investment USD 12,5 Bil. Number of Tourists 37 Mil. September 2, 2015 – Kuwait City A General Outlook to Turkish PPP Experience Vast Investment Needs Transportation Energy Education Healthcare Defense Housing September 2, 2015 – Kuwait City A General Outlook to Turkish PPP Experience GDP Growth and GDP Per Capita in -

Kanal İstanbul: Pipedream Or Politics? Actuelles De L‟Ifri

Actuelles de l‟Ifri Kanal İstanbul: This paper examines Kanal İstanbul, a plan proposed Pipedream or Politics? by recently re-elected Turkish Prime Minister Christian Keller Recep Tayyip Erdoğan to bypass the Bosphorus Strait by creating a canal west of Istanbul. stanbul has a history of grandeur. From the Byzantines to the Ottomans, Christian Keller, a recipient of the I the city of Istanbul has been designed as, in the words used by Emperor 2011 James A. Baker III Institute for Napoleon, the capital of the world. There was a sense of grandeur, too, when Public Policy / Leadership Rice Summer Mentorship Experience Prime Minister Recep Tayyip Erdoğan announced the construction of a canal Fellowship, is an intern at Ifri in the Energy Program. He studies Political to bypass the Bosphorus Straits, the maritime highway that bisects the City of Science and Policy Studies, with a concentration in urban politics and Istanbul and brings ships from the Mediterranean to the Black Sea and vice public policy, at Rice University. versa. Named Kanal İstanbul, Erdoğan proposed the project during his re- Ifri is a research center and a election campaign less than two months before the general election as a way forum for debate on the major to relieve stress from Turkey‟s prized city and solve some of the nation‟s most international political and economic issues. Headed by pressing issues. Thierry de Montbrial since its founding in 1979, Ifri is a non governemental and non profit organization. As an indepen- dent think tank, Ifri sets its own The Bosphorus agenda, publishing its findings regurlarly for an international audience. -

Tr 2016 Kasım-Aralık

Kasım / Aralık 2016 November-December 2016 Sayı Issue 11 15 TEMMUZ / July 15th CONTENTS KATMA DEĞER, DEMOKRASİ VE… 26 Dünya ülkeleri arasında birinci ligde olan Türkiye'yi, hain darbe girişimi ile dördüncü hatta beşinci lige indirmeye kalktılar. ADDED VALUE, DEMOCRACY AND… The aim of the heinous coup attempt was to drop Turkey among world countries from the first league to fourth, even fifth league. ŞAŞIRTAN TÜRK PARALARI 13 Ünlü Nümismat Mehmet Tezçakın, dünya DE tarihindeki en ilginç paraları seçti. AMAZING TURKISH CURRENCIES Famous Numismatist Mehmet Tezçakın selected the most interesting currencies in KI world history. LER 4 DERGİ / MAGAZINE TÜRKİYE’NİN KÜLTÜR DERGİSİ MAGAZINE of Culture of Turkey Yunus Emre Vakfı Adına Sahibi Yayın Danışmanı Publisher on Behalf of the YEE Editorial Consultant Yunus Emre Enstitüsü Başkanı Dr. Melike Günyüz President of Yunus Emre Institute Prof. Dr. Şeref Ateş Yönetim Yeri Management Location Sorumlu Yazı İşleri Müdürü Anafartalar Mah. Atatürk Bulvarı Editor in Chief No: 11 Ulus, Ankara Hüseyin Caner Akkurt İletişim Genel Yayın Yönetmeni Contact Executive Editor E-mail: [email protected] YUNUS EMRE ENSTİTÜSÜ Selçuk Turan Faks/Fax: +90 312 309 16 15 Yapım BÜYÜK TÜRK DİLİ Production KURULTAYI YAPILDI 11. Uluslararası Büyük Türk Dili Kurultayı 10 Cube Medya Yayıncılık Tanıtım Macaristan'ın başkentindeki Budapeşte Organizasyon Hizmetleri Tic. Ltd. Şti. Yunus Emre Enstitüsünde gerçekleştirildi. Genel Koordinatör Coordinator GRAND TURKİSH Ömer Arıcı LANGUAGE ASSEMBLY Grup Direktörü Manager HELD Mustafa Özkan 11th International Grand Turkish Language Yayınlar Koordinatörü Editorial Coordinator Assembly was held in Hungarian capital Melih Uslu of Budapest and was hosted by Budapest Sanat Yönetmeni Yunus Emre Enstitüsü. -

Turkey Activity Report 2013

BRAZIL - Activity Report 2012 TURKEY ACTIVITY REPORT 2013 Turkish Road Association (TRA) - Yollar Türk Milli Komitesi (YTMK) KGM Sitesi F Blok Kat: 1, 06100 Yücetepe - Ankara / Turkey E-mail : [email protected] Web: www.ytmk.org.tr TRA is an open association. Its function is to promote, coordinate and spread studies and research in the field of roads, highways, motorways, tunneling and other underground works. TRA was established on January 25, 1990. TRA has been a Member Nation of ITA since 1994. The main activities of the Association can be summarized as follows: - Developing the coordination between related national and international organizations. - Supporting the development of transportation network and transportation infrastructure in Turkey. - Following-up and supporting the latest developments in transportation and all related techniques, design, construction and sharing the knowledge and innovations among related institutions. - Organizing meetings, seminars and congress in order to evaluate and disseminate the accumulated knowledge, scientific and technological developments, in national and international domain. - Collecting, publishing and distributing all sorts of related information to its members in order to rise the road standards up to international level. TURKEY – Activity Report 2013 In Design Phase: Under Construction : New Zigana Tunnel: The Eurasia Tunnel Project: The Istanbul New Zigana Tunnel is under design phase. Strait Road Crossing Project will be The tunnel is twin tube each of which 12800 constructed in Istanbul. 14.6km route m. in length. There will be 23 cross-passages, including a 5.4km twin-deck tunnel with two 24 lay-bay areas, 1 escape tunnel and 2 U- lanes that will cross the Bosphorus beneath Turn passages. -

Eurasia Tunnel Archaeology Museum’S Zeynep S

the diggings were dropped to Yenikapı Archaeological Excavation coastline to be used in the construction of Team and Academic a wall to fill in the area in the sea. The new area that was acquired with filling in of the participants sea was rented to non-Muslims to build Excavations were carried out by a large homes and the revenue was forwarded to group, led by the Head Curator of Istanbul Laleli Mosque Foundation and used for the Eurasia Tunnel Archaeology Museum’s Zeynep S. Kızıltan. mosque’s expenditures. For the sake of the Site supervisors were Assistant Museum completion of this interesting story, finding Curator Rahmi Asal and Museum Among the projects towards amending the of noise pollution. To actualise the Eurasia of the wall was quite important. Because archaeologists Dr. Ö. Emre Öncü, Sırrı growing transportation issues, Eurasia Tunnel Tunnel Project’s design , construction and this brought back to mind a long forgotten Çölmekçi and Emir Son; archaeologists (Istanbul Straight Road Crossing Project) which operations, Directorate of Infrastructure matter about Istanbul’s urban history. There Çiğdem Aydın, Selma Ekşi, Melisa Şirazi, has been one of the biggest undertakings of Investments of the Ministry of Transport, is another characteristic of the wall which is Emek Uğurlar, Ozan Yıldırım, Evren Yıldız, the recent years, connects Asian side to the Maritime Affairs and Communications of important from an architectural perspective. Sinan Yiğit, art historian Alen Maşalı, European side with a 5 km road tunnel crossing Republic of Turkey (AYGM) has commissioned Because in water, especially in harbour restoration archaeologist Murat Akman beneath the seabed.