United States Patent Office Patented Dec

Total Page:16

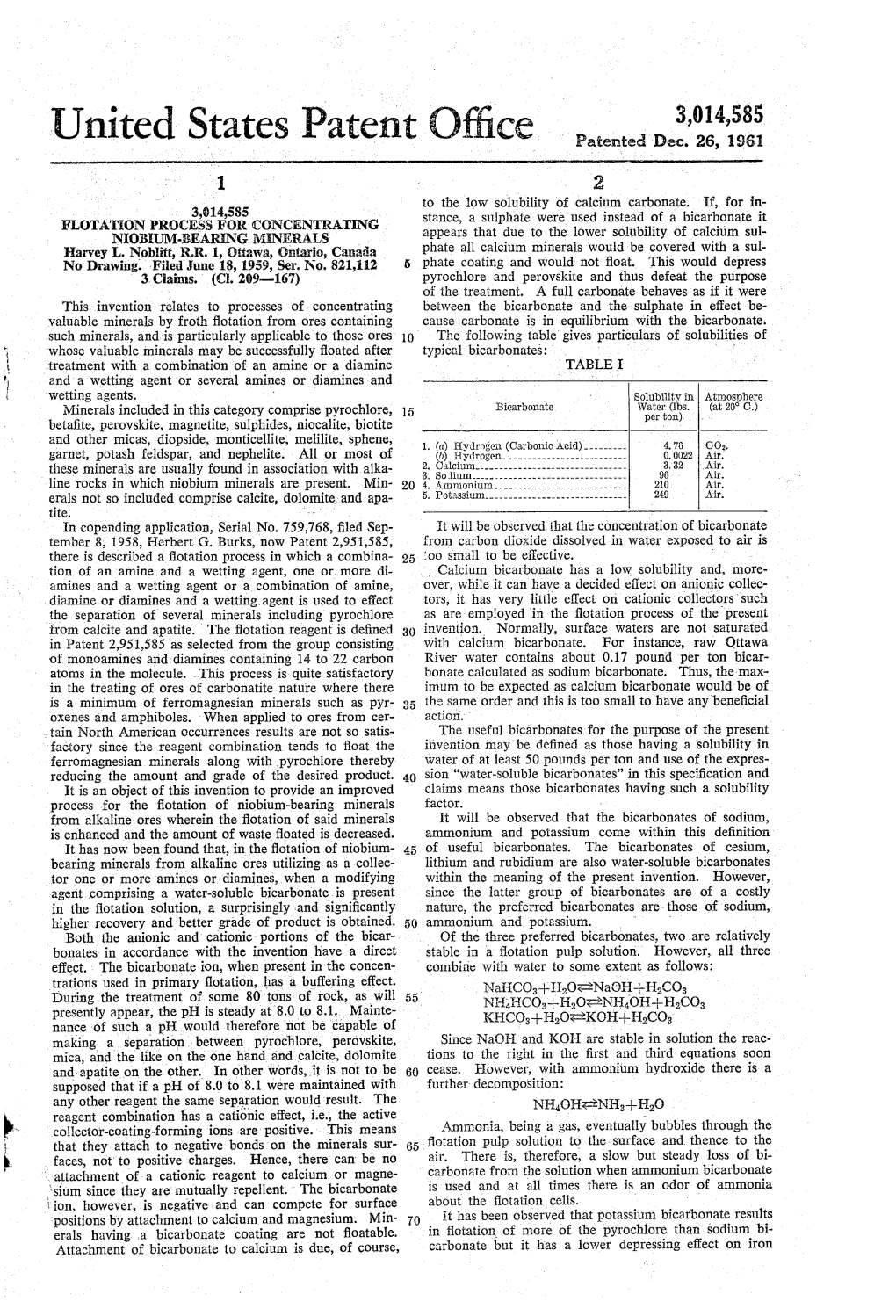

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Washington State Minerals Checklist

Division of Geology and Earth Resources MS 47007; Olympia, WA 98504-7007 Washington State 360-902-1450; 360-902-1785 fax E-mail: [email protected] Website: http://www.dnr.wa.gov/geology Minerals Checklist Note: Mineral names in parentheses are the preferred species names. Compiled by Raymond Lasmanis o Acanthite o Arsenopalladinite o Bustamite o Clinohumite o Enstatite o Harmotome o Actinolite o Arsenopyrite o Bytownite o Clinoptilolite o Epidesmine (Stilbite) o Hastingsite o Adularia o Arsenosulvanite (Plagioclase) o Clinozoisite o Epidote o Hausmannite (Orthoclase) o Arsenpolybasite o Cairngorm (Quartz) o Cobaltite o Epistilbite o Hedenbergite o Aegirine o Astrophyllite o Calamine o Cochromite o Epsomite o Hedleyite o Aenigmatite o Atacamite (Hemimorphite) o Coffinite o Erionite o Hematite o Aeschynite o Atokite o Calaverite o Columbite o Erythrite o Hemimorphite o Agardite-Y o Augite o Calciohilairite (Ferrocolumbite) o Euchroite o Hercynite o Agate (Quartz) o Aurostibite o Calcite, see also o Conichalcite o Euxenite o Hessite o Aguilarite o Austinite Manganocalcite o Connellite o Euxenite-Y o Heulandite o Aktashite o Onyx o Copiapite o o Autunite o Fairchildite Hexahydrite o Alabandite o Caledonite o Copper o o Awaruite o Famatinite Hibschite o Albite o Cancrinite o Copper-zinc o o Axinite group o Fayalite Hillebrandite o Algodonite o Carnelian (Quartz) o Coquandite o o Azurite o Feldspar group Hisingerite o Allanite o Cassiterite o Cordierite o o Barite o Ferberite Hongshiite o Allanite-Ce o Catapleiite o Corrensite o o Bastnäsite -

4Utpo3so UM-P-88/125

4utpo3So UM-P-88/125 The Incorporation of Transuranic Elements in Titanatc Nuclear Waste Ceramics by Hj. Matzke1, B.W. Seatonberry2, I.L.F. Ray1, H. Thiele1, H. Trisoglio1, C.T. Walker1, and T.J. White3'4'5 1 Commission of the European Communities, Joint Research Centre, i Karlsruhe Establishment, ' \ 'I European Institute for Transuranium Elements, Postfach 2340, D-7500 Karlsruhe, Federal Republic of Germany. 2 Advanced Materials Program, Australian Nuclear Science and Technology Organization, Private Mail Bag No. 1, Menai, N.S.W., 2234, Australia. 3 National Advanced Materials Analytical Centre, School of Physics, The University of Melbourne, Parkville, Vic, 3052, Australia. Supported by the Australian Natio-al Energy Research, Development and Demonstration Programme. 4 Member, The American Ceramic Society 5 Author to whom correspondence whould oe addressed 2 The incorporation of actinide elements and their rare earth element analogues in titanatc nuclear waste forms are reviewed. New partitioning data are presented for three waste forms contining Purex waste simulant in combination with either NpC^, PuC>2 or An^Oo. The greater proportion of transuranics partition between perovskitc and ztrconoiite, while some americium may enter loveringite. Autoradiography revealed clusters of plutonium atoms which have been interpreted as unrcacted dioxide or scsquioxide. It is concluded that the solid state behavior of transaranic elements in titanate waste forms is poorly understood; certainly inadequate to tailor a ceramic for the incorporation of fast breeder reactor wastes. A number of experiments are proposed that will provide an adequate, data base for the formulation and fabrication of transuranic-bearing jj [i waste forms. ' ' 1 ~> I. -

Carbonatites of the World, Explored Deposits of Nb and REE—Database and Grade and Tonnage Models

Carbonatites of the World, Explored Deposits of Nb and REE—Database and Grade and Tonnage Models By Vladimir I. Berger, Donald A. Singer, and Greta J. Orris Open-File Report 2009-1139 U.S. Department of the Interior U.S. Geological Survey U.S. Department of the Interior KEN SALAZAR, Secretary U.S. Geological Survey Suzette M. Kimball, Acting Director U.S. Geological Survey, Reston, Virginia: 2009 For product and ordering information: World Wide Web: http://www.usgs.gov/pubprod/ Telephone: 1-888-ASK-USGS For more information on the USGS—the Federal source for science about the Earth, its natural and living resources, natural hazards, and the environment: World Wide Web: http://www.usgs.gov/ Telephone: 1-888-ASK-USGS Suggested citation: Berger, V.I., Singer, D.A., and Orris, G.J., 2009, Carbonatites of the world, explored deposits of Nb and REE— database and grade and tonnage models: U.S. Geological Survey Open-File Report 2009-1139, 17 p. and database [http://pubs.usgs.gov/of/2009/1139/]. Any use of trade, product, or firm names is for descriptive purposes only and does not imply endorsement by the U.S. Government. ii Contents Introduction 1 Rules Used 2 Data Fields 2 Preliminary analysis: —Grade and Tonnage Models 13 Acknowledgments 16 References 16 Figures Figure 1. Location of explored Nb– and REE–carbonatite deposits included in the database and grade and tonnage models 4 Figure 2. Cumulative frequency of ore tonnages of Nb– and REE–carbonatite deposits 14 Figure 3 Cumulative frequency of Nb2O5 grades of Nb– and REE–carbonatite deposits 15 Figure 4 Cumulative frequency of RE2O3 grades of Nb– and REE–carbonatite deposits 15 Figure 4 Cumulative frequency of P2O5 grades of Nb– and REE–carbonatite deposits 16 Tables Table 1. -

A Glossary of Uranium- and Thorium-Bearing Minerals

GEOLOGICAL SURVEY CIRCULAR 74 April 1950 A GLOSSARY OF URANIUM AND THORIUM-BEARING MINERALS By Judith Weiss Frondel and Michael F1eischer UNITED STATES DEPARTMENT OF THE INTERIOR Oscar L. Chapman, Secretary GEOLOGICAL SURVEY W. E. Wrather, Director WASHINGTON. D. C. Free on application to the Director, Geological Survey, Washington 25, D. C. A GLOSSAR-Y OF URANIUM- AND THORIUM-BEARING MINERALS By Judith Weiss Fronde! and Michael Fleischer CONTENTS Introduction ••oooooooooo••••••oo•-•oo•••oo••••••••••oooo•oo••oooooo••oo•oo•oo•oooo••oooooooo•oo• 1 .A. Uranium and thorium minerals oooo oo oo ......................... oo .... oo oo oo oo oo oooooo oo 2 B. Minerals with minor amounts of uranium and thorium 000000000000000000000000.... 10 C. Minerals that should be tested for uranium and thorium ...... 00 .. 00000000000000 14 D. Minerals that are non-uranium- or non-thorium bearing, but that have been reported to contain impurities or intergrowths of uranium, thorium, or rare-earth minerals oooooo•oo ............ oo ... oo .. oooooo'""""oo" .. 0000 16 Index oo ...... oooooo•oo••••oo•oooo•oo•oooo•·~· .. •oooo•oooooooooooo•oooooo•oooooo•oooo••oo•••oooo••• 18 INTRODUCTION The U. S. ·Geological Survey has for some time been making a systematic survey of da~ pertaining to uranium and thorium minerals and to those minerals that contain trace1 or more of uranium and thorium. This survey consists of collecting authoritative chemical, optical, and X-ray diffraction data from the literature and of adding to these data, where inadequate, by work in the laboratory. The results will he reported from time to time, and the authors welcome in- formation on additional data and names. -

Investigations Into the Synthesis, Characterisation and Uranium Extraction of the Pyrochlore Mineral Betafite

Investigations into the Synthesis, Characterisation and Uranium Extraction of the Pyrochlore Mineral Betafite. A thesis submitted for the fulfilment of the requirements for the degree of Doctor of Philosophy (Ph.D.) Scott Alan McMaster B.Sc (App Chem) B.Sc (App Sci) (Hons) School of Applied Sciences College of Science, Engineering and Health RMIT University February 2016 II I Document of authenticity I certify that except where due acknowledgement has been made, the work is that of the author alone; the work has not been submitted previously, in whole or in part, to qualify for any other academic award; the content of the thesis is a result of work which has been carried out since the official commencement date of the approved research program; and, any editorial work, paid or unpaid, carried out by a third party is acknowledged. Scott A. McMaster February 2016 II Acknowledgements The research conducted in this thesis would not have been possible without the help of a number of people, and I would like to take this opportunity to personally thank them. Firstly, I’d like to thank my primary supervisor Dr. James Tardio; you have provided me with endless support and help throughout my 3rd year undergraduate research, honours and PhD candidature. Your enthusiasm, ideas, and patience have been essential in producing a thesis I can say I’m truly proud of. To Prof. Suresh Bhargava, I cannot thank you for your guidance and the opportunities that you have given me enough. You have taught me so much about being a good scientific communicator which I believe is one of the most valuable qualities I have gained throughout my candidature, for that I am extremely grateful. -

Glossary of Obsolete Mineral Names

Uaranpecherz = uraninite, László 282 (1995). überbasisches Cuprinitrat = gerhardtite, Hintze I.3, 2741 (1916). überbrannter Amethyst = heated 560ºC red-brown Fe-rich quartz, László 11 (1995). Überschwefelblei = galena + anglesite + sulphur-α, Chudoba RI, 67 (1939); [I.3,3980]. uchucchacuaïte = uchucchacuaite, MR 39, 134 (2008). uddervallite = pseudorutile, Hey 88 (1963). uddevallite = pseudorutile, Dana 6th, 218 (1892). uddewallite = pseudorutile, Des Cloizeaux II, 224 (1893). udokanite = antlerite, AM 56, 2156 (1971); MM 43, 1055 (1980). uduminelite (questionable) = Ca-Al-P-O-H, AM 58, 806 (1973). Ueberschwefelblei = galena + anglesite + sulphur-α, Egleston 132 (1892). Uekfildit = wakefieldite-(Y), Chudoba EIV, 100 (1974). ufalit = upalite, László 280 (1995). uferite = davidite-(La), AM 42, 307 (1957). ufertite = davidite-(La), AM 49, 447 (1964); 50, 1142 (1965). U-free thorite = huttonite, Clark 303 (1993). U-galena = U-rich galena, AM 20, 443 (1935). ugandite = bismutotantalite, MM 22, 187 (1929). ughvarite = nontronite ± opal-C, MAC catalog 10 (1998). ugol = coal, Thrush 1179 (1968). ugrandite subgroup = uvarovite + grossular + andradite ± goldmanite ± katoite ± kimzeyite ± schorlomite, MM 21, 579 (1928). uhel = coal, Thrush 1179 (1968). Uhligit (Cornu) = colloidal variscite or wavellite, MM 18, 388 (1919). Uhligit (Hauser) = perovskite or zirkelite, CM 44, 1560 (2006). U-hyalite = U-rich opal, MA 15, 460 (1962). Uickenbergit = wickenburgite, Chudoba EIV, 100 (1974). uigite = thomsonite-Ca + gyrolite, MM 32, 340 (1959); AM 49, 223 (1964). Uillemseit = willemseite, Chudoba EIV, 100 (1974). uingvárite = green Ni-rich opal-CT, Bukanov 151 (2006). uintahite = hard bitumen, Dana 6th, 1020 (1892). uintaite = hard bitumen, Dana 6th, 1132 (1892). újjade = antigorite, László 117 (1995). újkrizotil = chrysotile-2Mcl + lizardite, Papp 37 (2004). új-zéalandijade = actinolite, László 117 (1995). -

A Specific Gravity Index for Minerats

A SPECIFICGRAVITY INDEX FOR MINERATS c. A. MURSKyI ern R. M. THOMPSON, Un'fuersityof Bri.ti,sh Col,umb,in,Voncouver, Canad,a This work was undertaken in order to provide a practical, and as far as possible,a complete list of specific gravities of minerals. An accurate speciflc cravity determination can usually be made quickly and this information when combined with other physical properties commonly leads to rapid mineral identification. Early complete but now outdated specific gravity lists are those of Miers given in his mineralogy textbook (1902),and Spencer(M,i,n. Mag.,2!, pp. 382-865,I}ZZ). A more recent list by Hurlbut (Dana's Manuatr of M,i,neral,ogy,LgE2) is incomplete and others are limited to rock forming minerals,Trdger (Tabel,l,enntr-optischen Best'i,mmungd,er geste,i,nsb.ildend,en M,ineral,e, 1952) and Morey (Encycto- ped,iaof Cherni,cal,Technol,ogy, Vol. 12, 19b4). In his mineral identification tables, smith (rd,entifi,cati,onand. qual,itatioe cherai,cal,anal,ys'i,s of mineral,s,second edition, New york, 19bB) groups minerals on the basis of specificgravity but in each of the twelve groups the minerals are listed in order of decreasinghardness. The present work should not be regarded as an index of all known minerals as the specificgravities of many minerals are unknown or known only approximately and are omitted from the current list. The list, in order of increasing specific gravity, includes all minerals without regard to other physical properties or to chemical composition. The designation I or II after the name indicates that the mineral falls in the classesof minerals describedin Dana Systemof M'ineralogyEdition 7, volume I (Native elements, sulphides, oxides, etc.) or II (Halides, carbonates, etc.) (L944 and 1951). -

Zirconolite, Calzirtite, Baddeleyite, Betafite, Geikielite and Qandilite In

Geophysical Research Abstracts, Vol. 10, EGU2008-A-06674, 2008 SRef-ID: 1607-7962/gra/EGU2008-A-06674 EGU General Assembly 2008 © Author(s) 2008 Zirconolite, calzirtite, baddeleyite, betafite, geikielite and qandilite in skarn ejecta from Vesuvius - inferences for the magma-wallrock interactions. M.-L. Pascal (1), A. Di Muro (1), O. Boudouma (2), M. Fonteilles (1), C. Principe (3) (1) PMMP - CNRS UMR 7160, Université Pierre et Marie Curie, Paris, France, (2) Camparis, Université Pierre et Marie Curie, Paris, France, (3) CNR Istituto di Geoscienze e Georisore, Pisa, Italy ([email protected]) Zirconolite CaZrTi2O7, calzirtite Ca2Zr5Ti2O16, baddeleyite ZrO2, betafite (Ca,U,Th)2(Ti,Nb)2O6(OH)2, perovskite, geikielite MgTiO3 and qandilite Mg2TiO4 occur as minute crystals in a special type of finely banded skarn (forsterite- spinel/calcite), ejected by explosive eruptions of Vesuvius such as Avellino (3550 BC) and 1631. These skarns occur in contact with more-or-less contaminated magmatic rocks (pyroxenites, syenites, tephriphonolites), from which they are separated by a phlogopite reaction rim, and display mineralogical zonings that provide insights on their mode of formation. One type of zoning is characterized by Ti-, Nb- and (U,Th)-rich oxides (Nb- perovskite, zirconolite) occurring close to (< 2 mm) the phlogopite rim and the origi- nally magmatic rock, whereas those oxides observed farther (> 1cm) are Zr-rich and (Ti, Nb, U, Th)-poor or free (calzirtite, then baddeleyite). Qandilite, which occurs at some distance from the magmatic rock, is observed to result from desilication of the perovskite+forsterite association. The (Fe, Ti) contents of spinel and qandilite de- crease at increasing distance from the magmatic rock. -

Euxenite-(Y) (Y, Ca, Ce, U, Th)(Nb, Ta, Ti)2O6 C 2001-2005 Mineral Data Publishing, Version 1 Crystal Data: Orthorhombic; Typically Metamict

Euxenite-(Y) (Y, Ca, Ce, U, Th)(Nb, Ta, Ti)2O6 c 2001-2005 Mineral Data Publishing, version 1 Crystal Data: Orthorhombic; typically metamict. Point Group: 2/m 2/m 2/m. As stout prismatic crystals, to 10 cm, may be flattened k [100] or [010]; commonly in parallel, subparallel, or radiating aggregates; compact massive. Twinning: Common on {201}; rare on {101} or {013}. Physical Properties: Fracture: Conchoidal to subconchoidal. Tenacity: Brittle. Hardness = 5.5–6.5 VHN = 633–692 (50 g load). D(meas.) = 5.3–5.9 D(calc.) = [5.16] Radioactive. Optical Properties: Opaque, translucent on thin edges. Color: Black, brownish black, greenish black; brown to yellow-brown in transmitted light. Streak: Yellowish, grayish, or reddish brown. Luster: Brilliant submetallic, waxy to resinous on fractures. Optical Class: Isotropic. n = 2.06–2.24 R1–R2: (470) 13.7–15.6, (546) 13.0–15.6, (589) 12.5–15.0, (650) 12.4–15.0 Cell Data: Space Group: P cmn (synthetic YNbTiO6). a = 5.5528(6) b = 14.6432(20) c = 5.1953(7) Z = 4 X-ray Powder Pattern: Risør, Norway; after heating at 1200 ◦C. 2.99 (100), 3.66 (40), 2.95 (40), 2.60 (30), 1.830 (30), 1.727 (30), 2.78 (25) Chemistry: (1) (1) (1) UO3 0.04 SnO2 0.12 MnO 0.59 Nb2O5 41.43 UO2 0.67 PbO 0.37 Ta2O5 3.84 Al2O3 0.13 MgO 0.13 SiO2 0.07 Ce2O3 4.34 CaO 4.86 + TiO2 16.39 (Y, Er)2O3 18.22 H2O 1.90 − ThO2 4.95 Fe2O3 1.32 H2O 0.06 ZrO2 0.04 FeO 0.77 Total 100.24 (1) Lyndoch Township, Ontario, Canada. -

A Study of Pyrochlore and Betafite

A STUDYOF PYROCHLOREAND BETAFITE D. D. HOGARTH Unhsersityof Ottawo, Ottowa' Canad'a ASSIRACT several types canadian occur- Pvrochlore and betafrte were investigated from 9f eleven analyses for eight con- ,*iJ"""1it* ;;;G; f;t*;;ty ;nstituents and oH)18(F' oH)s is proposedfor stituenta are presented.2i;;;il;l*;lu-i*-"n'u(o' sites in the unit cell. Differen- the pyrochlore-betafite serie"switlr r representing vaLnt two states of water' Betafite and tial thermal and thermogravimetric curves indicate can begin w-ell the exo' thorian pyrochlore tt" t"l,i-i.i, id"i recrrs4li'ation .below edge of ignitea minerals tends to thermic reaction indicateiln b.r.n. ."*o. The cell *"ig-ttt" dirived from densitv-cell decrease as titanium i;;i;;;;;. Molec'lar ""i irom analyses. Observed r-ray edee data correspond q""fiilii""i' a. ii,o"e .al"ul"ted role of iron is uncertain. Frequency il1;#;;";;irh;d;;J;.iues, but the and betafite at 15 per cent uranium. dragrams suggesr u ,ru.ur;l*Jio-i;io" Jpyro"hloru Iutnoouctton long been disputed' The relationship of pyrochlore and betafite has betafite are very X-ray powder patterns of pyrochlore and ignited quite different. Pertinent ,i*if", tut chemical compositions are usually (1932), who showed chemical work has U""" i"ported by Machatschki flom stoichio- that membersof the;yro"hlo." seriesdepart considerably that vacant cationic ;"ary, and Ros6n &'W""tg'"" (1938), who showed structure' Borodin & sites are common it with the pyrochlore "o*pJt"ds structure occurs in Nazarenko (1957) mainiain that this type of defect the pyrochlore series natural pyrochlore. -

Geochemistry of Niobium and Tantalum

Geochemistry of Niobium and Tantalum GEOLOGICAL SURVEY PROFESSIONAL PAPER 612 Geochemistry of Niobium and Tantalum By RAYMOND L. PARKER and MICHAEL FLEISCHER GEOLOGICAL SURVEY PROFESSIONAL PAPER 612 A review of the geochemistry of niobium and tantalum and a glossary of niobium and tantalum minerals UNITED STATES GOVERNMENT PRINTING OFFICE, WASHINGTON : 1968 UNITED STATES DEPARTMENT OF THE INTERIOR STEWART L. UDALL, Secretary GEOLOGICAL SURVEY William T. Pecora, Director Library of Congress catalog-card No. GS 68-344 For sale by the Superintendent of Documents, U.S. Government Printing Office Washington, D.C. 20402 - Price 50 cents (paper cover) CONTENTS Page Page Abstract_ _ __-_.. _____________________ 1 Geochemical behavior Continued Introduction. _________________________ 2 Magmatic rocks Continued General geochemical considerations. _____ 2 Volcanic rock series______--____---__.__-_-__ 2. Abundance of niobium and tantalum_____ 3 Sedimentary rocks______________________________ 2. Crustal abundance-________________ 3 Deposits of niobium and tantalum.___________________ 2£ Limitations of data________________ 3 Suggestions for future work__--___-_------__-___---_- 26 Abundance in rocks._______________ 5 References, exclusive of glossary______________________ 27 Qualifying statement.__________ 5 Glossary of niobium and tantalum minerals.___________ 3C Igneous rocks_________________ 6 Part I Classification of minerals of niobium and Sedimentary rocks.____________ 10 tantalum according to chemical types_________ 31 Abundance in meteorites and tektites. 12 Part II Niobium and tantalum minerals..-_______ 32 Isomorphous substitution.______________ 13 Part III Minerals reported to contain 1-5 percent Geochemical behavior._________________ 15 niobium and tantalum_______________________ 38 Magma tic rocks ___________________ 15 Part IV Minerals in which niobium and tantalum Granitic rocks_________________ 16 have been detected in quantities less than 1 Albitized and greisenized granitic rocks. -

Mineral Chemistry and Evolution of Niobium Minerals from the Miaoya Carbonatite Complex, China

Goldschmidt2020 Abstract Mineral chemistry and evolution of niobium minerals from the Miaoya carbonatite complex, China YUAN-CAN YING1, WEI CHEN1, SHAO-YONG JIANG1 1 State Key laboratory of Geological Process and Mineral Resources, China University of Geosciences, 430074 Wuhan, China (correspondence: [email protected]) The Miaoya carbonatite complex is located at the southwestern margin of the Wudang Terrane along the southern edge of South Qinling orogen. The complex composes of both carbonatite and syenite and hosts abundant REE and Nb mineralization with estimated reserve of 1.21 Mt REE2O3 at 1.72 wt.% and 0.93 Mt Nb2O5 at 0.12 wt.%. Detailed petrographic and chemical investigations of Nb-bearing minerals at Miaoya are presented with the aim to identify the distribution and evolution of Nb mineralization. At Miaoya, Nb mineralization is predominantly hosted by carbonatite and shows a heterogeneous distribution varying from sample to sample. The main Nb-bearing minerals are columbite and Nb-rutile, with minor uranpyrochlore, betafite, fersmite, fergusonite, aeschynite and euxenite. The most dominant Nb- mineral is columbite, and both primary and secondary grains are identified. Primary columbite occur as disseminated grains or intergrow with fersmite, and have low Ta2O5 contents (< 1.0 wt.%). Secondary columbite are mostly pseudomorphs of the octahedral pyrochlore-group minerals, which are cavernous or atoll-like and contain pockets infilled with secondary calcite and apatite. They display variable Nb2O5 and FeO compositions (67.2~71.2 wt.% and 18.4~19.7 wt.%, respectively) and contain higher Ta2O5 contents (2.3 wt.% in average) compared to that of primary columbite. Nb-rutile grains are usually anhedral and disseminated in both carbonatite and syenite, which usually intergrow with biotite and ilmenite or occur as exsolutions of pyrochlore and betafite.