Statement of Qualifications

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Fire Service Features of Buildings and Fire Protection Systems

Fire Service Features of Buildings and Fire Protection Systems OSHA 3256-09R 2015 Occupational Safety and Health Act of 1970 “To assure safe and healthful working conditions for working men and women; by authorizing enforcement of the standards developed under the Act; by assisting and encouraging the States in their efforts to assure safe and healthful working conditions; by providing for research, information, education, and training in the field of occupational safety and health.” This publication provides a general overview of a particular standards- related topic. This publication does not alter or determine compliance responsibilities which are set forth in OSHA standards and the Occupational Safety and Health Act. Moreover, because interpretations and enforcement policy may change over time, for additional guidance on OSHA compliance requirements the reader should consult current administrative interpretations and decisions by the Occupational Safety and Health Review Commission and the courts. Material contained in this publication is in the public domain and may be reproduced, fully or partially, without permission. Source credit is requested but not required. This information will be made available to sensory-impaired individuals upon request. Voice phone: (202) 693-1999; teletypewriter (TTY) number: 1-877-889-5627. This guidance document is not a standard or regulation, and it creates no new legal obligations. It contains recommendations as well as descriptions of mandatory safety and health standards. The recommendations are advisory in nature, informational in content, and are intended to assist employers in providing a safe and healthful workplace. The Occupational Safety and Health Act requires employers to comply with safety and health standards and regulations promulgated by OSHA or by a state with an OSHA-approved state plan. -

Development News Highlights MANHATTAN - MID-2ND QUARTER 2019 PLUS an OUTER BOROUGH SNAPSHOT

Development News Highlights MANHATTAN - MID-2ND QUARTER 2019 PLUS AN OUTER BOROUGH SNAPSHOT Pictured: 315 Meserole Street Looking Ahead U.S. Treasury Releases Additional Opportunity Zones Guidelines On April 17th the U.S. Department of the Treasury issued a highly anticipated second set of proposed regulations related to the new Opportunity Zone (OZ) tax incentive. Created by the 2017 Tax Cuts and Jobs Act, the tax benefi t is designed to drive economic development and create jobs by encouraging long-term investments in economically distressed communities nationwide according to the Treasury department’s press release. The latest 169-page release reportedly delivered guidance in a broader range of areas than many expected, hoping to provide investors who have been on the fence with the clarity needed to begin developing projects in distressed areas nationwide. Some government offi cials anticipate the program could spur $100 billion in new investment into the more than 8,762 zones nationwide, of which 306 are located in New York City; however there exist some concerns among critics that the program will incentivize gentrifi cation, or provide added benefi t to developers for projects they would have been pursued anyway. According to the press release by the Internal Revenue Service (IRS), a key part of the newly released guidance clarifi es the “substantially all” requirements for the holding period and use of the tangible business property: • For use of the property, at least 70% of the property must be used in a qualifi ed OZ. • For the holding period of the property, tangible property must be qualifi ed opportunity zone business property for at least 90% of the Qualifi ed Opportunity Fund’s (QOF) or qualifi ed OZ business’s holding period. -

The World Trade Center, Then the World's Tallest Building, Was Built in Lower Manhattan in the Early 1970'S (Figure K – Su

Bedrock Control of a Boulder-Filled Valley Under the World Trade Center Site Cheryl J. Moss, Mueser Rutledge Consulting Engineers, 14 Penn Plaza, New York, NY 10122 ([email protected]), and, Charles Merguerian, Geology Department, 114 Hofstra University, Hempstead, NY 11549 ([email protected]; [email protected]) INTRODUCTION Then the world’s tallest buildings, the former World Trade Center Twin Towers were built in lower Manhattan in the early 1970’s. A new construction technology at the time, a slurry wall socketed into the bedrock was built to enable the Twin Towers construction. A geotechnical investigation undertaken for the project suggested that the site geology would be fairly typical for New York City. During construction of the slurry wall, however, an unexpected feature was discovered. In the southeast corner of the site the wall cut through a ledge of schistose bedrock and entered a curved, roughly E-W-trending valley filled with well- rounded glacial boulders and cobbles (Figure 1). The slurry wall had to be excavated deeper in two places to get through the boulders and socket back into solid bedrock. The trend of the valley is unusual because other known glacial valleys across Manhattan trend NW-SE including a nearby valley we reported on earlier (Moss and Merguerian 2006). When it was time to plan reconstruction of the new World Trade Center development, it was clear that extra attention would have to be focused on the southeast quadrant. The unusual geologic conditions present could pose significant difficulties for new design and construction. A more extensive boring program was undertaken by Mueser Rutledge Consulting Engineers, geotechnical engineers for the WTC Memorial and Towers 1, 2, 3 and 4. -

APC WTC Thesis V8 090724

A Real Options Case Study: The Valuation of Flexibility in the World Trade Center Redevelopment by Alberto P. Cailao B.S. Civil Engineering, 2001 Wentworth Institute of Technology Submitted to the Center for Real Estate in Partial Fulfillment of the Requirements for the Degree of Master of Science in Real Estate Development at the Massachusetts Institute of Technology September 2009 ©2009 Alberto P. Cailao All rights reserved. The author hereby grants MIT permission to reproduce and distribute publicly paper and electronic copies of this thesis document in whole or in part in any medium now known or hereafter created. Signature of Author________________________________________________________________________ Center for Real Estate July 24, 2009 Certified by_______________________________________________________________________________ David Geltner Professor of Real Estate Finance, Department of Urban Studies and Planning Thesis Supervisor Accepted by_____________________________________________________________________________ Brian A. Ciochetti Chairman, Interdepartmental Degree Program in Real Estate Development A Real Options Case Study: The Valuation of Flexibility in the World Trade Center Redevelopment by Alberto P. Cailao Submitted to the Center for Real Estate on July 24, 2009 in Partial Fulfillment of the Requirements for the Degree of Master of Science in Real Estate Development Abstract This thesis will apply the past research and methodologies of Real Options to Tower 2 and Tower 3 of the World Trade Center redevelopment project in New York, NY. The qualitative component of the thesis investigates the history behind the stalled development of Towers 2 and 3 and examines a potential contingency that could have mitigated the market risk. The quantitative component builds upon that story and creates a hypothetical Real Options case as a framework for applying and valuing building use flexibility in a large-scale, politically charged, real estate development project. -

'The Disappeared'

‘The disappeared’ Power over the dead in the aftermath of 9/11 Chip Colwell- The issue of disposition of and control over human way by family, these remains point to disappeared individ- Chanthaphonh remains is a sensitive subject in all human societies, usu- uals, left in limbo as the result of a terrorist attack. The fol- Chip Colwell-Chanthaphonh ally marked by taboos and rituals. That the unidentified lowing article by Chip Colwell-Chanthaphonh, advocate is Curator of Anthropology at human remains from the World Trade Center destruction for four 9/11 family advocacy groups, receives a response the Denver Museum of Nature should generate controversy is therefore not surprising. from Alice M. Greenwald, director of the 9/11 Memorial and Science. Since 2009, he has been an adviser to four Without the possibility of burial or cremation in the usual Museum. Editor 9/11 family advocacy groups, which have sought to consult On the morning of 11 September 2001, Scott Kopytko, with the 9/11 Museum on the human-remains issue. His a 32-year-old firefighter, was returning to his station in email is [email protected]. New York’s South Street Seaport just as fire engines were pulling out. Scott had been a firefighter for almost three years. It was the happiest period of his life. Though he was just coming back, no doubt exhausted, from a night shift, Scott soon realized that something big was happening on that bright September morning. He felt a duty to join his fellow firefighters, and as his vehicle was leaving, he told a probationary firefighter, ‘Get off, you’re in my spot’, leaping on in the rookie’s place. -

Sacred Secular Relics: World Trade Center Steel in Off-Site 9/11 Memorials in the United States

SACRED SECULAR RELICS: WORLD TRADE CENTER STEEL IN OFF-SITE 9/11 MEMORIALS IN THE UNITED STATES by Senem Guler-Biyikli B.A. in Business Administration, Koç University, 2008 M.A. in Anatolian Civilizations & Cultural Heritage Management, Koç University, 2010 Submitted to the Graduate Faculty of the Dietrich School of Arts and Sciences in partial fulfillment of the requirements for the degree of Doctor of Philosophy University of Pittsburgh 2017 UNIVERSITY OF PITTSBURGH THE DIETRICH SCHOOL OF ARTS AND SCIENCES This dissertation was presented by Senem Guler-Biyikli It was defended on December 5, 2016 and approved by Bryan K. Hanks, Associate Professor, Anthropology Laura C. Brown, Assistant Professor, Anthropology Kirk Savage, Professor, History of Art & Architecture Dissertation Advisor: Robert M. Hayden, Professor, Anthropology ii Copyright © by Senem Guler-Biyikli 2017 iii SACRED SECULAR RELICS: WORLD TRADE CENTER STEEL IN OFF-SITE 9/11 MEMORIALS IN THE UNITED STATES Senem Guler-Biyikli, PhD University of Pittsburgh, 2017 This dissertation analyzes material practices in the commemoration of violence and trauma through a focus on the memorialization of World Trade Center (WTC) structural steel across the United States to form hundreds of local 9/11 monuments. Less than one percent of the steel artifacts collected from the WTC site was reconfigured as sacred relics and became the focal elements of local memorials, while the rest was sold and recycled as scrap. Based on ten months of fieldwork at such local memorials primarily in the Northeastern United States, the study documents the artifacts’ memorialization, and discusses the socio-cultural factors involved in their transformation from rubble to sacred relics. -

As Lower Manhattan Rebuilds, a New Map Takes Shape

ID NAME: Nxxx,2004-07-04,A,024,Bs-BW,E2 3 7 15 25 50 75 85 93 97 24 Ø N THE NEW YORK TIMES METRO SUNDAY, JULY 4, 2004 CITY A Status Report: As Lower Manhattan Rebuilds, a New Map Takes Shape By DAVID W. DUNLAP and GLENN COLLINS Below are projects in and around ground DEVELOPMENT PLAN zero and where they stood as of Friday. Embassy Goldman Suites Hotel/ Sachs Bank of New York BUILDINGS UA Battery Park Building Technology and On the World Trade Center site City theater site 125 Operations Center PARKS GREENWICH ST. 75 Park Place Barclay St. 101 Barclay St. (A) FREEDOM TOWER / TOWER 1 2 MURRAY ST. Former site of 6 World Trade Center, the 6 United States Custom House 0Feet 200 Today, the cornerstone will be laid for this WEST BROADWAY skyscraper, with about 60,000 square feet of retail space at its base, followed by 2.6 mil- Fiterman Hall, lion square feet of office space on 70 stories, 9 Borough of topped by three stories including an obser- Verizon Building Manhattan PARK PL. vation deck and restaurants. Above the en- 4 World 140 West St. Community College closed portion will be an open-air structure Financial 3 5 with wind turbines and television antennas. Center 7 World The governor’s office is a prospective ten- VESEY ST. BRIDGE Trade Center 100 Church St. ant. Occupancy is expected in late 2008. The WASHINGTON ST. 7 cost of the tower, apart from the infrastruc- 3 World 8 BARCLAY ST. ture below, is estimated at $1 billion to $1.3 Financial Center billion. -

Negotiating the Mega-Rebuilding Deal at the World Trade Center: the Historical Context

NEGOTIATING THE MEGA-REBUILDING DEAL AT THE WORLD TRADE CENTER: THE HISTORICAL CONTEXT ALEX GARVIN * The decline of lower Manhattan as a business district relative to Midtown (and other United States business districts) became apparent after World War II. In the decade between 1947 and 1956, 15.1 million square feet of new office space— more than existed in the Loop in Chicago, the nation‘s second largest office district—was erected in Midtown. During that time, only 1.1 million square feet of office space was erected in lower Manhattan in three modest office structures and one six-story addition.1 The situation was so serious that in 1952, the Journal of Commerce published articles predicting that businesses would soon relocate from lower Manhattan to Midtown.2 The attempt to revive Lower Manhattan is central to an understanding of the World Trade Center. The first significant post-war revival effort came in November of 1955, when the Chase Manhattan Bank (under the leadership of David Rockefeller) announced that it would consolidate its nine-building, 8,700-employee operations on the two blocks bounded by Nassau, Liberty, William, and Pine Streets. The scheme that emerged was a superblock designed by the firm of Skidmore, Owings & Merrill. A one-block section of Cedar Street was closed, creating a 2.5- acre site to be shared by a new 60-story, 1.7 million-square-foot office slab; the existing 38-story building that had housed Chase headquarters since 1928; and a new, spacious plaza. Between 1960, when the new Chase Manhattan Bank Building was ready for occupancy, and 1972, the year before World Trade Center was officially dedicated, * Alexander Garvin is President and CEO of Alex Garvin & Associates, Inc. -

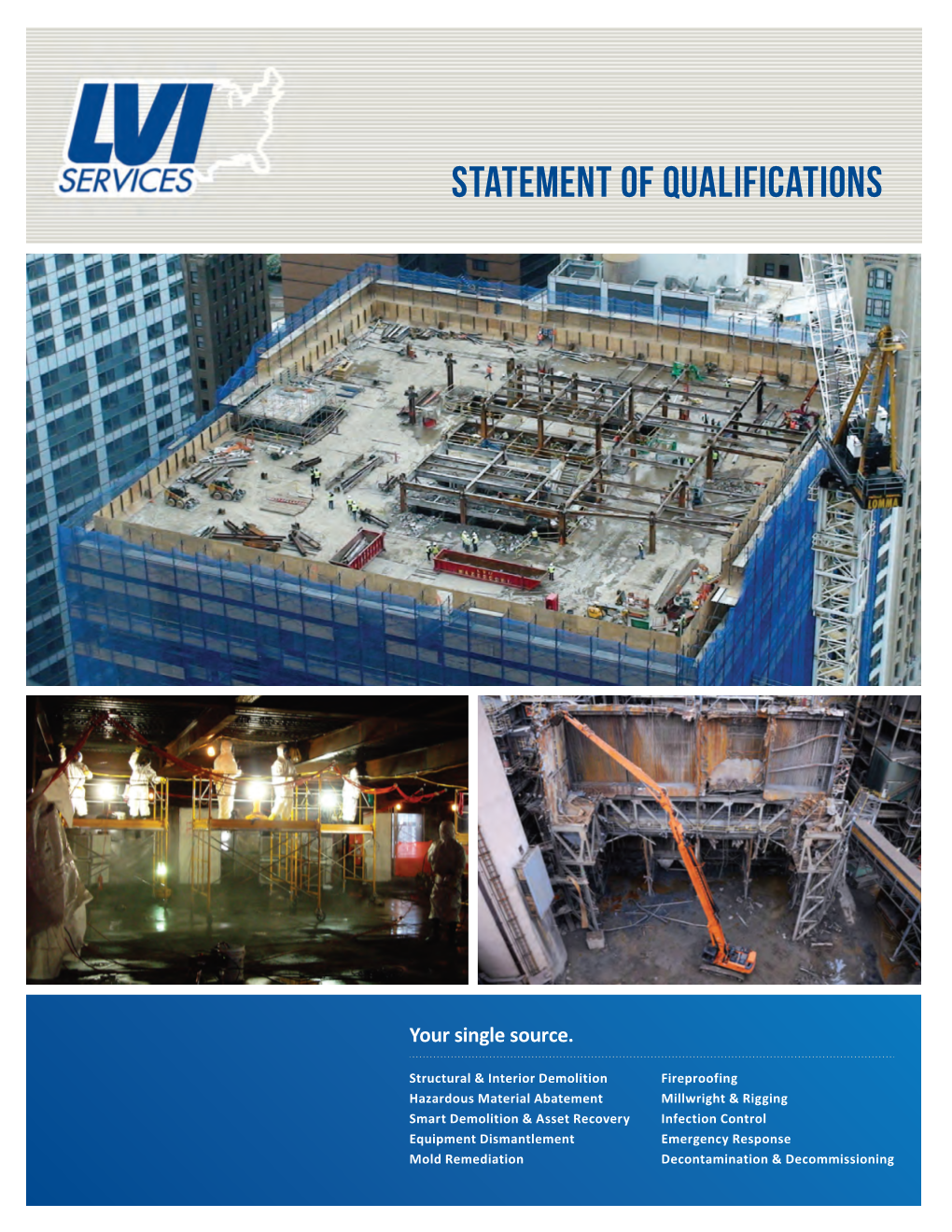

COMMERCIAL Experience 130 Liberty Street, Deutsche Bank Building | New York, NY

COMMERCIAL experience 130 Liberty Street, deutsche bank building | New York, NY 15-story gash created from WTC debris on 9/11 In April 2010, LVI completed the deconstruction to the 18th floor In January 2008, LVI began decontamination and decon- 26 Stories, 1.1 Million Square Foot of Unoccupied 40-Story struction of the remaining 26 stories of the Deutsche Bank Commercial High-Rise Building Building at 130 Liberty Street in Lower Manhattan, which January 2008 – February 2011 was badly damaged from the collapse of 2 World Trade $95,000,000 Abatement Center during the 9/11 terrorist attacks. $25,000,000 Demolition After sitting derelict for five years following 9/11, the building was deemed unsal- Bovis Lend Lease vageable. Another contractor began abatement and deconstruction of the 40-story building in 2006, and deconstructed to the 26th floor. After a fire in August 2007, which left extensive smoke and water damage, LVI was brought in to finish the job. Demolition DECONTAMINATION OF A TOXIC ENVIRONMENT Hazardous Material Abatement LVI’s first task was to remediate the smoke and fire damage. Phase I for the cleaning and decontamination of the remaining floors completed in September 2009. Concrete Recycling Conditions were toxic. On 9/11, the building’s facade endured a 15-story gash from the propelled debris. The gaping hole exposed the interior of the building to the debris ash from the felled WTC towers. Open exposure to rain and snow plus the 300 Workers, Multiple Shifts building’s own sprinkler system added excessive water inside the building creating 6 Days Per Week unabated black mold growth. -

Long-Term Health Impacts from September 11: a Review of Treatment, Diagnosis, and Monitoring Efforts Hearing

S. HRG. 110–197 LONG-TERM HEALTH IMPACTS FROM SEPTEMBER 11: A REVIEW OF TREATMENT, DIAGNOSIS, AND MONITORING EFFORTS HEARING OF THE COMMITTEE ON HEALTH, EDUCATION, LABOR, AND PENSIONS UNITED STATES SENATE ONE HUNDRED TENTH CONGRESS FIRST SESSION ON EXAMINING A REVIEW OF TREATMENT, DIAGNOSIS, AND MONITORING EFFORTS, FOCUSING ON THE LONG-TERM HEALTH IMPACTS FROM SEPTEMBER 11 MARCH 21, 2007 Printed for the use of the Committee on Health, Education, Labor, and Pensions ( Available via the World Wide Web: http://www.gpoaccess.gov/congress/senate U.S. GOVERNMENT PRINTING OFFICE 34–458 PDF WASHINGTON : 2008 For sale by the Superintendent of Documents, U.S. Government Printing Office Internet: bookstore.gpo.gov Phone: toll free (866) 512–1800; DC area (202) 512–1800 Fax: (202) 512–2104 Mail: Stop IDCC, Washington, DC 20402–0001 VerDate Aug 31 2005 16:08 Jul 30, 2008 Jkt 000000 PO 00000 Frm 00001 Fmt 5011 Sfmt 5011 S:\DOCS\34458.TXT SLABOR1 PsN: DENISE COMMITTEE ON HEALTH, EDUCATION, LABOR, AND PENSIONS EDWARD M. KENNEDY, Massachusetts, Chairman CHRISTOPHER J. DODD, Connecticut MICHAEL B. ENZI, Wyoming, TOM HARKIN, Iowa JUDD GREGG, New Hampshire BARBARA A. MIKULSKI, Maryland LAMAR ALEXANDER, Tennessee JEFF BINGAMAN, New Mexico RICHARD BURR, North Carolina PATTY MURRAY, Washington JOHNNY ISAKSON, Georgia JACK REED, Rhode Island LISA MURKOWSKI, Alaska HILLARY RODHAM CLINTON, New York ORRIN G. HATCH, Utah BARACK OBAMA, Illinois PAT ROBERTS, Kansas BERNARD SANDERS (I), Vermont WAYNE ALLARD, Colorado SHERROD BROWN, Ohio TOM COBURN, M.D., Oklahoma J. MICHAEL MYERS, Staff Director and Chief Counsel KATHERINE BRUNETT MCGUIRE, Minority Staff Director (II) VerDate Aug 31 2005 16:08 Jul 30, 2008 Jkt 000000 PO 00000 Frm 00002 Fmt 5904 Sfmt 5904 S:\DOCS\34458.TXT SLABOR1 PsN: DENISE CONTENTS STATEMENTS WEDNESDAY, MARCH 21, 2007 Page Kennedy, Hon. -

Comments on the DGEIS / Amended GPP Submitted Through LMDC Website

Comments on the DGEIS / Amended GPP Submitted through LMDC Website Development Comments # name organization profile category address city_stat telephone email comments dt_rec fname lname city state zip e_zip 1 Joseph NULL Survivor of Other 375 South End 212/321-3328 [email protected] Constructing a tunnel (of any length) under West Street will 3/14/04 Joseph Parent New NY 10280- Parente 9/11 Avenue, Apt. m be a nightmare for the residents of our Battery Park City 10:27 e York 1080 26-S community. Travel in and out of the area will be next to PM impossible - cabs will refuse to come down here as they did long after the attack on the WTC. Foot traffic will be impeded and our long-standing businesses will be driven out. The environmental impact will also be enormous - noise, pollution, etc. will cause even more residents to flee the area. And, just looking at other such tunnels in the city, the final result will be an ugly, unhealthy, unsafe mess for all of us down here. We all are trying to get our lives back to "normal" as much as that is possible, but this idiotic idea, and outrageous waste of money that many experts agree will provide no improvement in traffic flow will surely make any normalcy a fiction. Also, the Gateway buildings' common areas (hallways, rugs, etc.) were never replaced, and the venting systems not cleaned. The money for this ridiculous tunnel should be used to take care of these health issues. 2 Michael R Ramapo Resident of Neighborho 505 Ramapo 201-684-7745 medelste@ram TESTIMONY ON THE LMDC FGEIS Michael R. -

View the 130 Liberty Street EDPL Determination and Findings

DETERMINATION AND FINDINGS BY THE LOWER MANHATTAN DEVELOPMENT CORPORATION PURSUANT TO EDPL SECTION 204 WITH RESPECT TO THE 130 LIBERTY STREET LOCATED WITHIN THE WORLD TRADE CENTER MEMORIAL AND CULTURAL PROGRAM LAND USE IMPROVEMENT AND CIVIC PROJECT The real property known as 130 Liberty Street in Manhattan is to be Street. For over a year, the Deutsche Bank building has been shroud- acquired as part of the proposed World Trade Center Memorial and ed in dark netting which casts a foreboding specter over the WTC Site Cultural Program Land Use Improvement and Civic Project (the and adjoining community of Lower Manhattan. As such, it serves as “Project”) which includes the acquisition, cleanup and deconstruction a constant and vivid reminder of the tragic events of September 11, of a 41-story office building sometimes known as the Deutsche Bank 2001 and thereby hampers the economic redevelopment and revital- building. That building was substantially damaged and became con- ization of the WTC Site and the surrounding community and the cre- taminated as a result of the World Trade Center (“WTC”) terrorist ation of an appropriate Memorial for the victims of the September attacks on September 11, 2001 and requires cleanup. The 130 11th terrorists attacks. Liberty Street parcel consists of an entire city block bounded by Washington, Liberty, Greenwich and Albany Streets in Lower Before deconstruction proceeds, the Deutsche Bank building at 130 Manhattan. It is located immediately south of the current southerly Liberty Street would be decontaminated so as to avoid the release of boundary of the WTC Site. The Project is being coordinated among the possible contaminants into the local community.