289 Sleeve-Valve Engines. 19

Total Page:16

File Type:pdf, Size:1020Kb

Load more

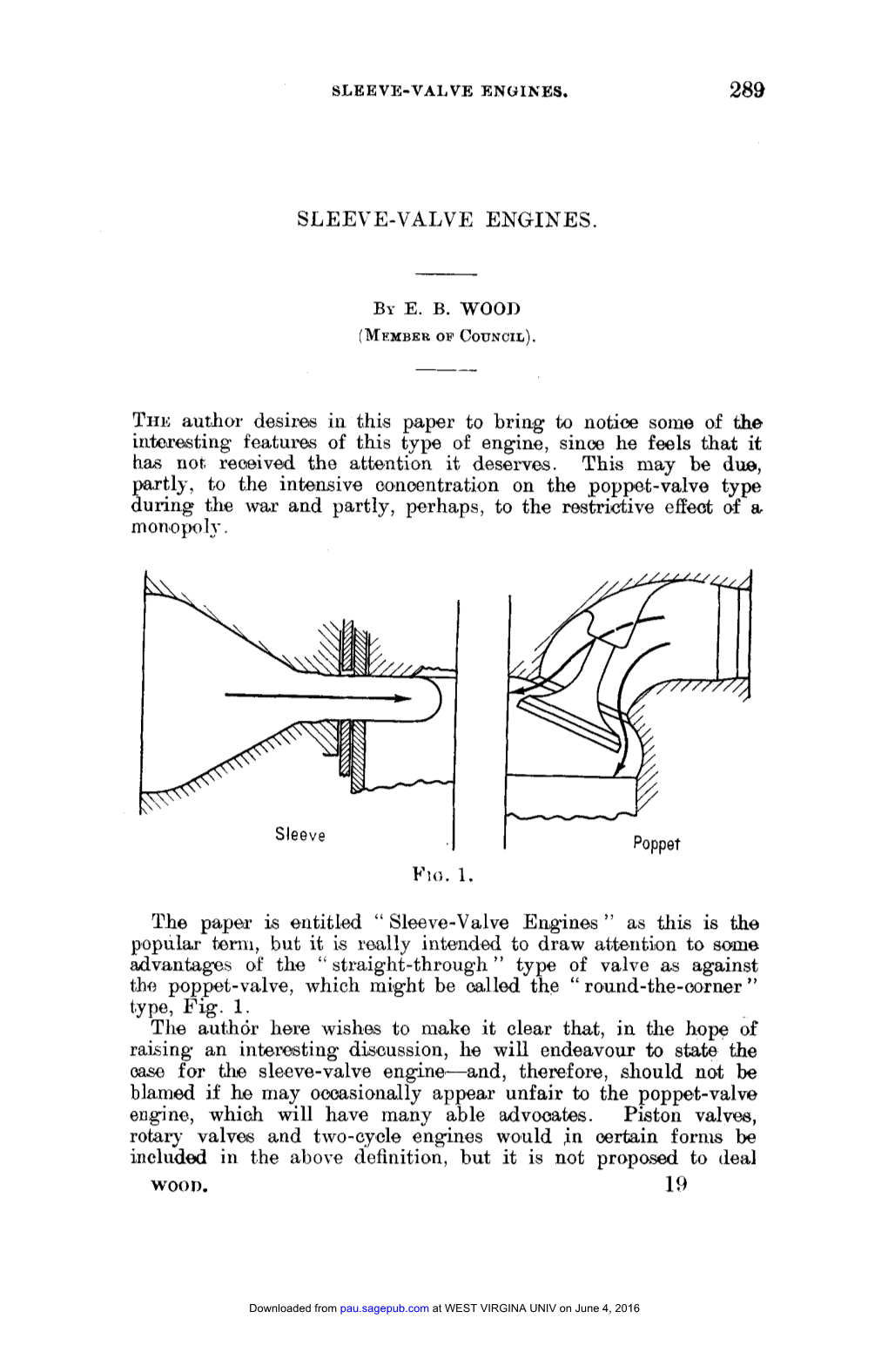

Recommended publications

-

Mean Value Modelling of a Poppet Valve EGR-System

Mean value modelling of a poppet valve EGR-system Master’s thesis performed in Vehicular Systems by Claes Ericson Reg nr: LiTH-ISY-EX-3543-2004 14th June 2004 Mean value modelling of a poppet valve EGR-system Master’s thesis performed in Vehicular Systems, Dept. of Electrical Engineering at Linkopings¨ universitet by Claes Ericson Reg nr: LiTH-ISY-EX-3543-2004 Supervisor: Jesper Ritzen,´ M.Sc. Scania CV AB Mattias Nyberg, Ph.D. Scania CV AB Johan Wahlstrom,¨ M.Sc. Linkopings¨ universitet Examiner: Associate Professor Lars Eriksson Linkopings¨ universitet Linkoping,¨ 14th June 2004 Avdelning, Institution Datum Division, Department Date Vehicular Systems, Dept. of Electrical Engineering 14th June 2004 581 83 Linkoping¨ Sprak˚ Rapporttyp ISBN Language Report category — ¤ Svenska/Swedish ¤ Licentiatavhandling ISRN ¤ Engelska/English ££ ¤ Examensarbete LITH-ISY-EX-3543-2004 ¤ C-uppsats Serietitel och serienummer ISSN ¤ D-uppsats Title of series, numbering — ¤ ¤ Ovrig¨ rapport ¤ URL for¨ elektronisk version http://www.vehicular.isy.liu.se http://www.ep.liu.se/exjobb/isy/2004/3543/ Titel Medelvardesmodellering¨ av EGR-system med tallriksventil Title Mean value modelling of a poppet valve EGR-system Forfattare¨ Claes Ericson Author Sammanfattning Abstract Because of new emission and on board diagnostics legislations, heavy truck manufacturers are facing new challenges when it comes to improving the en- gines and the control software. Accurate and real time executable engine models are essential in this work. One successful way of lowering the NOx emissions is to use Exhaust Gas Recirculation (EGR). The objective of this thesis is to create a mean value model for Scania’s next generation EGR system consisting of a poppet valve and a two stage cooler. -

117001 Tiertwo Cp6 14.Pdf

This is what it takes to be a PRO. Performance enhancing features like a heavy-duty air cleaner, forged-steel crankshaft, electronic ignition and cast-iron cylinder liner. KOHLER® Command PRO® is the standard for professional-grade power and performance. COURAGE XT COMMAND PRO® DEPENDABLE OPERATI COURAGE SINGLE ON • Quad-Clean ™ all-season four-stage cyclonic air filter – effective COURAGE TWINS engine protection for tough-and-dirty conditions. COURAGE XT • Protects from airborne contaminants that can easily clog COURAGE PRO TWINS COMMAND PRO® traditional air filters. LoNGER RUN TIMES COURAGE SINGLE • Large-capacity fuel tank means more time working, less time filling. COURAGE XT COURAGE TWINS • Electronic ignition and an advanced combustion system design help COMMAND PRO® reduce fuel consumption. COURAGE PRO TWINS COURAGE XT EASIER REPOWERING COURAGE SINGLE COMMAND PRO® • Power or repower your equipment without expensive modifications. COURAGE TWINS ALL-WEATHER P COURAGE SINGLE ERFORMANCE COURAGE PRO TWINS • Quad-Clean air filter reconfigures in seconds to recycle engine heat. COURAGE XT COURAGE TWINS • Command PRO starts effortlessly in all weather conditions, from COMMAND PRO® 0 to 110 degrees. COURAGE PRO TWINS BUILT TO LAST COURAGE SINGLE • Forged-steel crankshafts and tough Stellite ®-faced exhaust valves with COURAGE TWINS Tufftride ®-coated stems and cast-iron cylinder bores. • Oil Sentry ™ automatically shuts engine down in low-oil conditions. COURAGE PRO TWINS 6-HP HORIZONTAL-SHAFT ENGINES 6-HP HORIZONTAL-SHAFT ENGINES TOP VIEW -

MODULE 11: GLOSSARY and CONVERSIONS Cell Engines

Hydrogen Fuel MODULE 11: GLOSSARY AND CONVERSIONS Cell Engines CONTENTS 11.1 GLOSSARY.......................................................................................................... 11-1 11.2 MEASUREMENT SYSTEMS .................................................................................. 11-31 11.3 CONVERSION TABLE .......................................................................................... 11-33 Hydrogen Fuel Cell Engines and Related Technologies: Rev 0, December 2001 Hydrogen Fuel MODULE 11: GLOSSARY AND CONVERSIONS Cell Engines OBJECTIVES This module is for reference only. Hydrogen Fuel Cell Engines and Related Technologies: Rev 0, December 2001 PAGE 11-1 Hydrogen Fuel Cell Engines MODULE 11: GLOSSARY AND CONVERSIONS 11.1 Glossary This glossary covers words, phrases, and acronyms that are used with fuel cell engines and hydrogen fueled vehicles. Some words may have different meanings when used in other contexts. There are variations in the use of periods and capitalization for abbrevia- tions, acronyms and standard measures. The terms in this glossary are pre- sented without periods. ABNORMAL COMBUSTION – Combustion in which knock, pre-ignition, run- on or surface ignition occurs; combustion that does not proceed in the nor- mal way (where the flame front is initiated by the spark and proceeds throughout the combustion chamber smoothly and without detonation). ABSOLUTE PRESSURE – Pressure shown on the pressure gauge plus at- mospheric pressure (psia). At sea level atmospheric pressure is 14.7 psia. Use absolute pressure in compressor calculations and when using the ideal gas law. See also psi and psig. ABSOLUTE TEMPERATURE – Temperature scale with absolute zero as the zero of the scale. In standard, the absolute temperature is the temperature in ºF plus 460, or in metric it is the temperature in ºC plus 273. Absolute zero is referred to as Rankine or r, and in metric as Kelvin or K. -

Jennings: Two-Stroke Tuner's Handbook

Two-Stroke TUNER’S HANDBOOK By Gordon Jennings Illustrations by the author Copyright © 1973 by Gordon Jennings Compiled for reprint © 2007 by Ken i PREFACE Many years have passed since Gordon Jennings first published this manual. Its 2007 and although there have been huge technological changes the basics are still the basics. There is a huge interest in vintage snowmobiles and their “simple” two stroke power plants of yesteryear. There is a wealth of knowledge contained in this manual. Let’s journey back to 1973 and read the book that was the two stroke bible of that era. Decades have passed since I hung around with John and Jim. John and I worked for the same corporation and I found a 500 triple Kawasaki for him at a reasonable price. He converted it into a drag bike, modified the engine completely and added mikuni carbs and tuned pipes. John borrowed Jim’s copy of the ‘Two Stoke Tuner’s Handbook” and used it and tips from “Fast by Gast” to create one fast bike. John kept his 500 until he retired and moved to the coast in 2005. The whereabouts of Wild Jim, his 750 Kawasaki drag bike and the only copy of ‘Two Stoke Tuner’s Handbook” that I have ever seen is a complete mystery. I recently acquired a 1980 Polaris TXL and am digging into the inner workings of the engine. I wanted a copy of this manual but wasn’t willing to wait for a copy to show up on EBay. Happily, a search of the internet finally hit on a Word version of the manual. -

Section 2.3 – Linear and Angular Velocities

Section 2.3 – Linear and Angular Velocities The most intuitive measure of the rate at which the rider is traveling around the wheel is what we call linear velocity. Another way to specify how fast the rider is traveling around the wheel is with what we call angular velocity. Linear Speed Definition If P is a point on a circle of radius r, and P moves a distance s on the circumference of the circle in an amount of time t, then the linear velocity, v, of P is given by the formula speed distance time v s t Example A point on a circle travels 5 cm in 2 sec. Find the linear velocity of the point. Solution Given: s = 5cm t = 2 sec v s 5 cm t 2 sec 2.5 cm/ sec 21 Angular Speed Definition If P is a point moving with uniform circular motion on a circle of radius r, and the line from the center of the circle through P sweeps out a central angle in an amount of time t, then the angular velocity, (omega), of P is given by the formula where is measured in radians t Example A point on a circle rotates through 3 radians in 3 sec. Give the angular velocity of the point. 4 Solution Given: = rad t = 3sec 3 rad 4 3 sec rad/ sec 4 Example A bicycle wheel with a radius of 13.0 in. turns with an angular velocity of 3 radians per seconds. Find the distance traveled by a point on the bicycle tire in 1 minute. -

(12) United States Patent (10) Patent No.: US 7,387,018 B2 Wies (45) Date of Patent: Jun

USOO73870 18B2 (12) United States Patent (10) Patent No.: US 7,387,018 B2 Wies (45) Date of Patent: Jun. 17, 2008 (54) DISCRETE VARIABLE VALVE LIFT (56) References Cited DAGNOSTIC SYSTEMS AND METHODS U.S. PATENT DOCUMENTS (75) Inventor: Matthew A. Wiles, Royal Oak, MI (US) 7,047.924 B1* 5/2006 Waters et al. ............ 123.90.16 rsr rr 7,146,851 B2 * 12/2006 Wakahara et al. .......... 73/117.3 (73) Assignee: E. Slobal shots Operations, 2004/0129249 A1* 7/2004 Kondo .............. ... 123,346 2005/0204805 A1* 9, 2005 Wakahara et al. ... 73/118.1 (*) Notice: Subject to any disclaimer, the term of this 2007/0265805 A1* 11/2007 Lee et al. .................... 7O2,187 patent is extended or adjusted under 35 U.S.C. 154(b) by 0 days. * cited by examiner (21) Appl. No.: 11/561,041 Primary Examiner Eric S McCall (22) Filed: Nov. 17, 2006 (57) ABSTRACT (65) Prior Publication Data A diagnostic system for a discrete variable valve lift system of US 2008/O12OO18A1 May 22, 2008 an internal combustion engine is provided. The system includes: a Fast Fourier Transform (FFT) module that gener (51) Int. Cl. ates a frequency content signal based on a FFT method and a GOIM I5/00 (2006.01) valve impact sensor signal; and a malfunction module that (52) U.S. Cl. ...................................................... 73A118.1 selectively diagnoses a malfunction of a discrete variable (58) Field of Classification Search ................... 7.3/116 valve lift system based on the frequency content signal. 73/117.2, 117.3, 118.1, 119 R See application file for complete search history. -

330:148 (G) Machine Design 2. Force, Work and Power Weight, Force And

2. Force, Work and Power 330:148 (g) Objectives • Understand the difference between force, work, and power. Machine Design • Recognize and be able to convert between mass and weight. • Convert between English and metric units for force, work, and power. Nageswara Rao Posinasetti • Understand the basic principles of fluid mechanics as they apply to hydraulic and air cylinders or similar products. • Look up and/or calculate moments of inertia and section modulus for different shape parts. • Apply the principles of work, force, and power to moving machines. August 15, 2007 1 August 15, 2007 2 Weight, Force and Mass Work and Power Weight, W = m g Work = Force × Distance ft-lb or N m W = weight, lb or N Work done, W = F d M = Mass, lb or kg Power is rate of doing work W g = acceleration due to gravity, Power, P = 2 2 t 32.2 ft/s , 9.81 m/s t = time Force, F = m a a = acceleration August 15, 2007 3 August 15, 2007 4 Power and Speed Power and Speed 1 hp = 550 ft-lb/s P = T ω = 6600 in-lb/s P = Power, ft-lb/s or W T = Torque, ft-lb or N m = 33,000 ft-lb/min ω = Rotational speed in radians/second = 396,000 in-lb/min P T = Power in SI Units is Watts ω 1 hp = 746 W = 0.746 kW ω = 2 π n 60 n = revolutions per minute August 15, 2007 5 August 15, 2007 6 1 Torque Torque is a twisting moment Calculate the amount of torque in a shaft Rotates a part in relation to other transmitting 750 W of power while rotating T = F d at 183 rad/s. -

Preliminary Study of a Poppet Valve Two-Stroke Engine Operating with Controlled Auto Ignition Applied to Power Generation

Proceedings of COBEM 2009 20th International Congress of Mechanical Engineering Copyright © 2009 by ABCM November 15-20, 2009, Gramado, RS, Brazil PRELIMINARY STUDY OF A POPPET VALVE TWO-STROKE ENGINE OPERATING WITH CONTROLLED AUTO IGNITION APPLIED TO POWER GENERATION Pedro Hinckel, [email protected] Fabio Reis Naia, [email protected] Instituto Tecnológico Aeroespacial Endereço: Praça Marechal Eduardo Gomes, 50 - Vila das Acácias CEP 12.228-900 – São José dos Campos – SP – Brasil Abstract. The simpler and more common two-stroke engines are known for their high power density and high level of pollutant emissions. The use of a poppet valve design, combined with controlled auto ignition, can improve two-stroke engines efficiency and may achieve current emissions standards. This work presents a preliminary analysis of a poppet valve two stroke engine (PV2SE), aimed for power generation, working with controlled auto ignition (CAI) combustion and ethanol as fuel. The analysis consists of a set of computational performance simulations of a parameterized PV2SE feed by values found in literature. A conventional four-stroke engine model is also created to establish a benchmark. The simulation results are presented and some configurations for operation are proposed. Keywords: Two-Stroke Engines; Poppet Valve; CAI Combustion; Power Generation; Ethanol 1. INTRODUCTION The simpler and more common two-stroke engines are known for their high power density and high level of pollutant emissions. This is due mainly to the fact of: performing a complete cycle for each crankshaft turn; work with intake and exhaust systems by means of ports instead of valves and need lubricating oil added to the fuel. -

Aircraft Propeller Revolutions Per Minute

Aircraft Propeller Revolutions per Minute Subject Area(s) Introduction to Engineering Associated Unit None Associated Lesson None Activity Title Aircraft Propeller Revolutions per Minute Header Insert image 1 here, right justified to wrap Image 1 ADA Description: Students Performing Experiment Caption: Image 1: Students Recording Data Image file name: students.jpg Source/Rights: Copyright © 2010 Mihai Pruna NYU Poly Grade Level 11 (9-12) Activity Dependency None Time Required -45 minutes to build the propeller test rig with teacher assistance and program the NXT brick. -45 minutes to perform calculations and measurements. Interpretation of results (see worksheet attachment) can be assigned as homework or started in class if time permits. Group Size Three students Expendable Cost per Group US $3-4 (assuming school has NXT and LEGO kits) Summary Each group of students will construct a test rig for measuring the RPM (Revolutions per Minute) of a model aircraft (scaled) propeller. The test rig consists of a LEGO NXT Brick, NXT Motor and NXT Light sensor. The propeller is mounted on the motor and the students will measure the time elapsed between propeller blades passing over the light sensor. Two or three bladed propellers can be used. Engineering Connection Students will understand the basics of building a test rig to solve a specific problem. They will also learn about data collection and interpretation. Engineering Category Relates math and physics concept to engineering. Keywords propeller, revolution, RPM, blade, thrust, LEGO, experiment Educational Standards New York Science (Physics 9-12): Standard 2 New York Science (Physics 9-12): Standard 1 New York Math (9-12): Measurement Strand Pre-Requisite Knowledge Fractions Square Root Learning Objectives After this activity, students should have a basic understanding of how testing is done in an Engineering enterprise. -

Fluid Power Formulas Weightf Of

FLUID POWER FORMULAS WEIGHTF OF. ONEFCUBIC. - FOOT- OFTHEORETICAlflUID TOROUE TO ORIVE _ flOWFORCERATE(fXJUnds)(GPM)250,000" x \JSPECIFIClapprox.) GRAVITY U/IITUNITTHEORETICAllllPUTACTUAlINTERNAlAREATIMEHORSEPO'NER(Minute)(SquareTOROUEFLOWAREAInches)RATETO(Square231NEVIDRIVEOUTPUTSPEEDInches){RPM}{GPMJ flEW PRESSURE (PSI) J ==~ .32080==!!k~ x 100 = 2!!.§..2193VOLUMETRICOUTPUTFlO'NRPMPRESSURE.2253xSUS-~.3208ACTUALxRATEx PUMPHORSEPOWERSUSflOW(PSI)OUTPUTflOWElf._ADDITIONALDISPlACEMENTRATEVOLUMEx134.6xR.I,TEFLOWMECHANICAL(GFM)THROUGHxOUTPUT100(GPM)x PRESSURE(Cu.1.0.(GPMJElf231In.lRev.)(GPM)x(psi)100m1714 SUSA1714SUS=A=62.42831714AOfpv8M4.6354TElf712••1pSIx EFFICIE/ICY=1714E1fA (Ov-r:raU)Approximately0 = = EIf,'CL x EIf.EOt = PRESSUREr.!:.xX DIAMETER'RADIUS>(psi)(psi)WORDFORCEEIf.EO!(Inches)xx (Inches)NETVOLUME=AREAFORMULA:FORMULATTHEDOF(SquareOilX UNDER100Inct.es)PRESSURE= VOLUMEIfiPAFElf",==psixAorF=PATACT.=Y..(Gallons)r[»HP"O",roorA = .78S[» lETTERlETTER FORMULAFORMULA:RPMM PH COMPRESSIBILITY MECHANICAL IN PERCENT BULK MODULUS OF THE FLUID x 100 CIP) = AREAVELOCITYCENTISTOKESVOLUMETRICHORSEPOWERMECHANICALCEIITISTOKESOVERAllCElITISTOKESVALVEflOWSPECIACPRESSURE--1- FACTOREFACIENCYGRAVITYEFFICIENCYEFFICIENCYINPUT(e., ) SG c.s0CSEIf~.Elfa,c.sHP=VPVA=_W_==~BASIC·=.2253.219325O,ooolapprox.)SUS_O_PSUSFORMULAS_ _ or134.6194.4GPM\/2%x Perpsi 1000 psi FLaN RATE = VISCOSITY IN CENnSTOKES AREA c., = a VSG In AdditionalP/JUnds,Gal/ollS/MinulePushRequiredor PullOr7 ToReach Pressure 4.6354WEJGHT OF ONE1714 CUBICSUSSUSFOOTOF WATERVISCOSITY ININ CENTISTOKES -

Engineering Resource Guide Formulas for Fan Applications

ERG-100 May 2020 Twin City Fan Abbreviations, Fan Terminology and Definitions ARR. Arrangement of fan. BHP Brake horsepower, the fan’s power consumption. CCW Counterclockwise. Used to describe the rotation of an impeller. Rotation is determined by viewing the impeller from the drive side on centrifugal fans. Determining the rotation is not a factor on axial and inline centrifugal fans. CFM Cubic feet per minute, the volume of air moved per minute. CL Class of fan. The class identifies the limit of the fan’s performance range. CW Clockwise. Used to describe the rotation of an impeller. Rotation is determined by viewing the impeller from the drive side on centrifugal fans. dBA Estimated sound pressure level in the space using “A” weighting. DWDI Double width double inlet. EFFICIENCY A Ratio of the useful energy (work) provided by a system to the energy supplied to it. Used to provide a relative performance comparison of fans. FPM Feet per minute, the velocity of the airstream. HP Horsepower, the fan’s motor size. I.D. Inside diameter of fan, duct or transition. Lp Sound Pressure Level. Describes the loudness level of the sound, like the brightness level of a light bulb. This value varies with the distance from the sound source and the environment surrounding the sound source. Sound pressure is usually expressed in decibels with a reference level to 0.0002 microbars. Lw Sound Power Level. Describes the total amount of acoustical energy the fan emits, like the watt rating of a light bulb describes the total amount of energy the light emits. -

Diesel Engine Fundamentals Part 2 Course# ME406

® Diesel Engine Fundamentals Part 2 Course# ME406 © EZpdh.com All Rights Reserved Diesel Engine Fundamentals DOE-HDBK-1018/1-93 DIESEL ENGINES Air Intake System Because a diesel engine requires close tolerances to achieve its compression ratio, and because most diesel engines are either turbocharged or supercharged, the air entering the engine must be clean, free of debris, and as cool as possible. Turbocharging and supercharging are discussed in more detail later in this chapter. Also, to improve a turbocharged or supercharged engine's efficiency, the compressed air must be cooled after being compressed. The air intake system is designed to perform these tasks. Air intake systems vary greatly from vendor to vendor but are usually one of two types, wet or dry. In a wet filter intake system, as shown in Figure 14, the air is sucked or bubbled through a housing that holds a bath of oil such that the dirt in the air is removed by the oil in the filter. The air then flows through a screen-type material to ensure any entrained oil is removed from the air. In a dry filter system, paper, cloth, or a metal screen material is used to catch and trap dirt before it enters the engine (similar to the type used in automobile engines). In addition to cleaning the air, the intake system is usually designed to intake fresh air from as far away from the engine as practicable, usually just outside of the engine's building or enclosure. This provides the engine with a supply of air that has not been heated by the engine's own waste heat.