A&P Group Defence Brochure

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Primary Casualty Receiving Facility, RFA ARGUS

3 Operational Operational The UK maritime Role 3 medical treatment facility: the Primary Casualty Receiving Facility, RFA ARGUS Surg Capt J E Smith, Surg Cdr S R C Smith, Surg Capt G Hill Introduction that took over three years to complete. RFA ARGUS was The Royal Naval Medical Service has a maritime Role 3 named on 25 March 1987, and remains the maritime Role 3 medical treatment facility (MTF), in the form of the Primary MTF to this day. She has provided medical support to UK Casualty Receiving Facility (PCRF) on board Royal Fleet and Allied Forces during both Gulf Wars in her role as a Auxiliary (RFA) ARGUS, which in its largest confi guration primary casualty receiving ship. has 100 beds (4/4/10/20/70, indicating 4 resuscitation bays; 4 operating tables; 10 intensive care beds; 20 high- The ARGUS is not a designated hospital ship, as she carries dependency beds and 70 general beds). The purpose of this weapons systems and has other military roles. As a result article is to describe this facility, and its recent activities, in she does not operate under the protection of the Geneva particular with reference to the future potential capabilities Convention of 1949. This allows her to be placed much that are currently under review. closer to the battlespace, allowing for more rapid transfer of patients to defi nitive care. During her operational medical The ship deployment during the Iraq confl ict in 2003, she went to the The ARGUS is a 28,000 tonne Royal Fleet Auxiliary (RFA) Northern Arabian Gulf as a grey vessel (complete with her vessel, whose primary role is as a PCRF. -

Industry Recognises A&P As Best in Practice During

NEWSLETTER | ISSUE 6 SUMMER 2020 INDUSTRY RECOGNISES A&P AS BEST IN PRACTICE DURING COVID-19 A&P Defence has been praised for It is A&P Group’s strict programme of the risk of the virus entering our facilities its role in preparing RFA Argus Covid-19 measures that has made it and minimise disruption to vessels as and RFA Lyme Bay for urgent possible to continue essential ship repair they arrive at our sites. Customers can and maintenance work for the MoD, be assured that they face minimum deployment, as part of the UK Royal Fleet Auxiliary and Seaborne disruption when visiting our facilities as Government’s Covid-19 asset community during the pandemic. we’ve found effective ways to safeguard pandemic response. Throughout this period A&P Group our workforce and customers whilst has provided critical support to continuing to deliver essential projects.” Based at A&P Falmouth, A&P Defence RFA Mounts Bay. supported RFA Argus during an extended A&P’s Covid-19 Response Assisted Maintenance Period (AMP) A&P Tyne has also installed cable repair • Full contingency plans in place equipment to Prysmian’s North Sea Giant, earlier this year. RFA Lyme Bay was due across all three facilities. for scheduled maintenance at A&P which was essential to the safe and Falmouth in March, however the vessel continuous power supply to the • Enhanced cleaning & hygiene activities. was diverted to a Ministry of Defence National Grid. • Supply of appropriate PPE. facility to fully store for operations. A&P David McGinley, Chief Executive Officer • Enforced social distancing measures. -

Operation in Iraq, Our Diplomatic Efforts Were Concentrated in the UN Process

OPERATIONS IN IRAQ First Reflections IRAQ PUBLISHED JULY 2003 Produced by Director General Corporate Communication Design by Directorate of Corporate Communications DCCS (Media) London IRAQ FIRST REFLECTIONS REPORT Contents Foreword 2 Chapter 1 - Policy Background to the Operation 3 Chapter 2 - Planning and Preparation 4 Chapter 3 - The Campaign 10 Chapter 4 - Equipment Capability & Logistics 22 Chapter 5 - People 28 Chapter 6 - Processes 32 Chapter 7 - After the Conflict 34 Annex A - Military Campaign Objectives 39 Annex B - Chronology 41 Annex C - Deployed Forces and Statistics 43 1 Foreword by the Secretary of State for Defence On 20 March 2003 a US-led coalition, with a substantial contribution from UK forces, began military operations against the Saddam Hussein regime in Iraq. Just 4 weeks later, the regime was removed and most of Iraq was under coalition control. The success of the military campaign owed much to the determination and professionalism of the coalition’s Armed Forces and the civilians who supported them. I regret that, during the course of combat operations and subsequently, a number of Service personnel lost their lives. Their sacrifice will not be forgotten. The UK is playing a full part in the re-building of Iraq through the establishment of conditions for a stable and law-abiding Iraqi government. This process will not be easy after years of repression and neglect by a brutal regime. Our Armed Forces are performing a vital and dangerous role by contributing to the creation of a secure environment so that normal life can be resumed, and by working in support of humanitarian organisations to help the Iraqi people. -

Gunline Autumn07.Qxd 24/8/07 14:43 Page 1

Gunline Autumn07.qxd 24/8/07 14:43 Page 1 Gunline - The First Point of Contact Published by the Royal Fleet Auxiliary Service August 2007 www.rfa.mod.uk Inside this RFA SUPPORT! Issue... Remembering the Falklands Page 11 RFA Lyme Bay is welcomed Page 5 Sir Jim visits Mounts Bay Page 16 Wave Ruler visits Anguilla Page 7 Farewell Captain Roach Page 4 day out for the crew of RFA CARDIGAN BAY. She is the 3rd of the Bay Class and the 2nd to have been built in AGovan Ship Yard, Glasgow, Scotland. The ship left the Yard in early August and spent the rest of 2006 and early 2007, developing herself and crew into an operational capable platform. Formally welcomed to the Fleet on 6 March 2007 follow her story from launch to operational deployment. See Page 3 Gunline Autumn07.qxd 22/8/07 13:38 Page 2 2 - Gunline From the Commodore… his edition of Gunline follows hard on the comprehensive, vastly improved and much more tailored, initial training heels of the last and perhaps that is no bad courses now being delivered at RALEIGH. We will continue to do this with Tthing, for there are several items of news full STCW and VQ accreditation. SULTAN has recently gained similar that you need to be aware of. I will pick up the accreditation for the Engineering ratings courses and we will see more of this threads of my last article using our vision and in the near future. COLLINGWOOD continues to develop and deliver values and set some of the latest news into the excellent initial training packages, fully accredited and designed specifically context of development. -

Model Ship Book 4Th Issue

A GUIDE TO 1/1200 AND 1/1250 WATERLINE MODEL SHIPS i CONTENTS FOREWARD TO THE 5TH ISSUE 1 CHAPTER 1 INTRODUCTION 2 Aim and Acknowledgements 2 The UK Scene 2 Overseas 3 Collecting 3 Sources of Information 4 Camouflage 4 List of Manufacturers 5 CHAPTER 2 UNITED KINGDOM MANUFACTURERS 7 BASSETT-LOWKE 7 BROADWATER 7 CAP AERO 7 CLEARWATER 7 CLYDESIDE 7 COASTLINES 8 CONNOLLY 8 CRUISE LINE MODELS 9 DEEP “C”/ATHELSTAN 9 ENSIGN 9 FIGUREHEAD 9 FLEETLINE 9 GORKY 10 GWYLAN 10 HORNBY MINIC (ROVEX) 11 LEICESTER MICROMODELS 11 LEN JORDAN MODELS 11 MB MODELS 12 MARINE ARTISTS MODELS 12 MOUNTFORD METAL MINIATURES 12 NAVWAR 13 NELSON 13 NEMINE/LLYN 13 OCEANIC 13 PEDESTAL 14 SANTA ROSA SHIPS 14 SEA-VEE 16 SANVAN 17 SKYTREX/MERCATOR 17 Mercator (and Atlantic) 19 SOLENT 21 TRIANG 21 TRIANG MINIC SHIPS LIMITED 22 ii WASS-LINE 24 WMS (Wirral Miniature Ships) 24 CHAPTER 3 CONTINENTAL MANUFACTURERS 26 Major Manufacturers 26 ALBATROS 26 ARGONAUT 27 RN Models in the Original Series 27 RN Models in the Current Series 27 USN Models in the Current Series 27 ARGOS 28 CM 28 DELPHIN 30 “G” (the models of Georg Grzybowski) 31 HAI 32 HANSA 33 NAVIS/NEPTUN (and Copy) 34 NAVIS WARSHIPS 34 Austro-Hungarian Navy 34 Brazilian Navy 34 Royal Navy 34 French Navy 35 Italian Navy 35 Imperial Japanese Navy 35 Imperial German Navy (& Reichmarine) 35 Russian Navy 36 Swedish Navy 36 United States Navy 36 NEPTUN 37 German Navy (Kriegsmarine) 37 British Royal Navy 37 Imperial Japanese Navy 38 United States Navy 38 French, Italian and Soviet Navies 38 Aircraft Models 38 Checklist – RN & -

AP TRACK-RECORD.Pdf

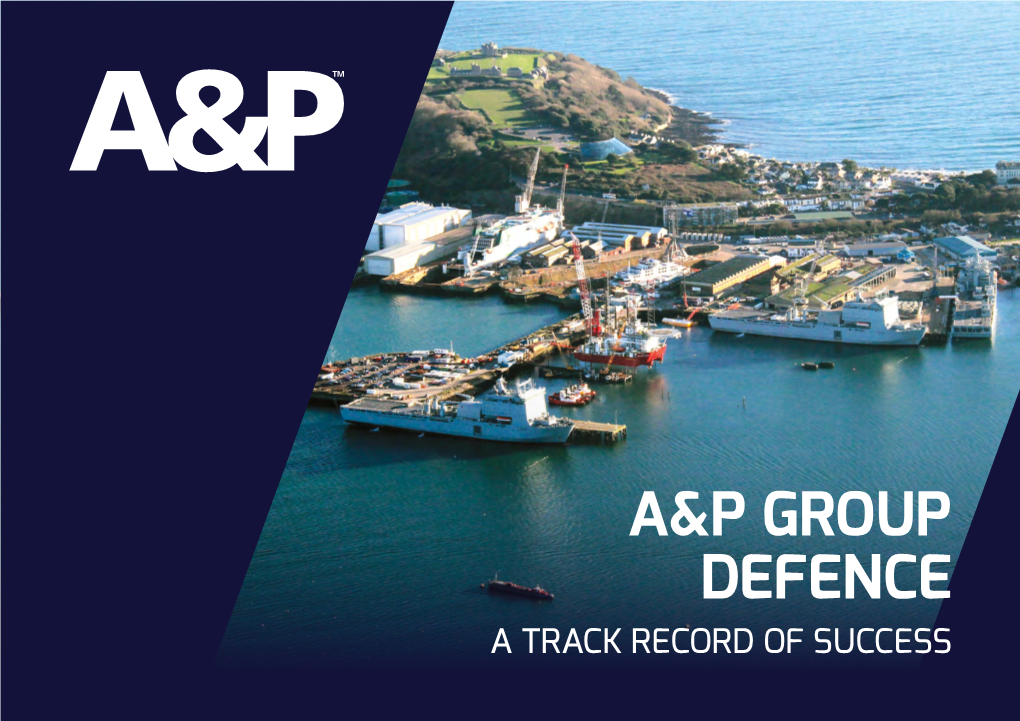

2 | A&P GROUP DEFENCE | A TRACK RECORD OF SUCCESS A TRACK RECORD OF SUCCESS A&P is proud of its 12 year partnership with the Ministry of Defence and the achievements that collaboration has delivered. Through working together we understand the unique requirements of the RFA and the importance placed upon it by NCHQ in supporting the Royal Navy and the UK’s operational military capability. Our expertise and experience has delivered: • A proven, low risk and cost-effective solution already in place. • A fully partnered, collaborative and mature working relationship between A&P, CSS and the wider stakeholder community. • Unique experience across Argus, LSDA, HMS Scott and Tide Class Tankers. • The procurement and delivery of spares and equipment all over the world to suit vessels’ operational requirements. • £24 million audited savings. Together we have maintained the highest level of vessel availability and increased real efficiencies in Fleet Time. Our low cost, collaborative approach has resulted in a 98% on time delivery record to the MoD. RFA Argus returns to A&P Falmouth The arrival of RFA Tiderace into A&P Falmouth At the heart of the A&P Cluster Support Team lies our commitment to uphold the DE&S and Commercially Supported Shipping’s Mission Statement. Delivering maritime capability by maximising best commercial practice to provide safe and effective platforms for global defence operations. 4 | A&P GROUP DEFENCE | A TRACK RECORD OF SUCCESS COLLABORATIVE WORKING In 2019, A&P was certificated to ISO 44001 for ‘Delivering maritime capability by maximising best commercial practice to provide safe and effective platforms for global defence operations’. -

HMCS Iroquois, Canada Cuauhtemoc, Mexico JS Shirane, Japan Etoile, France FNS Pohjanmaa, Finland Belle Poule, France RFA Argus, United Kingdom

this guide created by PortSide NewYork www.portsidenewyork.org www.opsail.org For info on ships docked in Manhattan and Staten Island, guides to the area, and updates on restaurant and business discounts for OpSail see www.portsidenewyork.org/OpSail2012 OpSail Red Hook Marine Terminal Schedule & Ship Information The Brooklyn ships will be open Saturday, May 26, Sunday May 27, and Monday, May 28 from 10am to 4pm. (The ships in Manhattan and Staten Island will also be open on Thursday, Monday and Tuesday or May 24 through May 29.) Enter the Red Hook Marine Terminal port gate at Congress Street on Columbia Street. PortSide will have a tourist info table outside the port gate. Look for a 6-foot tall red velvet hook. Due to the presence of Navy vessels and the need to secure an active containerport, you must show a government-issued photo ID and pass through metal detectors. If there are large crowds at the gate, there is a shady waiting area with lots of seating at the Van Voorhees Playground on Congress Street just inland of the tennis court at the corner of Columbia and Congress Streets. There will be four tall ships, four foreign navy vessels and two US Coast Guard cutters. TALL SHIPS: NAVY SHIPS: Juan Sebastian de Elcano, Spain HMCS Iroquois, Canada Cuauhtemoc, Mexico JS Shirane, Japan Etoile, France FNS Pohjanmaa, Finland Belle Poule, France RFA Argus, United Kingdom US COAST GUARD USCG Cutter Seneca USCG Cutter Willow This guide can be downloaded at www.portsidenewyork.org/PortSideOpSail2012Guide.pdf PortSide’s visitor guide to Columbia Waterfront District is at www.portsidenewyork.org/PortSideGuideToColumbiaWaterfront.pdf Directions to Red Hook Marine Terminal are on the last page of this document. -

British Ship RFA Argus Dispatched to Support Caribbean's Covid-19 Response

British Ship RFA Argus Dispatched to Support Caribbean's Covid-19 Response Pdf Published On April 03, 2020 03:24 PM Staff Consortium | April 03, 2020 03:24:51 PM 0 BRIDGETOWN, Barbados, CMC – The British casualty ship RFA Argus, has set sail for the Caribbean ahead of this year’s hurricane season to assist with the response to the COVID-19 pandemic across the region. Although the vessel’s deployment to the Caribbean had been scheduled for the hurricane season, she will now be able to play a part in ensuring the UK Government is ready to support the Overseas Territories during the pandemic. As Royal Navy sailors and Royal Marines continue to stand ready to assist the United Kingdom in its efforts to defeat the pandemic at home, the support ship left Devonport on Thursday, to cross the Atlantic and head south for the Caribbean. “RFA Argus’ ship’s company, consisting of both Royal Fleet Auxiliary and Royal Navy personnel, will rise to this challenge. We understand that there are people in need in the UK Overseas Territories who require our support,” said commanding officer Captain Terence Barke On board RFA Argus are Royal Marines, Royal Fleet Auxiliary and Royal Navy sailors and aviators from 815 Naval Air Squadron and 845 Naval Air Squadron. A medical team could later join Argus in the Caribbean to support the UK Government’s contribution to responding to Covid-19 in Overseas Territories. RFA Argus has a length of 175 metres for a displacement of 18,280 tonnes and a crew complement of 80 sailors. -

Gunline July09.Qxd:Gunline 15/7/09 11:59 Page 1

Gunline July09.qxd:Gunline 15/7/09 11:59 Page 1 Gunline - The First Point of Contact Published by the Royal Fleet Auxiliary Service July 2009 www.rfa.mod.uk RFA MEMORIAL NATIONAL MEMORIAL ARBORETUM he National Memorial Arboretum has recently Treceived a significant amount of high profile coverage in the national media. This has led to several suggestions being made by a number of sources in the RFA Service, that it would be appropriate for us to have our own memorial dedicated to all those who have served in the RFA since its inception in 1905. As a result of this and in conjunction with the RFA Association we are currently in the early stages of planning for an RFA Memorial to be built at the National Memorial Arboretum. The National Memorial Arboretum is located in the centre of the country near Lichfield in A view of the Arboretum including the Armed Forces Memorial and some other memorials Staffordshire within the National Forest and covers an area of about details on the venue can be found on purchase of the site, architect’s plans, 150 acres. The Arboretum which is their website: www.thenma.org.uk. materials, memorial stone with interspersed with tree plantations, is It is envisaged that the RFA inscription, and the construction work. home to the Armed Forces Memorial Memorial will have as a centre-piece a Costs have yet to be finalised, but from and many other Service and large standing anchor with fouled chain initial estimates received, it is expected Volunteer organisation memorials. In in the middle, an engraved granite block to be in the region of £10,000 of which addition there is a large visitor centre in the front and in-filled with large the RFAA has already pledged the initial staffed mainly by volunteers. -

British Uses of Aircraft Carriers and Amphibious Ships: 1945 – 2010

Corbett Paper No 9 British uses of Aircraft Carriers and Amphibious Ships: 1945 – 2010 Tim Benbow The Corbett Centre for Maritime Policy Studies March 2012 British uses of Aircraft Carriers and Amphibious Ships: 1945 – 2010 Tim Benbow Key Points . Recent British debates about defence policy and military capabilities have revealed a lack of understanding of the roles of aircraft carriers and amphibious forces. This paper provides a historical survey aiming to offer some empirical evidence to help correct this weakness. Aircraft carriers and amphibious forces have a repeatedly proven ability to conduct the more common smaller-scale operations alone or to act as the foundation enablers of rarer, larger-scale operations; they are particularly well suited to long- term engagement, crisis prevention, deterrence and early action that can make larger scale intervention unnecessary; and air bases and overflight rights have again and again proved unavailable or inadequate despite policy assumptions to the contrary. This survey shows the options and flexibility that carriers and amphibious ships have provided for policy makers over many years in just the sort of activities and operations that are likely to be required of the British armed forces in the future. Carriers and amphibious forces are not a strategic panacea and have limitations in their ability to dominate ground and in the scale of effort that they can take on without the backing of land-based forces. Nevertheless, they offer unique advantages and are essential for a viable British strategy. Dr Tim Benbow is a Senior Lecturer in the Department of Defence Studies, King’s College London, at the JSCSC. -

Tomahawk and Astute – a 21St Century Firepower Display

Dec 11 Issue 43 desthe magazine for defenceider equipment and support Tomahawk and Astute – a 21st century firepower display Virtual warfare in focus See inside Warrior Wildcat Daring packs Support takes Mapping out upgrade goes to sea a punch on a new look the future FEATURES 6 24 Warfare staff go to war The Royal Navy has unveiled its new Maritime Composite Training System to a fanfare of trumpets and applause, marking the most radical change to its training for more than 40 years. 26 It’s the Army’s PlayStation generation Members of the British Army's PlayStation generation head to Helmand Province on the latest Operation Herrick deployment having honed their soldiering skills in virtual combat 28 Kestrel reaches full flight Project Kestrel – Information Systems and Services' reliable backbone communications network – is now complete, guaranteeing increased capacity and improved quality of communications in Afghanistan 2011 30 Defence Secretary praises ‘dedicated people’ New Defence Secretary Philip Hammond has praised 'the cover image most dedicated people in the public service' as he outlined A Tomahawk land attack missile is pictured being his vision for defence in his first public speech since fired byHMS Astute during her latest set of trials. The succeeding Dr Liam Fox missile, one of two fired on the trial, demonstrated complex evasive manoeuvres during flight and hit its designated target on a missile range DECEMBER desider NEWS Assistant Head, Public Relations: Ralph Dunn - 9352 30257 or 0117 9130257 5 Warrior in £1 billion -

Friends of the Royal Naval Museum

friends of the Royal Naval Museum and HMS Victory Scuttlebutt The magazine of the National Museum of the Royal Navy (Portsmouth) and the Friends ISSUE 44 SPRING 2012 By subscription or £2 Scuttlebutt The magazine of the National Museum of the Royal Navy (Portsmouth) and the Friends CONTENTS Council of the Friends 4 Chairman’s Report (Peter Wykeham-Martin) 5 New Vice Chairman (John Scivier) 6 Treasurers Report (Roger Trise) 6 Prestigious BAFM Award for ‘Scuttlebutt’ (Roger Trise) 7 News from the National Museum of the Royal Navy (Graham Dobbin) 8 HMS Victory Change of Command (Rod Strathern) 9 Steam Pinnace 199 & London Boat Show (Martin Marks) 10 Lottery Bid Success 13 Alfred John West Cinematographer 15 Peter Hollins MBE, President 199 Group (Martin Marks) 17 Skills for the Future Project (Kiri Anderson) 18 New Museum Model Series – Part 1: HMS Vanguard (Mark Brady) 20 The National Museum of the Royal Navy: 100 Years of Naval Heritage 23 at Portsmouth Historic Dockyard (Campbell McMurray) The Royal Navy and Libya (Naval Staff) 28 The Navy Campaign – “We need a Navy” (Bethany Torvell) 31 The Story of Tactical Nuclear Weapons in the Royal Navy (John Coker) 32 The Falklands War Conference at the RNM – 19 May 2012 35 Thirtieth Anniversary of the Falklands Conflict (Ken Napier) 36 HMS Queen Elizabeth - Update on Progress (BAE Systems) 38 Lost CS Forester Manuscript Found (New CS Forester book) (John Roberts) 39 Museum Wreath Workshop 39 Geoff Hunt – Leading Marine Artist (Julian Thomas) 40 Book Reviews 40 AGM – 3 May 2012 (Executive Secretary)