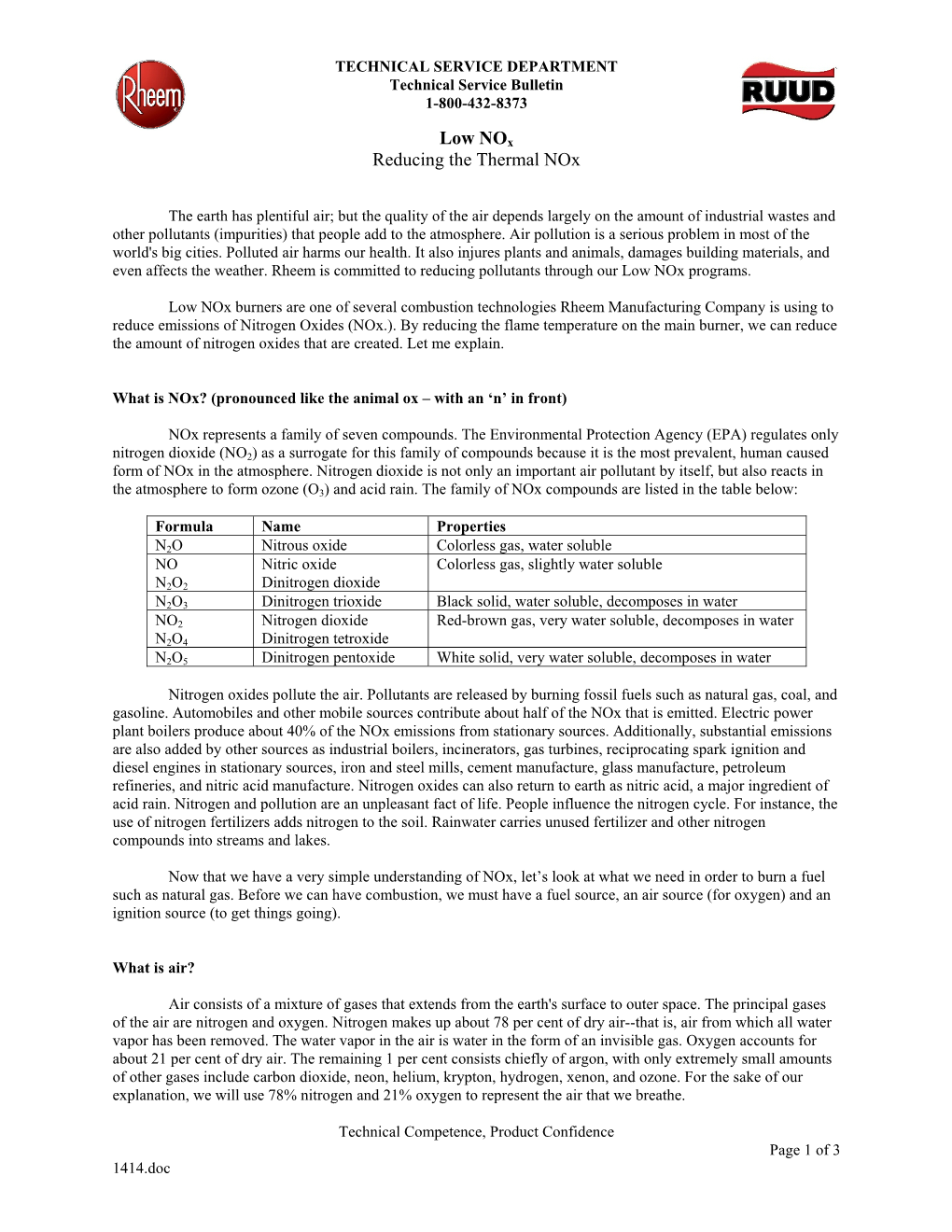

Low Nox Reducing the Thermal Nox

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Acute Exposure Guideline Levels for Selected Airborne Chemicals: Volume 11

This PDF is available from The National Academies Press at http://www.nap.edu/catalog.php?record_id=13374 Acute Exposure Guideline Levels for Selected Airborne Chemicals: Volume 11 ISBN Committee on Acute Exposure Guideline Levels; Committee on 978-0-309-25481-6 Toxicology; National Research Council 356 pages 6 x 9 PAPERBACK (2012) Visit the National Academies Press online and register for... Instant access to free PDF downloads of titles from the NATIONAL ACADEMY OF SCIENCES NATIONAL ACADEMY OF ENGINEERING INSTITUTE OF MEDICINE NATIONAL RESEARCH COUNCIL 10% off print titles Custom notification of new releases in your field of interest Special offers and discounts Distribution, posting, or copying of this PDF is strictly prohibited without written permission of the National Academies Press. Unless otherwise indicated, all materials in this PDF are copyrighted by the National Academy of Sciences. Request reprint permission for this book Copyright © National Academy of Sciences. All rights reserved. Acute Exposure Guideline Levels for Selected Airborne Chemicals: Volume 11 Committee on Acute Exposure Guideline Levels Committee on Toxicology Board on Environmental Studies and Toxicology Division on Earth and Life Studies Copyright © National Academy of Sciences. All rights reserved. Acute Exposure Guideline Levels for Selected Airborne Chemicals: Volume 11 THE NATIONAL ACADEMIES PRESS 500 FIFTH STREET, NW WASHINGTON, DC 20001 NOTICE: The project that is the subject of this report was approved by the Governing Board of the National Research Council, whose members are drawn from the councils of the National Academy of Sciences, the National Academy of Engineering, and the Insti- tute of Medicine. The members of the committee responsible for the report were chosen for their special competences and with regard for appropriate balance. -

Nitrogen Oxides (Nox), Why and How They Are Controlled

United States Office of Air Quality EPA 456/F-99-006R Environmental Protection Planning and Standards November 1999 Agency Research Triangle Park, NC 27711 Air EPA-456/F-99-006R November 1999 Nitrogen Oxides (NOx), Why and How They Are Controlled Prepared by Clean Air Technology Center (MD-12) Information Transfer and Program Integration Division Office of Air Quality Planning and Standards U.S. Environmental Protection Agency Research Triangle Park, North Carolina 27711 DISCLAIMER This report has been reviewed by the Information Transfer and Program Integration Division of the Office of Air Quality Planning and Standards, U.S. Environmental Protection Agency and approved for publication. Approval does not signify that the contents of this report reflect the views and policies of the U.S. Environmental Protection Agency. Mention of trade names or commercial products is not intended to constitute endorsement or recommendation for use. Copies of this report are available form the National Technical Information Service, U.S. Department of Commerce, 5285 Port Royal Road, Springfield, Virginia 22161, telephone number (800) 553-6847. CORRECTION NOTICE This document, EPA-456/F-99-006a, corrects errors found in the original document, EPA-456/F-99-006. These corrections are: Page 8, fourth paragraph: “Destruction or Recovery Efficiency” has been changed to “Destruction or Removal Efficiency;” Page 10, Method 2. Reducing Residence Time: This section has been rewritten to correct for an ambiguity in the original text. Page 20, Table 4. Added Selective Non-Catalytic Reduction (SNCR) to the table and added acronyms for other technologies. Page 29, last paragraph: This paragraph has been rewritten to correct an error in stating the configuration of a typical cogeneration facility. -

The Chemistry of Solvated Nitric Oxide

The Chemistry of Solvated Nitric Oxide: As the Free Radical and as Super-saturated Dinitrogen Trioxide Solutions By Kristopher A. Rosadiuk March, 2015 A thesis submitted to McGill University in partial fulfillment of the requirements in the degree of: DOCTORATE OF PHILOSOPHY Department of Chemistry, Faculty of Science McGill University Montreal, Quebec, Canada © Kristopher Rosadiuk, 2015. Abstract The unusual behaviour of the mid-oxidation state nitrogen oxides, nitric oxide (NO) and dinitrogen trioxide (N2O3), are explored in solution. Nitric oxide is shown to catalyze the cis-trans isomerizations of diazo species in aqueous and organic solutions, and a model is presented by which this proceeds by spin catalysis, making use of the unpaired electron of NO to permit access to triplet patways. Five diazo compounds are tested and compared to stilbene, which is not found to isomerize under these conditions. Dinitrogen trioxide is found to form easily in organic solvents, which stabilize the molecule even above room temperature. Solutions can be formed at chemically useful concentrations and levels of purity, and this result is compared with the sparse literature concerning this phenomenon. The chemistry of these solutions at 0˚C is surveyed extensively, with 23 distinct organic reactions and 15 inorganic reactions being described. The first reported room temperature adduct of dinitrogen trioxide is presented, as well as novel syntheses for nitrosyl chloride and nitrosylsulfuric acid. X-ray structures are also given for a previously reported benzoquinone-phenol adduct, as well as a new mixed valent-mercury nitride salt of the form Hg4N4O9. Résumé Le comportement inhabituel des oxydes d'azote aux états d’oxydations moyens, comme l’oxyde nitrique (NO) et le trioxyde dinitrique (N2O3), est exploré en solution. -

Proposed Adipic Acid Production Protocol

ADIPIC ACID PRODUCTION PROJECT PROTOCOL Proposed Protocol October 26, 2019 ClimeCo Corporation One E Philadelphia Ave Boyertown, Pennsylvania 19512 (484) 415-0501 climeco.com Adipic Acid Production Project Protocol Prepared by: Bill Flederbach & James Winch, ClimeCo Corporation Version: 2.0 (Proposed Public Protocol) Version Date: 10/26/2019 This proposed protocol, initially developed by ClimeCo Corporation, is for use by the Climate Action Reserve in the development and evaluation process for a standardized offset project protocol reducing N2O emissions from adipic acid production. Contact Information: Bill Flederbach, Jr. ClimeCo Corporation One E Philadelphia Ave, Boyertown, Pennsylvania 19512 (484) 415-0501 [email protected] Tip Stama ClimeCo Corporation One E Philadelphia Ave, Boyertown, Pennsylvania 19512 (484) 415-0501 [email protected] i Adipic Acid Production Project Protocol Table of Contents 1. Introduction .......................................................................................................................................... 2 2. The GHG Reduction Project .................................................................................................................. 3 2.1. Background ............................................................................................................................... 3 2.2. Project Definition ...................................................................................................................... 4 2.3. The Project Developer ............................................................................................................. -

III) Carbonate 3. Chromium (IV

I. Write the chemical formula from the names of inorganic compounds 1. Silver hydroxide 2. Iron (III) carbonate 3. Chromium (IV) nitrate 4. Dinitrogen tetraoxide 5. Ammonium sulfite 6. Gold (III) hydride 7. Bismuth (V) periodate 8. Gallium carbonate 9. Sodium sulfide 10. Cobalt (II) hypochlorite 11. Hydrosulfuric acid 12. Sulfuric acid 13. Tetraphosphorus hexafluoride 14. Calcium nitrate 15. Palladium (IV) phosphate 16. Nickel (III) nitrate 17. Hydrogen sulfide 18. Iodic acid 19. Aluminum bromide 20. Potassium iodide 21. Carbon disulfide 22. Dinitrogen tetroxide 23. Carbon tetrachloride 24. Trisulfur pentoxide 25. Hydroarsenic acid 26. Calcium bromide 27. Zinc sulfide 28. Chromium (II) nitrate 29. Aluminum acetate 30. Barium sulfite 31. Potassium chloride 32. Iron (II) permanganate 33. Hydrofluoric acid 34. Fluorous acid 35. Ammonium nitride 36. Cobalt (II) hypochlorite 37. Barium chloride 38. Lead (II) nitrate 39. Titanium (III) iodide 40. Ammonium hydroxide 41. Potassium chromate 42. Cobalt (II) oxide 43. Magnesium perchlorate 44. Copper (II) sulfate 45. Sodium sulfite 46. Iron (III) chloride 47. Calcium cyanide 48. Copper (II) sulfide 49. Copper (I) sulfide 50. Silver carbonate 51. Cadmium hypochlorite 52. Tin (IV) oxide 53. Sodium carbonate 54. Aluminum acetate 55. Nickel (II) phosphate 56. Barium nitride 57. Nitrogen trihydride 58. Dinitrogen dioxide 59. Carbon disulfide 60. Disulfur heptoxide II. Naming of inorganic compounds from their molecular formula or formula unit 1. K2SO 4 2. NH 4Cl 3. Mg(NO 3)2 4. FeCl 3 5. NaHCO 3 6. NaOH 7. CaO 8. CaCO 3 9. CS 2 10. PCl 3 11. N2O 12. N2O5 13. CO 2 14. -

Dipole Moment of Nitrogen Dioxide and Dinitrogen Dioxide—

DIPOLE MOMENT OF NITROGEN DIOXIDE AND DINITROGEN DIOXlDE--THE STRUCTURE OF THE DIMER BY S. V. ANANTAKRISHNAN, F.A.Sc. ANI)D. SETU RAO ( Contribution from the Department of Chemistry, Madres Christian College, Tambaram, Madras--45) Received January 13, 1964 THERE have been numerous studies on the properties of these eompounds and there have beon roviows of theso n,L12 but one property that appeared to be out of tuno with the accepted structuro of the dimer is the dielectric constant: 7 It appeared worthwhile studying this aspeet further. A difficulty in the measurements is the ease with which nitrogen dioxide and the dimer form complexes with a variety of otherwise desirablo solvents for these studies. Our measurements have ther•foro been cortfined to solvents with available pi-orbital electrons and to non-donor solvents whieh are non-aromatic. EXPERIMENTAL Solvents.--Benzene was purified by standard methods of chemical treatment and fractional crystallisation, distillod over sodium, allowed to stand over sodium partially meltod and the residuo then stored ovor sodium. p-Xylene was purified by similar methods and fractional crystallisation to constant freezing point was adopted for the final purification. Carbon tetrachloride was purified as in earlier studies frorn these labo- ratories and stored over sticks of potassium hydroxide. Phosphorus pen- toxide was unsuitable as drying agent and we confirm the observations of Smith and Witten ~1 on this. Cyclohexane was puri¡ by the method of Gillam and Stern9, washed froe from acid, treated with diluto pormanganate, dried first over caleium chloride and then over sodium and fractionated? Liquid dinitrogen tetro- xide was prepared from lead nitrate, freed from dissolved oxygon by repeated low pressure distillationTM and stored in sealed tubos. -

Calibration Gas

CALIBRATION GAS 2020 Visit our websites: www.gazdetect.com ▸ Online store: www.safetygas.com Visit our websites: www.gazdetect.com Online store: www.safetygas.com Calibration gas cylinders Calibration gas cylinders for bump tests, calibration and periodical checkings of gas detectors Product description GazDetect supplies standard and custom gas mixtures as well as pure gases in a range of lightweight, single-use, aluminum cylinders that are ideal for applications where portability is essential. Gaseous mixtures are mixed gravimetrically by generally applying the ISO6142 standard. Guarantying precision, optimum stability and maximum shelf life. These gaseous mixtures are mainly used for checkings and calibrations of gas detectors (fixed or portable) and other instru- ments : • Combustible gas detection • Toxic gas detection • Refrigerant gas detection • Breathalyzers and Ethanol • Gas chromatography Technical specifications • Analysis of agro-food atmospheres • Medical gas analysis • Wide range of standard or custom mixtures • Environmental monitoring • Gravimetric mixing for maximum accuracy • Standards (ISO 6142) and European legislation compliant The available offer covers a complete range from simple LEL cylinders. binary blends to complex and multiple lab mixtures with very low • From 6 to 60 months mixture stability (depending on gases) ppm levels.. Analysis certificated automatically provided • We have a large stock of the most common mixtures (especially • Portable, convenient and easy to use those associated with gas detection -

Contents 11/29 Molecular Constants

Contents 11/29 Molecular Constants Subvolume D3 1 General Introduction 1 1.1 General remarks 1 1.2 Review articles and tables 1 1.3 Arrangement of tables, substances and parameters 1 1.4 Error notation 2 1.5 Selection of data 3 1.6 Abbreviations used for experimental methods 3 1.7 Selected fundamental constants and conversion factors 3 1.8 References for 1 5 2 Asymmetric Top Molecules: Introduction 6 2.1 Rotational parameters 6 2.1.1 Defining equations 6 2.1.2 List of tabulated rotational parameters 10 2.1.3 References for 2.1 12 2.2. Hyperfine coupling constants 13 2.2.1 Quadrupole coupling constants, defining equations 13 2.2.2 Magnetic-interaction constants, defining equations 15 2.2.3 List of tabulated asymmetric-top hfs parameters 20 2.2.4 References for 2.2 21 2.3 Internal rotation 23 2.3.1 Defining equations 23 2.3.2 List of tabulated internal-rotation parameters 26 2.3.3 Conversion factors 28 2.3.4 References for 2.3 28 2.4 Symmetric top electric dipole moments 29 2.4.1 References for 2.4 29 2.5 External field magnetic interaction parameters 30 2.5.1 Defining equations 30 2.5.2 List of tabulated asymmetric-top external-magnetic-field parameters 30 2.5.3 References for 2.5 30 3 Data (J. DEMAISON, J. VOGT) 31 581 C6HN 2-(Cyanoethynyl)-2-cyclopropen-l-ylidene 31 582 C6H2 l,2,3-Hexatrien-5-yn-l-ylidene 32 583 C6H2 1,2,3,4,5-Hexapentaenylidene 33 584 C6H2S 1,2,3,4,5-Hexapentaene-l-thione 34 585 C6H3ArF3 1,2,3-Trifluorobenzene-argon (1/1) 35 586 C6H4 (3Z)-3-Hexene-l,5-diyne 36 587 C6H4 l-Hexene-3,5-diyne 38 588 C6H4 l,3-Cydohexadien-5-yne -

Equilibrium and Transport Properties of CO2+N2O and CO2+NO Mixtures : a Molecular Simulation and Equation of State Modelling Study

Equilibrium and transport properties of CO2+N2O and CO2+NO mixtures : a molecular simulation and equation of state modelling study. V. Lachet, B. Creton, T. de Bruin, E. Bourasseau, Nicolas Desbiens, O. Wilhelmsen, M. Hammer To cite this version: V. Lachet, B. Creton, T. de Bruin, E. Bourasseau, Nicolas Desbiens, et al.. Equilibrium and trans- port properties of CO2+N2O and CO2+NO mixtures : a molecular simulation and equation of state modelling study.. Fluid Phase Equilibria, Elsevier, 2012, 322, pp.66-78. 10.1016/j.fluid.2012.03.011. hal-00681797 HAL Id: hal-00681797 https://hal-ifp.archives-ouvertes.fr/hal-00681797 Submitted on 22 Mar 2012 HAL is a multi-disciplinary open access L’archive ouverte pluridisciplinaire HAL, est archive for the deposit and dissemination of sci- destinée au dépôt et à la diffusion de documents entific research documents, whether they are pub- scientifiques de niveau recherche, publiés ou non, lished or not. The documents may come from émanant des établissements d’enseignement et de teaching and research institutions in France or recherche français ou étrangers, des laboratoires abroad, or from public or private research centers. publics ou privés. Equilibrium and transport properties of CO 2+N2O and CO 2+NO mixtures. A molecular simulation and equation of state modelling study. V. Lachet a,*, B. Creton a, T. de Bruin a, E. Bourasseau b, N. Desbiensb, Ø. Wilhelmsen c, M. Hammer c a IFP Energies nouvelles, 1 et 4 avenue de Bois Préau, 92852 Rueil-Malmaison, France b CEA, DAM, DIF, F-91297 Arpajon, France c SINTEF Energy Research, Kolbjørn Hejes vei 1A, 7465 Trondheim, Norway Abstract In the present study, the thermodynamic behaviour and transport properties of CO 2+N2O and CO 2+NO mixtures have been investigated using molecular simulation and equation of state modelling. -

Common Cations, Anions, Acids, Salts and Hydrate Nomenclature

Common Cations, Anions, Acids, Salts and Hydrate Nomenclature Cations (positive ions) Anions (negative ions) Acids (H+ and anion) H+ Hydrogen ion (proton) H– Hydride ion + – NH4 Ammonium ion F Fluoride ion…………………………………… … HF Hydrofluoric acid Main Group Ions Cl – Chloride ion…………………………………… … HCl Hydrochloric acid Li+ Lithium ion Br – Bromide ion…………………………………… … HBr Hydrobromic acid Na+ Sodium ion I – Iodide ion …………………………………… … HI Hydroiodic acid K+ Potassium ion O2– Oxide ion Rb+ Rubidium ion OH– Hydroxide ion + 2– Cs Cesium ion O2 Peroxide ion 2+ 2– Be Beryllium ion S Sulfide ion …………………………………… … H2S Hydrosulfuric acid Mg2 Magnesium ion HS– Hydrogen sulfide ion Ca2+ Calcium ion Se2– Selenide Ion Sr2+ Strontium ion N3– Nitride ion 2+ – Ba Barium ion N3 Azide ion AI3+ Aluminum ion P3– Phosphide ion Sn2+ Tin(II) (stannous) ion As3- Arsinide ion Sn4+ Tin(IV) (stannic) ion C4– Carbide ion Pb2+ Lead(II) (plumbous) ion CN– Cyanide ion…………………………………… … HCN Hydrocyanic Acid Pb4+ Lead(IV) (plumbic) ion Oxoanions Oxoacids 3+ – Sb Antimony(III) (antimonous) ion CIO1 Hypochlorite ion……………………………… … HCIO Hypochlorous acid 5+ – Sb Antimony(V) (antimonic) ion CIO2 Chlorite ion…………………………………… … HCIO2 Chlorous acid 3+ – Bi Bismuth(III) (bismuthous) ion CIO3 Chlorate ion…………………………………… … HCIO3 Chloric acid 5+ – Bi Bismuth(V) (bismuthic) ion ClO4 Perchlorate ion ……………………………… … HClO4 Perchloric acid 2– Transition metal ions SO3 Sulfite ion……………………………………… … H2SO3 Sulfurous acid 2+ 2– Cr Chromium(II) (chromous) ion SO4 Sulfate ion …………………………………… … H2SO4 Sulfuric -

Synthetic, Natural, and Semisynthetic Polymer Carriers for Controlled Nitric Oxide Release in Dermal Applications: a Review

polymers Review Synthetic, Natural, and Semisynthetic Polymer Carriers for Controlled Nitric Oxide Release in Dermal Applications: A Review Carolina Gutierrez Cisneros 1 , Veerle Bloemen 1,2 and Arn Mignon 1,* 1 Surface and Interface Engineered Materials, Campus Group T, KU Leuven, Andreas Vesaliusstraat 13, 3000 Leuven, Belgium; [email protected] (C.G.C.); [email protected] (V.B.) 2 Prometheus, Division of Skeletal Tissue Engineering, KU Leuven, Herestraat 49, 3000 Leuven, Belgium * Correspondence: [email protected] Abstract: Nitric oxide (NO•) is a free radical gas, produced in the human body to regulate physiolog- ical processes, such as inflammatory and immune responses. It is required for skin health; therefore, a lack of NO• is known to cause or worsen skin conditions related to three biomedical applications— infection treatment, injury healing, and blood circulation. Therefore, research on its topical release has been increasing for the last two decades. The storage and delivery of nitric oxide in physiological conditions to compensate for its deficiency is achieved through pharmacological compounds called NO-donors. These are further incorporated into scaffolds to enhance therapeutic treatment. A wide range of polymeric scaffolds has been developed and tested for this purpose. Hence, this review aims to give a detailed overview of the natural, synthetic, and semisynthetic polymeric matrices that have been evaluated for antimicrobial, wound healing, and circulatory dermal applications. These matrices have already set a solid foundation in nitric oxide release and their future perspective Citation: Gutierrez Cisneros, C.; is headed toward an enhanced controlled release by novel functionalized semisynthetic polymer Bloemen, V.; Mignon, A. -

Performance of Nitrogen Oxides (NOX) Emission Controls at U.S. Power Plants

Inquiry into health impacts of air pollution in Victoria Submission 67 - attachment 2 Performance of Nitrogen Oxides (NOX) Emission Controls at U.S. Power Plants A comparison of combustion and post-combustion control technologies for coal-fired power plants Jeremy Schreifels (石智锐) 2008380009 PhD Candidate 80050012 ʹ 能源与环境 贺克斌教授 2008 Winter Ta ble of C onte nt s Abbreviations and Acronyms ......................................................................... i Notes ......................................................................................................... i Introduction ............................................................................................... 1 Health and Environmental Impacts of Nitrogen Oxides .................................... 2 Air Quality Standards for Nitrogen Dioxide and Secondary Pollutants ................ 4 Sources of Nitrogen Oxides Emissions ........................................................... 6 Formation of Nitrogen Oxides Emissions........................................................ 9 Technologies for Reducing or Controlling Nitrogen Oxides ..............................11 Combustion Modification Technologies ....................................................12 Post-Combustion Control Technologies ....................................................18 Emerging and Advanced Control Technologies ..........................................28 Technology Performance and Costs .........................................................29 Bibliography ..............................................................................................31