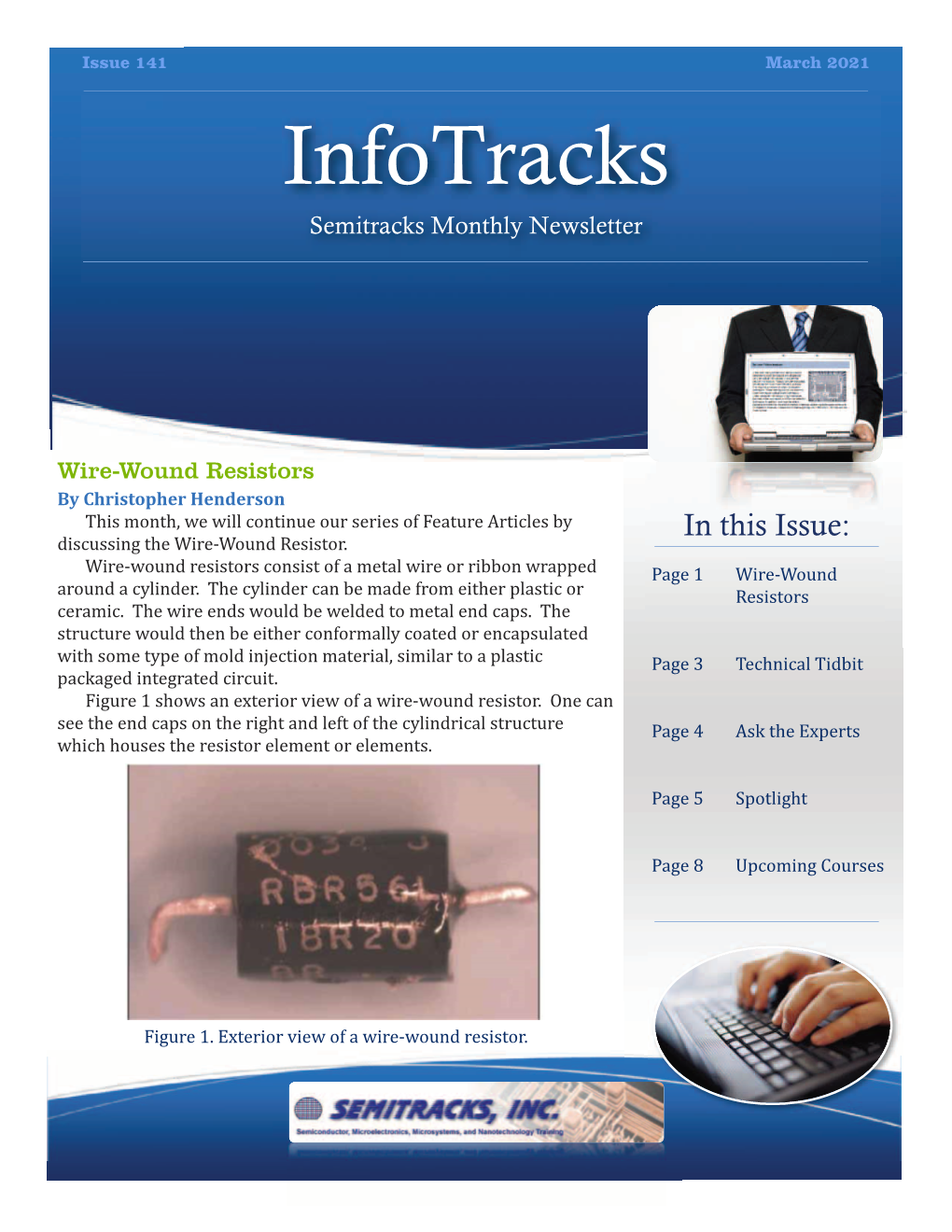

Wire-Wound Resistors by Christopher Henderson This Month, We Will Continue Our Series of Feature Articles by Discussing the WireWound Resistor

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Advanced MOSFET Structures and Processes for Sub-7 Nm CMOS Technologies

Advanced MOSFET Structures and Processes for Sub-7 nm CMOS Technologies By Peng Zheng A dissertation submitted in partial satisfaction of the requirements for the degree of Doctor of Philosophy in Engineering - Electrical Engineering and Computer Sciences in the Graduate Division of the University of California, Berkeley Committee in charge: Professor Tsu-Jae King Liu, Chair Professor Laura Waller Professor Costas J. Spanos Professor Junqiao Wu Spring 2016 © Copyright 2016 Peng Zheng All rights reserved Abstract Advanced MOSFET Structures and Processes for Sub-7 nm CMOS Technologies by Peng Zheng Doctor of Philosophy in Engineering - Electrical Engineering and Computer Sciences University of California, Berkeley Professor Tsu-Jae King Liu, Chair The remarkable proliferation of information and communication technology (ICT) – which has had dramatic economic and social impact in our society – has been enabled by the steady advancement of integrated circuit (IC) technology following Moore’s Law, which states that the number of components (transistors) on an IC “chip” doubles every two years. Increasing the number of transistors on a chip provides for lower manufacturing cost per component and improved system performance. The virtuous cycle of IC technology advancement (higher transistor density lower cost / better performance semiconductor market growth technology advancement higher transistor density etc.) has been sustained for 50 years. Semiconductor industry experts predict that the pace of increasing transistor density will slow down dramatically in the sub-20 nm (minimum half-pitch) regime. Innovations in transistor design and fabrication processes are needed to address this issue. The FinFET structure has been widely adopted at the 14/16 nm generation of CMOS technology. -

Coverage Layout Design Rules and Insertion Utilities for CMP-Related Processes

Journal of Low Power Electronics and Applications Review Coverage Layout Design Rules and Insertion Utilities for CMP-Related Processes Eitan N. Shauly 1,2,* and Sagee Rosenthal 1 1 Tower Semiconductor, Migdal Ha’Emek 10556, Israel; [email protected] 2 The Faculty of Materials Science and Engineering, Technion-Israel Institute of Technology, Haifa 32000, Israel * Correspondence: [email protected] Abstract: The continuous scaling needed for higher density and better performance has introduced some new challenges to the planarity processes. This has resulted in new definitions of the layout coverage rules developed by the foundry and provided to the designers. In advanced technologies, the set of rules considers both the global and the local coverage of the front-end-of line (FEOL) dielectric layers, to the back-end-of-line (BEOL) Cu layers and Al layers, to support high-k/Metal Gate process integration. For advance technologies, a new set of rules for dummy feature insertion was developed by the integrated circuit (IC) manufacturers in order to fulfill coverage limits. New models and utilities for fill insertion were developed, taking into consideration the design coverage, thermal effects, sensitive signal line, critical analog and RF devices like inductors, and double patterning requirements, among others. To minimize proximity effects, cell insertion was also introduced. This review is based on published data from leading IC manufacturers with a careful integration of new experimental data accumulated by the authors. We aim to present a typical foundry perspective. The review provides a detailed description of the chemical mechanical polishing (CMP) process and the coverage dependency, followed by a comprehensive description of coverage rules needed for dielectric, poly, and Cu layers used in advanced technologies. -

A Back-End, CMOS Compatible Ferroelectric Field Effect Transistor

A back-end, CMOS compatible ferroelectric Field Effect Transistor for synaptic weights , , Mattia Halter,∗ † ‡ Laura Bégon-Lours,† Valeria Bragaglia,† Marilyne Sousa,† Bert Jan Offrein,† Stefan Abel,† Mathieu Luisier,‡ and Jean Fompeyrine† IBM Research GmbH - Zurich Research Laboratory, CH-8803 RÃijschlikon, Switzerland † Integrated Systems Laboratory, ETH Zurich, CH-8092 Zurich, Switzerland ‡ E-mail: [email protected] Abstract Neuromorphic computing architectures enable the dense co-location of memory and processing elements within a single circuit. This co-location removes the communi- cation bottleneck of transferring data between separate memory and computing units as in standard von Neuman architectures for data-critical applications including ma- chine learning. The essential building blocks of neuromorphic systems are non-volatile synaptic elements such as memristors. Key memristor properties include a suitable non-volatile resistance range, continuous linear resistance modulation and symmetric arXiv:2001.06475v1 [cs.ET] 17 Jan 2020 switching. In this work, we demonstrate voltage-controlled, symmetric and analog po- tentiation and depression of a ferroelectric Hf0.57Zr0.43O2 (HZO) field effect transistor (FeFET) with good linearity. Our FeFET operates with a low writing energy (fJ) and fast programming time (40 ns). Retention measurements have been done over 4-bits depth with low noise (1 %) in the tungsten oxide (WOx) read out channel. By ad- justing the channel thickness from 15nm to 8nm, the on/off ratio of the FeFET can be engineered from 1 % to 200 % with an on-resistance ideally >100 kΩ, depending on the channel geometry. The device concept is using earth-abundant materials, and is 1 compatible with a back end of line (BEOL) integration into complementary metal-oxide- semiconductor (CMOS) processes. -

Design, Fabrication, and Characterization of Three‑Dimensional Embedded Capacitor in Through‑Silicon Via

This document is downloaded from DR‑NTU (https://dr.ntu.edu.sg) Nanyang Technological University, Singapore. Design, fabrication, and characterization of three‑dimensional embedded capacitor in through‑silicon via Lin, Ye 2019 Lin, Y. (2019). Design, fabrication, and characterization of three‑dimensional embedded capacitor in through‑silicon via. Doctoral thesis, Nanyang Technological University, Singapore. https://hdl.handle.net/10356/102666 https://doi.org/10.32657/10220/48586 Downloaded on 28 Sep 2021 02:52:36 SGT ( O n th e S p ine) DESIGN, FA BRICATION, AND CHARACTERIZATION OF 3 DESIGN, FABRICATION, AND CHARACTERIZATION OF THREE-DIMENSIONAL EMBEDDED CAPACITOR IN THROUGH-SILICON VIA - D EMBEDDED CAPACITOR IN TSV LIN YE LIN YE SCHOOL OF ELECTRICAL AND ELECTRONIC ENGINEERING 2019 2019 DESIGN, FABRICATION, AND CHARACTERIZATION OF THREE-DIMENSIONAL EMBEDDED CAPACITOR IN THROUGH-SILICON VIA LIN YE (B. Eng., Nanyang Technological University) SCHOOL OF ELECTRICAL AND ELECTRONIC ENGINEERING A thesis submitted to the Nanyang Technological University in partial fulfillment of the requirement for the degree of Doctor of Philosophy 2019 Statement of Originality I hereby certify that the work embodied in this thesis is the result of original research, is free of plagiarised materials, and has not been submitted for a higher degree to any other University or Institution. 28 May 2019 Date Lin Ye Supervisor Declaration Statement I have reviewed the content and presentation style of this thesis and declare it is free of plagiarism and of sufficient grammatical clarity to be examined. To the best of my knowledge, the research and writing are those of the candidate except as acknowledged in the Author Attribution Statement. -

2013 Edition

INTERNATIONAL TECHNOLOGY ROADMAP FOR SEMICONDUCTORS 2013 EDITION INTERCONNECT THE ITRS IS DEVISED AND INTENDED FOR TECHNOLOGY ASSESSMENT ONLY AND IS WITHOUT REGARD TO ANY COMMERCIAL CONSIDERATIONS PERTAINING TO INDIVIDUAL PRODUCTS OR EQUIPMENT. THE INTERNATIONAL TECHNOLOGY ROADMAP FOR SEMICONDUCTORS: 2013 Table of Content Interconnect .......................................................................................................................... 1 1. Scope ................................................................................................................ 1 1.1. Introduction ..................................................................................................................................... 1 1.2. What’s new for 2013? .................................................................................................................... 1 2. Summary ........................................................................................................... 2 2.1. Difficult Challenges......................................................................................................................... 2 2.2. Interconnect Architectures ............................................................................................................. 4 2.3. 3D Interconnect Architectures ........................................................................................................ 6 2.4. Passive Devices .......................................................................................................................... -

Physical, Electrical, and Reliability Considerations for Copper BEOL Layout Design Rules

Journal of Low Power Electronics and Applications Review Physical, Electrical, and Reliability Considerations for Copper BEOL Layout Design Rules Eitan N. Shauly 1,2 1 TowerJazz Corporation, Migdal Ha’Emek 10556, Israel; [email protected]; Tel.: +972-4-6506570 2 The Faculty of Materials Science and Engineering, Technion-Israel Institute of Technology, Haifa 32000, Israel Received: 16 March 2018; Accepted: 18 May 2018; Published: 14 June 2018 Abstract: The continuous scaling needed for better performance and higher density has introduced some new challenges to the back end of line (BEOL) in terms of layout and design. Reductions in metal line width, spacing, and thickness require major changes in both process and design environments. Advanced deep-submicron layout design rules (DRs) should now consider many new proximity effects and reliability concerns due to high electrical fields and currents, planarization-related coverage effects, etc. It is, therefore, necessary to redefine many of the common DRs. For example, space rules now have a complex definition, including both line width and parallel length. In addition, new rules have been introduced to represent the challenges of reliability such as stress-induced voids, time-dependent dielectric breakdowns of intermetal dielectrics, dependency on misalignment, sensitivity to double patterning, etc. This review describes a set of copper (Cu) BEOL layout design rules, as used in technologies featuring lengths ranging from 0.15 µm to 20 nm. The verification of layout rules and sensitivity issues related to them are presented. Reliability-related aspects of some rules, like space, width, and via density, are also discussed with additional design-for-manufacturing layout recommendations. -

Dissertation Pretext

AN ABSTRACT OF THE DISSERTATION OF Dustin Zachary Austin for the degree of Doctor of Philosophy in Electrical and Computer Engineering presented on May 19, 2017. Title: Atomic Layer Deposition of Multi-Insulator Metal-Insulator-Metal Capacitors. Abstract approved: ______________________________________________________ John F. Conley Jr. Back end of line (BEOL) metal-insulator-metal capacitors (MIMCAPs) have become a core passive component in modern integrated circuits. International Technology Roadmap for Semiconductors (ITRS) projections for scaling of analog/mixed-signal MIMCAP applications require simultaneously increasing capacitance density while maintaining low leakage current density and low voltage nonlinearity (characterized by the quadratic voltage coefficient of capacitance, αVCC). In addition to these conflicting performance requirements, BEOL processing allows for temperatures of no more than 400°C. In this work, atomic layer deposition (ALD) of both dielectrics and metals have been investigated to develop complementary multi-insulator MIMCAPs to meet future ITRS requirements. Initially Al2O3/SiO2 bilayers are assessed for targeting the ITRS 2020 node. These oxides are attractive due to their large metal-insulator barrier heights, high dielectric breakdown strength, and common usage in IC fabrication. SiO2 is one of only a few materials to exhibit a negative αVCC, which in combination with the positive αVCC of Al2O3 enables ultra-low device αVCC through the "canceling" effect. ALD for these ultra- thin insulators has become the preferred deposition method due to the inherent low deposition temperatures, precise film thickness control, and excellent film quality. Next, to support scaling beyond the 2020 node, novel ALD processes are developed for bismuth oxide (Bi2O3), ruthenium oxide (RuO2), and ruthenium metal (Ru). -

Semiconductor Production Equipment

Semiconductor Production Equipment Continuous advances in semiconductors are driving the information and without continuous advances in the semiconductor production equipment (SPE) tion by helping chipmakers execute their product strategies successfully. RAPIDLY EXPANDING END-USE APPLICATIONS DRIVE INDUSTRY GROWTH At one time, personal computers were the main end-use application for semiconductors. Today, however, a broad array of products rely on semiconductors to offer increased performance and functionality, including mobile phones, personal digital assistants (PDAs), game consoles, DVD play- ers and other digital consumer electronic products. Furthermore, new, yet-to-be-imagined applica- tions will continue to fuel demand for chips. Thermal Systems Ion Implantation Systems TOKYO ELECTRON IS A LEADER IN WAFER FABRICATION EQUIPMENT Film Deposition Systems Wafer fabrication equipment uses mainly physical and chemical processes to create minute, multi-layer cir- Wafer cuits on round silicon wafers. While various types of Fabrication equipment are used for performing these microscopic Equipment processes, most of these products can be grouped into several broad categories. Most equipment sup- Lithography/Patterning Systems pliers focus on a single market segment, but Tokyo Electron is a world leader in many of them. Removal Systems 8 TOKYO ELECTRON LIMITED — The Source of Innovation communications revolution. This revolution, however, would not be possible that is used to make chips. Tokyo Electron operates at the heart of this revolu- SEMICONDUCTOR PRODUCTION EQUIPMENT – A LARGE AND INTEGRAL PART OF THE SEMICONDUCTOR INDUSTRY The semiconductor production equipment industry is a large and integral part of the semi- conductor industry. Information and communications products demand higher perfor- mance chips from chipmakers, who demand higher performance equipment from equip- ment suppliers, whose advances drive the information and communications revolution. -

Semiconductor Terms

Glossary of Terms 47 Molter Street Cranston, Rhode Island 02910-1032 401-781-6100 • [email protected] • www.technic.com SEMICONDUCTOR TERMS Symbols BHF buffered hydrofluoric acid symbol for Angstrom BiCMOS bipolar and complimentary metal wavelength oxide semiconductor combined BGA micro ball grid into a single IC m micron BIM binary intensity mask P microprocessor Bipolar two polarities; IC in which both W microwave; microwatt electrons and holes flow 100 silicon <100> crystal facet Bit binary information digit 111 silicon <111> crystal facet BJT bipolar junction transistor BOE buffered oxide etch A BPSG borophosphosilicate glass AC alternating current voltage BSE backscattered electron AES auger electron spectroscopy BSG borosilicate glass AFM atomic force microscopy BSR ball size ratio AI aluminum ALE atomic layer epitxy ALSiCu aluminum / silicon / copper alloy AMU atomic mass unit APCVD atmospheric pressure chemical C vapor deposition C carbon APSM absorptive phase shift mask CAD computer-aided design Ar argon CAIBE chemical assisted ion beam etch ARC antireflective coating CAM computer-aided manufacturing ARDE aspect ratio dependent etching CBE chemical beam epitaxy As arsenic CCD charge-coupled device ASTM American Society of Testing and CD critical dimension Materials CEL contrast enhancement layer ASIC application specific integrated CERDIP ceramic dual inline package circuit CF4 carbon tetrafluoride, freon-14 ATE automatic test equipment CFM contamination free Au gold manufacturing; cubic feet per minute Cl chlorine B CL cathodoluminescence -

TSV Through Silicon Via Technology for 3D-Integration

TSV Through Silicon Via Technology for 3D-integration Solience Ngansso Prof. Dr. Peter Fischer Department of Circuit Design Department of Circuit Design ZITI, University of Heidelberg ZITI, University of Heidelberg Germany, 68131 Mannheim Germany, 68131 Mannheim Email: [email protected] Email: [email protected] Abstract—In this paper the Through Silicon Via Technology 1) Via formation by either deep reactive-ion etch for 3D-integration will be presented. This technology is an (DRIE) or laser drilling important developing technology that utilises short, vertical 2) Dielectric layer deposition by either thermal electrical connections or “vias” that pass through a silicon wafer oxidation for passive interposers or plasma-enhanced chemical in order to establish an electrical connection from the active side vapor deposition (PECVD) to the backside of the die, thus providing the shortest interconnect path and creating an avenue for the ultimate in 3D 3) Barrier and seed layer deposition by physical vapor integration. In the first part of this paper, the steps of the deposition (PVD) through silicon vias (TSV) technology will be discussed: from the 4) Cu plating to fill the vias or W (tungsten) sputtering via first approach, a front-end process, to the via last approach, a (CVD) for very tiny vias back-end process. Each of these different ways of elaborating the 5) Chemical and mechanical polishing (CMP) of Cu vias has its advantages and drawbacks. Some Morphological and plating residues (overburden) electrical characterizations of the TSV technology -via shapes, 6) TSV revealing depths, and sizes- will also be showed. In a second part, some applications for TSV in research and industry will be introduced. -

Basic Failure Mechanisms Particles and Defects

Issue 143 May 2021 Basic Failure Mechanisms By Christopher Henderson This month, we begin a new series of Feature Articles that will cover Failure Mechanisms. While there are literally hundreds of Page 1 Basic Failure semiconductor and integrated circuitrelated failure mechanisms, Mechanisms there are some common ones of which you should be aware. Over the next four Feature Articles, we will cover these basic failure mechanisms: Particles and Defects, Die ReliabilityRelated Failure Page 7 Technical Tidbit Mechanisms, PackageRelated Failure Mechanisms, and Use Condition Failure Mechanisms. We begin this month with Particles and Defects. Page 8 Ask the Experts Particles and Defects Defects are one of the more important concerns to the manufacturing staff in a semiconductor manufacturing plant. Defects Page 9 Spotlight can be introduced from a wide variety of sources. These sources include the wafer processing equipment, the chemicals and gases used during processing, wafer handling, and a host of other sources. Page 12 Upcoming Courses These defects will have a distribution that covers a wide range of sizes and types. Process and yield engineers have consistently observed that the number of particles increases as the size of the particle decreases. Therefore, fewer large particles make it to the wafer surface, while more smaller particles do. Particles that land on the wafer surface can create defects during processing that can cause the chip to fail. Issue 143 May 2021 An obvious aspect of defects is that they reduce yields on semiconductor components. Let’s use the following example to illustrate this point. Let’s assume that we have patterned an integrated circuit such that it has a number of parallel interconnect segments, as shown in Figure 1. -

Through-Silicon Via (TSV)

INVITED PAPER Through-Silicon Via (TSV) This technology allows stacked silicon chips to interconnect through direct contact to provide high-speed signal processing and improved photo detection for image sensing. By Makoto Motoyoshi, Member IEEE ABSTRACT | Recently, the development of three-dimensional large-scale integration (3D-LSI) has been accelerated. Its stage has changed from the research level or limited production level to the investigation level with a view to mass production [1]–[10]. The 3D-LSI using through-silicon via (TSV) has the simplest structure and is expected to realize a high-performance, high- functionality, and high-density LSI cube. This paper describes the current and future 3D-LSI technologies with TSV. KEYWORDS | Chip size package (CSP); image sensor; micro bump; three-dimensional large-scale integration (3D-LSI); through-silicon via (TSV) I. INTRODUCTION Semiconductor integration technology has been widely spread in two-dimensional applications over the past three Fig. 1. TSV for 3D-LSI technology road map. decades. This wide application has been employed not only in the field of the electronics industries but also in a lot of related industries such as optoelectronics, bioelectronics, approaches. One is reconsidering circuits and system medical systems, electronics analysis, computer systems, architecture from view point of power consumption. military systems, satellite systems, submarine systems, and Another is concerning LSI structure. In recent devices, so on. From the consumer area to ultra-high-end products the signal propagation delay is mainly determined by and military usage, almost all industrial products incorpo- wiring length and pin capacitance. Three-dimensional rate semiconductor devices. One significant reason for this large-scale integration (3D-LSI) is the one solution to rapid progress is the good scalability of metal–oxide– improve performance without increase of power consump- semiconductor (MOS) devices [11].