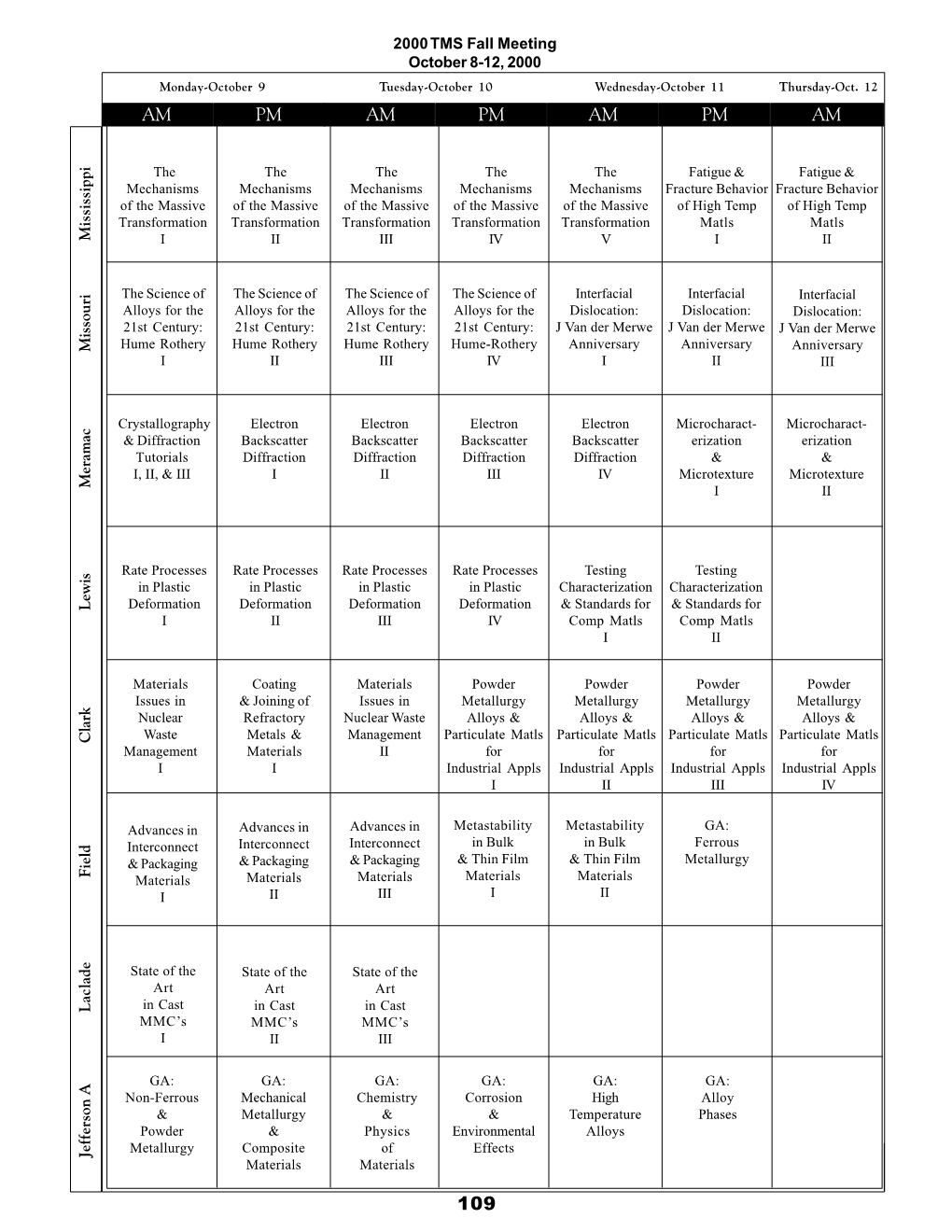

TMS 2000 Fall Meeting

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Effect of Tensile Load on the Mechanical Properties of Alsic

EKPU: EFFECT OF TENSILE LOAD ON THE MECHANICAL PROPERTIES OF AlSiC COMPOSITE MATERIALS 301 Effect of Tensile Load on the Mechanical Properties of AlSiC Composite Materials using ANSYS Design Modeller Mathias Ekpu* Department of Mechanical Engineering, Delta State University, Abraka, Oleh Campus, Nigeria. ABSTRACT: Aluminium Silicon Carbide (AlSiC) composite materials are used in the electronics industries and other manufacturing companies hence, manufacturing of AlSiC composite materials with the right properties for different applications are vital to most industries. The challenge of testing the same specimens for different properties remains, because most of the tests carried out are destructive. Hence, the use of ANSYS finite element simulation software for the design and analysis of a flat bar specimen. Loads between 3 kN to 21 kN were applied on the specimen since it is within the operating limit of a Universal Tensile Testing Machine (UTTM), while both ends are fixed. The AlSiC composite materials used in this study have a composition of 63 vol% Al (356.2) and 37 vol% SiC and, the results showed that stress was directly proportional to strain. While the calculated Young’s modulus from the stress versus strain plot was approximately 167 GPa for the different tensile loads applied. In addition, the total deformation of the AlSiC composite material increased as the load was increased. Also, the highest deformation of the material was observed around the centre of the test specimen. This is synonymous with the failure observed in practical testing of specimens. KEYWORDS: AlSiC, tensile load, aluminium MMC, stress analysis, deformation, ANSYS [Received May 31, 2020, Revised Oct. -

Parametricstudyoffrictionstirweldi

www.ijcrt.org © 2018 IJCRT | Volume 6, Issue 2 April 2018 | ISSN: 2320-2882 Parametricstudyoffrictionstirweldingofaluminiumall oy6061andaluminium Sic matrix composite Chintan Patel1,Mr.chinmay shah2, PGFellow, MechanicalEngineeringDept., Parulinstituteoftechnology, 2Dept.ofMech.Engg. FacultyofEnggandtech., ParulUniversityofBaroda, Abstract: Now, a day’s friction stir welding process has many advantages compared to tradinational welding process. The present work aims assign to prospect to weld two work pieces of aluminum alloy 6061 and aluminum silicon carbide composite and study the effect of mechanical properties of welding joints. In this experimental work welding will be carried out by using different welding speed and tool rotation speed. The Hardness, tensile strength and mechanical properties will be carried out by using different mechanical test. Introduction: Friction stir welding invented by Wayne Thomas at TWI( The Welding institute) Ltd in 1991.It overcomes many of the problem associated with convention joining techniques. Friction stir welding is solid state joining process that uses a non-consumable tool to join two facing work pieces without melting the work pieces material. Heat is generated by friction between the rotating tool and work piece material, which leads to a soften region near the tool. This heat is without reaching melting point and allows traversing of the tool along the weld line. The plasticized material is transferred the front edge of the tool to back edge of the tool of the tool probe and it’s forged by the intimate contact of the tool shoulder and pin profile There are important welding parameters are: 1. Tool design: The design of the tool is critical factor as good tool can improve both the quality of the weld and the maximum possible welding speed. -

STUDY of Alsic METAL MATRIX COMPOSITE BASED FLAT THIN

13th International Heat Pipe Conference (13th IHPC), Shanghai, China, September 21-25, 2004. 678'<2)$O6L&0(7$/0$75,;&20326,7(%$6(' )/$77+,1+($73,3( ;LQKH7DQJ (UQVW+DPPHO:DOWHU)LQGO7KHRGRU6FKPLWW'LHWHU7KXPIDUW Electrovac GmbH, Aufeldgasse 37-39, 3400 Klosterneuburg, Austria. *Corresponding author: [email protected], www.electrovac.com Tel: (+43)-2243-450405, Fax: (+43)-2243-450698 0DQIUHG*UROO0DUFXV6FKQHLGHU6DPHHU.KDQGHNDU IKE, Universität Stuttgart, Pfaffenwaldring 31, 70569 Stuttgart, Germany. Tel: (+49)-711-685-2481/2138, Fax: (+49)-711-685-2010, www-ew.ike.uni-stuttgart.de $%675$&7 AlSiC based flat thin heat pipe prototypes (143.8 x 80.8 x 5 mm3 outer dimensions) are manufactured. The manufacture process including wick structure design, AlSiC plate processing and plating, soldering the subparts, and finally filling and sealing is presented in this paper. Considering satellite launch conditions, vibration tests involving low/high level sine sweep, medium/low level random and full random are carried out. The temperature profiles over the entire heat pipe are measured by means of infrared (IR) scanning to study the thermal resistance, heat transfer capacity and heat pipe performance degradation, if any. Both horizontal and vertical orientations with different heating-cooling modes are employed in the performance tests. AlSiC based flat thin heat pipes are proven to have excellent performance characteristics. After 42 weeks life test, thermal resistance in the range from 0.15 K/W to 0.5 K/W has been measured at thermal loads from 20 W to 140 W. The lowest thermal resistance is achieved by testing the performance vertically in the top-cooling and bottom-heating mode. -

Metals Polymers Ceramics

INDUSTRY NEWS METALS POLYMERS CERAMICS Carbon fiber and aluminum honeycomb chassis enhance safety BRIEFS The chassis of this CCX Edition Koenigsegg AGY has developed sports car consists of carbon fiber and alu- ThermoBallistic composite minum honeycomb with an integrated fuel armor system laminates that combine continuous tank to optimize weight distribution and structural S-2 Glass, safety, says Koenigsegg Automotive AG, E Glass, or aramid fibers to Sweden. The body is made of pre-impreg- form X-ply sheets or nated carbon fiber/Kevlar and lightweight unidirectional tapes that sandwich reinforcements. The chrome-moly can be molded to create stainless steel subframe has integrated crash members. thermoformable ballistic The cast aluminum V-8 engine has a carbon-fiber intake manifold and a TIG-welded, ceramic- and blast protection. coated stainless steel exhaust manifold. Forged aluminum wheels are stopped by ventilated ceramic www.agy.com brake disks with aluminum calipers. Allegheny Technologies Inc. has ArvinMeritor Inc. For more information: Koenigsegg Automotive AB, An- reached an agreement with Gulf Petro- announces that its Light gelholm, Sweden; www.koenigsegg.com. chemical Industries Co. to supply ATI Vehicle Systems business group has been OmegaBond advanced tubing for GPIC’s Shape-memory polymers awarded a multi-year fertilizer production complex in the make implantable stents contract to supply Kingdom of Bahrain. OmegaBond enables Hyundai North the use of dissimilar metals in the same Shape-memory polymers that can be temporarily stretched America with an tube or pipe by advanced joining tech- or compressed into forms several times larger or smaller innovative plastic door nologies such as extrusion bonding or in- than their final shape have been developed by Georgia Insti- module and accompanying tute of Technology, Atlanta, Ga. -

Investigation of Mechanical Properties of Aluminium Silicon Carbide Hybride Metal Matrix Composite (Mmcs)

International Journal of Research in Engineering and Science (IJRES) ISSN (Online): 2320-9364, ISSN (Print): 2320-9356 www.ijres.org Volume 5 Issue 4 ǁ Apr. 2017 ǁ PP.88-105 Investigation of Mechanical Properties of Aluminium Silicon Carbide Hybride Metal Matrix Composite (Mmcs) Bhagwat T. Dhekwar, Aliva Mohanty, Jagdish Pradhan, Saswati Nayak Department of Mechanical Engineering, NM Institute of Engineering and Technology,Bhubaneswar , Odisha Department of Mechanical Engineering, Raajdhani Engineering College,Bhubaneswar,Odisha Department of Mechanical Engineering,Aryan Institute of Engineering and Technology Bhubnaeswar , Odisha Department of Mechanical Engineering,Capital Engineering College,Bhubaneswar,Odisha ABSTRACT: Metal Matrix Composites (MMCs) have shown great interest in recent times dueto its poetental of applications in aerospace and automotive industries because of having superior strength to weight ratio. The wide use of particular metal matrix composites for engineering application has been obstructed by the exact use of silicon carbide ( SiC) by % , hence high cost of components. Although there are several techniques used for casting technology rather it can be used to overcome this problem. Materials are frequently chosen for structural applications because they have desirable combinations of mechanical characteristics. Development of hybrid metal matrix composities has became important area of research interest in Material Science . In view of this , the present study focuses on the behaviour of aluminium silicon carbide ( AlSiC) hybrid metal matrix composities .The present study was aimed at evaluating the mechanical properties of Aluminium in the presence of silicon carbidewith different weight percentage ofsilicon carbide (5%,10%,15%& 20%)combinations.ConsequentlyAluminium metal matrix composite combines and exhibits huge strength of the reinforcement with the toughness of the matrix to achieve a combination of desirable properties not avilable in any single conventional metarial . -

Beryllium Composites for Advanced Avionics Systems Howard Berkowitz, Lockheed Martin Electronics & Missile Systems Tom Parsonage, Materion Beryllium & Composites

Use of Aluminum-Beryllium Composites for Advanced Avionics Systems Howard Berkowitz, Lockheed Martin Electronics & Missile Systems Tom Parsonage, Materion Beryllium & Composites ABSTRACT Avionics requirements for aircraft and satellite systems continue to increase, requiring higher packaging densities, lower delta junction temperatures, higher heat loads, smaller and lighter packaging utilizing chip on board, BGA and surface mount technologies that continue to challenge materials development. To address these increased performance needs, Materion Beryllium & Composites has developed a family of new metal matrix materials, AlBeMet® and E-Materials, for these increased performance avionics systems. This paper will describe the general material attributes of AlBeMet and E- Materials first, and then look at the application of these properties in the design and packaging of advanced avionics electronic products. These materials offer the design engineer a combination of light weight, high thermal conductivity, and tailorable coefficient of thermal expansion (CTE), high specific stiffness and thermal stability, with mechanical properties that have a high degree of isotropy. These materials are manufactured by conventional powder metallurgy technology, while at the same time being able to be fabricated with conventional aluminum technology. Keywords: Metal Matrix Composites, Aluminum-Beryllium, AlBeMet, E-Materials, Avionics Systems INTRODUCTION AlBeMet® is a family of metal matrix composite made up principally of beryllium and aluminum. We can vary the ratio of the two metals to alter the physical, thermal and mechanical properties. The first composition offered to the market is AlBeMet® 162, a 62% Beryllium/38% Aluminum composite. This material is a powder metallurgy product produced by gas atomization, and the final product forms, rod, bar, tube, sheet are derived by consolidating the aluminum/beryllium powder by Hot Isostatic Pressing (HIP) and Cold Isostatic Pressing (CIP) followed by extrusion or sheet rolling processes. -

Cláudia Sofia De Andrade Redondo Murilhas Buchheim

Universidade de Aveiro Departamento de Engenharia Mecânica Ano 2013 Cláudia Sofia de Comportamento mecânico de AlSiC nanocompositos produzido Andrade Redondo em moínho de bolas e compactado por Spark Plasma Sintering Murilhas Buchheim Mechanical Behavior of AlSiC nano composites produced by Ball Milling and Spark Plasma Sintering Universidade de Aveiro Departamento de Engenharia Mecânica Ano 2013 Cláudia Sofia de Comportamento mecânico de AlSiC nanocompositos produzido Andrade Redondo em moínho de bolas e compactado por Spark Plasma Sintering Murilhas Buchheim Mechanical Behavior of AlSiC nano composites produced by Ball Milling and Spark Plasma Sintering Tese apresentada à Universidade de Aveiro para cumprimento dos requisitos necessários à obtenção do grau de Doutor em Engenharia Mecânica, realizada sob a orientação científica do Doutor José Joaquim de Almeida Grácio, Professor Catedrático do Departamento de Engenharia Mecânica da Universidade de Aveiro e coorientação do Doutor Wilfried Georg Smarsly, Diretor de Investigação na Indústria Aeroespacial na Alemanha Dedico este trabalho aos meus pais, ao meu marido e às minhas filhas, Marie e Sofia. o júri presidente Doutor Helmuth Robert Malonek Professor Catedrático da Universidade de Aveiro Doutor Hamid Garmestani Professor Catedrático do Instituto de Tecnologia da Geórgia Doutor Saïd Ahzi Professor Catedrático da Universidade de Estrasburgo Doutor José Joaquim de Almeida Grácio Professor Catedrático da Universidade de Aveiro (orientador) Doutora Maria Leopoldina Mendes Ribeiro de Sousa Alves Professora Coordenadora do Instituto Politécnico de Leiria Doutor José Manuel Ferreira Duarte Professor Auxiliar da Universidade do Porto Doutora Gabriela Tamara Vincze Professora Auxiliar Convidada da Universidade de Aveiro Doutor Wilfried Georg Smarsly Diretor de Investigacão na Indústria Aeroespacial na Alemanha (coorientador) agradecimentos Gostaria de expressar os meus sinceros agradecimentos a todas as pessoas e instituicões que proporcionaram a realização deste trabalho. -

PROGRAM Energy Conversion Innovation for a Clean Energy Future

SPONSORED BY THE IEEE POWER ELECTRONICS AND INDUSTRY APPLICATIONS SOCIETIES IEEE ENERGY CONVERSION CONGRESS & EXPOSITION® PROGRAM Energy Conversion Innovation for a Clean Energy Future SEPTEMBER 17‐22, 2011 • HYATT REGENCY PHOENIX & PHOENIX CONVENTION CENTER • PHOENIX, ARIZONA ecce11_progcovers.indd 1 8/30/2011 3:13:25 PM Carrier . Hamilton Sundstrand . Otis . Pratt & Whitney . Sikorsky . UTC Fire & Security . UTC Power . UTRC Pratt & Whitney Carrier Otis Hamilton Sundstrand UTCUTC PPowerower Sikorsky UTCUTC FiFire & Security S ittyt UTRCUUTTR United Technologies Research Center (UTRC) The Systems Department at UTRC develops innovative technology develops the world’s most advanced technologies solutions and concepts in the area of complex adaptive systems to and processes to help ensure the products provide growth and competitive advantage to UTC's businesses. delivered to market by the UTC businesses are the best available. We focus on solving problems related to designing, controlling and managing systems that are characterized by complex interactions The challenges undertaken at UTRC require the between a large number of independent and heterogeneous best minds working together to generate ideas, components (and sub-systems). test theories, challenge assumptions and ultimately deliver solutions. The Department’s core strengths and expertise are articulated along the following disciplines: UTRC has approximately 500 employees and more than 96% of our technical staff hold advanced Systems Dynamics & Optimization degrees. Controls Systems -

Metals Polymers Ceramics

INNOVATIONS IN MATERIALS TECHNOLOGY METALS POLYMERS CERAMICS Mars lander to explore the history of water in the arctic BRIEFS Scheduled for launch in August 2007, the Alcoa announces a new Phoenix Mars Mission is the first in NASA’s name for its investment cast Scout Program, designed to be highly inno- and forged products business unit: Alcoa vative and relatively low-cost complements Power and Propulsion. to major missions being planned as part of Additionally, the two NASA’s Mars exploration effort. The goal of divisions that make up Phoenix is to study the history of water and this business unit were habitability potential in the Martian arctic’s renamed. Howmet ice-rich soil. If Phoenix looks familiar, it Castings is now Alcoa should: It is a modified and enhanced ver- Howmet. Howmet sion of the Mars Surveyor lander from 2001. Aerospace & Industrial Products division is now The Lockheed Martin engineering team is Alcoa Forged and Cast restoring and enhancing the 2001 lander to a flight-ready Phoenix spacecraft. Throughout all Products. phases of the mission, the Lockheed Martin team will closely monitor Phoenix’s health by linking www.alcoa.com their spacecraft operations centers with those at the Jet Propulsion laboratory and the Univer- sity of Arizona. For more information, visit http://phoenix.lpl.arizona.edu. Lots more informa- The American Iron and tion and images are available at www.lockheedmartin.com. (Type “phoenix” in the search box.). Steel Institute has made Watch an animation of the landing and deployment of the Phoenix on Mars at available online the Power http://phoenix.lpl.arizona.edu/video/phoenix_landing_low.mov Point presentations from the 2007 Great Designs Nanodispersions of NbC strengthen austenitic steel in Steel seminar. -

Optimal Machining Conditions for Turning of Alsic Metal Matrix Composites Using ANOVA

ISSN: 2319-8753 International Journal of Innovative Research in Science, Engineering and Technology (An ISO 3297: 2007 Certified Organization) Vol. 2, Issue 11, November 2013 Optimal Machining Conditions For Turning Of AlSiC Metal Matrix Composites Using ANOVA J. Satheesh1 , Tajamul Pasha2, Harish3 , T. Madhusudhan4 Professor, Department of Mechanical Engineering, SJB Institute of Technology, Bangalore, India1 Associate Professor, Department of Mech. Engg, National Institute of Engineering, Mysore, India2 Asst. Professor, Department of Mech. Engg. Maharaja Institute of Technology, Mysore, India3 Professor, Department of Mechanical Engineering, SJB Institute of Technology, Bangalore,India4 Abstract: Metal matrix composite (MMC) is an advanced engineering material possessing numerous favourable characteristics like light weight, high strength, high stiffness , ability to be operated at elevated temperatures etc. However, it is very difficult to machine these materials as they contain very hard abrasive ceramic as a dispersed phase in a ductile material matrix phase. Our study aims at casting of AlSiC composite rods with 25% w/w SiC as a composition. The study employs CNC turning operation and Taguchi's L8 orthogonal array is used for experimental design. An attempt is made to optimise the effects of the three parameters viz. Cutting Velocity, Feed Rate and Depth of Cut on the Surface Roughness values (Ra and Rz). Analysis of Variance (ANOVA) has been performed to know the effects of these three factors on the responses using statistical software MINTAB 16. Keywords: Machining, Cutting Parameters, Anova, Statistical Analysis I. INTRODUCTION Metal matrix composites are widely used composite materials in aerospace, automobile, electronics and medical industries. This is because of their superior mechanical properties like strength to weight ratio and high thermal conductivity. -

Heat Pipe Embedded Alsic Plates for High Conductivity – Low Cte Heat Spreaders

HEAT PIPE EMBEDDED ALSIC PLATES FOR HIGH CONDUCTIVITY – LOW CTE HEAT SPREADERS J. Weyant1, S. Garner1, M. Johnson2, M. Occhionero3 1Advanced Cooling Technologies, Inc 1046 New Holland Ave, Lancaster, Pa 17601 Phone: (717) 295-6093 Fax: (717) 295-6064 Email: [email protected] 2National Nuclear Security Administration's Kansas City Plant 3CPS Technologies Corporation Operated by Honeywell Federal Manufacturing & 111 South Worcester Street, Norton, MA 02766 Technologies, LLC Phone: (508) 222-0614 x242 Phone: (816) 997-4172 Fax: 508 222-0220 Email: [email protected] Email: [email protected] ABSTRACT affordable. Packaging materials with device and substrate compatible CTE values minimize the thermally induced Heat pipe embedded aluminum silicon carbide (AlSiC) plates stresses during power cycling [2]. Thermal stresses often are innovative heat spreaders that provide high thermal result in the delamination of substrates that disrupts the conductivity and low coefficient of thermal expansion (CTE). thermal dissipation path causing electronics thermal failure. Since heat pipes are two phase devices, they demonstrate CTE compatibility allows substrates/solder layers to be effective thermal conductivities ranging between 10,000 and optimized by reducing thickness to take full advantage of 200,000 W/m-K, depending on the heat pipe length. Installing packaging material thermal conductivity and the integrated heat pipes into an AlSiC plate dramatically increases the cooling systems. plate’s effective thermal conductivity. AlSiC plates alone have a thermal conductivity of roughly 200 W/m-K and a CTE Lightweight, high strength, high stiffness packaging materials ranging from 7-12 ppm/°C. Silicon alone has a thermal minimize failures due to shock and vibration in service as well expansion coefficient of 3 ppm/°C, which makes AlSiC a as shock that occurs during high speed automated assembly. -

Randall M. German Fundamentals and Applications

Randall M. German Particulate Composites Fundamentals and Applications Particulate Composites Randall M. German Particulate Composites Fundamentals and Applications Randall M. German San Diego State University San Diego, CA, USA ISBN 978-3-319-29915-0 ISBN 978-3-319-29917-4 (eBook) DOI 10.1007/978-3-319-29917-4 Library of Congress Control Number: 2016933672 © Springer International Publishing Switzerland 2016 This work is subject to copyright. All rights are reserved by the Publisher, whether the whole or part of the material is concerned, specifically the rights of translation, reprinting, reuse of illustrations, recitation, broadcasting, reproduction on microfilms or in any other physical way, and transmission or information storage and retrieval, electronic adaptation, computer software, or by similar or dissimilar methodology now known or hereafter developed. The use of general descriptive names, registered names, trademarks, service marks, etc. in this publication does not imply, even in the absence of a specific statement, that such names are exempt from the relevant protective laws and regulations and therefore free for general use. The publisher, the authors and the editors are safe to assume that the advice and information in this book are believed to be true and accurate at the date of publication. Neither the publisher nor the authors or the editors give a warranty, express or implied, with respect to the material contained herein or for any errors or omissions that may have been made. Printed on acid-free paper This Springer imprint is published by Springer Nature The registered company is Springer International Publishing AG Switzerland Dedicated to John Lee Johnson Preface Engineering materials continue to encounter challenges for new property combi- nations, and these challenges are leading to many hybrid materials known as composites.