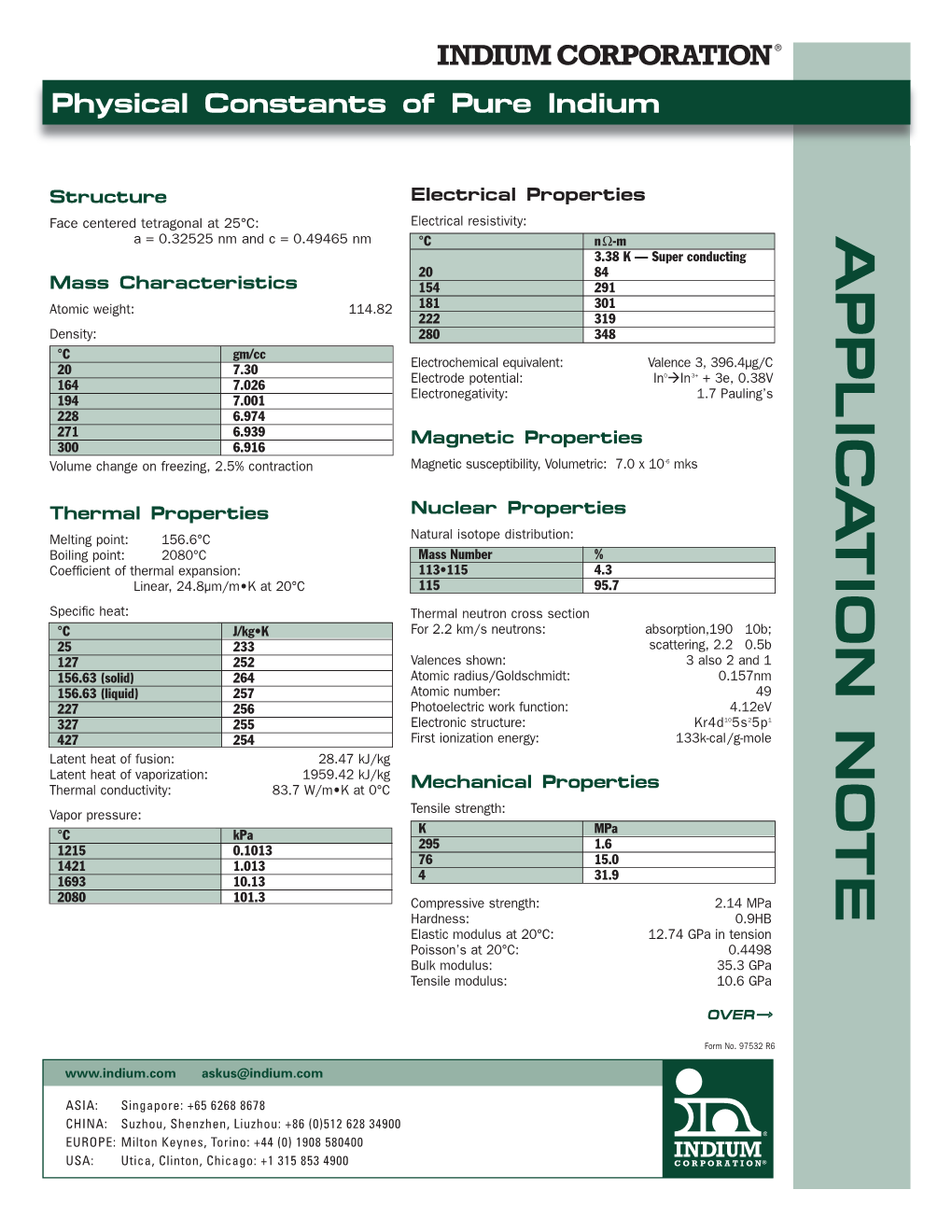

Physical Constants of Pure Indium

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Indium, Caesium Or Cerium Compounds for Treatment of Cerebral Disorders

Europaisches Patentamt 298 644 J European Patent Office Oy Publication number: 0 A3 Office europeen des brevets EUROPEAN PATENT APPLICATION © Application number: 88305895.0 © intci.s A61K 31/20, A61K 31/28, A61K 33/24 @ Date of filing: 29.06.88 © Priority: 07.07.87 GB 8715914 © Applicant: EFAMOL HOLDINGS PLC Efamol House Woodbridge Meadows © Date of publication of application: Guildford Surrey GU1 1BA(GB) 11.01.89 Bulletin 89/02 @ Inventor: Horrobin, David Frederick © Designated Contracting States: c/o Efamol House Woodbridge Meadows AT BE CH DE ES FR GB GR IT LI LU NL SE Guildford Surrey GU1 1BA(GB) Inventor: Corrigan, Frank ® Date of deferred publication of the search report: c/o Argyll & Bute Hospital 14.11.90 Bulletin 90/46 Lochgilphead, Argyll PA3T 8ED Scotland(GB) © Representative: Caro, William Egerton et al J. MILLER & CO. Lincoln House 296-302 High Holborn London WC1V 7 JH(GB) © Indium, caesium or cerium compounds for treatment of cerebral disorders. © A method of treatment of schizophrenia or other chronic cerebral disorder in which cerebral atrophy is shown, is characterised in that one or more as- similable or pharmaceutically acceptable indium caesium or cerium compounds is associated with a pharmaceutically acceptable diluent or carrier. CO < CD 00 O> Xerox Copy Centre PARTIAL EUROPEAN SEARCH REPORT Application number European Patent J which under Rule 45 of the European Patent Convention Office shall be considered, for the purposes of subsequent EP 88 30 5895 proceedings, as the European search report DOCUMENTS CONSIDERED TO BE RELEVANT Citation of document with indication, where appropriate, Relevant CLASSIFICATION OF THE ategory of relevant passages to claim APPLICATION (Int. -

The Infrared Spectrum of Indium in Silicon Revisited A

The infrared spectrum of indium in silicon revisited A. Tardella, B. Pajot To cite this version: A. Tardella, B. Pajot. The infrared spectrum of indium in silicon revisited. Journal de Physique, 1982, 43 (12), pp.1789-1795. 10.1051/jphys:0198200430120178900. jpa-00209562 HAL Id: jpa-00209562 https://hal.archives-ouvertes.fr/jpa-00209562 Submitted on 1 Jan 1982 HAL is a multi-disciplinary open access L’archive ouverte pluridisciplinaire HAL, est archive for the deposit and dissemination of sci- destinée au dépôt et à la diffusion de documents entific research documents, whether they are pub- scientifiques de niveau recherche, publiés ou non, lished or not. The documents may come from émanant des établissements d’enseignement et de teaching and research institutions in France or recherche français ou étrangers, des laboratoires abroad, or from public or private research centers. publics ou privés. J. Physique 43 (1982) 1789-1795 DTCEMBRE 1982, 1789 Classification Physics Abstracts 71.55 - 78.50 The infrared spectrum of indium in silicon revisited A. Tardella and B. Pajot Groupe de Physique des Solides de l’Ecole Normale Supérieure, Université Paris VII, Tour 23, 2, place Jussieu, 75251 Paris Cedex 05, France (Reçu le 27 mai 1982, révisé le 22 juillet, accepté le 23 août 1982) Résumé. 2014 Le spectre d’absorption de l’indium dans le silicium a été mesuré dans des conditions où l’élargisse- ment des raies par effet de concentration est négligeable. Avec une résolution appropriée, on détecte 17 transitions et les composantes d’un doublet serré sont attribuées à deux transitions calculées. A 6 K, la largeur intrinsèque des raies varie de 2,6 à 0,8 cm-1, ce qui indique un effet lié à la structure de la bande de valence du silicium. -

Soldering to Gold Films

Soldering to Gold Films THE IMPORTANCE OF LEAD-INDIUM ALLOYS Frederick G. Yost Sandia Laboratories, Albuquerque, New Mexico, U.S.A. Reliable solder joints can be made on gold metallised microcircuits using lead-indium solders providing certain important conditions are understood and carefully controlled. This paper reviews the three fundamental concepts of scavenging, wetting, and ageing, which are relevant when soldering to gold films. Alloys containing indium have been used for solder- sition and a body centred tetragonal space lattice. ing electronic components to thin gold films and wires Although considerable work has been addressed for at least 14 years. Braun (1, 2) investigated the to the question of clustering and phase separation potential of several multicomponent alloys based in the a field below 20°C (7, 8, 9) the practical signifi- upon the lead-tin-indium ternary alloy system. cance of this phenomenon has not yet materialised. More recently, work on lead-indium binary alloys The most commonly used alloy is the 50 weight has been reported by Jackson (3) and Yost, et al per cent indium composition which has a liquidus (4, 5, 6). In this paper we intend to define, to discuss, temperature of approximately 210°C and a solidus and to illustrate three fundamental concepts relevant temperature of approximately 185°C. Alloys in the to soldering to gold films using lead-indium solders. lead rich phase field, a, freeze dendritically by The lead-indium phase diagram, shown in Figure forming lead rich stalks. The formation of these 1, contains a wealth of useful solder alloys having dendrites causes a surface rumpling which gives the solidus temperatures which range from 156.6°C solder surface a somewhat frosty rather than a shiny (pure indium) to 327.5 °C (pure lead). -

Periodic Table 1 Periodic Table

Periodic table 1 Periodic table This article is about the table used in chemistry. For other uses, see Periodic table (disambiguation). The periodic table is a tabular arrangement of the chemical elements, organized on the basis of their atomic numbers (numbers of protons in the nucleus), electron configurations , and recurring chemical properties. Elements are presented in order of increasing atomic number, which is typically listed with the chemical symbol in each box. The standard form of the table consists of a grid of elements laid out in 18 columns and 7 Standard 18-column form of the periodic table. For the color legend, see section Layout, rows, with a double row of elements under the larger table. below that. The table can also be deconstructed into four rectangular blocks: the s-block to the left, the p-block to the right, the d-block in the middle, and the f-block below that. The rows of the table are called periods; the columns are called groups, with some of these having names such as halogens or noble gases. Since, by definition, a periodic table incorporates recurring trends, any such table can be used to derive relationships between the properties of the elements and predict the properties of new, yet to be discovered or synthesized, elements. As a result, a periodic table—whether in the standard form or some other variant—provides a useful framework for analyzing chemical behavior, and such tables are widely used in chemistry and other sciences. Although precursors exist, Dmitri Mendeleev is generally credited with the publication, in 1869, of the first widely recognized periodic table. -

Highly Selective and Rapid Uptake of Radionuclide Cesium

Article pubs.acs.org/cm Highly Selective and Rapid Uptake of Radionuclide Cesium Based on Robust Zeolitic Chalcogenide via Stepwise Ion-Exchange Strategy † † † † † † † Huajun Yang, Min Luo, Li Luo, Hongxiang Wang, Dandan Hu, Jian Lin, Xiang Wang, ‡ ‡ § ⊥ † Yanlong Wang, Shuao Wang, Xianhui Bu,*, Pingyun Feng,*, and Tao Wu*, † College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Jiangsu 215123, China ‡ School for Radiological and Interdisciplinary Sciences (RAD-X), Soochow University, Jiangsu 215123, China § Department of Chemistry and Biochemistry, California State University Long Beach, 1250 Bellflower Boulevard, Long Beach, California 90840, United States ⊥ Department of Chemistry, University of California, Riverside, Riverside, California 92521, United States *S Supporting Information ABSTRACT: The safe use of nuclear energy requires the development of advanced adsorbent technology to address environment damage from nuclear waste or accidental release of radionuclides. Recently developed amine-directed chalcogenide frameworks have intrinsic advantages as ion-exchange materials to capture radionuclides, because their exceptionally negative framework charge can lead to high cation-uptake capacity and their 3-D multidimensional intersecting channel promotes rapid ion diffusion and offer a unique kinetic advantage. Prior to this work, however, such advantages could not be realized because organic cations in the as-synthesized materials are sluggish during ion exchange. Here we report an ingenious approach on the activation of amine- directed zeolitic chalcogenides through a stepwise ion-exchange strategy and their use in cesium adsorption. The activated porous chalcogenide exhibits highly enhanced cesium uptake compared to the pristine form and is comparable to the best metal chalcogenide sorbents so far. Further ion-exchange experiments in the presence of competing ions confirm the high selectivity for cesium ions. -

INDALLOY CONTAINING INDIUM with TIN, LEAD, SILVER, COPPER.Rtf

MSDS - IN 009 INDALLOY CONTAINING INDIUM WITH TIN, LEAD OR SILVER OR COPPER INDIUM CORPORATION OF AMERICA ®\EUROPE \ASIA-PACIFIC INDIUM CORPORATION (SUZHOU) SAFETY DATA SHEET This material safety data sheet represents a family grouping of all metal mixes that contain indium metal. A table is provided at the end that lists all metal groupings. 1. PRODUCT AND COMPANY IDENTIFICATION Product Identifier: INDALLOY CONTAINING INDIUM WITH TIN, LEAD, SILVER, COPPER MSDS Number: MSDS-IN 009 Revised Date: 11 JUNE 2012 Product Use: INDUSTRIAL USE - METAL ALLOY CONSISTING OF INDIUM MIXED WITH ONLY TIN AND/OR, LEAD AND/OR SILVER AND/OR COPPER. SEE TABLE FOR VARIOUS MIX PERCENTAGES. MANUFACTURER: In America: EMERGENCY PHONE: The Indium Corporation of America CHEMTREC 24 hrs. 1676 Lincoln Ave., Utica NY 13502 USA: 1 (800) 424-9300 Information: (315) 853-4900 Outside USA: +1 (703) 527-3887 [email protected] In Europe: In China: Indium Corporation of Europe Indium Corporation (Suzhou), Co. Ltd. 7 Newmarket Ct. No. 428 Xinglong Street Kingston, Milton Keynes, UK, MK 10 OAG Suzhou Industrial Park Information: +44 [0] 1908 580400 Suchun Industrial Square Unit No. 14-C Jiangsu Province, China 215126 Information: (86) 512-6283-4900 In Asia: Asia-Pacific Operations-Singapore 29 Kian Teck Avenue Singapore 628908 Information: +65 6268-8678 Page 1 of 12 MSDS - IN 009 INDALLOY CONTAINING INDIUM WITH TIN, LEAD OR SILVER OR COPPER 2. HAZARDS IDENTIFICATION lead containing products Signal Word: Warning Hazard statement(s) H303 May be harmful if swallowed H315 Causes -

Indium Article2

A Study of Indium/Lead Solders Karl Seelig AIM Cranston, Rhode Island Indium/Lead Solders on Gold Because they do not leach or dissolve gold as readily as tin/lead solders, indium/lead solders are recommended for soldering to gold. As seen in fig. 1, the phase diagrams of tin/gold shows that tin dissolves approximately 18 percent by weight of gold at soldering temperatures of 225-250°C.1 Under the same conditions the indium/gold phase diagram shows dissolution of only 2 to 4 percent of gold in indium. Thus, with a substantial reduction in the dissolution of gold, less intermetallics are formed and improved solder flow over the gold surface occurs. Tin/lead soldering of gold is possible if the layer of gold is sufficiently thin (1.27 µm (50 µin) or less) to allow dipping in a pre-solder to remove the gold. However, if this does not occur then there is a high probability of solder joint failure. Immediately after soldering, a neat solder joint will be observed and it will pass electrical test. However, over time the tin will dissolve the gold by solid state diffusion and leave an opening in the electrical contact. For the above reasons, whenever possible an indium/lead solder should be used on a gold alloy. If indium/lead cannot be used due to either environmental reasons or temperature conditions, it is recommended to use a gold/tin alloy. The two gold/tin alloys that are Fig. 1 commonly used are the Sn90/Au80 217°C eutectic and the Au80/Sn20 280°C eutectic. -

Agenda 10/25/2017 Slip Quiz - Last One in This Booklet

Agenda 10/25/2017 Slip quiz - Last one in this booklet Turn in homework notes The Modern Periodic Table - Pointing Out Patterns Main Groups - (Group 1 Demonstration) Group 2 - students can do Periodic table - cut and stick activity Element research project + poster Slip Quiz - You may refer to your notes from the video. 1) Name 2 elements that can be added to iron and carbon to make special steels with special properties. 2) Which 3 elements are found in “Field’s metal”? What are their symbols and atomic numbers? Slip Quiz - You may refer to your notes from the video. 1) Name 2 elements that can be added to iron and carbon to make special steels with special properties. 2 from niobium, nickel, chromium, manganese, or aluminum. 2) Which 3 elements are found in “Field’s metal”? What are their symbols and atomic numbers? Slip Quiz - You may refer to your notes from the video. 2) Which 3 elements are found in “Field’s metal”? What are their symbols and atomic numbers? Indium In atomic number = 49 Tin Sn atomic number = 50 Bismuth Bi atomic number = 83 Turn in the “The Modern Periodic Table” Sheet with notes from video and your Metallic Bonding notes Periodic Table - Patterns and Useful Classifications Periods - go across the periodic table - rows Row 1 has 2 elements 1 Periods - go across the periodic table - rows Row 2 has 8 elements (2.8. 2 Periods - go across the periodic table - rows 8 elements (2.8.8. 3 Periods - go across the periodic table - rows 18 elements (2.8.8.18 4 Periods - go across the periodic table - rows 18 elements (2.8.8.18.18. -

Intermetallic Reaction of Indium and Silver in an Electroplating Process

View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by Springer - Publisher Connector Journal of ELECTRONIC MATERIALS, Vol. 38, No. 9, 2009 Regular Issue Paper DOI: 10.1007/s11664-009-0845-9 Ó 2009 The Author(s). This article is published with open access at Springerlink.com Intermetallic Reaction of Indium and Silver in an Electroplating Process PIN J. WANG,1,2 JONG S. KIM,1 and CHIN C. LEE1 1.—Electrical Engineering and Computer Science, Materials and Manufacturing Technology, University of California, Irvine, CA 92697-2660, USA. 2.—e-mail: [email protected] The reaction of indium (In) and silver (Ag) during the electroplating process of indium over a thick silver layer was investigated. It was found that the plated In atoms react with Ag to form AgIn2 intermetallic compounds at room tem- perature. Indium is commonly used in the electronics industry to bond delicate devices due to its low yield strength and low melting temperature. In this study, copper (Cu) substrates were electroplated with a 60-lm-thick Ag layer, followed by electroplating an In layer with a thickness of 5 lmor10lm, at room temperature. To investigate the chemical reaction between In and Ag, the microstructure and composition on the surface and the cross section of samples were observed by scanning electron microscopy (SEM) with energy- dispersive x-ray spectroscopy (EDX). The x-ray diffraction method (XRD) was also employed for phase identification. It was clear that indium atoms reacted with underlying Ag to form AgIn2 during the plating process. After the sample was stored at room temperature in air for 1 day, AgIn2 grew to 5 lmin thickness. -

The Elements.Pdf

A Periodic Table of the Elements at Los Alamos National Laboratory Los Alamos National Laboratory's Chemistry Division Presents Periodic Table of the Elements A Resource for Elementary, Middle School, and High School Students Click an element for more information: Group** Period 1 18 IA VIIIA 1A 8A 1 2 13 14 15 16 17 2 1 H IIA IIIA IVA VA VIAVIIA He 1.008 2A 3A 4A 5A 6A 7A 4.003 3 4 5 6 7 8 9 10 2 Li Be B C N O F Ne 6.941 9.012 10.81 12.01 14.01 16.00 19.00 20.18 11 12 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 3 Na Mg IIIB IVB VB VIB VIIB ------- VIII IB IIB Al Si P S Cl Ar 22.99 24.31 3B 4B 5B 6B 7B ------- 1B 2B 26.98 28.09 30.97 32.07 35.45 39.95 ------- 8 ------- 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 4 K Ca Sc Ti V Cr Mn Fe Co Ni Cu Zn Ga Ge As Se Br Kr 39.10 40.08 44.96 47.88 50.94 52.00 54.94 55.85 58.47 58.69 63.55 65.39 69.72 72.59 74.92 78.96 79.90 83.80 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 5 Rb Sr Y Zr NbMo Tc Ru Rh PdAgCd In Sn Sb Te I Xe 85.47 87.62 88.91 91.22 92.91 95.94 (98) 101.1 102.9 106.4 107.9 112.4 114.8 118.7 121.8 127.6 126.9 131.3 55 56 57 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 6 Cs Ba La* Hf Ta W Re Os Ir Pt AuHg Tl Pb Bi Po At Rn 132.9 137.3 138.9 178.5 180.9 183.9 186.2 190.2 190.2 195.1 197.0 200.5 204.4 207.2 209.0 (210) (210) (222) 87 88 89 104 105 106 107 108 109 110 111 112 114 116 118 7 Fr Ra Ac~RfDb Sg Bh Hs Mt --- --- --- --- --- --- (223) (226) (227) (257) (260) (263) (262) (265) (266) () () () () () () http://pearl1.lanl.gov/periodic/ (1 of 3) [5/17/2001 4:06:20 PM] A Periodic Table of the Elements at Los Alamos National Laboratory 58 59 60 61 62 63 64 65 66 67 68 69 70 71 Lanthanide Series* Ce Pr NdPmSm Eu Gd TbDyHo Er TmYbLu 140.1 140.9 144.2 (147) 150.4 152.0 157.3 158.9 162.5 164.9 167.3 168.9 173.0 175.0 90 91 92 93 94 95 96 97 98 99 100 101 102 103 Actinide Series~ Th Pa U Np Pu AmCmBk Cf Es FmMdNo Lr 232.0 (231) (238) (237) (242) (243) (247) (247) (249) (254) (253) (256) (254) (257) ** Groups are noted by 3 notation conventions. -

Material Safety Data Sheet Complies with 29 Cfr 1910.1200

MATERIAL SAFETY DATA SHEET COMPLIES WITH 29 CFR 1910.1200. OSHA HAZARD COMMUNICATION RULE DATE OF LAST REVISION: 05-29-02 CHEMICAL IDENTITY LABEL IDENTITY INDIUM CHEMICAL NAME/SYNONYMS INDIUM FORMULA In CHEMICAL FAMILY ELEMENT CAS REGISTRY NUMBER 7740-74-6, Listed on the TSCA Inventory. HAZARDOUS INGREDIENTS INDIUM %: 100 TLV: 0.1 mg/m3 OSHA/PEL: 0.1 mg/m3 PHYSICAL AND CHEMICAL PROPERTIES COLOR, FORM AND ODOR Odorless, Soft, silvery-white metal BOILING POINT 2080 C (3776 F) DENSITY (gm/cc) NA VAPOR PRESSURE @ 20° NA % VOLATILE BY VOLUME (%) NA REACTION WITH WATER NA EVAPORATION RATE (H20=1) NA SOLUBILITY IN WATER Insoluble MELTING POINT 156.7 C (314 F) FIRE AND EXPLOSION HAZARD DATA FLASH POINT NE AUTOIGNITION TEMPERATURE (°C) NE FLAMMABILITY Non-flammable EXTINGUISHING MEDIA Use extinguishers appropriate for the surrounding conditions SPECIAL FIRE FIGHTING PROCEDURES Wear a self-contained breathing apparatus UNUSUAL FIRE & EXPLOSION HAZARDS Moderate fire hazard in the form of dust INDIUM MATERIAL SAFETY DATA SHEET HEALTH HAZARD INFORMATION HMIS RATING: HEALTH: nd FLAMMABILITY: nd REACTIVITY: nd PERSONAL PROTECTION: nd ROUTES OF ENTRY INHALATION: Yes SKIN: Yes INGESTION: Yes EYE: Yes MEDICAL CONDITIONS AGGRAVATED BY OVEREXPOSURE: No Data POTENTIAL HEALTH EFFECTS: INHALATION: Inhalation of fume or dust may cause local irritation to the respiratory system. Inhalation of fume or dust may cause headache, nausea, abdominal pain, fatigue and pain in the legs, arms and joints. Inhalation can cause shortness of breath and sore throat. INGESTION: Ingestion of dust may cause headache, nausea, abdominal pain, fatigue and pain in the legs, arms and joints. -

Indium Zinc Oxide As Conductive Coating: a Review

1R5e0v. Adv. Mater. Sci. 49 (2017) 150-157O. Edynoor, A.R.M. Warikh, T. Moriga, K. Murai and M.E.A. Manaf TRANSPARENT COATING OXIDE – INDIUM ZINC OXIDE AS CONDUCTIVE COATING: A REVIEW O. Edynoor1,2,3, A.R.M. Warikh1,2, T. Moriga2,3, K. Murai3 and M.E.A. Manaf3 1Department of Materials Engineering, Faculty of Manufacturing Engineering, Universiti Teknikal Malaysia Melaka, Hang Tuah Jaya, 76100 Durian Tunggal, Melaka, Malaysia 2Tokushima-UTeM Academic Center, Tokushima University, 2-1 Minami-Josanjima, 770-8506 Tokushima, Japan 3Department of Chemical Science and Technology, Graduate School Advanced Technology and Science, Tokushima University, 2-1 Minami-Josanjima, 770-8506 Tokushima, Japan Received: March 13, 2017 Abstract. This paper reviews the transparent conductive oxide with emphasis on indium doped zinc oxide (TCO-IZO). TCO has been growing faster year by year, especially in semiconductor, solar devices and electronic field. There are many methods that can be used to produce IZO coating such as dip coating, sol-gel, magnetron sputtering, thermal evaporation and atomic layer deposition. IZO has gained significant attention for transparent electrodes due to its good elec- trical conductivity, high visible transmittance in the range from 400 to 900 nm, large work function, excellent surface smoothness, and low deposition temperature. Many studies have been done on the IZO coating onto glass substrate, but there is still less study on the low processing temperature substrates such as polymers and natural fibres. Parameters such as coating thick- ness, annealing temperature and number of cycles have to be considered in order to achieve the desired electrical conductivity and optical properties of IZO.