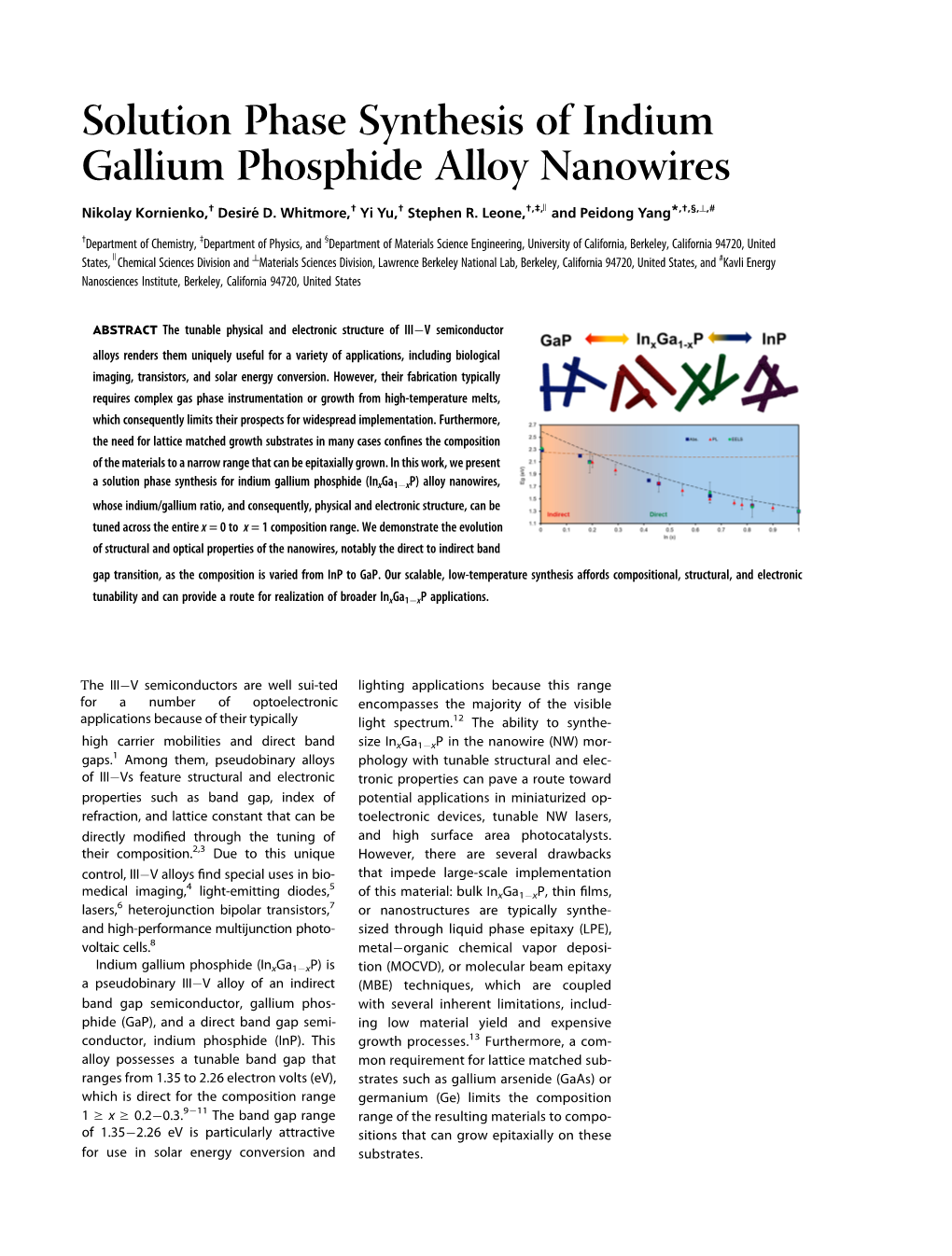

Solution Phase Synthesis of Indium Gallium Phosphide Alloy Nanowires

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

TR-499: Indium Phosphide (CASRN 22398-80-7) in F344/N Rats And

NTP TECHNICAL REPORT ON THE TOXICOLOGY AND CARCINOGENESIS STUDIES OF INDIUM PHOSPHIDE (CAS NO. 22398-80-7) IN F344/N RATS AND B6C3F1 MICE (INHALATION STUDIES) NATIONAL TOXICOLOGY PROGRAM P.O. Box 12233 Research Triangle Park, NC 27709 July 2001 NTP TR 499 NIH Publication No. 01-4433 U.S. DEPARTMENT OF HEALTH AND HUMAN SERVICES Public Health Service National Institutes of Health FOREWORD The National Toxicology Program (NTP) is made up of four charter agencies of the U.S. Department of Health and Human Services (DHHS): the National Cancer Institute (NCI), National Institutes of Health; the National Institute of Environmental Health Sciences (NIEHS), National Institutes of Health; the National Center for Toxicological Research (NCTR), Food and Drug Administration; and the National Institute for Occupational Safety and Health (NIOSH), Centers for Disease Control and Prevention. In July 1981, the Carcinogenesis Bioassay Testing Program, NCI, was transferred to the NIEHS. The NTP coordinates the relevant programs, staff, and resources from these Public Health Service agencies relating to basic and applied research and to biological assay development and validation. The NTP develops, evaluates, and disseminates scientific information about potentially toxic and hazardous chemicals. This knowledge is used for protecting the health of the American people and for the primary prevention of disease. The studies described in this Technical Report were performed under the direction of the NIEHS and were conducted in compliance with NTP laboratory health and safety requirements and must meet or exceed all applicable federal, state, and local health and safety regulations. Animal care and use were in accordance with the Public Health Service Policy on Humane Care and Use of Animals. -

Indium, Caesium Or Cerium Compounds for Treatment of Cerebral Disorders

Europaisches Patentamt 298 644 J European Patent Office Oy Publication number: 0 A3 Office europeen des brevets EUROPEAN PATENT APPLICATION © Application number: 88305895.0 © intci.s A61K 31/20, A61K 31/28, A61K 33/24 @ Date of filing: 29.06.88 © Priority: 07.07.87 GB 8715914 © Applicant: EFAMOL HOLDINGS PLC Efamol House Woodbridge Meadows © Date of publication of application: Guildford Surrey GU1 1BA(GB) 11.01.89 Bulletin 89/02 @ Inventor: Horrobin, David Frederick © Designated Contracting States: c/o Efamol House Woodbridge Meadows AT BE CH DE ES FR GB GR IT LI LU NL SE Guildford Surrey GU1 1BA(GB) Inventor: Corrigan, Frank ® Date of deferred publication of the search report: c/o Argyll & Bute Hospital 14.11.90 Bulletin 90/46 Lochgilphead, Argyll PA3T 8ED Scotland(GB) © Representative: Caro, William Egerton et al J. MILLER & CO. Lincoln House 296-302 High Holborn London WC1V 7 JH(GB) © Indium, caesium or cerium compounds for treatment of cerebral disorders. © A method of treatment of schizophrenia or other chronic cerebral disorder in which cerebral atrophy is shown, is characterised in that one or more as- similable or pharmaceutically acceptable indium caesium or cerium compounds is associated with a pharmaceutically acceptable diluent or carrier. CO < CD 00 O> Xerox Copy Centre PARTIAL EUROPEAN SEARCH REPORT Application number European Patent J which under Rule 45 of the European Patent Convention Office shall be considered, for the purposes of subsequent EP 88 30 5895 proceedings, as the European search report DOCUMENTS CONSIDERED TO BE RELEVANT Citation of document with indication, where appropriate, Relevant CLASSIFICATION OF THE ategory of relevant passages to claim APPLICATION (Int. -

Discovering Amorphous Indium Phosphide Nanostructures with High-Temperature Ab Initio Molecular Dynamics

Discovering Amorphous Indium Phosphide Nanostructures with High-Temperature ab Initio Molecular Dynamics The MIT Faculty has made this article openly available. Please share how this access benefits you. Your story matters. Citation Zhao, Qing, Lisi Xie, and Heather J. Kulik. “Discovering Amorphous Indium Phosphide Nanostructures with High-Temperature Ab Initio Molecular Dynamics.” The Journal of Physical Chemistry C 119.40 (2015): 23238–23249. As Published http://dx.doi.org/10.1021/acs.jpcc.5b07264 Publisher American Chemical Society (ACS) Version Author's final manuscript Citable link http://hdl.handle.net/1721.1/105155 Terms of Use Article is made available in accordance with the publisher's policy and may be subject to US copyright law. Please refer to the publisher's site for terms of use. Discovering Amorphous Indium Phosphide Nanostructures with High-Temperature Ab Initio Molecular Dynamics Qing Zhao1,2, Lisi Xie1, and Heather J. Kulik1,* 1Department of Chemical Engineering, Massachusetts Institute of Technology, Cambridge, MA 02139 2Department of Mechanical Engineering, Massachusetts Institute of Technology, Cambridge, MA 02139 ABSTRACT: We employ high-temperature ab initio molecular dynamics (AIMD) as a sampling approach to discover low-energy, semiconducting, indium phosphide nanostructures. Starting from under-coordinated models of InP (e.g. a single layer of InP(111)), rapid rearrangement into a stabilized, higher-coordinate but amorphous cluster is observed across the size range considered (In3P3 to In22P22). These clusters exhibit exponential decrease in energy per atom with system size as effective coordination increases, which we define through distance-cutoff coordination number assignment and partial charge analysis. The sampling approach is robust to initial configuration choice as consistent results are obtained when alternative crystal models or computationally efficient generation of structures from sequential addition and removal of atoms are employed. -

COMBINED LIST of Particularly Hazardous Substances

COMBINED LIST of Particularly Hazardous Substances revised 2/4/2021 IARC list 1 are Carcinogenic to humans list compiled by Hector Acuna, UCSB IARC list Group 2A Probably carcinogenic to humans IARC list Group 2B Possibly carcinogenic to humans If any of the chemicals listed below are used in your research then complete a Standard Operating Procedure (SOP) for the product as described in the Chemical Hygiene Plan. Prop 65 known to cause cancer or reproductive toxicity Material(s) not on the list does not preclude one from completing an SOP. Other extremely toxic chemicals KNOWN Carcinogens from National Toxicology Program (NTP) or other high hazards will require the development of an SOP. Red= added in 2020 or status change Reasonably Anticipated NTP EPA Haz list COMBINED LIST of Particularly Hazardous Substances CAS Source from where the material is listed. 6,9-Methano-2,4,3-benzodioxathiepin, 6,7,8,9,10,10- hexachloro-1,5,5a,6,9,9a-hexahydro-, 3-oxide Acutely Toxic Methanimidamide, N,N-dimethyl-N'-[2-methyl-4-[[(methylamino)carbonyl]oxy]phenyl]- Acutely Toxic 1-(2-Chloroethyl)-3-(4-methylcyclohexyl)-1-nitrosourea (Methyl-CCNU) Prop 65 KNOWN Carcinogens NTP 1-(2-Chloroethyl)-3-cyclohexyl-1-nitrosourea (CCNU) IARC list Group 2A Reasonably Anticipated NTP 1-(2-Chloroethyl)-3-cyclohexyl-1-nitrosourea (CCNU) (Lomustine) Prop 65 1-(o-Chlorophenyl)thiourea Acutely Toxic 1,1,1,2-Tetrachloroethane IARC list Group 2B 1,1,2,2-Tetrachloroethane Prop 65 IARC list Group 2B 1,1-Dichloro-2,2-bis(p -chloropheny)ethylene (DDE) Prop 65 1,1-Dichloroethane -

The Infrared Spectrum of Indium in Silicon Revisited A

The infrared spectrum of indium in silicon revisited A. Tardella, B. Pajot To cite this version: A. Tardella, B. Pajot. The infrared spectrum of indium in silicon revisited. Journal de Physique, 1982, 43 (12), pp.1789-1795. 10.1051/jphys:0198200430120178900. jpa-00209562 HAL Id: jpa-00209562 https://hal.archives-ouvertes.fr/jpa-00209562 Submitted on 1 Jan 1982 HAL is a multi-disciplinary open access L’archive ouverte pluridisciplinaire HAL, est archive for the deposit and dissemination of sci- destinée au dépôt et à la diffusion de documents entific research documents, whether they are pub- scientifiques de niveau recherche, publiés ou non, lished or not. The documents may come from émanant des établissements d’enseignement et de teaching and research institutions in France or recherche français ou étrangers, des laboratoires abroad, or from public or private research centers. publics ou privés. J. Physique 43 (1982) 1789-1795 DTCEMBRE 1982, 1789 Classification Physics Abstracts 71.55 - 78.50 The infrared spectrum of indium in silicon revisited A. Tardella and B. Pajot Groupe de Physique des Solides de l’Ecole Normale Supérieure, Université Paris VII, Tour 23, 2, place Jussieu, 75251 Paris Cedex 05, France (Reçu le 27 mai 1982, révisé le 22 juillet, accepté le 23 août 1982) Résumé. 2014 Le spectre d’absorption de l’indium dans le silicium a été mesuré dans des conditions où l’élargisse- ment des raies par effet de concentration est négligeable. Avec une résolution appropriée, on détecte 17 transitions et les composantes d’un doublet serré sont attribuées à deux transitions calculées. A 6 K, la largeur intrinsèque des raies varie de 2,6 à 0,8 cm-1, ce qui indique un effet lié à la structure de la bande de valence du silicium. -

Soldering to Gold Films

Soldering to Gold Films THE IMPORTANCE OF LEAD-INDIUM ALLOYS Frederick G. Yost Sandia Laboratories, Albuquerque, New Mexico, U.S.A. Reliable solder joints can be made on gold metallised microcircuits using lead-indium solders providing certain important conditions are understood and carefully controlled. This paper reviews the three fundamental concepts of scavenging, wetting, and ageing, which are relevant when soldering to gold films. Alloys containing indium have been used for solder- sition and a body centred tetragonal space lattice. ing electronic components to thin gold films and wires Although considerable work has been addressed for at least 14 years. Braun (1, 2) investigated the to the question of clustering and phase separation potential of several multicomponent alloys based in the a field below 20°C (7, 8, 9) the practical signifi- upon the lead-tin-indium ternary alloy system. cance of this phenomenon has not yet materialised. More recently, work on lead-indium binary alloys The most commonly used alloy is the 50 weight has been reported by Jackson (3) and Yost, et al per cent indium composition which has a liquidus (4, 5, 6). In this paper we intend to define, to discuss, temperature of approximately 210°C and a solidus and to illustrate three fundamental concepts relevant temperature of approximately 185°C. Alloys in the to soldering to gold films using lead-indium solders. lead rich phase field, a, freeze dendritically by The lead-indium phase diagram, shown in Figure forming lead rich stalks. The formation of these 1, contains a wealth of useful solder alloys having dendrites causes a surface rumpling which gives the solidus temperatures which range from 156.6°C solder surface a somewhat frosty rather than a shiny (pure indium) to 327.5 °C (pure lead). -

DFB Lasers Between 760 Nm and 16 Μm for Sensing Applications

Sensors 2010, 10, 2492-2510; doi:10.3390/s100402492 OPEN ACCESS sensors ISSN 1424-8220 www.mdpi.com/journal/sensors Review DFB Lasers Between 760 nm and 16 µm for Sensing Applications Wolfgang Zeller *, Lars Naehle, Peter Fuchs, Florian Gerschuetz, Lars Hildebrandt and Johannes Koeth nanoplus Nanosystems and Technologies GmbH, Oberer Kirschberg 4, 97218 Gerbrunn, Germany; E-Mails: [email protected] (L.N.); [email protected] (P.F.); [email protected] (F.G.); [email protected] (L.H.); [email protected] (J.K.) * Author to whom correspondence should be addressed; E-Mail: [email protected]; Tel.: +49-931-90827-10; Fax: +49-931-90827-19. Received: 20 January 2010; in revised form: 22 February 2010 / Accepted: 6 March 2010 / Published: 24 March 2010 Abstract: Recent years have shown the importance of tunable semiconductor lasers in optical sensing. We describe the status quo concerning DFB laser diodes between 760 nm and 3,000 nm as well as new developments aiming for up to 80 nm tuning range in this spectral region. Furthermore we report on QCL between 3 µm and 16 µm and present new developments. An overview of the most interesting applications using such devices is given at the end of this paper. Keywords: DFB; laser; QCL; sensing Classification: PACS 42.55.Px; 42.62.Fi; 42.62.-b 1. Introduction In recent years the importance of lasers in optical sensing has been continuously increasing [1]. Many apparatus use long-known techniques like fluorescence measurements after excitation by photons, e.g., to detect petroleum contamination in soils [2]. -

Binary and Ternary Transition-Metal Phosphides As Hydrodenitrogenation Catalysts

Research Collection Doctoral Thesis Binary and ternary transition-metal phosphides as hydrodenitrogenation catalysts Author(s): Stinner, Christoph Publication Date: 2001 Permanent Link: https://doi.org/10.3929/ethz-a-004378279 Rights / License: In Copyright - Non-Commercial Use Permitted This page was generated automatically upon download from the ETH Zurich Research Collection. For more information please consult the Terms of use. ETH Library Diss. ETH No. 14422 Binary and Ternary Transition-Metal Phosphides as Hydrodenitrogenation Catalysts A dissertation submitted to the Swiss Federal Institute of Technology Zurich for the degree of Doctor of Natural Sciences Presented by Christoph Stinner Dipl.-Chem. University of Bonn born February 27, 1969 in Troisdorf (NRW), Germany Accepted on the recommendation of Prof. Dr. Roel Prins, examiner Prof. Dr. Reinhard Nesper, co-examiner Dr. Thomas Weber, co-examiner Zurich 2001 I Contents Zusammenfassung V Abstract IX 1 Introduction 1 1.1 Motivation 1 1.2 Phosphides 4 1.2.1 General 4 1.2.2 Classification 4 1.2.3 Preparation 5 1.2.4 Properties 12 1.2.5 Applications and Uses 13 1.3 Scope of the Thesis 14 1.4 References 16 2 Characterization Methods 1 2.1 FT Raman Spectroscopy 21 2.2 Thermogravimetric Analysis 24 2.3 Temperature-Programmed Reduction 25 2.4 X-Ray Powder Diffractometry 26 2.5 Nitrogen Adsorption 28 2.6 Solid State Nuclear Magnetic Resonance Spectroscopy 28 2.7 Catalytic Test 33 2.8 References 36 3 Formation, Structure, and HDN Activity of Unsupported Molybdenum Phosphide 37 3.1 Introduction -

Red-Light Leds for Next-Generation Displays 6 July 2020

Red-light LEDs for next-generation displays 6 July 2020 indium gallium nitride (InGaN) semiconductors. Integrating two material systems is difficult. "Creating RGB displays requires the mass transfer of the separate blue, green and red LEDs together," says KAUST researcher Zhe Zhuang. An easier solution would be to create different-colored LEDs all on a single semiconductor chip. Optimizing the geometry, fabrication and electrical contacts is vital to maximizing the efficiency of the LED. Credit: Zhuag et al. Novel red LEDs are more temperature stable than those made using the conventional semiconductor of choice. In efforts to optimize the performance of light- emitting diodes (LEDs), King Abdullah University of Science and Technology researchers are looking at every aspect of the design, fabrication and operation of these devices. Now, they have succeeded in fabricating red LEDs, based on the The team developed an InGaN red LED structure where naturally blue-emitting semiconductor indium the output power is more stable than that of InGaP red gallium nitride, that are as stable as those based LEDs. Credit: Zhe Zhuang on indium gallium phosphide. LEDs are optical sources made from semiconductors that offer improvements on Since InGaP semiconductors are unable to emit conventional visible-light sources in terms of blue or green light, the only solution to making energy saving, smaller size and longer lifetimes. monolithic RGB micro-LEDs is to use InGaN. This LEDs can emit across the spectrum, from the material has the potential to shift its emission from ultraviolet to blue (B), green (G), red (R) and into blue to green, yellow and red by introducing more the infrared. -

Theoretical Study of Ternary Cosp Semiconductor

Theoretical Study of Ternary CoSP Semiconductor: a Candidate for Photovoltaic Applications Abdesalem Houari∗ and Fares Benissad Theoretical Physics Laboratory, Department of Physics, University of Bejaia, Bejaia, Algeria (Dated: March 24, 2020) Abstract The electronic structure of pyrite-type cobalt phosphosulfide (CoSP) has been studied using density-functional theory. The calculated band structure reveals the non-magnetic semiconducting character of the compound. The electronic structure is described through the electronic band structure and the densities of states. A band gap of 1.14 eV has been computed within standard GGA, a value which is enhanced using hybrid functional. It separates the upper part of the valence band dominated by Co-3d-t2g states from the lower part of the conduction band made exclusively of Co-3d-eg, above of which lie S-3p and P-3p ones. The obtained values are suitable for applications in solar cells, according to Shockley-Queisser theory of light to electric conversion efficiency. The origin of the larger CoSP band gap, with respect to the one of the promising FeS2 compound, is explained and the chemical bonding properties are addressed. A comparative picture is established where several similarities have been found, suggesting that CoSP could be for a great practical interest in photovoltaics. arXiv:2003.09864v1 [cond-mat.mtrl-sci] 22 Mar 2020 ∗corresponding author:[email protected] 1 Contents I. Introduction 2 II. Computational Method 4 III. Results and Discussions 5 IV. Summary and Conclusion 9 Acknowledgments 10 References 10 I. INTRODUCTION Pyrite-type iron disulfide (FeS2) is considered as a promising material for photovoltaic applications [1–3]. -

Reducing Bow of Ingap on Silicon Wafers

94 Technology focus: III-Vs on silicon Reducing bow of InGaP on silicon wafers Researchers use strain engineering without impacting dislocation density. esearchers based in Singapore and the USA have been working to control the wafer bow of Rindium gallium phosphide (InGaP) epitaxial lay- ers on 200mm silicon (Si) wafers [Bing Wang et al, Semicond. Sci. Technol., vol32, p125013, 2017]. “Based on these Wafer bow is caused by observations, we can stress arising mainly conclude that the from mismatches of threading dislocation coefficients of thermal expansion between densities of the InGaP InGaP, or other III-V wafers are not compound semiconduc- affected by the lattice tors, and silicon. The mismatch. Our Ge bow (more than 200µm buffers have similar in one recent report of gallium arsenide on threading dislocation 300mm silicon wafer) is density of 3x107/cm2. introduced when the The hetero-epitaxy of material cools after high- GaAs buffers and temperature epitaxial Figure 1. Epitaxial layer structure of three InGaP/Si deposition. Bowing InGaP films did not wafers. adversely affects wafer- increase the scale processing, partic- threading dislocation was by metal-organic chemical vapor deposition ularly for large-diameter density, which (MOCVD). The germanium on silicon template layer substrates. Wafer-scale was prepared separately in a two-step low/high-tem- indicates very good equipment typically perature process, using germane (GeH4) precursor. restricts the permitted epitaxy quality.” Plan-view transmission electron microscopy (PV-TEM) bow to less than 50µm. The team believes and etch pit density (EPD) analysis gave an estimate of 7 2 The team from the that the technique dislocation density of the order 3x10 /cm . -

Supporting Information For: Solution Phase Synthesis of Indium Gallium Phosphide Alloy Nanowires Nikolay Kornienko , Desiré D

Supporting Information for: Solution Phase Synthesis of Indium Gallium Phosphide Alloy Nanowires Nikolay Kornienko1, Desiré D. Whitmore1, Yi Yu1, Stephen R. Leone1,2,4, Peidong Yang*1,3,5,6 1Department of Chemistry, 2Department of Physics and 3Department of Materials Science Engineering, University of California, Berkeley 94720, United States 4Chemical Sciences Division and 5Materials Sciences Division, Lawrence Berkeley National Lab, Berkeley CA 94720, United States 6Kavli Energy Nanosciences Institute, Berkeley, California 94720, United States * Correspondence to: [email protected] Table of Contents: Figure S1. TEM In/Ga growth seeds ............................................................................................................................. 2 Figure S2. TEM of InP and GaP NWs ............................................................................................................................. 2 Figure S3. Composition and diameter control ......................................................................................................... 3 Figure S4. XRD of InxGa1‐xP NWs .................................................................................................................................. 4 Figure S5. Electron diffraction of InxGa1‐xP NWs ................................................................................................... 5 Figure S6. Raman spectra of InP and GaP .................................................................................................................. 6