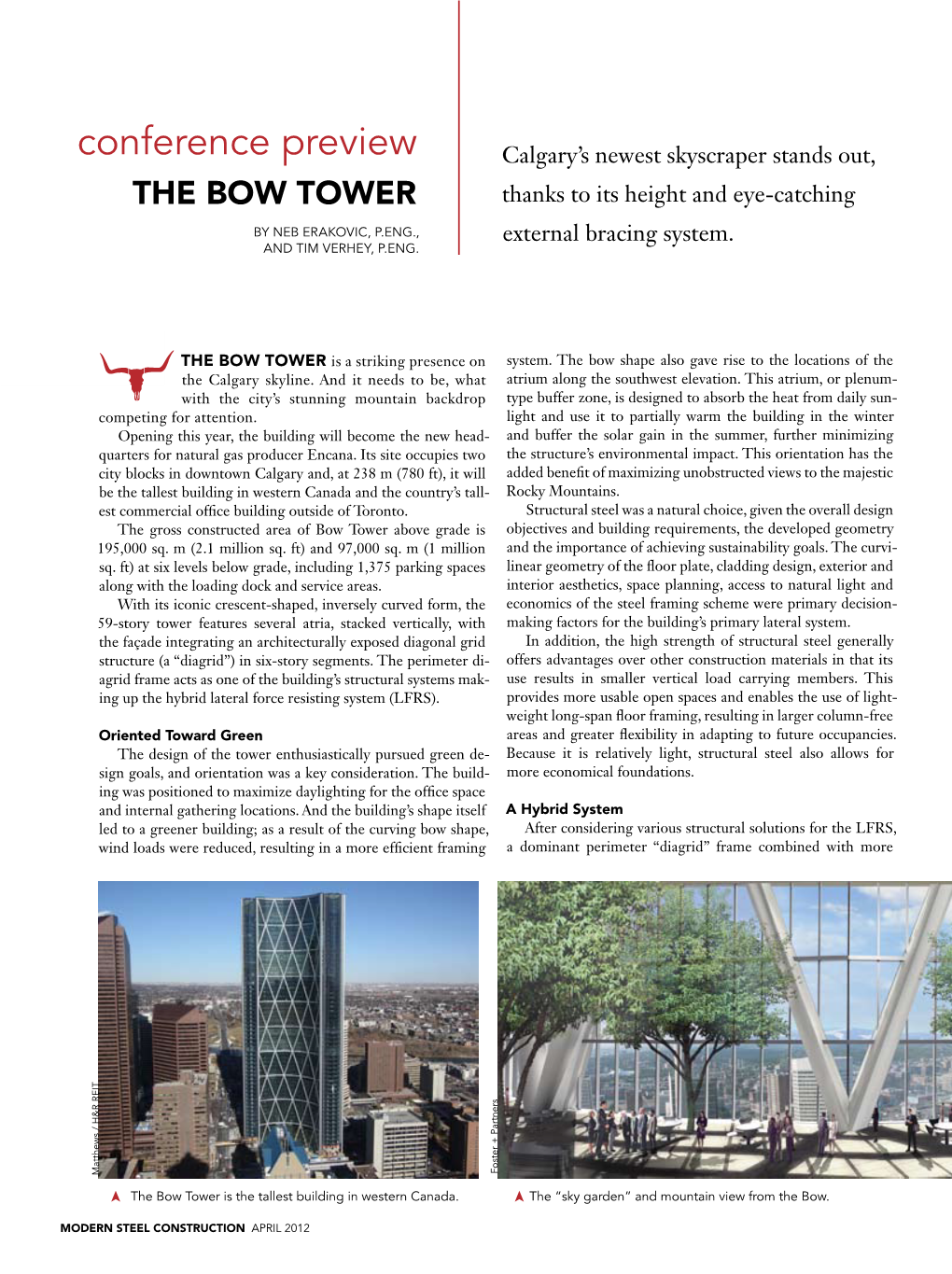

The Bow Tower Thanks to Its Height and Eye-Catching by Neb Erakovic, P.Eng., External Bracing System

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Previous Council Direction

CPS2017-0391 ATTACHMENT 1 Previous Council Direction On 2004 April 26, Council approved Mayor Bronconnier's NM2004-17, which established the Community Investment Fund (CIF) and approved contributions including $40 million towards the development of a new Central Library. On 2005 April 25, Council approved CIF2005-08 which authorized Administration to release up to 10 per cent of each project’s allocation as seed funding to support the development of project business plans by each participating organization. $4 million was approved to transfer to Calgary Public Library Capital Program Number 479. On 2005 July 04, Council approved LAS2005-127 and directed Administration to work with the Calgary Public Library (CPL) and Bow Valley College (BVC) to comprehensively redevelop Block 40. Administration was also directed to jointly undertake an analysis of the user’s needs including common program areas, development capacity of the site, potential partners, critical timelines and funding decisions. At the same time, Council directed Administration to develop a triple bottom line list of the requirements and desired uses which would contribute to the vision for the block. On 2005 December 06, Administration provided a status update to the Land and Asset Strategy Committee with LAS2005-209 and were directed to report back to the Committee regarding the analysis and recommendations included in the Block 40 Redevelopment Analysis report, no later than 2006 March 14. In addition, Administration was directed to include an order of magnitude cost estimate in the Block 40 Redevelopment Study Report and to confirm the funding for the Bow Valley College facility expansion project from the Provincial Government. -

Bow River Basin State of the Watershed Summary 2010 Bow River Basin Council Calgary Water Centre Mail Code #333 P.O

30% SW-COC-002397 Bow River Basin State of the Watershed Summary 2010 Bow River Basin Council Calgary Water Centre Mail Code #333 P.O. Box 2100 Station M Calgary, AB Canada T2P 2M5 Street Address: 625 - 25th Ave S.E. Bow River Basin Council Mark Bennett, B.Sc., MPA Executive Director tel: 403.268.4596 fax: 403.254.6931 email: [email protected] Mike Murray, B.Sc. Program Manager tel: 403.268.4597 fax: 403.268.6931 email: [email protected] www.brbc.ab.ca Table of Contents INTRODUCTION 2 Overview 4 Basin History 6 What is a Watershed? 7 Flora and Fauna 10 State of the Watershed OUR SUB-BASINS 12 Upper Bow River 14 Kananaskis River 16 Ghost River 18 Seebe to Bearspaw 20 Jumpingpound Creek 22 Bearspaw to WID 24 Elbow River 26 Nose Creek 28 WID to Highwood 30 Fish Creek 32 Highwood to Carseland 34 Highwood River 36 Sheep River 38 Carseland to Bassano 40 Bassano to Oldman River CONCLUSION 42 Summary 44 Acknowledgements 1 Overview WELCOME! This State of the Watershed: Summary Booklet OVERVIEW OF THE BOW RIVER BASIN LET’S TAKE A CLOSER LOOK... THE WATER TOWERS was created by the Bow River Basin Council as a companion to The mountainous headwaters of the Bow our new Web-based State of the Watershed (WSOW) tool. This Comprising about 25,000 square kilometres, the Bow River basin The Bow River is approximately 645 kilometres in length. It begins at Bow Lake, at an River basin are often described as the booklet and the WSOW tool is intended to help water managers covers more than 4% of Alberta, and about 23% of the South elevation of 1,920 metres above sea level, then drops 1,180 metres before joining with the water towers of the watershed. -

Layout 1 Copy

COVER FEATURE HCM Contractors Inc and RWH Engineering Inc Reach for the Sky From New Depths in Western Canada By Kailey DenBraber, EIT, RWH Engineering Inc. and Jason Weck MESc, P.Eng, President, HC Matcon Inc. Project Summary involved in the early stages of the project and were awarded the shoring scope prior to a geotechnical investigation being completed based on their Set to transform the skyline and become Calgary’s newest landmark, the in depth knowledge of the surrounding geological conditions and experi - TELUS Sky Tower is the next addition to the city’s downtown core. Located ence shoring in Calgary. The result was a Design-Build shoring solution in in the corner block of 7th Avenue SW and Centre Street, directly adjacent combination with monitoring services to be able to use an observational to The Bow, the 59-story tower will be the third tallest building in Calgary, method approach and manage risk. Alberta. The building is a combination of spaces for working and living The TELUS Sky project presented unique challenges due to the small foot - that give the architecture its unique sculptural shape and vertical ele - print of the project site and proximity to existing sensitive infrastructure; a gance to the skyline. The mixed-use TELUS Sky Tower was developed with 26-story building to the north separated only by a laneway, a 12-story build - an emphasis on sustainability using innovative design and technologies ing directly along the west side of the site, LRT tracks to the south and large Rendering of TELUS Sky Tower. -

Crude Optimism Romanticizing Alberta’S Oil Frontier at the Calgary Stampede Kimberly Skye Richards

Crude Optimism Romanticizing Alberta’s Oil Frontier at the Calgary Stampede Kimberly Skye Richards An immaculate young woman regally waves at a sea of enthusiastic fans. Perched on her head is a white cowboy hat embellished with a tiara that has “Calgary Stampede Queen” written on it in rhinestones. She is a vision of “westernness” in cowboy boots, a buckskin skirt and jacket, and turquoise jewels. Her express purpose this hot July afternoon is to welcome the 115,000 folks attending the “Greatest Outdoor Show on Earth,” the Calgary Exhibition and Stampede. She is a “welcome figure,”1 like those white-cowboy-hat-wearing individuals in the Calgary air- port who stand in the arrivants’ path and greet travelers. These performances of western hospi- tality amount to a performance of power: the assertion of settler rights to land.2 They are just 1. I borrow this term from Stó:lō scholar Dylan Robinson’s essay “Welcoming Sovereignty,” which examines Indigenous sovereignty and gestures of welcome that take place in spaces of transit and gathering (2016:24). 2. In using the term “settler” to describe non-Indigenous people living in western Canada, I am referring to the idea within settler colonial studies that being a settler is not an identity, but a structural position and experience of power and privilege. Settlers settle into land appropriated by imperial nations and create independent homelands for themselves. They are defined by conquest; they are “founders of political orders and carry their sovereignty TDR: The Drama Review 63:2 (T242) Summer 2019. ©2019 138 New York University and the Massachusetts Institute of Technology Downloaded from http://www.mitpressjournals.org/doi/pdf/10.1162/dram_a_00839 by guest on 26 September 2021 Student Essay Contest Winner Kimberly Skye Richards is a PhD Candidate in Performance Studies at the University of California-Berkeley. -

205 - 5Th Avenue SW, Calgary, AB

FOR SUBLEASE - BOW VALLEY SQUARE II 205 - 5th Avenue SW, Calgary, AB Eric Horne, Principal Jason Kopchia, Associate 403.232.4339 587.293.3361 [email protected] [email protected] PROPERTY SUMMARY LOCATION AVAILABLE SUITES A rare sublease opportunity in one of Calgary’s most recognizable 1600: 13,560 sf LEASED office complexes. Bow Valley Square is centrally located 1800: 13,460 sf Immediately Downtown with connection to the Plus 15 network. The complex 1900: 13,599 sf Immediately is less than one block from the C-Train line and has direct access to 2000: 13,636 sf Immediately 3400: 13,836 sf Immediately major thoroughfares and numerous bus routes. Bow Valley Square 3500: 13,981 sf Immediately boasts two stories of various amenities and is a short walk to TD 3600: 13,981 sf LEASED Square through the Plus 15. EXPIRY March 30, 2021 Headlease Wrap Available FEATURES OP. COSTS $18.93 psf (2020) Plus Downtown Core location, PARKING 15 connected to the Plus 15 CONNECTED Ratio 1:2,000 sf 15% reserved unreserved at $495/m - reserved at $585/m Easy accessibility BUILDING COMPLEX AMENITIES INCLUDE: from Main Thoroughfares RESTAURANTS/FOOD FINANCIAL A&W Canada CIBC Analog Coffee Credit Suisse AG Excellent LRT & Transit Butcher and the Baker Manulife Financial Options Hankki RBC Royal Bank Olly Fresco’s Société Générale Capital Inc. Starbucks Taco Time HEALTH Close to Pathway Tim Hortons Bow Valley Chiropractic System Township Bar & Grill Bow Valley Dental Verona Pizza The Bow Valley Club The Downtown Sports Clinic Vo Kitchen & Bar Retail, Restaurants SERVICES & Professional Services Aero Travel Best of Seven Barbers Bow Valley Child Care Gateway Newstand Fitness Centre on site Licensing Co. -

Calgary Municipal Land Corporation (CMLC) Contacts: Kate Thompson, VP Development [email protected] Website

Private and Confidential. For X-Culture use only. 2019 X-Culture Global Business Week, Calgary, Canada Updated June 8, 2019 Challenge Presented by: Calgary Municipal Land Corporation (CMLC) Contacts: Kate Thompson, VP Development [email protected] Website: https://www.calgarymlc.ca/#home-intro THE CITY OF CALGARY The City of Calgary is referred to as the “Gateway to the Rockies”. Calgary sits in the sunny eastern foothills of Canada’s Rocky Mountains, where the Bow and Elbow rivers meet. It is the major urban center for the entire southern half of the province of Alberta, and is surrounded by an area of profound beauty with an unspoiled, resource-rich natural environment. It is no surprise to Calgarians that their home has been ranked among Top 5 most liveable city in the world by The Economist Intelligence Unit every year between 2009 and 2018 (#4 in 2018). The population density in Calgary is low, the quality of life is high, and housing abundant. Calgary’s population is young, well educated, entrepreneurial, community minded, generous and well paid. As individuals, Calgarians are family-focused, recreation lovers, that are committed to a healthy work-life balance. As citizens, Calgarians are enthusiastic supporters of community organizations: there are more volunteers in Alberta than the national average. The top priority of most Calgarians is sustaining the city’s superb quality of life. This means ensuring the economic, environmental, health and wellness, recreational, educational and social service advantages that Calgarians have today will be here in the future. A few helpful Calgary websites: Life in Calgary: www.lifeincalgary.ca/moving/calgary-facts Tourism Calgary: www.visitcalgary.com 1 BACKGROUND INFORMATION Calgary Municipal Land Corporation (CMLC) was incorporated in 2007 as a wholly owned subsidiary of the City of Calgary to implement and execute the Rivers District Community Revitalization Plan – a public infrastructure program approved by the City of Calgary and the Province of Alberta to kick-start Calgary’s urban renewal. -

Download Leasing Brochure

WHERE THE NEW DEFINITION OFFICE OF OFFICE LIFE It’s a first for Calgary: Class A office space in the downtown core, with a brand-new way to work. An entire floor at the Plus 15 level dedicated to SPACE the employee experience. Space to lounge, relax, collaborate, meet, eat, and exercise. Room in each day for wellness, social connection, and the pleasure of business. Market-leading focus on employee health and safety. Space to enjoy the PUTS views. A new way to attract and retain the best talent – with office space that puts people first. This is where work meets life. Where people and companies thrive, and office life takes on a whole PEOPLE new meaning. FIRST 1 2 WORK, MEET LIFE Step on to the Plus 15 and into a new definition of office life. An entire floor of amazing amenities, designed to put people first. COLLABORATE PLAY Spaces to connect, Pool table beats boardroom table brainstorm and inspire. for a casual meeting of minds. 3 4 LOUNGE Relax and enjoy a moment with colleagues. 5 6 MEET ENJOY SWEAT Beautifully designed Fresh air and great views from An incredible gym seconds from your boardroom space invites the activated outdoor terrace. desk, for workouts whenever you want. the exchange of ideas. 7 8 HEALTH AND PERSONAL TENANT HEALTH, SAFETY AND WELLNESS SAFETY FIRST Hines takes the utmost care to ensure the health, safety, and well-being of our tenants and visitors. With a global presence in 225 cities and 25 countries, Hines has a unique AIR QUALITY ability to leverage global best practices to ensure First Tower is operated in Efficient HVAC systems and the installation a best-in-class manner to keep tenants and employees safe, healthy, happy, of MERV-13 air filters throughout First Tower and productive. -

Bow to Bluff Public Realm Plan — Design Update

Bow to Bluff Public Realm Plan — Design Update December 2017 Great public spaces encourage people to gather, recreate, explore and discover. Introduction The City of Calgary is planning to improve the corridor along the northwest C-train line from McHugh Bluff to the Bow River. The corridor design began in 2012 as a community-led The Plan combines input from the public and stakeholders initiative to develop an urban design framework that regarding elements that contribute to the vitality of a place, ff would transform the public corridor along the Light Rail including traffic movement, fences, placemaking, safety, lu Transit (LRT) line into a great public space. In the fall of play, gardens, cooking, cycling and strolling. The Plan McHugh B 2016, The City began the process toward implementation amends the proposed public realm improvements based of the framework. Public and stakeholder engagement in on new community and City input. As funding becomes the spring of 2017 brought forward updated issues and available, the revised design and associated budgets will LANEWAY MEWS opportunities as well as program ideas to guide the Bow to guide The City in determining the implementation process. Bluff Public Realm Plan (The Plan). What has changed since the completion of the 2012 Urban Design PARKETTE 2 4 AVE NW Framework? 10 ST NW SUNNYSIDE CTRAIN STATION ■ Calgary Transit extension to the Light Rail Transit ■ The previous City-owned warehouse on 2nd (LRT) platform and installation of a power Avenue and 9 Street has been demolished, substation -

2018 Historic Calgary Week Events

HISToRIC C TGARY STpEKAT A GI-IT.ICE ! Fnroeyrlurv 27 WnoNESDAY, Aucusr 1 9:45 am-3:00 pm SoursERN Arspnre PToNEERS 10:00 am Partnering with History: The Ciry's Civic 9:45 am HC\)f Opening Ceremonies Partners 10:00 am Shaws of Midnapore 10:00 am Lougheed House: Reliving the Restoration 11:00 am My Eady Years in the Canadtan Rockies 10:00 am Your Story Matters 12:00 pm Picnic Lunch 11:00 am Read with Engine 23: Special HC$7 Edition 1:00 pm William Scott and Mana Gough 12:00 pm Calgary's Connection to Northern Flying 2:00 pm Forging the Future 2:00 pm Lougheed House: Reliving the Restoration 6:00 pm Cantonese Experience and Dinner 4:30 pm Calgary Stampede Flistoncalf Art Sfalking Tour SerunDAY, 28 6:00 pm Partners ... In Crime! Jurv \il7riters 10:00 am EP Ranch 7:00 pm Stephen Avenue Through the Eyes of 10:00 am Lougheed House Garden Party THunsDAY, Aucusr 2 11:00 am Flistoric Chinatown Tour 10:00 am The Alberta You Never l(new 1 1:00 am Quirky Characters Cem etery Tour, High River 10:30 am HistoricalLaunch Trip on Chestermere Lake 12:00 pm Family Heritage Festival20l,B 12:00 pm The Power of Partnerships 2:00 pm Memorial Park Llbrary and Central Memorial 1234 pm HistoricalLaunch Trip on Chestermere Lake Park rWalking Tour 1:30 pm HistoricalLaunch Trip on Chestermere Lake 2:00 pm Every Stone Tells a Story, Okotoks 1:30 pm Celebratirg Alexander Calhoun at N{emorial 7:00 pm $Tindows to the Past 2:00 pm The Fvolution of the Libnry Through SuNoevrJurv 29 Buildings 10:00 am Cycling the Bow River Pathway 6:30 pm CaIgary Heritage Authority Lion -

THE BOW 500 Centre Street SE, CALGARY, AB the BOW for SUBLEASE 500 CENTRE STREET SE, CALGARY, AB

THE BOW 500 Centre Street SE, CALGARY, AB THE BOW FOR SUBLEASE 500 CENTRE STREET SE, CALGARY, AB THE BOW is one of Calgary’s most recognizable buildings and an iconic structure in Calgary. The impressive 2,079,150 square foot building is 58 storeys tall and can be seen from almost anywhere in Calgary. The unique crescent shape of the building offers magnificent panoramic views of the city and exceptional natural light. THE BOW Sky Garden features a state-of-the art 250-seat auditorium, large multi-purpose room, kitchen, commercial grade food preparation area, soft seating and trees. There is a mountain view room which can host theatre or banquet style seating and has an adjoining buffet servery area. THE BOW is +15 connected to the Suncor Energy Centre and F1RST Tower. © 2018, Avison Young Real Estate Alberta Inc. All rights reserved. The information contained herein was obtained from sources which we deem reliable and, while thought to be correct, is not guaranteed by Avison Young. THE BOW FOR SUBLEASE 500 CENTRE STREET SE, CALGARY, AB Building Details Address 500 Centre Street SE Year Built 2012 Building Size 58 Storeys 54 Office Floors Totalling: 1,995,146 SF 2 Retail Floors Totalling: 26,000 SF 54th Floor Sky Garden Available Sublandlord Encana Corporation Available Space 29th Floor - 35,862 SF 30th Floor - 40,128 SF 31st Floor - 40,175 SF Total: 116,165 SF (Can be leased by floor) Occupancy Immediately Asking Net Rent Market Rates Operating Costs & Taxes $25.65 psf (2018 est.) Term Negotiable Parking Negotiable 1,358 total stalls -

CALGARY PUBLIC LIBRARY Board Meeting 5:30 PM, Wednesday, June 26, 2019 0-11 Boardroom, Central Library

CALGARY PUBLIC LIBRARY Board Meeting 5:30 PM, Wednesday, June 26, 2019 0-11 Boardroom, Central Library Calgary Public Library Board Meeting June 26, 2019 I. Treaty 7 Opening 1 II. Chair’s Opening Remarks III. Review of Agenda IV. Consent Agenda A. Record of Urgent Motion May 27, 2019 (Ad hoc Committee Formation) 3 B. Record of Urgent Motion June 7, 2019 (Signing Authority) 5 C. Minutes of the March 27, 2019 Board Meeting x V. Business Arising verbal A. Business Arising from the Minutes B. Advocacy Updates, including ALTA Report VI. Chair’s Report verbal VII. Operational Update (April – June 2019) 7 discussion VIII. Audit & Finance Committee Mr. Andrew Rodych, Committee Chair information A. Report of the April 16, 2019 Meeting (based on draft unapproved minutes) xx B. Motion to Receive Controller's Report and the Calgary Public Library Board’s financial statements and reserve reports for the period ended March 31, 2019. 19 IX. Strategy & Community Committee Mr. Isaac Elias, Committee Chair information A. Report of the April 9, 2019 Meeting 28 B. Motion to Receive Report on Fine Free Youth Material 32 C. Report of the May 15, 2019 Meeting 40 D. Report of the June 11, 2019 Meeting (based on draft unapproved minutes) 44 X. Governance Committee Ms. Shereen Samuels, Committee Chair information A. Report of the April 3, 2019 Meeting 48 B. Report of the May 22, 2019 Meeting 52 C. Report of the June 5, 2019 Meeting (based on draft unapproved minutes) 56 D. Motion to Approve Revised Board Naming Policies 60 E. -

Historic Downtown Calgary Introduction

Stephen Avenue Timeline 1875 Inspector Brisebois and 50 members of the “F” Troop of the 1910 The Nielson Block is enlarged and two more storeys are added. North-West Mounted Police (NWMP) establish a fort on the 1911 The Dominion Bank Building is under construction on Stephen banks of the Bow and Elbow River. Avenue. The jewellery store in the Doll Block is robbed of Downtow� 1876 Fort Brisebois is renamed Fort Calgary by Colonel James $11,000 worth of diamonds. P.O. Box 2100 Station M, #8117 Macleod of the NWMP after the ancestral estate of his cousins 1912 The Molson’s Bank opens on Stephen Avenue. The Calgary Calgary, Alberta, Canada on the Isle of Mull, Scotland. Milling Company is sold to Robin Hood Milling. The build- T2P 2M5 Calgary 1883 The Canadian Pacific Railway arrives in town. A young lawyer, ing is sold to John Irwin who opens a fancy food grocery store. www.calgary.ca/heritage James Alexander Lougheed, purchases five lots from the CPR at 1913 The Burns Building opens as the head offices for Pat Burns’ cattle $300 each, on what became Stephen Avenue. operations. The Main Post office built in 1894 is torn down to 1884 Calgary is incorporated as a town. Calgary has its first make way for a newer and bigger building, The Calgary Public Including Calgary’s National Historic District newspaper, 30 major buildings and a population of over 1,000. Building, which is not constructed until 1930. Hudson’s Bay Stephen Avenue Stephen Avenue is named after George Stephen, President of opens store #4, the site of the present “Bay.” the CPR.