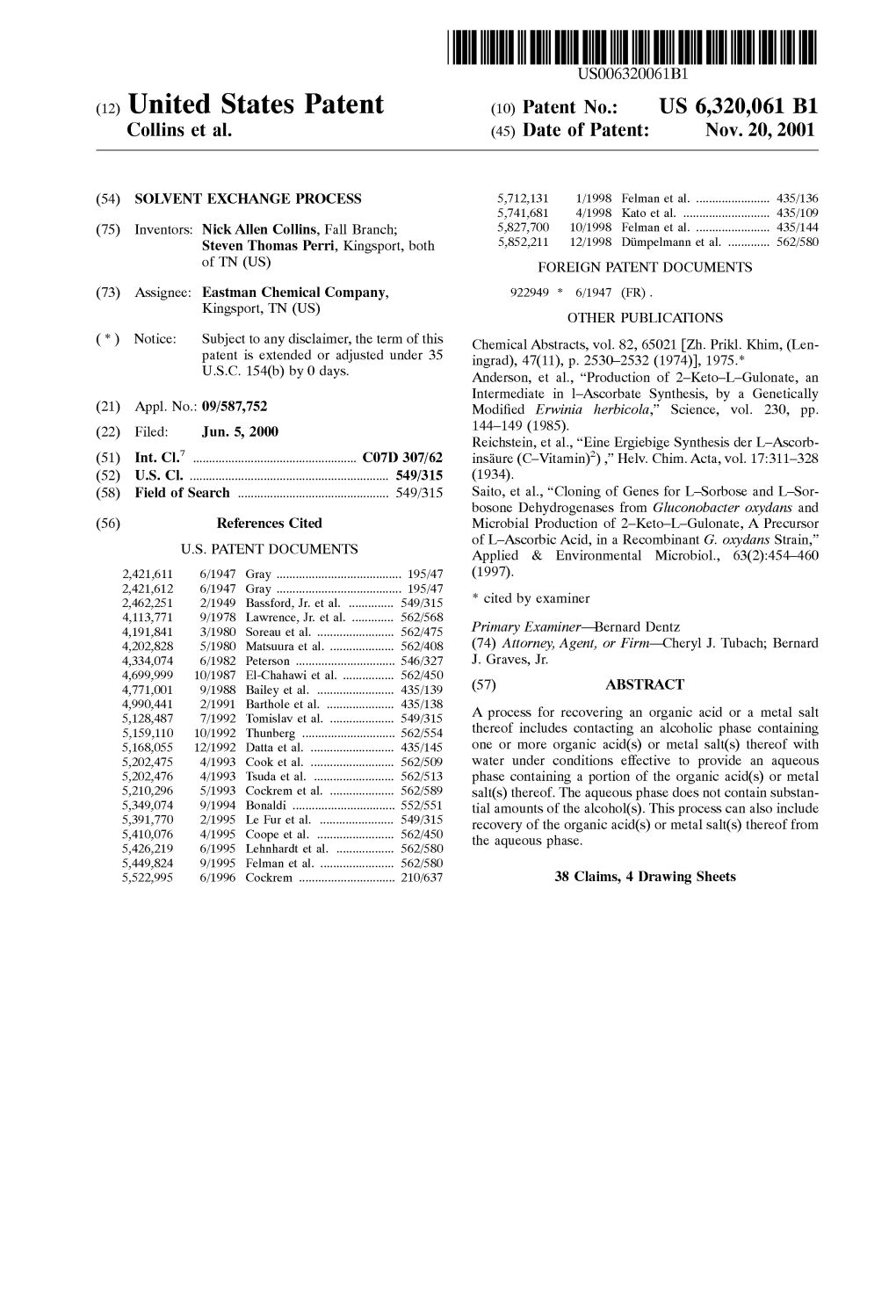

(12) United States Patent (10) Patent No.: US 6,320,061 B1 Collins Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Dr. Soumendu Bisoi Assistant Professor Department of Chemistry, Narajole Raj College

Dr. Soumendu Bisoi Assistant Professor Department of Chemistry, Narajole Raj College Vitamin C Vitamin C, also named as L-ascorbic acid (Asc), is a water-soluble vitamin that is essential for humans, non-human primates and a few other mammals. Vitamin C (L-ascorbic acid; Asc) is a powerful antioxidant and essential human nutrient that has extensive industrial and medicinal applications resulting in global requirements estimated at 154 thousand tons in 2007. The discovery of Asc is related with the disease of scurvy. Scurvy was a common disease in the world’s navies and sailors until the beginning of the nineteenth century, with serious symptoms such as bleeding of mucous membranes, anaemia and eventually death. In 1928, Albert Szent-Gyørgyi first isolated the Asc from adrenal glands and called it hexuronic acid. Four years later, Charles Glen King isolated Asc in his laboratory and concluded that it was the same as hexuronic acid. In 1933, Norman Haworth deduced the chemical structure of Asc (Figure 1). Figure 1 Vitamin C (L-ascorbic acid). Between 1933 and 1934, not only Haworth and fellow British chemist Edmund Hirsthad synthesised Asc, but also, independently, the Polish chemist Tadeus Reichstein, succeeded in synthesising the vitamin in bulk, making it the first vitamin to be artificially produced. The latter process made possible the cheap mass-production of semi-synthetic Asc, which was quickly marketed. Haworth was awarded the 1937 Nobel Prize in Chemistry in part for this work, but the Reichstein process, a combined chemical and bacterial fermentation sequence still used today to produce vitamin C, retained Reichstein’s name. -

Synthesis and Characterization of New Metal-Carbon Catalysts for Hydrogenation of D-Glucose

SYNTHESIS AND CHARACTERIZATION OF NEW METAL-CARBON CATALYSTS FOR HYDROGENATION OF D-GLUCOSE LIU JIAJIA NATIONAL UNIVERSITY OF SINGAPORE 2010 SYNTHESIS AND CHARACTERIZATION OF NEW METAL-CARBON CATALYSTS FOR HYDROGENATION OF D-GLUCOSE LIU JIAJIA (M.Eng, Tianjin University) A THESIS SUBMITTED FOR THE DEGREE OF DOCTOR OF PHILOSOPHY DEPARTMENT OF CHEMICAL AND BIOMOLECULAR ENGINEERING NATIONAL UNIVERSITY OF SINGAPORE 2010 Acknowledgement Acknowledgement I am heartily thankful to my supervisor, Assoc. Prof. Zhao X. S., George, whose constant encouragement, invaluable guidance, patience and support throughout the whole period of my PhD candidature. I would also like to thank Assoc. Prof. Zhao for his guidance on writing scientific papers including this PhD thesis. In addition, I want to express my sincerest appreciation to the Department of Chemical and Biomolecular Engineering for offering me the chance to study at NUS with a scholarship. It’s my pleasure to work with a group of brilliant, warmhearted and lovely people. Wish all my lab mates go well with their work. Particular acknowledgement goes to Dr. Liu Tao, Mr. Chia Phai Ann, Mr. Shang Zhenhua, Dr. Yuan Zeliang, Mr. Mao Ning, Mr. Liu Zhicheng, Dr. Rajarathnam D., Madam Chow Pek Jaslyn, Mdm Fam Hwee Koong Samantha, Ms Lee Chai Keng, Ms Tay Choon Yen, Mr. Toh Keng Chee, Mr. Chun See Chong, Ms. Ng Ai Mei, Ms. Lum Mei Peng Sharon, and Ms. How Yoke Leng Doris for their kind supports. I thank my parents and my husband. It is no exaggeration to say that I could not complete the PhD work without their generous help, boundless love, encouragement and support. -

Ethoxylation of Fatty Acids

S B N P Enzymatic Synthesis & Functional Characterization Fredrik Viklund Department of Biotechnology Stockholm Royal Institute of Technology Surfactants based on natural products — Enzymatic synthesis and functional characterization Copyright © by Fredrik Viklund ISBN --- is is the electronic version of the thesis. Compared to the printed version, it includes some minor typographical corrections. Royal Institute of Technology Printed in Stockholm AlbaNova University Center May Department of Biotechnology SE- Stockholm, Sweden Universitetsservice AB http://www.biotech.kth.se/ http://www.us-ab.se/ To Explorers Sammanfattning Tensider är molekyler som består av en vattenlöslig och en fettlöslig del. De spelar en viktig roll i produkter som rengöringsmedel, kosmetika, läkemedel och mat såväl som i många industriella processer. Tensider används i mycket stor skala vilket gör det viktigt att minska deras påverkan på miljön. Det kan åstadkommas genom att använda naturprodukter som råvaror, genom att förbättra tillverkningsmetoderna och genom att minska användningen av begränsade resurser som energi och lösningsmedel. Den här avhandlingen behandlar lipaskatalyserad syntes av naturprodukts- baserade tensider. Den omfattar också studier av de framställda tensiderna; dels som antioxidanter i oljor, dels som tensider för att öka lösligheten av läkemedel. Omättade fettsyraestrar av askorbinsyra framställdes genom katalys med Candida antarctica lipas B i t-amylalkohol och i joniska vätskor. Höga utbyten av askorbyloleat erhölls i en jonisk vätska som formgivits för att öka lösligheten av fettsyran, när reaktionen kördes under vakuum. Vi fann att askorbyloleat är amorft och att det är en bättre antioxidant än askorbylpalmitat i rapsolja. Polyetylenglykol (PEG)-stearat, PEG -hydroxystearat och en rad PEG -acyloxy-stearater framställdes i en vakuumdriven och lösningsmedels- fri uppställning med lipas B från C. -

(12) United States Patent (10) Patent No.: US 6,610,863 B2 Arumugam Et Al

USOO6610863B2 (12) United States Patent (10) Patent No.: US 6,610,863 B2 Arumugam et al. (45) Date of Patent: Aug. 26, 2003 (54) CONTINUOUS PROCESS FOR PRODUCING DE 199 04 821 C1, 7/2000 L-ASCORBIC ACID EP O554090 A2 4/1983 EP 1 048 663 A1 11/2000 (75) Inventors: Bhaskar Krishna Arumugam, SE 1. is : 3.3. Kingsport, TN (US); Nick Allen GB 2O34 315 * 6/1980 Collins, Fall Branch, TN (US); JP 73015931 5/1973 Transito Lynne Macias, Petal, MS WO WO 87/0O839 2/1987 (US); Steven Thomas Perri, Kingsport, WO WO 97/13761 4/1997 TN (US); Jeffrey Earl Grant Powell, WO WO 99/07691 2/1999 Blountville, TN (US); Chester Wayne WO WOOO46216 8/2000 Sink, Kingsport, TN (US); Michael Roy Cushman, Punta Gorda, FL (US) OTHER PUBLICATIONS Anderson, S. et al., Production of 2-Keto-L-Gulonate, an (73) Assignee: Eastman Chemical Company, Intermediate in L-AScorbate Synthesis, by a Genetically Kingsport, TN (US) Modified Erwinia herbicola, Science, 230, pp. 144-149, 1985. (*) Notice: Subject to any disclaimer, the term of this Regna, P.P. et al., Kinetics of Transformation of 2-Keto patent is extended or adjusted under 35 polyhydroxy Acids, J. Am. Chem. Soc., 66, pp. 246-250, U.S.C. 154(b) by 0 days. 1944. Reichstein, T. et al., Eine ergiebige Synthese der 1-AScorb (21) Appl. No.: 10/037,126 ins?ure (C-Vitamine)) Helv. Chim. Acta, 17, pp. 311-328, 1934 * See Information Disclosure Statement for Descrip (22) Filed: Dec. 21, 2001 tion. (65) Prior Publication Data Saito, Y., Direct Fermentation of 2-Keto-L-Gulonic Acid in Recombinant Gluconobacter Oxydans, Biotechnol. -

Chemistry: Human Activity, Chemical Reactivity

Chemistry: Human Activity, Chemical chapters. For example, the chapter on carbon com- Reactivity pounds starts with a case study of methane clathrates, Peter Mahaffy, Roy Tasker, Bob Bucat, John C. and that on chemical reactions and energy, with a Kotz, Gabriela C. Weaver, Paul M. Treichel, John E. case study of hydrogen as a fuel. The more obviously McMurry organic chapters use contexts from pharmaceuticals Nelson Education Ltd., 2010 or biological chemistry, with case studies on curing ISBN-13: 978-0-17660-625-1 and death and dying in the aromatics compounds ISBN-10: 0176606254 chapter, and a case study on the discovery of penicillin in the carbonyl compound chapter. These case studies are fascinating and a useful resource in themselves, reviewed by Tina L. Overton and I looked forward to each one. It is perhaps a little unfortunate that the first two are about drug abuse, There are many general chemistry textbooks on the and that some potential adopters may be prudish market and they all almost inevitably cover similar enough to be put off by that. But in each case the content. Academic staff choose these books for topics are discussed in their scientific context, and in their undergraduate students based on many crite- a way that helps us to appreciate (in these cases) the ria; level, detailed content, layout, design, chapter power of analytical techniques. order, habit, etc. Chemistry: Human Activity, Chemical The case studies are not the only place that Reactivity may give academics additional criteria the essential importance of chemistry is discussed. to consider. The book is authored by a well-known Real-life context is embedded within the text, often team of chemical educators who in a way that encourages stu- have a particular passion for rep- dents to think about how we know resenting chemistry visually, using what we know, and that demon- electronic resources to enhance strates the scientific method effec- conceptual understanding, and for tively. -

Recent Patents on Vitamin C: Opportunities for Crop Improvement and Single-Step Biological Manufacture Robert D

Recent Patents on Food, Nutrition & Agriculture, 2009, 1, 39-49 39 Recent Patents on Vitamin C: Opportunities for Crop Improvement and Single-Step Biological Manufacture Robert D. Hancock* Plant Products and Food Quality, Scottish Crop Research Institute, Invergowrie, Dundee DD2 5DA. United Kingdom Received: August 1, 2008; Accepted: September 9, 2008; Revised: September 9, 2008 Abstract: Vitamin C is an essential human nutrient obtained primarily from plant foods. Despite the necessity of the vitamin for human health and the essential role that it plays in plant stress resistance, it is only in the last decade that an understanding of its biosynthesis in plants has emerged. These fundamental discoveries present for the first time the opportunity to manipulate crop plants for improved human nutrition and enhanced agronomic performance and are discussed in relation to recent patents protecting aspects of vitamin C synthesis and degradation in plants. Vitamin C has a wide range of medicinal and industrial uses resulting in an annual market exceeding US$600 million. In recent years, there has been strong competition in vitamin C markets as a result of emerging Chinese producers and one response has been increased investment in research and development for the biological manufacture of the vitamin. Knowledge of the plant biosynthetic pathway has provided novel opportunities for the synthesis of vitamin C in yeasts, although successes have been limited to date. A more promising route is the direct synthesis of vitamin C in acetic acid bacteria and significant research and development has gone into the genetic improvement of appropriate strains. Keywords: Ascorbic acid, fermentation, Reichstein process, Gluconobacter, sorbitol, sorbosone dehydrogenase. -

Ascorbic Acid Handling/Processing

United States Department of Agriculture Agricultural Marketing Service | National Organic Program Document Cover Sheet https://www.ams.usda.gov/rules-regulations/organic/national-list/petitioned Document Type: ☐ National List Petition or Petition Update A petition is a request to amend the USDA National Organic Program’s National List of Allowed and Prohibited Substances (National List). Any person may submit a petition to have a substance evaluated by the National Organic Standards Board (7 CFR 205.607(a)). Guidelines for submitting a petition are available in the NOP Handbook as NOP 3011, National List Petition Guidelines. Petitions are posted for the public on the NOP website for Petitioned Substances. ☒ Technical Report A technical report is developed in response to a petition to amend the National List. Reports are also developed to assist in the review of substances that are already on the National List. Technical reports are completed by third-party contractors and are available to the public on the NOP website for Petitioned Substances. Contractor names and dates completed are available in the report. Ascorbic Acid Handling/Processing 1 Identification of Petitioned Substance 18 2 Chemical Names: 19 Trade Names: 3 Ascorbic Acid Magnorbin 4 L-Ascorbic Acid Ascorbicap 5 (2R)-2-[(1S)-1,2-dihydroxyethyl]-3,4-dihydroxy- Hybrin 6 2H-furan-5-one Cescorbat 7 L-Threoascorbic Acid 8 CAS Numbers: 9 Other Names: 50-81-7 10 Vitamin C 11 Cevitamic Acid Other Codes: 12 Xyloascorbic Acid, L EC No. 200-066-2 13 Vitacimin ICSC No. 0379 14 Vitacin FEMA No. 2109 15 Ascoltin RTECS No. -

The Roots—A Short History of Industrial Microbiology and Biotechnology

Appl Microbiol Biotechnol (2013) 97:3747–3762 DOI 10.1007/s00253-013-4768-2 MINI-REVIEW The roots—a short history of industrial microbiology and biotechnology Klaus Buchholz & John Collins Received: 20 December 2012 /Revised: 8 February 2013 /Accepted: 9 February 2013 /Published online: 17 March 2013 # Springer-Verlag Berlin Heidelberg 2013 Abstract Early biotechnology (BT) had its roots in fasci- mainly secondary metabolites, e.g. steroids obtained by nating discoveries, such as yeast as living matter being biotransformation. By the mid-twentieth century, biotech- responsible for the fermentation of beer and wine. Serious nology was becoming an accepted specialty with courses controversies arose between vitalists and chemists, resulting being established in the life sciences departments of several in the reversal of theories and paradigms, but prompting universities. Starting in the 1970s and 1980s, BT gained the continuing research and progress. Pasteur’s work led to the attention of governmental agencies in Germany, the UK, establishment of the science of microbiology by developing Japan, the USA, and others as a field of innovative potential pure monoculture in sterile medium, and together with the and economic growth, leading to expansion of the field. work of Robert Koch to the recognition that a single path- Basic research in Biochemistry and Molecular Biology dra- ogenic organism is the causative agent for a particular matically widened the field of life sciences and at the same disease. Pasteur also achieved innovations for industrial time unified them considerably by the study of genes and processes of high economic relevance, including beer, wine their relatedness throughout the evolutionary process. -

S42452-020-2604-8.Pdf

Research Article Process design and economic studies of two‑step fermentation for production of ascorbic acid Shi Min Lim1 · Michelle Siao Li Lau1 · Edward Ing Jiun Tiong1 · Mun Min Goon1 · Roger Jhee Cheng Lau1 · Wan Sieng Yeo1 · Sie Yon Lau1 · Nabisab Mujawar Mubarak1 Received: 7 November 2019 / Accepted: 26 March 2020 / Published online: 5 April 2020 © Springer Nature Switzerland AG 2020 Abstract The current study presents the conceptual design of a chemical plant for an annual production of 500 tonne ascorbic acid or Vitamin C with a high purity of 95% via fermentation of D-sorbitol. In this study, two-step fermentation with a single culture process is operated with a proper ISO 14000 Environmental Management procedure. A process fow diagram of the processing plant and the plant-wide simulation fowsheet that was generated by SuperPro Designer Simulation software, as well as the material and energy balances are also depicted. Meanwhile, the process is optimized through the recycling of sorbose and heat integration. By recycling sorbose, the production of ascorbic acid has increased by 24% while the total energy consumption had reduced by 20% after heat integration. Furthermore, economic and sen- sitivity analysis was performed to calculate the proftability of the plant and predict the efect of market conditions on the investments. After the economic analysis, total capital investment and total production cost for the best scenario were found to be roughly USD 52 million and USD 43 million, respectively with a return on investment of 78.73% and a payback period of 1.17 years since the selling price of Vitamin C is high. -

Survase 1658.Vp

S.A. SURVASE et al.: Production of Vitamins, Food Technol. Biotechnol. 44 (3) 381–396 (2006) 381 ISSN 1330-9862 review (FTB-1658) Biotechnological Production of Vitamins Shrikant A. Survase, Ishwar B. Bajaj and Rekha S. Singhal* Food and Fermentation Technology Department, Institute of Chemical Technology, University of Mumbai, Matunga, Mumbai 400019, India Received: December 20, 2005 Accepted: March 20, 2006 Summary Vitamins are defined as essential micronutrients that are required in trace quantity and cannot be synthesized by mammals. Apart from their in vivo nutritional and physio- logical roles as growth factors for men, animals, plants and microorganisms, vitamins are now being increasingly introduced as food/feed additives, as medical-therapeutic agents, as health aids, and also as technical aids. Production of vitamins by chemical synthesis, or extraction from their known sources has serious disadvantages. This led to an increased in- terest in substituting these processes with biotechnological processes. For several of these compounds microbiological and algal processes exist, or are rapidly emerging. Different methods like media optimization, mutation and screening, genetic engineering and bioca- talyst conversion have been used for improvement of the production of vitamins. The sur- vey describes the current state of vitamin production by biotechnological processes and their significance, as compared to the existing chemical processes. Key words: vitamins, fermentation, biotechnological production Introduction these processes have growing consumer consciousness with regard to food additive safety. This has led to in- Vitamins, defined as essential micronutrients re- creased interest in substituting these processes with bio- quired in trace quantities that cannot be synthesized by technological processes. -

The Chemistry of L-Ascorbic Acid Derivatives in the Asymmetric Synthesis of C2- and C3- Substituted Aldono-Γ-Lactones

The Chemistry of L-Ascorbic Acid Derivatives in the Asymmetric Synthesis of C2- and C3- Substituted Aldono-γ-lactones A Dissertation by Ayodele O. Olabisi M. S., Wichita State University, 2004 B. S., Wichita State University, 1999 Submitted to the College of Liberal Arts and Sciences and the Faculty of the Graduate School of Wichita State University in partial fulfillment of the requirements for the Degree of Doctor of Philosophy August 2005 The Chemistry of L-Ascorbic Acid Derivatives in the Asymmetric Synthesis of C2- and C3- Substituted Aldono-γ-lactones I have examined the final copy of this dissertation for form and content and recommend that it be accepted in partial fulfillment of the requirements for the degree of Doctor of Philosophy, with a major in Chemistry. ______________________________________ Professor Kandatege Wimalasena, Committee Chair We have read this dissertation and recommend its acceptance: __________________________________________ Professor William C. Groutas, Committee Member __________________________________________ Professor Ram P. Singhal, Committee Member __________________________________________ Professor Francis D’Souza, Committee Member __________________________________________ Professor George R. Bousfield, Committee Member Accepted for the College of Liberal Arts and Sciences __________________________________________ Dr. William Bischoff, Dean Accepted for the Graduate School __________________________________________ Dr. Susan K. Kovar, Dean ii DEDICATION To My Parents iii ACKNOWLEDMENTS I wish to express my deepest and sincerest appreciation to my advisor, Dr Kandatege Wimalasena for his positive guidance, enlightened mentoring and encouragement. His passion for the subject matter has greatly improved my knowledge and interest. My sincere appreciation extends to Dr. Shyamali Wimalasena and Dr. Mathew Mahindaratne, who helped me with my initial research training and their assistance in the preparation of my manuscripts. -

Manipulation of B. Megaterium Growth for Efficient 2-KLG Production by K

Process Biochemistry 45 (2010) 602–606 Contents lists available at ScienceDirect Process Biochemistry journal homepage: www.elsevier.com/locate/procbio Short communication Manipulation of B. megaterium growth for efficient 2-KLG production by K. vulgare Jing Zhang a,b, Jie Liu c, Zhongping Shi b, Liming Liu a,c, Jian Chen a,b,* a State Key Laboratory of Food Science and Technology, Jiangnan University, Wuxi 214122, China b The Key Laboratory of Industrial Biotechnology, Ministry of Education, Jiangnan University, 1800 Lihu Road, Wuxi 214122, China c Jiangsu Jiangshan Pharmaceutical Co., Ltd., Jingjiang 214500, China ARTICLE INFO ABSTRACT Article history: In the two-step Vitamin C fermentative production, its precursor 2-keto-L-gulonic acid (2-KLG) was Received 5 June 2009 synthesized by Ketogulonicigenium vulgare through co-culture with Bacillus megaterium. The rates of K. Received in revised form 20 November 2009 vulgare cell growth and 2-KLG production were closely related with B. megaterium concentration in the Accepted 28 November 2009 co-culture system. To enhance the 2-KLG production efficiency, a strategy of manipulating B. megaterium growth in the co-culture system and properly releasing its intracellular components was introduced. Keywords: Lysozyme was used specifically to damage B. megaterium cell wall structure and subsequently inhibit its Bacillus megaterium cell growth. When 10,000 U mLÀ1 lysozyme was fed to the co-culture system at 12 h, the growth rate of Ketogulonicigenium vulgare K. vulgare, sorbose consumption rate, and 2-KLG productivity could increase 27.4%, 37.1%, and 28.2%, 2-Keto-L-gulonic acid Lysozyme respectively. Productivity ß 2009 Elsevier Ltd.