|Spotion Analgesic Aetion and May Be Used As Substitutes (CH3)2C-CHCH.N(CH3), (CH3):NH (C.H.G-HCH,61 for Morphine

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Transport of Dangerous Goods

ST/SG/AC.10/1/Rev.16 (Vol.I) Recommendations on the TRANSPORT OF DANGEROUS GOODS Model Regulations Volume I Sixteenth revised edition UNITED NATIONS New York and Geneva, 2009 NOTE The designations employed and the presentation of the material in this publication do not imply the expression of any opinion whatsoever on the part of the Secretariat of the United Nations concerning the legal status of any country, territory, city or area, or of its authorities, or concerning the delimitation of its frontiers or boundaries. ST/SG/AC.10/1/Rev.16 (Vol.I) Copyright © United Nations, 2009 All rights reserved. No part of this publication may, for sales purposes, be reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, electrostatic, magnetic tape, mechanical, photocopying or otherwise, without prior permission in writing from the United Nations. UNITED NATIONS Sales No. E.09.VIII.2 ISBN 978-92-1-139136-7 (complete set of two volumes) ISSN 1014-5753 Volumes I and II not to be sold separately FOREWORD The Recommendations on the Transport of Dangerous Goods are addressed to governments and to the international organizations concerned with safety in the transport of dangerous goods. The first version, prepared by the United Nations Economic and Social Council's Committee of Experts on the Transport of Dangerous Goods, was published in 1956 (ST/ECA/43-E/CN.2/170). In response to developments in technology and the changing needs of users, they have been regularly amended and updated at succeeding sessions of the Committee of Experts pursuant to Resolution 645 G (XXIII) of 26 April 1957 of the Economic and Social Council and subsequent resolutions. -

02/06/2019 12:05 PM Appendix 3745-21-09 Appendix A

ACTION: Final EXISTING DATE: 02/06/2019 12:05 PM Appendix 3745-21-09 Appendix A List of Organic Chemicals for which Paragraphs (DD) and (EE) of Rule 3745-21-09 of the Administrative Code are Applicable Organic Chemical Organic Chemical Acetal Benzaldehyde Acetaldehyde Benzamide Acetaldol Benzene Acetamide Benzenedisulfonic acid Acetanilide Benzenesulfonic acid Acetic acid Benzil Acetic Anhydride Benzilic acid Acetone Benzoic acid Acetone cyanohydrin Benzoin Acetonitrile Benzonitrile Acetophenone Benzophenone Acetyl chloride Benzotrichloride Acetylene Benzoyl chloride Acrolein Benzyl alcohol Acrylamide Benzylamine Acrylic acid Benzyl benzoate Acrylonitrile Benzyl chloride Adipic acid Benzyl dichloride Adiponitrile Biphenyl Alkyl naphthalenes Bisphenol A Allyl alcohol Bromobenzene Allyl chloride Bromonaphthalene Aminobenzoic acid Butadiene Aminoethylethanolamine 1-butene p-aminophenol n-butyl acetate Amyl acetates n-butyl acrylate Amyl alcohols n-butyl alcohol Amyl amine s-butyl alcohol Amyl chloride t-butyl alcohol Amyl mercaptans n-butylamine Amyl phenol s-butylamine Aniline t-butylamine Aniline hydrochloride p-tertbutyl benzoic acid Anisidine 1,3-butylene glycol Anisole n-butyraldehyde Anthranilic acid Butyric acid Anthraquinone Butyric anhydride Butyronitrile Caprolactam APPENDIX p(183930) pa(324943) d: (715700) ra(553210) print date: 02/06/2019 12:05 PM 3745-21-09, Appendix A 2 Carbon disulfide Cyclohexene Carbon tetrabromide Cyclohexylamine Carbon tetrachloride Cyclooctadiene Cellulose acetate Decanol Chloroacetic acid Diacetone alcohol -

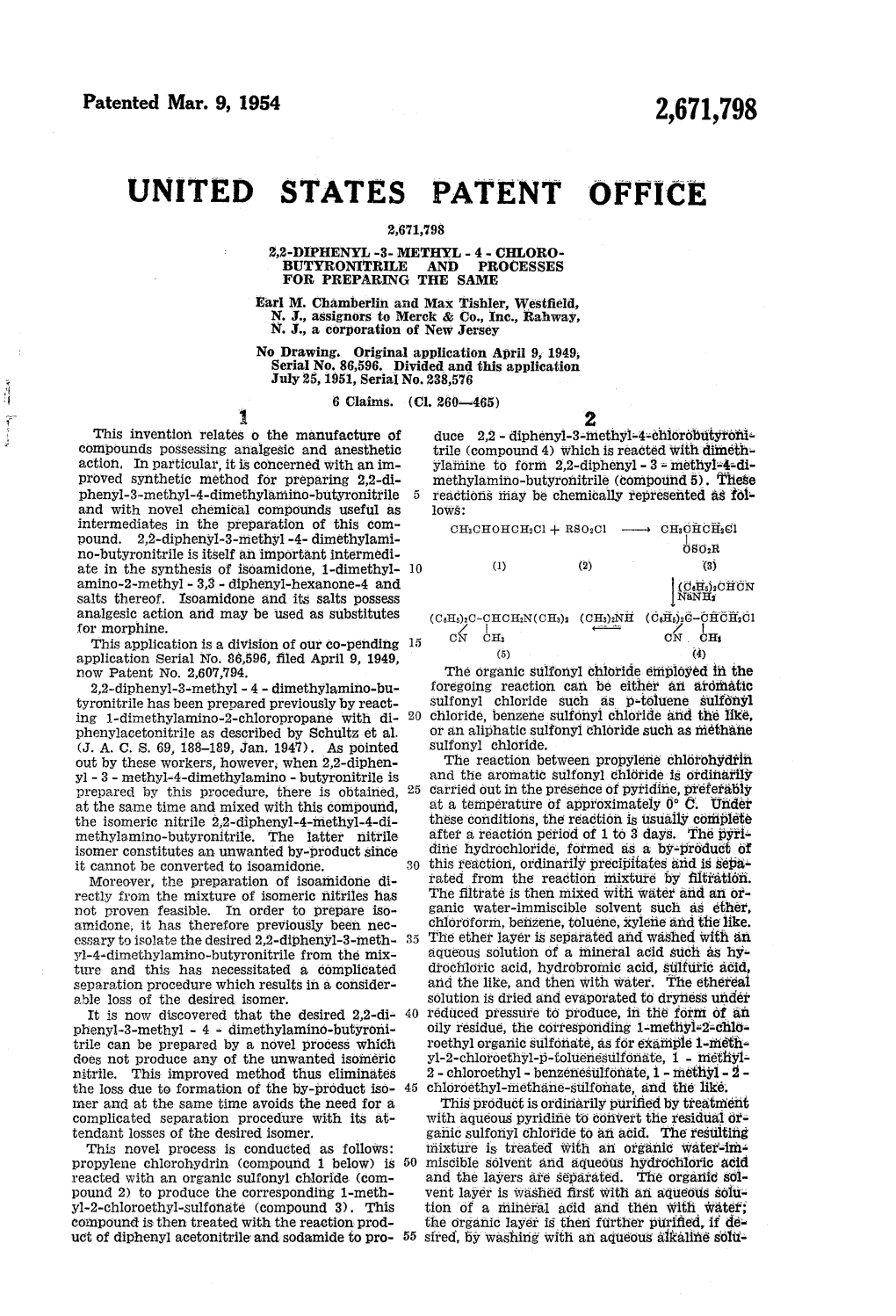

UNITED STATES PATENT OFFICE PROCESS of PREPARING 2,2-DIPHENYL-3- TRILEMETHYL-4-Dimethylamino-BUTYRONI Earl M

Patented Aug. 19, 1952 2,607,794 UNITED STATES PATENT OFFICE PROCESS OF PREPARING 2,2-DIPHENYL-3- TRILEMETHYL-4-DIMETHYLAMINo-BUTYRONI Earl M. Chamberlin, Rahway, and Max Tishler, Westfield, N.J., assignors to Merck & Co., Inc., Rahway, N.J., a corporation of New Jersey No Drawing. Application April 9, 1949, Seria No. 86,596 6 Claims. (CL 260-465) . 2 This invention relates to the manufacture of dimethylamino-butyronitrile (compound 5). Compounds possessing analgesic and anesthetic These reactions may be chemically represented action. In particular, it is concerned with an as follows: improved synthetic method for preparing 2,2-di phenyl 3-methyl-4-dimethylamino - butyronia CH3CHOHCHCl + RSO: C1 - cHipHCHCI trile and With novel chemical compounds useful Öso, R. as intermediates in the preparation of this come (1) (2) (3) pound. , 2,2-diphenyl-3-methyl - 4-dimethylami (C6H5)2CHCN no-butyronitrile is itself an important interne NaNH diate in the Synthesis of isoamidone, 1-dimethyl O amino-2-methyl-3,3-diphenylhexanone - 4 and (CH3)NH SaltS thereof. ISOamidone and its salts possess (C.H.)--HCH.N(CH), --- (CH)--HCH.Cl analgesic action and may be used as substitutes CE CH: for morphine. - N N 2,2-diphenyl-3-methyl - 4 - dimethylamino 5 (5) (4) butyronitrile has been prepared previously by The organic Sulfonyl chloride employed in the reacting 1-dimethylamino-2-chloropropane with foregoing reaction can be either an aromatic diphenylacetonitrile as described by Schultz et al. Sulfonyl chloride such as p-toluene sulfonyl chlo (J. A. C. S. 69, 188-189, Jan. 1947). As pointed ride, benzene Sulfonyl chloride and the like, or out by these workers, however, when 2,2-di 20 an aliphatic Sulfonyl chloride such as methane phenyl - 3 - methyl - 4-dimethlamino-butyroni Sulfonyl chloride. -

Synchronous Fluorescence Spectroscopic Study Of

Spectrochimica Acta Part A 79 (2011) 1034–1041 Contents lists available at ScienceDirect Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy jou rnal homepage: www.elsevier.com/locate/saa Synchronous fluorescence spectroscopic study of solvatochromic curcumin dye ∗ Digambara Patra , Christelle Barakat Department of Chemistry, Faculty of Arts and Sciences, American University of Beirut, P.O. Box 11-0236, Riad El Solh, Beirut 1107-2020, Lebanon a r t i c l e i n f o a b s t r a c t Article history: Curcumin, the main yellow bioactive component of turmeric, has recently acquired attention by chemists Received 1 July 2010 due its wide range of potential biological applications as an antioxidant, an anti-inflammatory, and an Accepted 13 April 2011 anti-carcinogenic agent. This molecule fluoresces weakly and poorly soluble in water. In this detailed study of curcumin in thirteen different solvents, both the absorption and fluorescence spectra of curcumin Keywords: was found to be broad, however, a narrower and simple synchronous fluorescence spectrum of curcumin Curcumin was obtained at = 10–20 nm. Lippert–Mataga plot of curcumin in different solvents illustrated two Solvent polarity E sets of linearity which is consistent with the plot of Stokes’ shift vs. the 30. When Stokes’s shift in SFS T wavenumber scale was replaced by synchronous fluorescence maximum in nanometer scale, the solvent max E polarity dependency measured by SFS vs. Lippert–Mataga plot or T30 values offered similar trends as max measured via Stokes’ shift for protic and aprotic solvents for curcumin. Better linear correlation of SFS vs. -

Itll Lawrence Berkeley Laboratory Iii:~ UNIVERSITY of CALIFORNIA APPLIED SCIENCE

LBL-24543 C'_~ ITll Lawrence Berkeley Laboratory iii:~ UNIVERSITY OF CALIFORNIA APPLIED SCIENCE -. ~ ., .. I DIVISION. •-, l:: '-' 1:: v L _ LAWRENCE EJr.:ov~L''"V_, .nc: c' LABORATORY APR 1 9 1988 LIBRARY AND The Use of Basic Polymer Sorbents DOCUMENTS SECTION for the Recovery of Acetic Acid from Dilute Aqueous Solution A.A. Garcia and C.J. King January 1988 '· . J I • .I APPLIED SCIENCE DIVISION Prepared for the U.S. Department of Energy under Contract DE-AC03-76SF00098 DISCLAIMER This document was prepared as an account of work sponsored by the United States Government. While this document is believed to contain correct information, neither the United States Government nor any agency thereof, nor the Regents of the University of California, nor any of their employees, makes any warranty, express or implied, or assumes any legal responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by its trade name, trademark, manufacturer, or otherwise, does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof, or the Regents of the University of Califomia. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof or the Regents of the University of California. LBL-24543 The Use of Basic Polymer Sorbents For The Recovery of Acetic Acid From Dilute Aqueous Solution Antonio Agustin Garcia and C. -

House Fly Attractants and Arrestante: Screening of Chemicals Possessing Cyanide, Thiocyanate, Or Isothiocyanate Radicals

House Fly Attractants and Arrestante: Screening of Chemicals Possessing Cyanide, Thiocyanate, or Isothiocyanate Radicals Agriculture Handbook No. 403 Agricultural Research Service UNITED STATES DEPARTMENT OF AGRICULTURE Contents Page Methods 1 Results and discussion 3 Thiocyanic acid esters 8 Straight-chain nitriles 10 Propionitrile derivatives 10 Conclusions 24 Summary 25 Literature cited 26 This publication reports research involving pesticides. It does not contain recommendations for their use, nor does it imply that the uses discussed here have been registered. All uses of pesticides must be registered by appropriate State and Federal agencies before they can be recommended. CAUTION: Pesticides can be injurious to humans, domestic animals, desirable plants, and fish or other wildlife—if they are not handled or applied properly. Use all pesticides selectively and carefully. Follow recommended practices for the disposal of surplus pesticides and pesticide containers. ¿/áepé4áaUÁí^a¡eé —' ■ -"" TMK LABIL Mention of a proprietary product in this publication does not constitute a guarantee or warranty by the U.S. Department of Agriculture over other products not mentioned. Washington, D.C. Issued July 1971 For sale by the Superintendent of Documents, U.S. Government Printing Office Washington, D.C. 20402 - Price 25 cents House Fly Attractants and Arrestants: Screening of Chemicals Possessing Cyanide, Thiocyanate, or Isothiocyanate Radicals BY M. S. MAYER, Entomology Research Division, Agricultural Research Service ^ Few chemicals possessing cyanide (-CN), thio- cyanate was slightly attractive to Musca domes- eyanate (-SCN), or isothiocyanate (~NCS) radi- tica, but it was considered to be one of the better cals have been tested as attractants for the house repellents for Phormia regina (Meigen). -

Environmental Protection Agency § 52.741

Environmental Protection Agency § 52.741 (z) Rules stayed. Not withstanding OCPDB Chemical any other provision of this subpart, the No.1 effectiveness of the following rules is 185 ........ Adiponitrile. stayed as indicated below. 190 ........ Alkyl naphthalenes. (1) [Reserved] 200 ........ Allyl alcohol. 210 ........ Allyl chloride. (2) Compliance with all of 40 CFR 220 ........ Aminobenzoic acid. 52.741 is stayed for 60 days (July 1, 1991, 230 ........ Aminoethylethanolamine. until August 30, 1991) as it pertains to 235 ........ p-aminophenol. the following parties: The Illinois En- 240 ........ Amyl acetates. 250 ........ Amyl alcohols. vironmental Regulatory Group includ- 260 ........ Amyl amine. ing its approximately 40 member firms; 270 ........ Amyl chloride. Allsteel, Incorporated; Riverside Lab- 280 ........ Amyl mercaptans. 290 ........ Amyl phenol. oratories, Incorporated; the Printing 300 ........ Aniline. Industry of Illinois/Indiana Association 310 ........ Aniline hydrochloride. including its member firms, and R.R. 320 ........ Anisidine. Donnelley & Sons Company; the rules 330 ........ Anisole. 340 ........ Anthranilic acid. applicable to General Motors Corpora- 350 ........ Anthraquinone. tion; Reynolds Metals Company; 360 ........ Benzaldehyde. Stepan Company; and Duo-Fast Cor- 370 ........ Benzamide. 380 ........ Benzene. poration. Final compliance for these 390 ........ Benzenedisulfonic acid. parties is extended 60 days from July 1, 400 ........ Benzene-sulfonic acid. 1991 until August 30, 1991. 410 ........ Benzil. (3) The following rules are stayed 420 ........ Benzilic acid. 430 ........ Benzoic acid. from July 23, 1991, until USEPA com- 440 ........ Benzoin. pletes its reconsideration as indicated: 450 ........ Bennzonitrile. (i) 40 CFR 52.741(e) only as it applies 460 ........ Benzophenone. 480 ........ Benzotrichloride. to Duo-Fast Corporation's Franklin 490 ........ Benzoyl chloride. Park, Illinois ``power-driven metal fas- 500 ........ Benzyl chalcohol. tener'' manufacturing facility, and 510 ....... -

2020 Emergency Response Guidebook

2020 A guidebook intended for use by first responders A guidebook intended for use by first responders during the initial phase of a transportation incident during the initial phase of a transportation incident involving hazardous materials/dangerous goods involving hazardous materials/dangerous goods EMERGENCY RESPONSE GUIDEBOOK THIS DOCUMENT SHOULD NOT BE USED TO DETERMINE COMPLIANCE WITH THE HAZARDOUS MATERIALS/ DANGEROUS GOODS REGULATIONS OR 2020 TO CREATE WORKER SAFETY DOCUMENTS EMERGENCY RESPONSE FOR SPECIFIC CHEMICALS GUIDEBOOK NOT FOR SALE This document is intended for distribution free of charge to Public Safety Organizations by the US Department of Transportation and Transport Canada. This copy may not be resold by commercial distributors. https://www.phmsa.dot.gov/hazmat https://www.tc.gc.ca/TDG http://www.sct.gob.mx SHIPPING PAPERS (DOCUMENTS) 24-HOUR EMERGENCY RESPONSE TELEPHONE NUMBERS For the purpose of this guidebook, shipping documents and shipping papers are synonymous. CANADA Shipping papers provide vital information regarding the hazardous materials/dangerous goods to 1. CANUTEC initiate protective actions. A consolidated version of the information found on shipping papers may 1-888-CANUTEC (226-8832) or 613-996-6666 * be found as follows: *666 (STAR 666) cellular (in Canada only) • Road – kept in the cab of a motor vehicle • Rail – kept in possession of a crew member UNITED STATES • Aviation – kept in possession of the pilot or aircraft employees • Marine – kept in a holder on the bridge of a vessel 1. CHEMTREC 1-800-424-9300 Information provided: (in the U.S., Canada and the U.S. Virgin Islands) • 4-digit identification number, UN or NA (go to yellow pages) For calls originating elsewhere: 703-527-3887 * • Proper shipping name (go to blue pages) • Hazard class or division number of material 2. -

Nitriles, C – C , Hydrocarbons, C

Nitriles, C1 – C4, Hydrocarbons, C1 – C6 Application Note Energy & Fuels Authors Introduction Agilent Technologies, Inc. Gas chromatography using an Agilent CP-Sil 5 CB column separates 42 C1 to C4 nitriles and C1 to C6 hydrocarbons in 35 minutes. Conditions Technique : GC-capillary Column : Agilent CP-Sil 5 CB, 0.15 mm x 50 m fused silica WCOT CP-Sil 5 CB (df = 2.0 µm) (Part no. CP7692) Temperature : 20 °C (35 min) Carrier Gas : H2, 0.6 mL/min, 160 kPa (1.6 bar, 22.4 psi) Injector : Split, 1:300 Detector : FID Concentration Range : 1 - 5 nmol injected Courtesy : Prof. F. Raulin and M. L. Do, University Paris, France Peak identifi cation 1. methane 15. 1,3-butadiene 29. methacrylonitrile 2. ethylene 16. butane 30. 3-methylpentane 3. ethyne 17. trans-2-butene 31. 1-hexene 4. ethane 18. 1-butyne 32. isobutyronitrile 5. cyanogen 19. cis-2-butene 33. n-hexane 6. propene 20. butadiyne 34. trans-2-butenenitrile 7. propane 21. cyanoacetylene 35. 3-butenenitrile 8. hydrocyanic acid 22. acetonitrile 36. 2-butynenitrile 9. propyne 23. 1-pentene 37. butyronitrile 10. propadiene 24. acrylonitrile 38. cis-2-butenenitrile 11. cyclopropane 25. n-pentane 39. benzene 12. isobutane 26. 2-methyl-2-butene 40. cyclohexane 13. 1-butene 27. propionitrile 41. cyclohexene 14. isobutene 28. cyclopentane 42. cyclopropanecarbonitrile 2 Conditions Technique : GC-capillary Column : Agilent CP-Sil 5 CB, 0.15 mm x 50 m fused silica WCOT CP-Sil 5 CB (df = 2.0 µm) (Part no. CP7692) Temperature : 20 °C (4 min) → 6 °C/min → 80 °C (2 min) Carrier Gas : H2, 0.6 mL/min, 160 kPa (1.6 bar, 22.4 psi) Injector : Split, 1:300 Detector : FID Concentration Range : 1 - 5 nmol injected Courtesy : Prof. -

Butyronitrile Bni

BUTYRONITRILE BNI CAUTIONARY RESPONSE INFORMATION 4. FIRE HAZARDS 7. SHIPPING INFORMATION 4.1 Flash Point: 62°F O.C. 7.1 Grades of Purity: 99 +% Common Synonyms Liquid Colorless Sharp suffocating 4.2 Flammable Limits in Air: 1.65% (LFL) 7.2 Storage Temperature: Currently not available Butanenitrile odor 4.3 Fire Extinguishing Agents: Dry Butyric acid nitrile 7.3 Inert Atmosphere: Currently not available chemical, alcohol foam, CO2, water. Cyanopropane 7.4 Venting: Currently not available Propyl cyanide 4.4 Fire Extinguishing Agents Not to Be Used: Not pertinent 7.5 IMO Pollution Category: Currently not available 7.6 Ship Type: Currently not available AVOID CONTACT WITH LIQUID OR VAPOR. EVACUATE AREA. 4.5 Special Hazards of Combustion Shut off all sources of ignition, call fire department. Products: Toxic cyanide fumes 7.7 Barge Hull Type: Currently not available Wear self-contained breathing apparatus and protective clothing. 4.6 Behavior in Fire: Currently not available Notify local health and pollution control agencies. 4.7 Auto Ignition Temperature: 910°F 8. HAZARD CLASSIFICATIONS Protect water intakes. 4.8 Electrical Hazards: Currently not 8.1 49 CFR Category: Flammable liquid available FLAMMABLE 8.2 49 CFR Class: 3 Fire 4.9 Burning Rate: Currently not available Toxic fumes are released in fire. 8.3 49 CFR Package Group: II Flashback may occur along vapor trail. 4.10 Adiabatic Flame Temperature: Currently Containers may explode under fire conditions. not available 8.4 Marine Pollutant: No Extinguish with dry chemical, alcohol foam, CO2 4.11 Stoichometric Air to Fuel Ratio: 32.1 8.5 NFPA Hazard Classification: Wear self-contained breathing apparatus and protective clothing. -

Dielectric Constant Chart

Dielectric Constants of Common Materials DIELECTRIC MATERIALS DEG. F CONSTANT ABS RESIN, LUMP 2.4-4.1 ABS RESIN, PELLET 1.5-2.5 ACENAPHTHENE 70 3 ACETAL 70 3.6 ACETAL BROMIDE 16.5 ACETAL DOXIME 68 3.4 ACETALDEHYDE 41 21.8 ACETAMIDE 68 4 ACETAMIDE 180 59 ACETAMIDE 41 ACETANILIDE 71 2.9 ACETIC ACID 68 6.2 ACETIC ACID (36 DEGREES F) 36 4.1 ACETIC ANHYDRIDE 66 21 ACETONE 77 20.7 ACETONE 127 17.7 ACETONE 32 1.0159 ACETONITRILE 70 37.5 ACETOPHENONE 75 17.3 ACETOXIME 24 3 ACETYL ACETONE 68 23.1 ACETYL BROMIDE 68 16.5 ACETYL CHLORIDE 68 15.8 ACETYLE ACETONE 68 25 ACETYLENE 32 1.0217 ACETYLMETHYL HEXYL KETONE 66 27.9 ACRYLIC RESIN 2.7 - 4.5 ACTEAL 21 3.6 ACTETAMIDE 4 AIR 1 AIR (DRY) 68 1.000536 ALCOHOL, INDUSTRIAL 16-31 ALKYD RESIN 3.5-5 ALLYL ALCOHOL 58 22 ALLYL BROMIDE 66 7 ALLYL CHLORIDE 68 8.2 ALLYL IODIDE 66 6.1 ALLYL ISOTHIOCYANATE 64 17.2 ALLYL RESIN (CAST) 3.6 - 4.5 ALUMINA 9.3-11.5 ALUMINA 4.5 ALUMINA CHINA 3.1-3.9 ALUMINUM BROMIDE 212 3.4 ALUMINUM FLUORIDE 2.2 ALUMINUM HYDROXIDE 2.2 ALUMINUM OLEATE 68 2.4 1 Dielectric Constants of Common Materials DIELECTRIC MATERIALS DEG. F CONSTANT ALUMINUM PHOSPHATE 6 ALUMINUM POWDER 1.6-1.8 AMBER 2.8-2.9 AMINOALKYD RESIN 3.9-4.2 AMMONIA -74 25 AMMONIA -30 22 AMMONIA 40 18.9 AMMONIA 69 16.5 AMMONIA (GAS?) 32 1.0072 AMMONIUM BROMIDE 7.2 AMMONIUM CHLORIDE 7 AMYL ACETATE 68 5 AMYL ALCOHOL -180 35.5 AMYL ALCOHOL 68 15.8 AMYL ALCOHOL 140 11.2 AMYL BENZOATE 68 5.1 AMYL BROMIDE 50 6.3 AMYL CHLORIDE 52 6.6 AMYL ETHER 60 3.1 AMYL FORMATE 66 5.7 AMYL IODIDE 62 6.9 AMYL NITRATE 62 9.1 AMYL THIOCYANATE 68 17.4 AMYLAMINE 72 4.6 AMYLENE 70 2 AMYLENE BROMIDE 58 5.6 AMYLENETETRARARBOXYLATE 66 4.4 AMYLMERCAPTAN 68 4.7 ANILINE 32 7.8 ANILINE 68 7.3 ANILINE 212 5.5 ANILINE FORMALDEHYDE RESIN 3.5 - 3.6 ANILINE RESIN 3.4-3.8 ANISALDEHYDE 68 15.8 ANISALDOXINE 145 9.2 ANISOLE 68 4.3 ANITMONY TRICHLORIDE 5.3 ANTIMONY PENTACHLORIDE 68 3.2 ANTIMONY TRIBROMIDE 212 20.9 ANTIMONY TRICHLORIDE 166 33 ANTIMONY TRICHLORIDE 5.3 ANTIMONY TRICODIDE 347 13.9 APATITE 7.4 2 Dielectric Constants of Common Materials DIELECTRIC MATERIALS DEG. -

Intramolecular Light Induced Activation of a Salen-Mniii Complex by a Ruthenium Photosensitizer

Supplementary Material (ESI) for Chemical Communications This journal is (c) The Royal Society of Chemistry 2010 Supporting information for Intramolecular Light Induced Activation of a Salen-MnIII Complex by a Ruthenium Photosensitizer Christian Herrero,*a Joseph L. Hughes,a Annamaria Quaranta,a Nicholas Cox,b A. William Rutherford,a Winfried Leibl,a Ally Aukaulooac aCEA, iBiTec-S, Service de Bioénergétique Biologie Structurale et Mécanismes (SB2SM), F-91191 Gif-sur-Yvette, France, CNRS, URA 2096, F-91191 Gif-sur-Yvette, France b Max Planck Institute für Bioanorganische Chemie, Stiftstrasse 34-36, D-45470, Mülheim an der Ruhr, Germany cInstitut de Chimie Moléculaire et des Matériaux d’Orsay, UMR-CNRS 8182, Université de Paris-Sud XI, F-91405 Orsay, France E-mail : [email protected] Index Page Figures S1. Transient absorption in the absence of electron acceptor 2 S2. Transient absorption in the presence of electron acceptor 2 S3. X-band EPR spectra of light induced oxidation of RuII-Salen. 3 S4. EPR and absorption spectra of chemically oxidized RuII-Salen-MnIII. 3 Synthesis and structural characterization 4 Laser Flash Photolysis 8 EPR spectroscopy and Sample Illuminations 8 Steady state absorption 8 Chemical oxidations 9 Electrochemistry 9 References 9 Supplementary Material (ESI) for Chemical Communications This journal is (c) The Royal Society of Chemistry 2010 Figure S1. Transient absorption in the absence of electron acceptor RuII-polypyridyl 1MLCT transient absorption kinetics at 20°C of absorption matched (A~0.2 at 460 nm) RuII-Salen-MnIII (7) (black traces) and RuII-Salen (6) (grey traces) dissolved in acetonitrile following a ~10 mJ ~7 ns flash at 460 nm.