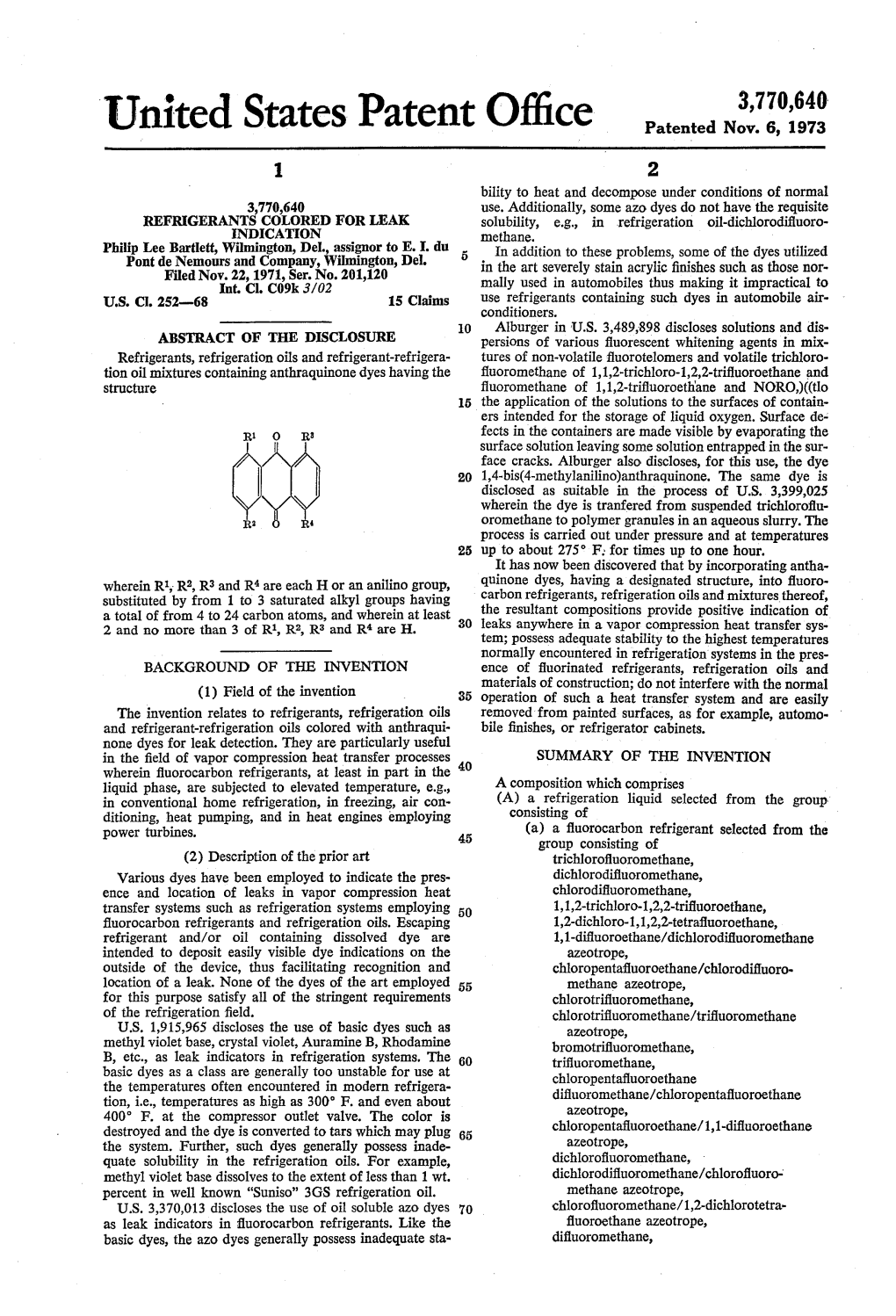

United States Patent Office Patented Nov

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

SAFETY DATA SHEET Halocarbon R-503

SAFETY DATA SHEET Halocarbon R-503 Section 1. Identification GHS product identifier : Halocarbon R-503 Other means of : Not available. identification Product type : Liquefied gas Product use : Synthetic/Analytical chemistry. SDS # : 007306 Supplier's details : Airgas USA, LLC and its affiliates 259 North Radnor-Chester Road Suite 100 Radnor, PA 19087-5283 1-610-687-5253 24-hour telephone : 1-866-734-3438 Section 2. Hazards identification OSHA/HCS status : This material is considered hazardous by the OSHA Hazard Communication Standard (29 CFR 1910.1200). Classification of the : GASES UNDER PRESSURE - Liquefied gas substance or mixture HAZARDOUS TO THE OZONE LAYER - Category 1 GHS label elements Hazard pictograms : Signal word : Warning Hazard statements : Contains gas under pressure; may explode if heated. May cause frostbite. May displace oxygen and cause rapid suffocation. Harms public health and the environment by destroying ozone in the upper atmosphere. Precautionary statements General : Read and follow all Safety Data Sheets (SDS’S) before use. Read label before use. Keep out of reach of children. If medical advice is needed, have product container or label at hand. Close valve after each use and when empty. Use equipment rated for cylinder pressure. Do not open valve until connected to equipment prepared for use. Use a back flow preventative device in the piping. Use only equipment of compatible materials of construction. Always keep container in upright position. Prevention : Not applicable. Response : Not applicable. Storage : Protect from sunlight. Store in a well-ventilated place. Disposal : Refer to manufacturer or supplier for information on recovery or recycling. Hazards not otherwise : Liquid can cause burns similar to frostbite. -

"Fluorine Compounds, Organic," In: Ullmann's Encyclopedia Of

Article No : a11_349 Fluorine Compounds, Organic GU¨ NTER SIEGEMUND, Hoechst Aktiengesellschaft, Frankfurt, Federal Republic of Germany WERNER SCHWERTFEGER, Hoechst Aktiengesellschaft, Frankfurt, Federal Republic of Germany ANDREW FEIRING, E. I. DuPont de Nemours & Co., Wilmington, Delaware, United States BRUCE SMART, E. I. DuPont de Nemours & Co., Wilmington, Delaware, United States FRED BEHR, Minnesota Mining and Manufacturing Company, St. Paul, Minnesota, United States HERWARD VOGEL, Minnesota Mining and Manufacturing Company, St. Paul, Minnesota, United States BLAINE MCKUSICK, E. I. DuPont de Nemours & Co., Wilmington, Delaware, United States 1. Introduction....................... 444 8. Fluorinated Carboxylic Acids and 2. Production Processes ................ 445 Fluorinated Alkanesulfonic Acids ...... 470 2.1. Substitution of Hydrogen............. 445 8.1. Fluorinated Carboxylic Acids ......... 470 2.2. Halogen – Fluorine Exchange ......... 446 8.1.1. Fluorinated Acetic Acids .............. 470 2.3. Synthesis from Fluorinated Synthons ... 447 8.1.2. Long-Chain Perfluorocarboxylic Acids .... 470 2.4. Addition of Hydrogen Fluoride to 8.1.3. Fluorinated Dicarboxylic Acids ......... 472 Unsaturated Bonds ................. 447 8.1.4. Tetrafluoroethylene – Perfluorovinyl Ether 2.5. Miscellaneous Methods .............. 447 Copolymers with Carboxylic Acid Groups . 472 2.6. Purification and Analysis ............. 447 8.2. Fluorinated Alkanesulfonic Acids ...... 472 3. Fluorinated Alkanes................. 448 8.2.1. Perfluoroalkanesulfonic Acids -

Refrigerants

Related Commercial Resources CHAPTER 29 REFRIGERANTS Refrigerant Properties .................................................................................................................. 29.1 Refrigerant Performance .............................................................................................................. 29.6 Safety ............................................................................................................................................. 29.6 Leak Detection .............................................................................................................................. 29.6 Effect on Construction Materials .................................................................................................. 29.9 EFRIGERANTS are the working fluids in refrigeration, air- cataracts, and impaired immune systems. It also can damage sensi- R conditioning, and heat-pumping systems. They absorb heat tive crops, reduce crop yields, and stress marine phytoplankton (and from one area, such as an air-conditioned space, and reject it into thus human food supplies from the oceans). In addition, exposure to another, such as outdoors, usually through evaporation and conden- UV radiation degrades plastics and wood. sation, respectively. These phase changes occur both in absorption Stratospheric ozone depletion has been linked to the presence of and mechanical vapor compression systems, but not in systems oper- chlorine and bromine in the stratosphere. Chemicals with long ating on a gas cycle using a -

Inventory of US Greenhouse Gas Emissions and Sinks: 1990-2015

ANNEX 6 Additional Information 6.1. Global Warming Potential Values Global Warming Potential (GWP) is intended as a quantified measure of the globally averaged relative radiative forcing impacts of a particular greenhouse gas. It is defined as the cumulative radiative forcing–both direct and indirect effectsintegrated over a specific period of time from the emission of a unit mass of gas relative to some reference gas (IPCC 2007). Carbon dioxide (CO2) was chosen as this reference gas. Direct effects occur when the gas itself is a greenhouse gas. Indirect radiative forcing occurs when chemical transformations involving the original gas produce a gas or gases that are greenhouse gases, or when a gas influences other radiatively important processes such as the atmospheric lifetimes of other gases. The relationship between kilotons (kt) of a gas and million metric tons of CO2 equivalents (MMT CO2 Eq.) can be expressed as follows: MMT MMT CO2 Eq. kt of gas GWP 1,000 kt where, MMT CO2 Eq. = Million metric tons of CO2 equivalent kt = kilotons (equivalent to a thousand metric tons) GWP = Global warming potential MMT = Million metric tons GWP values allow policy makers to compare the impacts of emissions and reductions of different gases. According to the IPCC, GWP values typically have an uncertainty of 35 percent, though some GWP values have larger uncertainty than others, especially those in which lifetimes have not yet been ascertained. In the following decision, the parties to the UNFCCC have agreed to use consistent GWP values from the IPCC Fourth Assessment Report (AR4), based upon a 100 year time horizon, although other time horizon values are available (see Table A-263). -

Improving Thermodynamic Consistency Among Vapor Pressure, Heat of Vaporization, and Liquid and Ideal Gas Heat Capacities Joseph Wallace Hogge Brigham Young University

Brigham Young University BYU ScholarsArchive All Theses and Dissertations 2017-12-01 Improving Thermodynamic Consistency Among Vapor Pressure, Heat of Vaporization, and Liquid and Ideal Gas Heat Capacities Joseph Wallace Hogge Brigham Young University Follow this and additional works at: https://scholarsarchive.byu.edu/etd Part of the Chemical Engineering Commons BYU ScholarsArchive Citation Hogge, Joseph Wallace, "Improving Thermodynamic Consistency Among Vapor Pressure, Heat of Vaporization, and Liquid and Ideal Gas Heat Capacities" (2017). All Theses and Dissertations. 6634. https://scholarsarchive.byu.edu/etd/6634 This Dissertation is brought to you for free and open access by BYU ScholarsArchive. It has been accepted for inclusion in All Theses and Dissertations by an authorized administrator of BYU ScholarsArchive. For more information, please contact [email protected], [email protected]. Improving Thermodynamic Consistency Among Vapor Pressure, Heat of Vaporization, and Liquid and Ideal Gas Heat Capacities Joseph Wallace Hogge A dissertation submitted to the faculty of Brigham Young University In partial fulfillment of the requirements for the degree of Doctor of Philosophy W. Vincent Wilding, Chair Thomas A. Knotts Dean Wheeler Thomas H. Fletcher John D. Hedengren Department of Chemical Engineering Brigham Young University Copyright © 2017 Joseph Wallace Hogge All Rights Reserved ABSTRACT Improving Thermodynamic Consistency Among Vapor Pressure, Heat of Vaporization, and Liquid and Ideal Gas Heat Capacity Joseph Wallace Hogge Department of Chemical Engineering, BYU Doctor of Philosophy Vapor pressure ( ), heat of vaporization ( ), liquid heat capacity ( ), and ideal gas heat capacity ( ) are important properties for process design and optimization. This work vap Δvap focuses on improving the thermodynamic consistency and accuracy of the aforementioned properties since these can drastically affect the reliability, safety, and profitability of chemical processes. -

ASPEN Refrigerants, Inc

SAFETY DATA SHEET Halocarbon R-503 Section 1. Identification GHS product identifier : Halocarbon R-503 Other means of : Not available. identification Product use : Synthetic/Analytical chemistry. SDS # : 000503 Supplier's details : ASPEN Refrigerants, Inc. 38-18 33rd Street Long Island City, NY 11101 1800-473-3766 Emergency telephone 1-800-424-9300 number (with 24 hours of operation) Section 2. Hazards identification OSHA/HCS status : This material is considered hazardous by the OSHA Hazard Communication Standard (29 CFR 1910.1200). Classification of the : GASES UNDER PRESSURE - Compressed gas substance or mixture HAZARDOUS TO THE OZONE LAYER - Category 1 GHS label elements Hazard pictograms : Signal word : Warning Hazard statements : Contains gas under pressure; may explode if heated. May displace oxygen and cause rapid suffocation. Harms public health and the environment by destroying ozone in the upper atmosphere. Precautionary statements General : Read and follow all Safety Data Sheets (SDS’S) before use. Read label before use. Keep out of reach of children. If medical advice is needed, have product container or label at hand. Close valve after each use and when empty. Use equipment rated for cylinder pressure. Do not open valve until connected to equipment prepared for use. Use a back-flow preventative device in the piping. Use only equipment of compatible materials of construction. Prevention : Use and store only outdoors or in a well-ventilated place. Response : Not applicable. Storage : Protect from sunlight. Protect from sunlight when ambient temperature exceeds 52°C/125°F. Store in a well-ventilated place. Disposal : Refer to manufacturer/supplier for information on recovery/recycling. -

Safe Use of Hcfc Alternatives in Refrigeration and Air-Conditioning

SAFE USE OF HCFC ALTERNATIVES IN REFRIGERATION AND AIR-CONDITIONING An overview for developing countries ROGRAMME P NVIRONMENT E ATIONS N NITED U Copyright © United Nations Environment Programme, 2015 This publication may be reproduced in whole or in part and in any form for educational or non-profit purposes without special permission from the copyright holder, provided acknowledgement of the source is made. UNEP would appreciate receiving a copy of any publication that uses this publication as a source. No use of this publication may be made for resale or for any other commercial purpose whatsoever without prior permission in writing from the United Nations Environment Programme. Disclaimer The designations employed and the presentation of the material in this publication do not imply the expression of any opinion whatsoever on the part of the United Nations Environment Programme concerning the legal status of any country, territory, city or area or of its authorities, or concerning delimitation of its frontiers or boundaries. Moreover, the views expressed do not necessarily represent the decision or the stated policy of the United Nations Environment Programme, nor does citing of UNEP trade names or commercial processes constitute promotes environ- endorsement. mentally sound practices globally and in its own activities. This publication is printed on 100% recycled paper, using vegetable -based inks and other eco-friendly practices. Our distribution policy aims to reduce UNEP’s carbon footprint. Acknowledgements 1 This document was produced by UNEP Division of Technology, Industry and Economics (UNEP DTIE) OzonAction as part of UNEP’s work programme under the Multilateral Fund for the Implementation of the Montreal Protocol. -

6 NYCRR Part

6 NYCRR PART 597 HAZARDOUS SUBSTANCES IDENTIFICATION, RELEASE PROHIBITION, AND RELEASE REPORTING (Statutory authority: Environmental Conservation Law sections 1-0101, 3-0301, 3-0303, 17-0301, 17-0303, 17-0501, 17-1743, 37-0101 through 37-0107, and 40-0101 through 40-0121) TABLE OF CONTENTS 597.1 General. ....................................................................................................................2 597.2 Criteria for identifying a hazardous substance or acutely hazardous substance. .....5 597.3 List of hazardous substances. ...................................................................................6 597.4 Spills and Releases of hazardous substances. ..........................................................6 Table 1 Hazardous Substances – Sorted by Name ................................................................9 Table 2 Hazardous Substances – Sorted by CAS Number .................................................49 6 NYCRR Part 597 – Oct. 11, 2015 Page 1 of 88 597.1 597.1 General. (a) Purpose. The purpose of this Part is to: (1) set forth criteria for identifying a hazardous substance or acutely hazardous substance; (2) set forth a list of hazardous substances; (3) identify reportable quantities for the spill or release of hazardous substances; (4) prohibit the unauthorized release of hazardous substances; and (5) establish requirements for reporting of releases of hazardous substances. (b) Definitions. The following definitions apply to this Part: (1) Authorized means the possession of a valid license, permit, or certificate issued by an agency of the state of New York or the federal government, or an order issued by the Department or United States Environmental Protection Agency under applicable statutes, rules or regulations regarding the possession or release of hazardous substances or otherwise engaging in conduct which is exempt under applicable statutes, rules or regulations from the requirements of possessing such a license, permit, certificate or order. -

Refrigerants

CHAPTER 19 REFRIGERANTS Phaseout of Refrigerants .............................................................................................................. 19.1 Refrigerant Properties .................................................................................................................. 19.4 Refrigerant Performance ............................................................................................................. 19.6 Safety ............................................................................................................................................ 19.6 Leak Detection ............................................................................................................................. 19.7 Effect on Construction Materials ................................................................................................ 19.11 EFRIGERANTS are the working fluids in refrigeration, air- Transport properties of thermal conductivity and viscosity affect Rconditioning, and heat pumping systems. They absorb heat the performance of heat exchangers and piping. High thermal con- from one area, such as an air-conditioned space, and reject it into ductivity and low viscosity are desirable. another, such as outdoors, usually through evaporation and conden- No single fluid satisfies all the attributes desired of a refrigerant; sation, respectively. These phase changes occur both in absorption as a result, a variety of refrigerants is used. This chapter describes and mechanical vapor compression systems, but -

C1-C4 Halogenated HC Info 16FEB2018.Xlsx

C1-C4 Halogenated Hydrocarbons/Halocarbons Not Otherwise Listed (C1-C4 NOL) Feb 28, 2018 Administrative Council Mtg - Printed 2/16/20184:11 PM Reported Uses (SOURCES:HAZMAP, NJDHSS, Wikipedia, TSCA CDR, mfr literature) TURA TSCA CDR Chemical CAS/Chemica chemical name chemical fire 2015 Chemical Name Pesti- blowing feedstock / supressant / propell- Inventory? TRI? List l Number (synonyms) formula Solvent refriger-ant etchant Other Tier II cide agent intermed-iate flame ant status* retardant insulation for refrigerators, freezers, commercial refrigeration equipment, refrigerated containers and LNG ships; spray foam insulation; insulated metal panels; slabstock and molded flexible foam; refrigerant for chillers; and solvents for metal cleaning and electronics, and circuit flush. https://www.honeywell-blowingagents.com/?document=solstice-lba-technical- HFO-1233zd (E) brochure&download=1 Hydro-fluoro-olefin C H ClF YYY yhttps://www.honeywell-refrigerants.com/americas/product/solstice-zd/ (HFO) 3 2 3 CDR 2016 Honeywell: 100% as propellants and blowing agents for plastics product mfg; R-1233zd CDR Honeywell Solstice® ZD refrigerant, Solstice® 1233zdE, Solstice Blowing Agent; Arkema (current Forane® 1233zd blowing agent for spray PU foam, appliance insulation, etc. and solvent (may Honeywell not be available in US) product) C1-C4 Cat 102687-65-0 1-Chloro-3,3,3-trifluoropropene Y 106‐95‐6 Allyl bromide 2-Propenyl bromide C3H5Br Y y Manufacture of synthetic perfumes, other allyl compounds; Insecticidal fumigant; 1-Propene, 3-bromo- Chemical intermediate in organic synthesis, for resins (copolymer with sulfur dioxide) and fragrances; As a fumigant (if quite volatile) or as a contact poison; C1-C4 Cat Used in the manufacture of plastics and dyestuff. -

ODS Destruction in the United States and Abroad

ODS Destruction in the United States and Abroad Prepared for the U.S. Environmental Protection Agency by ICF February 2018 EPA 430-R-18-001 Table of Contents Controlled ODS under the Montreal Protocol ........................................................................................... iii Acronyms ............................................................................................................................................... iv 1. Introduction ........................................................................................................................................ 1 2. Sources of ODS for Destruction ............................................................................................................ 2 2.1. ODS-Containing Equipment ................................................................................................................. 2 2.2. Bulk ODS ............................................................................................................................................... 3 3. The Process of ODS Destruction: Best Management Practices ............................................................... 4 3.1. Recovery and Collection ....................................................................................................................... 4 3.2. Consolidation and Storage ................................................................................................................... 5 3.3. Transportation .................................................................................................................................... -

NJAC 7:1E DISCHARGES of PETROLEUM and OTHER HAZARDOUS SUBSTANCES RULES Statutory Authority

This is a courtesy copy of this rule. All of the Department's rules are compiled in Title 7 of the New Jersey Administrative Code. N.J.A.C. 7:1E DISCHARGES OF PETROLEUM AND OTHER HAZARDOUS SUBSTANCES RULES Statutory authority: N.J.S.A. 58:10-23.11, N.J.S.A. 58:10-46 to 50, N.J.S.A. 13:1K-1 et seq., and N.J.S.A.13:1D-125 through 133 Date last adopted: January 27, 2014 Date last amended: June 1, 2020 For regulatory history and effective dates, see the New Jersey Administrative Code TABLE OF CONTENTS APPENDIX A - LIST OF HAZARDOUS SUBSTANCES Alphabetical Order CAS Number Order 1 This is a courtesy copy of this rule. All of the Department's rules are compiled in Title 7 of the New Jersey Administrative Code. APPENDIX A List of Hazardous Substances (Alphabetical Order) Name CAS Number --------------------------------------------------- ---------------- Abamectin 71751-41-2 Acenaphthene 83-32-9 Acenaphthylene 208-96-8 Acephate 30560-19-1 Acetaldehyde 75-07-0 Acetamide 60-35-5 Acetic acid 64-19-7 Acetic anhydride 108-24-7 Acetone 67-64-1 Acetone cyanohydrin 75-86-5 Acetone thiosemicarbazide 1752-30-3 Acetonitrile 75-05-8 Acetophenone 98-86-2 Acetoxytriphenylstannane 900-95-8 2-Acetylaminofluorene 53-96-3 Acetyl bromide 506-96-7 Acetyl chloride 75-36-5 Acetylene* 74-86-2 1-Acetyl-2-thiourea 591-08-2 Acifluorfen, sodium salt 62476-59-9 Acrolein 107-02-8 Acrylamide 79-06-1 Acrylic acid 79-10-7 Acrylonitrile 107-13-1 Acrylyl chloride 814-68-6 Adipic acid 124-04-9 Adiponitrile 111-69-3 Alachlor 15972-60-8 Aldicarb 116-06-3 Aldicarb sulfone 1646-88-4 Aldrin 309-00-2 d-trans-Allethrin 28057-48-9 Allyl alcohol 107-18-6 Allyl amine 107-11-9 Allyl chloride 107-05-1 Aluminum (fume or dust) 7429-90-5 Aluminum oxide (fibrous forms) 1344-28-1 Aluminum phosphide 20859-73-8 Aluminum sulfate 10043-01-3 *In accordance with N.J.A.C.