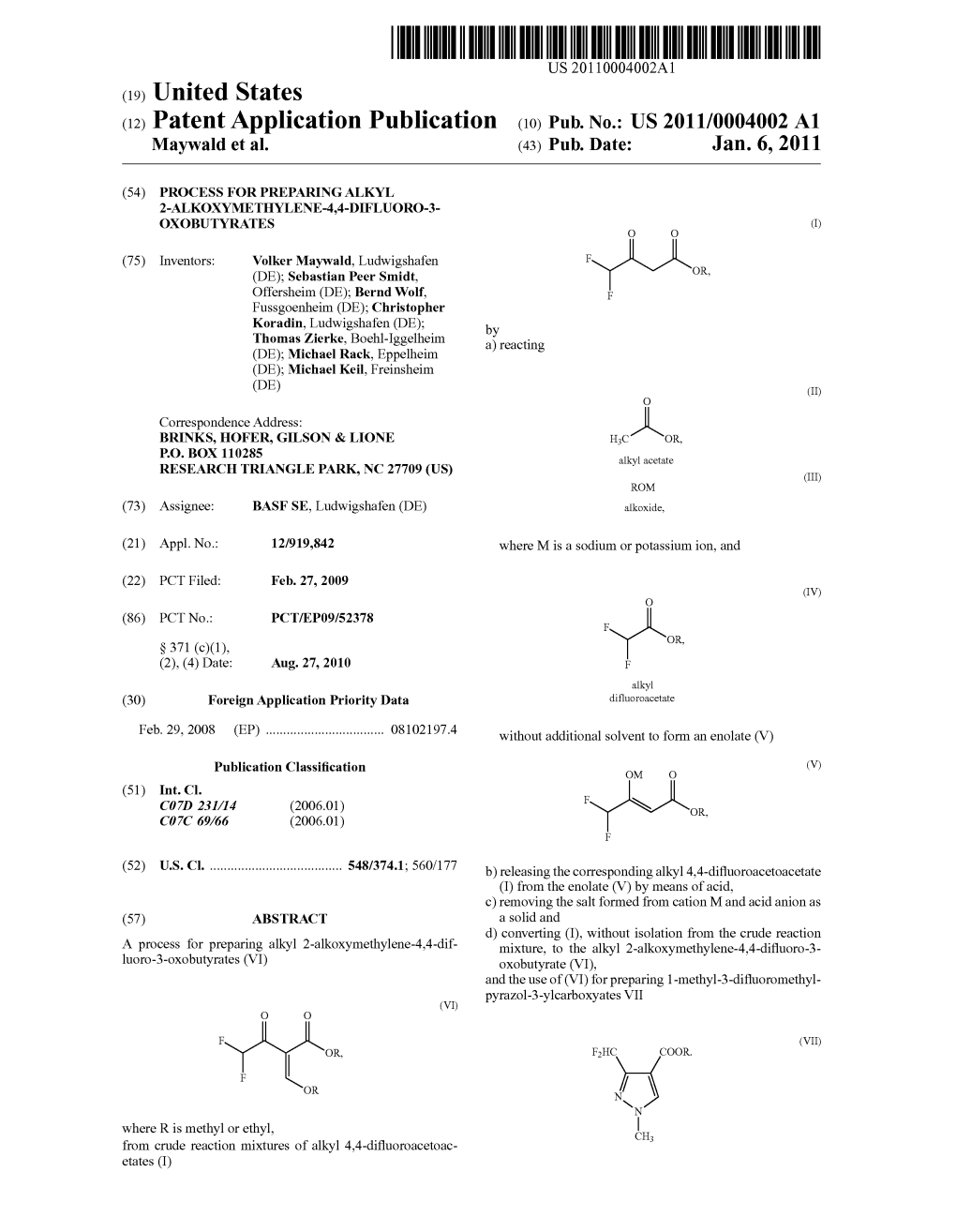

(12) Patent Application Publication (10) Pub. No.: US 2011/0004.002 A1 Maywald Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Campro Catalog Stable Isotope

Introduction & Welcome Dear Valued Customer, We are pleased to present to you our Stable Isotopes Catalog which contains more than three thousand (3000) high quality labeled compounds. You will find new additions that are beneficial for your research. Campro Scientific is proud to work together with Isotec, Inc. for the distribution and marketing of their stable isotopes. We have been working with Isotec for more than twenty years and know that their products meet the highest standard. Campro Scientific was founded in 1981 and we provide services to some of the most prestigious universities, research institutes and laboratories throughout Europe. We are a research-oriented company specialized in supporting the requirements of the scientific community. We are the exclusive distributor of some of the world’s leading producers of research chemicals, radioisotopes, stable isotopes and environmental standards. We understand the requirements of our customers, and work every day to fulfill them. In working with us you are guaranteed to receive: - Excellent customer service - High quality products - Dependable service - Efficient distribution The highly educated staff at Campro’s headquarters and sales office is ready to assist you with your questions and product requirements. Feel free to call us at any time. Sincerely, Dr. Ahmad Rajabi General Manager 180/280 = unlabeled 185/285 = 15N labeled 181/281 = double labeled (13C+15N, 13C+D, 15N+18O etc.) 186/286 = 12C labeled 182/282 = d labeled 187/287 = 17O labeled 183/283 = 13C labeleld 188/288 = 18O labeled 184/284 = 16O labeled, 14N labeled 189/289 = Noble Gases Table of Contents Ordering Information.................................................................................................. page 4 - 5 Packaging Information .............................................................................................. -

European Journal of Chemistry 5 (4) (2014) 681‐694

European Journal of Chemistry 5 (4) (2014) 681‐694 European Journal of Chemistry Journal homepage: www.eurjchem.com Synthesis, reactions and applications of pyranotriazolopyrimidines Ashraf Hassan Fekry Abd El‐Wahab a,b,*, Ibrahim Ali Radini a and Hany Mostafa Mohamed a,b a Chemistry Department, Faculty of Science, Jazan University, 2097, Jazan, Saudi Arabia b Chemistry Department, Faculty of Science, Al‐Azhar University, 11884, Nasr City, Cairo, Egypt *Corresponding author at: Chemistry Department, Faculty of Science, Jazan University, 2097, Jazan, Saudi Arabia. Tel.: +966.054.0963753. Fax: +966.017.3230028. E‐mail address: [email protected] (A.H.F.A. El‐Wahab). REVIEW INFORMATION ABSTRACT This review deals with synthesis, reactions and their applications of pyranotriazolo‐ pyrimidines. The main purpose of this review is present a survey of literatures on the reactivity of amino imino derivatives and carboxylic acid derivatives. Some of these reactions have been applied successfully to the synthesis of biological important compounds. DOI: 10.5155/eurjchem.5.4.681‐694.1087 Received: 30 April 2014 Received in revised form: 27 May 2014 Accepted: 27 May 2014 Online: 31 December 2014 KEYWORDS Naphthols Pyrimidine Biological activity Pyranopyrimidines α‐Cyanocinnamonitriles Carboxylic acid derivatives 1. Introduction chemical and biological view points, due to their diverse pharmacological activities, such as antitumor potency [19,20], Pyran derivatives have attracted a great deal of interest inhibition of KDR kinase [21], antifungal effect [22] and owing to their antimicrobial activity [1‐7], inhibition of influ‐ macrophage activation [23]. enza, virus sialidase [8], mutagenic activity [9], activity as antiviral [10], anti‐proliferaction agents [11], sex pheromones [12], antitumor [13] and anti‐inflammatory agents [14]. -

Download Article (PDF)

SYNTHESIS OF FUSED AND NONFUSED HETEROCYCLES FROM 5- AND 8-SUBSTITUTED 3-HYDRAZINO-l,2,4-TRIAZINO[5,6-Z>]INDOLE Hamida Abdel Hamid, Ahmed Mousaad, El Sayed Ramadan and El Sayed H. El Ashry* Chemistry Department, Faculty of Science, Alexandria University, Alexandria, Egypt Abstract: The 7-and 10-substituted 1,2,4-triazolo[4\3':2,3][l,2,4]triazino[5,6-i]indoles were prepared by the reaction of 5- and 8-substituted-3-hydrazino-l,2,4-triazino[5,6-i>]indole with formic acid ortriethyl orthoformate. Reaction of the hydrazines with acetylacetone, ethyl acetoacetate and ethyl cyanoacetate gave the respective biheterocycles containing pvrazole and pyrazolone rings. Reaction of the hydrazines with carbondisulphide, thiourea, urea, ethyl chloroformate as well as nitrous acid have been investigated. Reaction of 5-allyl-3-methylthio-1,2,4-triazino[5,6-6]indole with ethanolamine followed by cyclization gave the imidazotriazinoindole. INTRODUCTION The l,2,4-triazino[5,6-i]indole ring has been found to be a useful carrier for various functional groups for developing antiviral and antibacterial activities [1-8], The imidazo, pyrimido or triazolo-1,2,4- triazino[5,6-6]indoles showed also antiviral and antibacterial properties [9], The arylidene moiety of 3- arylidene and heterocyclic formylidenehydrazono-l,2,4-triazino[5,6-&]indole derivatives has been found to play a role on their activity against Staphylococcus aureus and Bacillus cereus as well as Ρ 388 lymphocytic leukemia [8]. The 3-hydrazino-1,2,4-triazino[5,6-A]indole and 3-hydrazino-5,6-diphenyl-l,2,4-triazine have an effect on the carbohydrate metabolism and lipid components in rat [10,11], The regioselective annelation of a triazole ring to the 1,2,4-triazino[5,6-b] indole either via the dehydrative cyclization of the respective hydrazide or the dehydrogenative cyclization of the hydrazones has been reported [12-16]. -

Hazardous Substances (Chemicals) Transfer Notice 2006

16551655 OF THURSDAY, 22 JUNE 2006 WELLINGTON: WEDNESDAY, 28 JUNE 2006 — ISSUE NO. 72 ENVIRONMENTAL RISK MANAGEMENT AUTHORITY HAZARDOUS SUBSTANCES (CHEMICALS) TRANSFER NOTICE 2006 PURSUANT TO THE HAZARDOUS SUBSTANCES AND NEW ORGANISMS ACT 1996 1656 NEW ZEALAND GAZETTE, No. 72 28 JUNE 2006 Hazardous Substances and New Organisms Act 1996 Hazardous Substances (Chemicals) Transfer Notice 2006 Pursuant to section 160A of the Hazardous Substances and New Organisms Act 1996 (in this notice referred to as the Act), the Environmental Risk Management Authority gives the following notice. Contents 1 Title 2 Commencement 3 Interpretation 4 Deemed assessment and approval 5 Deemed hazard classification 6 Application of controls and changes to controls 7 Other obligations and restrictions 8 Exposure limits Schedule 1 List of substances to be transferred Schedule 2 Changes to controls Schedule 3 New controls Schedule 4 Transitional controls ______________________________ 1 Title This notice is the Hazardous Substances (Chemicals) Transfer Notice 2006. 2 Commencement This notice comes into force on 1 July 2006. 3 Interpretation In this notice, unless the context otherwise requires,— (a) words and phrases have the meanings given to them in the Act and in regulations made under the Act; and (b) the following words and phrases have the following meanings: 28 JUNE 2006 NEW ZEALAND GAZETTE, No. 72 1657 manufacture has the meaning given to it in the Act, and for the avoidance of doubt includes formulation of other hazardous substances pesticide includes but -

OZO-L-CYCLOPBNTBNE. 1-CAEBOXYLATE and ETHYL 2-METHYL-3-OXOCYCLOPENTANECAKBOXYLATE

PART I THE SYNTHESES AND EEACTIONS OF METHYL 2-METHYL-^-OZO-l-CYCLOPBNTBNE. 1-CAEBOXYLATE AND ETHYL 2-METHYL-3-OXOCYCLOPENTANECAKBOXYLATE PAET II A STUDY OF THE REACTIONS OF GRIGNARD REAGENTS WITH ESTERS OF LEVULINIC ACID DISSERTATION Presented. In Partial Fulfillment of the Requirements for the Degree Doctor of Philosophy in the Graduate School of the Ohio State University By James Li McPherson, B.S., M.A, The Ohio State University 1955 Approved by: Adviser ACKNOWLEnXSMEWT It is a pleasure to express ray deep appreciation to Dr. Melvin S. Nevraan who suggested this problem, and whose advice and encouragement were an invaluable aid throughout this investigation, and to extend to the Upjohn Company, Kalamazoo, Michigan, ray sincere appreciation for a fellowship in connection with this work. il TABLE OF CONTENTS Aoknowledgeinent Part I The Syntheses and Beaotlons of Methyl S-raethyl-l-oxo-l-cyclopentene- 1-carhoxylate (IX) and ethyl 2-methyl~5-oxocyclopentanecarboxylate (Vl) Chapter Page I Introduction 1 II Synthesis 1. Discussion of Results 12 2. Flor Sheet (Fig. 5) 15 5. Diethyl 2-cyanc«3-taethylhutanedioate (ll) l6 k . Diethyl 2-cyano-2.-(2-oyanoethyl)-3- methylhutanedioate (ill) l8 5, Tfiethyl ^-metbyl-l, $,4-pentanetricarhoxylate (l?) 19 6 , Diethyl 2-methyl-3"Oxo«l,it— cyclopentane dicarhoxylate (v) 22 7, Ethyl 2~methyl-3-oxocyclopentanecar'boxylate (Vl) 2 k 8 , 2«Methyl*-3-'Oxo"l-cyclopentene-*l« carhoxylic acid (VIIl) 26 9* 2r^ethyl-3»-oxocyclopentaneoarh0xylic acid 29 10 0 Methyl 2p-methyl"3~oxo«l-cyclopentene" 1-carhoxylate (ix) 52 11. Ethyl 2-methyl~3'*oxor«l-cyclopentene" Imcarhoxylate (VIl) 55 III Reactions 1. -

Synthesis and Reactions of Novel Thienotetrahydroisoquinoline Compounds

Synthesis and reactions of novel thienotetrahydroisoquinoline compounds Remon M. Zaki*, Adel M. Kamal El-Dean, Shaban M. Radwan Chemistry Department, Faculty of Science, Assiut University, Assiut 71516, Egypt Síntesis y reacciones de nuevos compuestos de tienotetrahidroisoquinolina Síntesi i reaccions de nous derivats de tientetrahidroisoquinolina Recibido:2 de octubre de 2011; aceptado: 16 de febrero de 2012 RESUMEN for synthesis of triazepinopyrimido 10. Reaction of 1 with carbon disulfide in pyridine afforded the pyrimidinethione La cloroacetilación de 1-Aminocarboxamida 1 propor- 13 which underwent double Mannich reaction to give the cionó la cloroacetilamina 2 la cual experimentó el cierre novel thiadiazinopyrimido compound 14. Reaction of tet- del anillo al ser sometida a reflujo con anhídrido acético rahydroisoquinoline thione 15 with 2-chloromethylbenz- para proporcionar el derivado clorometilpirimido 3. Este imidazole followed by Thorpe-Zeigler cyclization to afford último compuesto experimenta reacciones de sustitución the aminobenzoimidazolyl 18 which proved its versatil- nucleofílica con varias aminas primarias y secundarias ity as starting material for synthesis of novel heterocyclic que, a través de la reacción de Mannich proporcionaron compounds 19-22. las imidazopirimidotienoisoquinolinas 5a-c. El compuesto 1 reacciona con anhídrido ftálico en ácido acético y DMF Keywords: Imidazole, Triazepine, Thiadiazine, Pyrimidine, para proporcionar phthalimido- e isoindolopymimidotieno- synthesis, reactions tetrahidroisoquinolinas -

Spectra Library Index Ichem/SDBS Raman Library

Ichem / SDBS Raman スタンダードライブラリー 株式会社 エス・ティ・ジャパン S p e c t r a L i b r a r y I n d e x (Ver. 40) Ichem / SDBS Raman Library ライブラリー名:ラマンスタンダードライブラリー 商品番号:60001-40 株式会社 エス・ティ・ジャパン 〒103-0014 東京都中央区日本橋蛎殻町 1-14-10 Tel: 03-3666-2561 Fax:03-3666-2658 http://www.stjapan.co.jp 1 【販売代理店】(株)テクノサイエンス Tel:043-206-0155 Fax:043-206-0188 https://www.techno-lab-co.jp/ Ichem / SDBS Raman スタンダードライブラリー 株式会社 エス・ティ・ジャパン ((1,2-DIETHYLETHYLENE)BIS(P-PHENYLENE))DIACETATE ((2-(3-BENZYLSULFONYL-4-METHYLCYCLOHEXYL)PROPYL)SULFONYLMETHYL)BENZENE ((2,4,6-TRIOXOHEXAHYDRO-5-PYRIMIDINYL)IMINO)DIACETIC ACID ((2-CARBOXYETHYL)IMINO)DIACETIC ACID ((2-HYDROXYETHYL)IMINO)DIACETIC ACID ((2-NITROBENZYL)IMINO)DIACETIC ACID ((2-SULFOETHYL)IMINO)DIACETIC ACID ((3-(1-BROMO-1-METHYLETHYL)-7-OXO-1,3,5-CYCLOHEPTATRIEN-1-YL)OXY)DIFLUOROBORANE ((N-BENZYLOXYCARBONYL-L-ISOLEUCYL)-L-PROLYL-L-PHENYLALANYL)-N(OMEGA)-NITRO-L-ARGININE 4-NITROBENZYL ESTER (-)-2-AMINO-1-BUTANOL (-)-2-AMINO-6-MERCAPTOPURINE RIBOSIDE (-)-6,8-P-MENTHADIEN-2-OL (-)-DIACETYL-L-TARTARIC ACID (-)-DIBENZOYL-L-TARTARIC ACID (-)-DI-P-ANISOYL-L-TARTARIC ACID (-)-DI-P-TOLUOYL-L-TARTARIC ACID (-)-KAURENE (-)-MENTHOL (-)-MYRTENOL (-)-N,N,N',N'-TETRAMETHYL-D-TARTARDIAMIDE (-)-N,N'-DIBENZYL-D-TARTRAMIDE (+)-1,3,3-TRIMETHYLNORBORNANE-2-ONE (+)-2-(2,4,5,7-TETRANITRO-9-FLUORENYLIDENEAMINOOXY)PROPIONIC ACID (+)-2-AMINO-1-BUTANOL (+)-2-PINENE (+)-3,9-DIBROMOCAMPHOR (+)-3-CARENE (+)-5-BROMO-2'-DEOXYURIDINE (+)-AMMONIUM 3-BROMO-8-CAMPHORSULFONATE (+)-CAMPHOR (+)-CAMPHOR OXIME (+)-CAMPHORIC ACID (+)-CATECHIN (+)-DI-P-ANISOYL-D-TARTARIC -

Nicolet Vapor Phase

Nicolet Vapor Phase Library Listing – 8,654 spectra This library is one the most comprehensive collections of vapor phase FT-IR spectra. It is an invaluable tool for scientist involved in investigations on gas phase materials. The Nicolet Vapor Phase Library contains 8654 FT-IR spectra of compounds measured in gas phase. Most spectra were acquired by the Sigma-Aldrich Co. using product samples. Additional spectra were collected by Hannover University, University of Wurzburg and Thermo Fisher Scientific applications scientists. Spectra were collected using sampling techniques including heated or room temperature gas cell or a heated light-pipe connected to the outlet of a gas chromatograph. Nicolet Vapor Phase Index Compound Name Index Compound Name 8402 ((1- 5457 (-)-8-Phenylmenthol; (-)-(1R,2S,5R)-5- Ethoxycyclopropyl)oxy)trimethylsilane Methyl-2-(2-phenyl-2-propyl)cyc 4408 (+)-1,3-Diphenylbutane 1095 (-)-Carveol, mixture of isomers; p- 4861 (+)-1-Bromo-2,4-diphenylbutane Mentha-6,8-dien-2-ol 2406 (+)-3-(Heptafluorobutyryl)camphor 3628 (-)-Diisopropyl D-tartrate 2405 (+)-3-(Trifluoroacetyl)camphor 1427 (-)-Limonene oxide, cis + trans; (-)-1,2- 281 (+)-3R-Isolimonene, trans-; (1R,4R)- Epoxy-4-isopropenyl-1-methyl (+)-p-Mentha-2,8-diene 1084 (-)-Menthol; [1R-(1a,2b,5a)]-(-)-2- 289 (+)-Camphene; 2,2-Dimethyl-3- Isopropyl-5-methylcyclohexanol methylenebicyclo[2.2.1]heptane 2750 (-)-Menthoxyacetic acid 3627 (+)-Diisopropyl L-tartrate 1096 (-)-Myrtanol, cis-; (1S,2R)-6,6- 2398 (+)-Fenchone; (+)-1,3,3- Dimethylbicyclo[3.1.1]heptane-2-metha -

Air Toxics Report

Toxicological Advisory Committee AIR TOXICS REPORT Prepared for State of Vermont Agency of Natural Resources February, 1998 Table of Contents I. Executive Summary 1 II. Review of Hazardous Ambient Air Standards 7 III. Measurement of Hazardous Air Contaminants in 19 Ambient Air IV. Priority Compounds 27 V. Management Options 56 VI. Risk Issues 58 VII. Future Actions 63 Appendix A Category I - Algorithm and Tables Appendix B Category II and Category III Tables Appendix C Air Monitoring Data - Tables Appendix D Research Status Report-Mercury Deposition and Effects in the Lake Champlain Basin Appendix E The Toxicological Advisory Committee List of Acronyms ACGIH - American Conference of Governmental Industrial Hygienists AEGL - Acute Exposure Guideline Level Agency - Vermont Agency of Natural Resources Category I - A contaminant that is known or suspected to be a carcinogen. Category II - A contaminant that is a noncarcinogen with potential/systemic effects due to long term exposure. Category III - A contaminant that is a noncarcinogen considered to have primarily short term irritant effects. CPF - Cancer Potency Factor CPFi - Inhalation Cancer Potency Factor CPFo- Oral Cancer Potency Factor Committee - Toxicological Advisory Committee HAAS - Hazardous Ambient Air Standard HEAST - Health Effects Summary Tables, US EPA IARC - International Agency for Research on Cancer IRIS - Integrated Risk Information System database, US EPA MDL - Method Detection Limit NCI - National Cancer Institute NIOSH - National Institute for Occupational Safety and Health NTP - National Toxicological Program OSHA - United States Department of Labor Occupational Safety and Health Administration PAH - Polynuclear Aromatic Hydrocarbons PCB - Polychlorinated Biphenyl PCDD/PCDF - Polychlorinated Dibenzo-P-Dioxins/Furans PEL - Permissible Exposure Limit, derived by OSHA REL - Recommended Exposure Limit, derived by NIOSH RfC - Inhalation Reference Concentration TLV - Threshold Limit Value, derived by ACGIH US EPA - United States Environmental Protection Agency VOC - Volatile Organic Compound I. -

Working with Hazardous Chemicals

A Publication of Reliable Methods for the Preparation of Organic Compounds Working with Hazardous Chemicals The procedures in Organic Syntheses are intended for use only by persons with proper training in experimental organic chemistry. All hazardous materials should be handled using the standard procedures for work with chemicals described in references such as "Prudent Practices in the Laboratory" (The National Academies Press, Washington, D.C., 2011; the full text can be accessed free of charge at http://www.nap.edu/catalog.php?record_id=12654). All chemical waste should be disposed of in accordance with local regulations. For general guidelines for the management of chemical waste, see Chapter 8 of Prudent Practices. In some articles in Organic Syntheses, chemical-specific hazards are highlighted in red “Caution Notes” within a procedure. It is important to recognize that the absence of a caution note does not imply that no significant hazards are associated with the chemicals involved in that procedure. Prior to performing a reaction, a thorough risk assessment should be carried out that includes a review of the potential hazards associated with each chemical and experimental operation on the scale that is planned for the procedure. Guidelines for carrying out a risk assessment and for analyzing the hazards associated with chemicals can be found in Chapter 4 of Prudent Practices. The procedures described in Organic Syntheses are provided as published and are conducted at one's own risk. Organic Syntheses, Inc., its Editors, and its Board of Directors do not warrant or guarantee the safety of individuals using these procedures and hereby disclaim any liability for any injuries or damages claimed to have resulted from or related in any way to the procedures herein. -

New Thienopyridines, Pyridothienopyrimidines and Pyridothienotriazines

Synthesis and Reactions of New Thienopyridines Bull. Korean Chem. Soc. 2002, Vol. 23, No. 12 1709 Synthesis and Reactions of New Thienopyridines, Pyridothienopyrimidines and Pyridothienotriazines E. A. Bakhite,* A. E. Abdel-Rahman, O. S. Mohamed, and E. A. Thabet Chemistry Department, Faculty ofScience, Assiut University, Assiut 71516, Egypt Received June 11, 2002 4-Aryl-3-cyano-6-(2'-thienyl)-pyridine-2(LH)-thiones (1a-c) were reacted with phenacyl bromide, chloro-N- arylacetamides or 2-chloroacetylaminopyridine to furnish 2-functionalized 3-amino-4-aryl-6-(2'-thienyl)- thieno [2,3 -b]py ridines 4a-c and 5a-c or 5d respectively. The compounds 5a-d underwent different sequence of reactions to produce a variety of thienylpyridothienopyrimidines and, thienylpyridothienotriazines. Some of the prepared compounds were tested in vitro for their antimicrobial activities. Key Words : Thienopyridines, Pyrimidines, Triazines Introduction antianaphylactic,12 and antiallergic activity.13 In view of these facts and as a continuation of our previous work on The biological activities of condensed pyrimidines as thieno[2,3-b]pyridines,14-17 we report herein the synthesis of sedatives, antibacterials and antimalarials are well document the title compounds and their evaluation regarding anti ed.1,2 Several thieno[2,3-b]pyridine derivatives are known to microbial activities. possess antibacterial,3-5 antihypertensive6 and gonadotropin releasing hormone antagonizing7,8 activity. Pyridothieno- Results and Discussion pyrimidine derivatives have been found applications as analgesics,9 antipyretics10 and anti-inflammatories.11 More Based on the important synthetic utility of many 3- over, some pyridothienotriazines are known to exhibit cyanopyridine-2(1H)-thione derivatives,12-17 the 4-aryl-3- Scheme 1 *Corresponding Author. -

Rapport En Français

Additifs du 1,1,1-trichloroéthane État de l’art et enjeux en contexte « sites et sols pollués » Rapport final BRGM/RP-70190-FR Décembre 2020 Additifs du 1,1,1-trichloroéthane État de l’art et enjeux en contexte « sites et sols pollués » Rapport final BRGM/RP-70190-FR Décembre 2020 G. Boissard Vérificateur : Approbateur : Nom : Aline Coftier Nom : Sandrine Lemal Fonction : Cheffe de projets Fonction : Responsable Unité Sites Sols Pollués Date : 08/12/2020 Date : 14/12/2020 Signature : Signature : Le système de management de la qualité et de l’environnement est certifié par AFNOR selon les normes ISO 9001 et ISO 14001. Contact : [email protected] Mots-clés : Émergents, Pollution, Solvant, Sites pollués. En bibliographie, ce rapport sera cité de la façon suivante : Boissard G. (2020) - Additifs du 1,1,1-trichloroéthane – État de l’art et enjeux en contexte « sites et sols pollués ». Rapport final. BRGM/RP-70190-FR, 262 p., 4 fig., 23 tab., 12 ann. © BRGM, 2020, ce document ne peut être reproduit en totalité ou en partie sans l’autorisation expresse du BRGM. Additifs du 1,1,1-trichloroéthane - État de l’art et enjeux en contexte « sites et sols pollués » Synthèse Le 1,1,1-trichloroéthane (nommé TCA dans la suite du document) est un composé chloré largement utilisé comme solvant pour le dégraissage des métaux. Comme de nombreux autres solvants chlorés, il est généralement formulé avec des additifs pour augmenter sa stabilité et améliorer ses performances. Le TCA est considéré comme le solvant le moins stable parmi d’autres solvants tels que le trichloroéthylène (TCE), le tétrachloroéthylène (PCE) et le dichlorométhane.