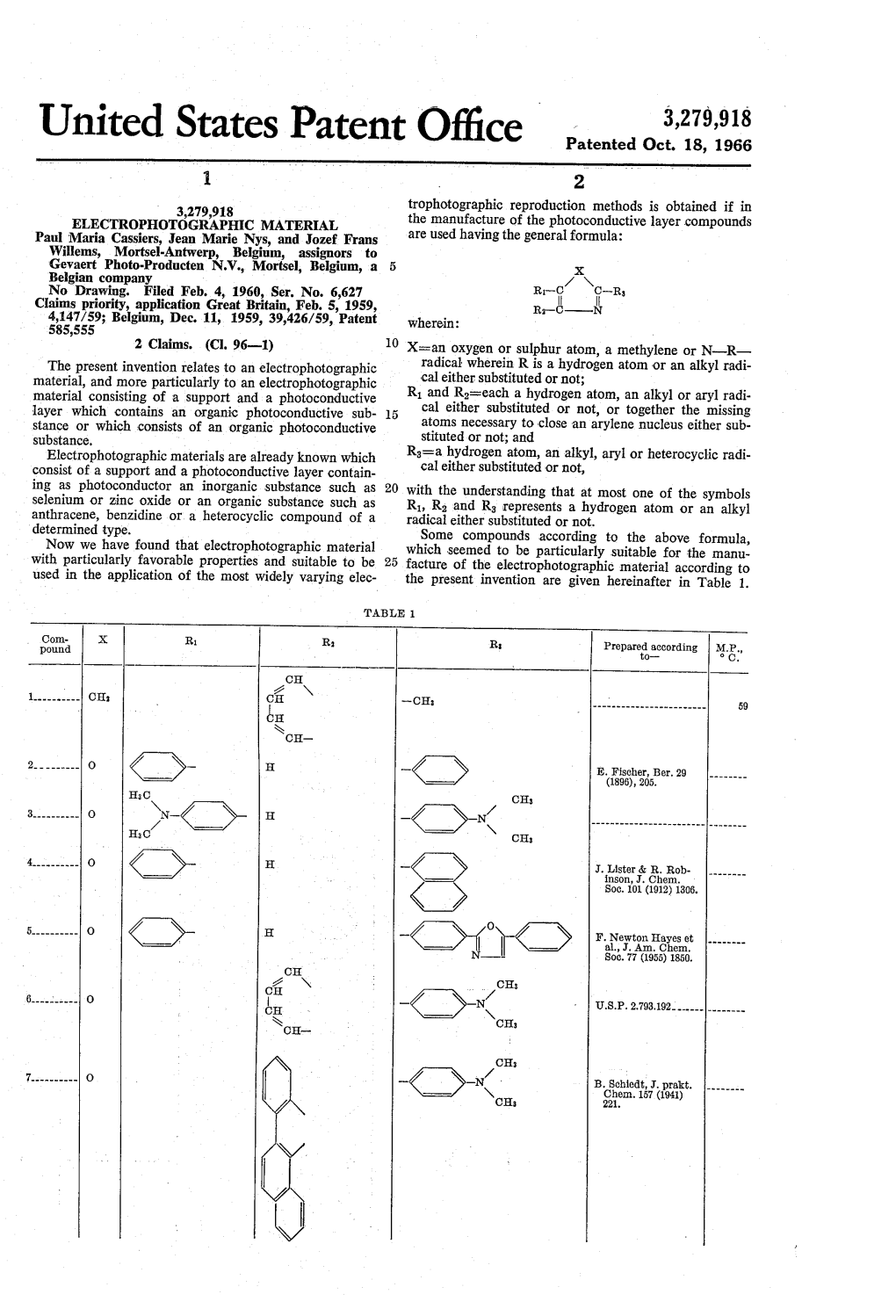

United States Patent Office -- 3,279,918 Patented Oct

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

![Triazene (H2NNNH) Or Triimide (HNHNNH) Markofçrstel,[A, D] Yetsedaw A](https://docslib.b-cdn.net/cover/4724/triazene-h2nnnh-or-triimide-hnhnnh-markof%C3%A7rstel-a-d-yetsedaw-a-184724.webp)

Triazene (H2NNNH) Or Triimide (HNHNNH) Markofçrstel,[A, D] Yetsedaw A

DOI:10.1002/cphc.201600414 Articles On the Formation of N3H3 Isomers in Irradiated Ammonia Bearing Ices:Triazene (H2NNNH) or Triimide (HNHNNH) MarkoFçrstel,[a, d] Yetsedaw A. Tsegaw,[b] Pavlo Maksyutenko,[a, d] Alexander M. Mebel,[c] Wolfram Sander,[b] and Ralf I. Kaiser*[a, d] The remarkable versatility of triazenesinsynthesis, polymer theoretical studies with our novel detection scheme of photo- chemistry and pharmacology has led to numerousexperimen- ionization-driven reflectron time-of-flight mass spectroscopy tal and theoretical studies.Surprisingly,only very little is we can obtain information on the isomersoftriazene formed known aboutthe most fundamental triazene:the parentmole- in the films. Using isotopically labeled starting material, we can cule with the chemical formula N3H3.Here we observe molecu- additionally gain insightinthe formation pathways of the iso- lar,isolated N3H3 in the gas phase after it sublimes from ener- mers of N3H3 under investigation and identify the isomers getically processed ammonia and nitrogen films. Combining formedastriazene (H2NNNH) andpossibly triimide(HNHNNH). 1. Introduction During the last decades, triazenes—a class of organic mole- life time of at least 1mswas also inferred as an intermediate cules carrying the =N N=N moiety—have received substan- in the radiolysis of an aqueous solution of hydrazine based on À À tial attention both from the theoretical and organic chemistry asingle absorption feature at 230 nm.[6] The cyclic isomer of [1] communities. Derived from cis-and trans-triazene (HN=NNH2 ; triazene, cyclotriazane, was first reported crystallographically in Scheme1), the substituted counterparts have significant appli- zeolite A, where it was stabilized by asilver cation as [1a,c] [1d] + [7] + cations in synthetic chemistry, polymer science, and phar- Ag(N3H3) . -

Ammonia a Very Important Molecule for Biological Organisms to Make Proteins Or Nucleic Acids

Ammonia A very important molecule for biological organisms to make proteins or nucleic acids by QH, and Niloy Kumar Das Shahjalal Science & Technology University, Bangladesh Molecule of the Month - June 2013 Introduction Ammonia or azane is a compound of nitrogen and hydrogen with the formula NH3. It is a colorless gas with a characteristic pungent smell, which is very common in toilets sometime. It is used in industry and commerce, and also exists naturally in humans and in the environment. Ammonia is essential for many biological processes and serves as a precursor for amino acid and nucleotide synthesis. In the environment, ammonia is part of the nitrogen cycle and is produced in soil from bacterial processes. Ammonia is also produced naturally from decomposition of organic matter, including plants and animals. Sal Ammoniacus Sal ammoniac is a mineral composed of ammonium chloride. The Romans called the ammonium chloride deposits they collected from near the Temple of Jupiter Amun in ancient Libya 'sal ammoniacus' (salt of Amun) because of proximity to the nearby temple. It is the earliest known mineral source of ammonia. Fig: Sal ammoniac is a mineral Guano & saltpeter Later alternative sources of ammonia mineral were discovered. Guano and saltpeter played valuable roleas strategic commodity. Guano consists of ammonium oxalate and urate, phosphates, as well as some earth salts and impurities. Guano also has a high concentration of nitrates. Saltpeter is the mineral form of potassium nitrate (KNO3). Potassium and other nitrates are of great importance for use in fertilizers, and, historically, gunpowder. Fig: Guano is simply deposits of bird droppings Independence from mineral dependency Even though our atmosphere consists 78% nitrogen, atmospheric nitrogen is nutritionally unavailable to plants or animals because nitrogen molecules are held together by strong triple bonds. -

Adapting Neural Machine Translation to Predict IUPAC Names from a Chemical Identifier

Translating the molecules: adapting neural machine translation to predict IUPAC names from a chemical identifier Jennifer Handsel*,a, Brian Matthews‡,a, Nicola J. Knight‡,b, Simon J. Coles‡,b aScientific Computing Department, Science and Technology Facilities Council, Didcot, OX11 0FA, UK. bSchool of Chemistry, Faculty of Engineering and Physical Sciences, University of Southampton, Southampton, SO17 1BJ, UK. KEYWORDS seq2seq, InChI, IUPAC, transformer, attention, GPU ABSTRACT We present a sequence-to-sequence machine learning model for predicting the IUPAC name of a chemical from its standard International Chemical Identifier (InChI). The model uses two stacks of transformers in an encoder-decoder architecture, a setup similar to the neural networks used in state-of-the-art machine translation. Unlike neural machine translation, which usually tokenizes input and output into words or sub-words, our model processes the InChI and predicts the 1 IUPAC name character by character. The model was trained on a dataset of 10 million InChI/IUPAC name pairs freely downloaded from the National Library of Medicine’s online PubChem service. Training took five days on a Tesla K80 GPU, and the model achieved test-set accuracies of 95% (character-level) and 91% (whole name). The model performed particularly well on organics, with the exception of macrocycles. The predictions were less accurate for inorganic compounds, with a character-level accuracy of 71%. This can be explained by inherent limitations in InChI for representing inorganics, as well as low coverage (1.4 %) of the training data. INTRODUCTION The International Union of Pure and Applied Chemistry (IUPAC) define nomenclature for both organic chemistry2 and inorganic chemistry.3 Their rules are comprehensive, but are difficult to apply to complicated molecules. -

Chapter 9 Hydrogen

Chapter 9 Hydrogen Diborane, B2 H6• is the simplest member of a large class of compounds, the electron-deficient boron hydrid Like all boron hydrides, it has a positive standard free energy of formation, and so cannot be prepared direct from boron and hydrogen. The bridge B-H bonds are longer and weaker than the tenninal B-H bonds (13: vs. 1.19 A). 89.1 Reactions of hydrogen compounds? (a) Ca(s) + H2Cg) ~ CaH2Cs). This is the reaction of an active s-me: with hydrogen, which is the way that saline metal hydrides are prepared. (b) NH3(g) + BF)(g) ~ H)N-BF)(g). This is the reaction of a Lewis base and a Lewis acid. The product I Lewis acid-base complex. (c) LiOH(s) + H2(g) ~ NR. Although dihydrogen can behave as an oxidant (e.g., with Li to form LiH) or reductant (e.g., with O2 to form H20), it does not behave as a Br0nsted or Lewis acid or base. It does not r with strong bases, like LiOH, or with strong acids. 89.2 A procedure for making Et3MeSn? A possible procedure is as follows: ~ 2Et)SnH + 2Na 2Na+Et3Sn- + H2 Ja'Et3Sn- + CH3Br ~ Et3MeSn + NaBr 9.1 Where does Hydrogen fit in the periodic chart? (a) Hydrogen in group 1? Hydrogen has one vale electron like the group 1 metals and is stable as W, especially in aqueous media. The other group 1 m have one valence electron and are quite stable as ~ cations in solution and in the solid state as simple 1 salts. -

Inorganic Seminar Abstracts

C 1 « « « • .... * . i - : \ ! -M. • ~ . • ' •» »» IB .< L I B RA FLY OF THE. UN IVERSITY Of 1LLI NOIS 546 1^52-53 Return this book on or before the Latest Date stamped below. University of Illinois Library «r L161— H41 Digitized by the Internet Archive in 2012 with funding from University of Illinois Urbana-Champaign http://archive.org/details/inorganicsemi195253univ INORGANIC SEMINARS 1952 - 1953 TABLE OF CONTENTS 1952 - 1953 Page COMPOUNDS CONTAINING THE SILICON-SULFUR LINKAGE 1 Stanley Kirschner ANALYTICAL PROCEDURES USING ACETIC ACID AS A SOLVENT 5 Donald H . Wilkins THE SOLVENT PHOSPHORYL CHLORIDE, POCl 3 12 S.J. Gill METHODS FOR PREPARATION OF PURE SILICON 17 Alex Beresniewicz IMIDODISULFINAMIDE 21 G.R. Johnston FORCE CONSTANTS IN POLYATOMIC MOLECILES 28 Donn D. Darsow METATHESIS IN LIQUID ARSENIC TRICHLORIDE 32 Harold H. Matsuguma THE RHENI DE OXIDATION STATE 40 Robert L. Rebertus HALOGEN CATIONS 45 L.H. Diamond REACTIONS OF THE NITROSYL ION 50 M.K. Snyder THE OCCURRENCE OF MAXIMUM OXIDATION STATES AMONG THE FLUOROCOMPLEXES OF THE FIRST TRANSITION SERIES 56 D.H. Busch POLY- and METAPHOSPHATES 62 V.D. Aftandilian PRODUCTION OF SILICON CHLORIDES BY ELECTRICAL DISCHARGE AND HIGH TEMPERATURE TECHNIQUES 67 VI. £, Cooley FLUORINE CONTAINING OXYHALIDES OF SULFUR 72 E.H. Grahn PREPARATION AND PROPERTIES OF URANYL CARBONATES 76 Richard *• Rowe THE NATURE OF IODINE SOLUTIONS 80 Ervin c olton SOME REACTIONS OF OZONE 84 Barbara H. Weil ' HYDRAZINE BY ELECTROLYSIS IN LIQUID AMMONIA 89 Robert N. Hammer NAPHTHAZARIN COMPLEXES OF THORIUM AND RARE EARTH METAL IONS 93 Melvin Tecotzky THESIS REPORT 97 Perry Kippur ION-PAIR FORMATION IN ACETIC ACID 101 M.M. -

Detection of the Elusive Triazane Molecule (N3H5) in the Gas Phase

DOI:10.1002/cphc.201500560 Communications Detection of the Elusive Triazane Molecule (N3H5)inthe Gas Phase MarkoFçrstel,[a] PavloMaksyutenko,[a] BrantM.Jones,[a] Bing-Jian Sun,[b] Shih-Hua Chen,[b] Agnes. H.-H. Chang,*[b] and Ralf I. Kaiser*[a] We report the detection of triazane (N3H5)inthe gas phase. Tri- ful and only potential decompositionproducts of triazane azane is ahigher order nitrogen hydride of ammonia (NH3) (N3H5)—diazane (HNNH) and ammonia (NH3)—could be sam- [1c] [1d] and hydrazine (N2H4)offundamentalimportance for the un- pled. Finally,Fuji et al. made an effort to detect free tria- derstanding of the stability of single-bonded chains of nitro- zane in the microwave discharge of hydrazine, but only the + gen atomsand apotentialkey intermediate in hydrogen–nitro- lithium salt of triazane (LiN3H5 )and the triazane cation + gen chemistry. The experimental resultsalongwith electronic- (N3H5 )could be identified. Therefore, whether free triazane structurecalculations reveal that triazane presentsastable (N3H5)can surviveprompt dissociation in the gas phase has re- molecule with anitrogen–nitrogen bond length that is afew mained an unanswered question. This lack of experimental evi- picometers shorter than that of hydrazineand has alifetime dence on the stability of triazane has triggered substantial exceeding 6 2 msatasublimation temperature of 170 K. Tria- computational efforts.[1a,b] An evaluation of the thermodynamic Æ zane was synthesized throughirradiation of ammonia ice with stability, accounting for hydrogen bonding as well as hyper- energetic electrons and was detected in the gas phase upon conjugation effects, reveals three triazane conformers with C1 sublimation of the ice through soft vacuum ultraviolet (VUV) and Cs symmetries, which range in stability within 24 kJ 1 [1a,b] photoionization coupled with areflectron-time-of-flight mass molÀ . -

Solid-State Chemistry with Nonmetal Nitrides

Solid-State Chemistry with Nonmetal Nitrides By Wolfgang Schnick* Among the nonmetal nitrides, the polymeric binary compounds BN and Si3N4 are of partic ular interest for the development of materials for high-performance applications. The out standing features of both substances are their thermal, mechanical, and chemical stability, coupled with their low density. Because of their extremely low reactivity, boron and silicon nitride are hardly ever used as starting materials for the preparation of ternary nitrides, but are used primarily in the manufacture of crucibles or other vessels or as insulation materials. The chemistry of ternary and higher nonmetal nitrides that contain electropositive elements and are thus analogous with the oxo compounds such as borates, silicates, phosphates, or sulfates was neglected for many years. Starting from the recent successful preparation of pure P3N5, a further binary nonmetal nitride which shows similarities with Si3N4 with regard to both its structure and properties, this review deals systematically with the solid-state chemistry of ternary and higher phosphorus(v) nitrides and the relationship between the various types of structure found in this class of substance and the resulting properties and possible applications. From the point of view of preparative solid-state chemistry the syntheses, structures, and properties of the binary nonmetal nitrides BN, Si3N4, and P3N5 will be compared and con trasted. The chemistry of the phosphorus(v) nitrides leads us to expect that other nonmetals such as boron, silicon, sulfur, and carbon will also participate in a rich nitride chemistry, as initial reports indeed indicate. 1. Introduction tors: extremely strong bonds between the elements and the presence of highly crosslinked covalent structures. -

Zirconium and Hafnium Complexes with New Tetra-Azane Ligands

Polyhedron 102 (2015) 337–343 Contents lists available at ScienceDirect Polyhedron journal homepage: www.elsevier.com/locate/poly Zirconium and hafnium complexes with new tetra-azane ligands: Synthesis, characterization and catalytic properties for ethylene polymerization ⇑ ⇑ Xiangdong Ji, Xuyang Luo, Wei Gao , Ying Mu State Key Laboratory for Supramolecular Structure and Materials, School of Chemistry, Jilin University, 2699 Qianjin Street, Changchun 130012, People’s Republic of China article info abstract 0 1 Article history: Two new anilido-imine tetra-azane ligands, 1,2-[(2 -(ArNH)C6H4HC@N)]2C6H4 (Ar = 2,6-Me2C6H3 (L H2) Received 23 August 2015 i 2 and 2,6- Pr2C6H3 (L H2)), were synthesized by the condensation reaction of o-phenylenediamine with Accepted 3 October 2015 1 the corresponding 2-(arylamino)benzaldehyde, and their zirconium and hafnium complexes, L MCl2 2 (M = Zr (1b), Hf (1c)) and L MCl2 (M = Zr (2b), Hf (2c)), were synthesized in high yields (61–66%) by 1 2 1 the reactions of L Li2 and L Li2 with MCl4 in toluene. Direct HCl-elimination reactions of L H2 with Keywords: 1 0 MCl4 (M = Ti, Zr, Hf) in toluene at 140 °C under vacuum afforded the products L HMCl3 [M = Ti (1a ), Zr Ethylene polymerization (1b0), Hf (1c0)] with a partially deprotonated tridentate ligand in good to high yields (48–70%). All the Group 4 complexes new complexes were characterized by 1H and 13C NMR spectroscopy and the molecular structures of Homogeneous catalysis Olefin polymerization 1b and 2c were determined by single crystal X-ray diffraction analysis. The metal centers in both com- Tetra-azane ligands plexes are six-coordinated with a distorted octahedral geometry. -

Organophosphorus-Tellurium Chemistry: from Fundamentals to Applications

Organophosphorus-Tellurium Chemistry: From Fundamentals to Applications Andreas Nordheider,a J. Derek Woollinsa and Tristram Chiversb* a. EaStCHEM School of Chemistry, University of St Andrews, St Andrews, Fife, KY16 9ST, UK b. Department of Chemistry, University of Calgary, Calgary, AB, Canada T2N 1N4 CONTENTS 1. Introduction 2. Fundamental Considerations 3. Binary Phosphorus-Tellurium Species 4. Phosphine Complexes of Tellurium Cations 5. Organophosphorus(III)-Tellurium Compounds 5.1 Acyclic Organophosphorus(III)-Tellurium Compounds 5.1.1 With P‒Te‒C Linkages 5.1.2 With P‒Te‒P Linkages 5.2 Organophosphorus(III)-Tellurium Heterocycles 5.3 Weak Phosphorus(III)···Tellurium Interactions 6. Organophosphorus(V) Tellurides 6.1 Synthesis and Spectroscopic Characterization 6.2 NMR Spectra and Phosphorus-Tellurium Exchange 6.3 X-Ray Structures 6.4 Bonding and Electronic Structure 6.5 Reaction with Electrophiles and Redox Behavior 6.6 Coordination Complexes 6.7 Applications as Tellurium-Transfer Reagents 7 Anionic Phosphorus-Tellurium Ligands 7.1 Tellurophosphates 7.2 Tellurophosphinites and Ditellurophosphinates 7.3 Telluroimidophosphinites, Tellurobisimidophosphinates. Mono- and Di- telluroimidodiphosphinates 7.3.1 Alkali-Metal Derivatives 1 7.3.2 Redox Chemistry 7.3.3 p-Block, d-Block and f-Block Metal Complexes 7.4 PCP-Bridged Tellurium-Centered Anions 7.5 A Carbon-Bridged P‒Te‒Al Heterocycle 7.6 Tellurium-Centered Anions Supported by a P2N2 Ring 7.6.1 Alkali-Metal Derivatives 7.6.2 Redox Chemistry 7.6.3 p-Block Metal Complexes 8 Single-Source Precursors for Metal Telluride Thin Films 9 Conclusions and Prospects 10 Acknowledgments 11 Addendum Author Information Corresponding Author Notes Biographies Abbreviations Dedication References 2 1. -

Cha'pter 8 Physical Techniques in Inorganic Chemistry

iranchembook.ir/edu iranchembook.ir/edu U niversity LIBRARIES This book has been purchased by The Dean and Barbara Martin Endowed Book Fund in Chemistry To support and enhance the Department of Chemistry, Eberly College of Science, The Pennsylvania State University 2010 pennState ptNN State m CHSCiist'RY This book has been purchased by The Dean and Barbara Martin Endowed Book Fund in Chemistry To support and enhance the Department of Chemistrj, Eberly College of Science, The Pennsylvania State University June 2010 iranchembook.ir/edu Solutions Manual to Accompany Inorganic Chemistry Sixth Edition Alen Hadzovic University of Toronto W. H. FREEMAN AND COMPANY New York OXFORD University Press iranchembook.ir/edu Solutions Manual to Accompany Inorganic Chemistry, Sixth Edition © 2014,2010,2006, and 1999 by Oxford University Press All rights reserved. Printed in the United States of America First printing Published, under license, in the United States and Canada by W. H. Freeman and Company 41 Madison Avenue New York, NY 10010 www.whfreeman.com ISBN-13: 978-1-4641-2438-9 ISBN-10: 1-4641-2438-8 Published in the rest of the world by Oxford University Press Great Clarendon Street Oxford, 0X2 6DP United Kingdom www.oup.com ISBN-13: 9780198701712 ISBN-10: 0198701713 u iranchembook.ir/edu TABLE OF CONTENTS Preface, v Acknowledgments, vii PART 1 Foundations Chapter 1 Atomic Structure 1 Chapter 2 Molecular Structure and Bonding 13 Chapter 3 The Structures of Simple Solids 27 Chapter 4 Acids and Bases 43 Chapter 5 Oxidation and Reduction 61 Chapter -

Nomenclature of Organic Chemistry. IUPAC Recommendations and Preferred Names 2013

International Union of Pure and Applied Chemistry Division VIII Chemical Nomenclature and Structure Representation Division Nomenclature of Organic Chemistry. IUPAC Recommendations and Preferred Names 2013. Prepared for publication by Henri A. Favre and Warren H. Powell, Royal Society of Chemistry, ISBN 978-0-85404-182-4 Chapter P-6 APPLICATIONS TO SPECIFIC CLASSES OF COMPOUNDS (continued) (P-66 to P-69) (continued from P-60 to P-65) P-60 Introduction P-61 Substitutive nomenclature: prefix mode P-62 Amines and imines P-63 Hydroxy compounds, ethers, peroxols, peroxides and chalcogen analogues P-64 Ketones, pseudoketones and heterones, and chalcogen analogues P-65 Acids and derivatives P-66 Amides, hydrazides, nitriles, aldehydes P-67 Oxoacids used as parents for organic compounds P-68 Nomenclature of other classes of compounds P-69 Organometallic compounds P-66 AMIDES, IMIDES, HYDRAZIDES, NITRILES, AND ALDEHYDES, P-66.0 Introduction P-66.1 Amides P-66.2 Imides P-66.3 Hydrazides P-66.4 Amidines, amidrazones, hydrazidines, and amidoximes (amide oximes) P-66.5 Nitriles P-66.6 Aldehydes P-66.0 INTRODUCTION The classes dealt with in this Section have in common the fact that their retained names are derived from those of acids by changing the ‘ic acid’ ending to a class name, for example ‘amide’, ‘ohydrazide’, ‘nitrile’, or ‘aldehyde’. Their systematic names are formed substitutively by the suffix mode using one of two types of suffix, one that includes the carbon atom, for example, ‘carbonitrile’ for –CN, and one that does not, for example, ‘-nitrile’ for –(C)N. Amidines are named as amides, hydrazidines as hydrazides, and amidrazones as amides or hydrazides. -

Principles of Chemical Nomenclature a GUIDE to IUPAC RECOMMENDATIONS Principles of Chemical Nomenclature a GUIDE to IUPAC RECOMMENDATIONS

Principles of Chemical Nomenclature A GUIDE TO IUPAC RECOMMENDATIONS Principles of Chemical Nomenclature A GUIDE TO IUPAC RECOMMENDATIONS G.J. LEIGH OBE TheSchool of Chemistry, Physics and Environmental Science, University of Sussex, Brighton, UK H.A. FAVRE Université de Montréal Montréal, Canada W.V. METANOMSKI Chemical Abstracts Service Columbus, Ohio, USA Edited by G.J. Leigh b Blackwell Science © 1998 by DISTRIBUTORS BlackweilScience Ltd Marston Book Services Ltd Editorial Offices: P0 Box 269 Osney Mead, Oxford 0X2 0EL Abingdon 25 John Street, London WC1N 2BL Oxon 0X14 4YN 23 Ainslie Place, Edinburgh EH3 6AJ (Orders:Tel:01235 465500 350 Main Street, Maiden Fax: MA 02 148-5018, USA 01235 465555) 54 University Street, Carlton USA Victoria 3053, Australia BlackwellScience, Inc. 10, Rue Casmir Delavigne Commerce Place 75006 Paris, France 350 Main Street Malden, MA 02 148-5018 Other Editorial Offices: (Orders:Tel:800 759 6102 Blackwell Wissenschafts-Verlag GmbH 781 388 8250 KurfUrstendamm 57 Fax:781 388 8255) 10707 Berlin, Germany Canada Blackwell Science KK Copp Clark Professional MG Kodenmacho Building 200Adelaide St West, 3rd Floor 7—10 Kodenmacho Nihombashi Toronto, Ontario M5H 1W7 Chuo-ku, Tokyo 104, Japan (Orders:Tel:416 597-1616 800 815-9417 All rights reserved. No part of Fax:416 597-1617) this publication may be reproduced, stored in a retrieval system, or Australia BlackwellScience Pty Ltd transmitted, in any form or by any 54 University Street means, electronic, mechanical, Carlton, Victoria 3053 photocopying, recording or otherwise, (Orders:Tel:39347 0300 except as permitted by the UK Fax:3 9347 5001) Copyright, Designs and Patents Act 1988, without the prior permission of the copyright owner.