Development of PV Production Equipment Business

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

CORPORATE DIRECTORY (As of June 28, 2000)

CORPORATE DIRECTORY (as of June 28, 2000) JAPAN TOKYO ELECTRON KYUSHU LIMITED TOKYO ELECTRON FE LIMITED Saga Plant 30-7 Sumiyoshi-cho 2-chome TOKYO ELECTRON LIMITED 1375-41 Nishi-Shinmachi Fuchu City, Tokyo 183-8705 World Headquarters Tosu City, Saga 841-0074 Tel: 042-333-8411 TBS Broadcast Center Tel: 0942-81-1800 District Offices 3-6 Akasaka 5-chome, Minato-ku, Tokyo 107-8481 Kumamoto Plant Osaka, Kumamoto, Iwate, Tsuruoka, Sendai, Tel: 03-5561-7000 2655 Tsukure, Kikuyo-machi Aizuwakamatsu, Takasaki, Mito, Nirasaki, Toyama, Fax: 03-5561-7400 Kikuchi-gun, Kumamoto 869-1197 Kuwana, Fukuyama, Higashi-Hiroshima, Saijo, Oita, URL: http://www.tel.co.jp/tel-e/ Tel: 096-292-3111 Nagasaki, Kikuyo, Kagoshima Regional Offices Ozu Plant Fuchu Technology Center, Osaka Branch Office, 272-4 Takaono, Ozu-machi TOKYO ELECTRON DEVICE LIMITED Kyushu Branch Office, Tohoku Regional Office, Kikuchi-gun, Kumamoto 869-1232 1 Higashikata-cho, Tsuzuki-ku Yamanashi Regional Office, Central Research Tel: 096-292-1600 Yokohama City, Kanagawa 224-0045 Laboratory/Process Technology Center Koshi Plant Tel: 045-474-7000 Sales Offices 1-1 Fukuhara, Koshi-machi Sales Offices Sendai, Nagoya Kikuchi-gun, Kumamoto 861-1116 Utsunomiya, Mito, Kumagaya, Kanda, Tachikawa, Tel: 096-349-5500 Yamanashi, Matsumoto, Nagoya, Osaka, Fukuoka TOKYO ELECTRON TOHOKU LIMITED Tohoku Plant TOKYO ELECTRON MIYAGI LIMITED TOKYO ELECTRON LEASING CO., LTD. 52 Matsunagane, Iwayado 1-1 Nekohazama, Nemawari, Matsushima-machi 30-7 Sumiyoshi-cho 2-chome Esashi City, Iwate 023-1101 Miyagi-gun, Miyagi -

INVESTORS GUIDE 2019 Osaka Office to Our Shareholders and Investors Fukuoka Sales Office Shinjuku Office Shinjuku Support Center Tachikawa Sales Office

TOKYO ELECTRON DEVICE LIMITED Securities code: 2760 Business Locations (As of July 1, 2019) Business Location Domestic Subsidiary Omiya Sales Office Matsumoto Sales Office Sendai Sales Office Tsukuba Sales Office Iwaki Sales Office Nagoya Sales Office Mito Sales Office Kyoto Sales Office INVESTORS GUIDE 2019 Osaka Office To Our Shareholders and Investors Fukuoka Sales Office Shinjuku Office Shinjuku Support Center Tachikawa Sales Office Engineering Center Headquarters (Yokohama) FAST CORPORATION (Yamato-city, Kanagawa prefecture) TOKYO ELECTRON DEVICE Mishima Sales Office NAGASAKI LTD. Hamamatsu Sales Office (Isahaya-city, Nagasaki prefecture) Business/Marketing location Overseas Design and development location Dalian Yokohama Ottawa Seoul Silicon Valley Shanghai Taipei Shenzhen Bangkok Wuxi Hong Kong Singapore Philippines Note on forward-looking statements This Investors Guide was prepared on July 1, 2019. Forward looking statements, including business strategies and business forecasts, were made by the Company’s management, based on information available at that time, and may be revised due to changes in the business environment. Therefore, please be advised that the Company cannot guarantee the accuracy or the reliability of the statements. For the latest information, please refer to our information releases or our website. Note also that product and service names remain the trademarks of their respective owners. Corporate Communications Dept. https://www.teldevice.co.jp World Headquarters Yokohama East Square, 1-4 Kinko-cho, Kanagawa-ku,Yokohama -

ISSM2020 –International Symposium on Semiconductor Manufacturing SPONSORSHIP December 15-16, 2020, Tokyo, Japan

ISSM2020 –International Symposium on Semiconductor Manufacturing SPONSORSHIP December 15-16, 2020, Tokyo, Japan Shozo Saito Chairman, ISSM2020 Organizing Committee Device & System Platform Development Center Co., Ltd. Shuichi Inoue, ATONARP INC. It is our great pleasure to announce that The 28th annual International Symposium on Semiconductor Manufacturing (ISSM) 2020 will be held on December 15-16, 2020 at KFC Hall, Ryogoku, Tokyo in cooperation with e-Manufacturing & Design Collaboration Symposium (eMDC) which is sponsored by TSIA with support from SEMI and GSA. The program will feature keynote speeches by world leading speakers, timely and highlighted topics and networking sessions focusing on equipment/materials/software/services with suppliers' exhibits. ISSM continues to contribute to the growth of the semiconductor industry through its infrastructure for networking, discussion, and information sharing among the world's professionals. We would like you to cooperate with us by supporting the ISSM 2020. Please see the benefit of ISSM2020 sponsorship. Conference Overview Date: December 15-16, 2020 Location: KFC (Kokusai Fashion Center) Hall 1-6-1 Yokoami Sumidaku, Tokyo 130-0015 Japan +81-3-5610-5810 Co-Sponsored by: IEEE Electron Devices Society Minimal Fab Semiconductor Equipment Association of Japan (SEAJ) Semiconductor Equipment and Materials International (SEMI) Taiwan Semiconductor Industry Association (TSIA) Endorsement by: The Japan Society of Applied Physics Area of Interest: Fab Management Factory Design & Automated Material -

XINT N Japan 225 P JPY Index

As of December 30, 2020 XINT N Japan 225 P JPY Index JPY DE000A13PWP8 The XINT N Japan 225 P JPY Index is a price-weighted average of 225 top-rated Japanese companies listed in the First Section of the Tokyo Stock Exchange. INDEX PERFORMANCE - PRICE RETURN 130 120 110 100 90 80 70 Feb-19 May-19 Aug-19 Nov-19 Feb-20 May-20 Aug-20 Nov-20 Returns (p.a) Standard Deviation (p.a) Maximum Drawdown 3M 96.33% 3M 14.42% From 20.01.2020 6M 51.63% 6M 51.63% To 19.03.2020 1Y 16.01% 1Y 16.01% Return -31.27% Index Intelligence GmbH - Grosser Hirschgraben 15 - 60311 Frankfurt am Main Tel.: +49 69 247 5583 50 - [email protected] www.index-int.com Top 10 Constituents FFMV (JPYm) Weight % Industry Sector Fast Retailing Co Ltd 5 12.13 Retail SoftBank Group Corp 2 6.34 Telecommunications Tokyo Electron Ltd 2 5.04 Technology FANUC Corp 1 3.33 Industrial Goods & Services M3 Inc 1 3.07 Health Care Daikin Industries Ltd 1 3.01 Construction & Materials KDDI Corp 1 2.41 Telecommunications Shin-Etsu Chemical Co Ltd 1 2.37 Chemicals Terumo Corp 1 2.26 Health Care Chugai Pharmaceutical Co Ltd 1 2.17 Health Care Total 16 42.13 This information has been prepared by Index Intelligence GmbH (“IIG”). All information is provided "as is" and IIG makes no express or implied warranties, and expressly disclaims all warranties of merchantability or fitness for a particular purpose or use with respect to any data included herein. -

Roundtable Meeting with Stakeholders Reducing the Environmental Impact of Semiconductor Production Equipment

H ighlights Roundtable Meeting with Stakeholders Reducing the Environmental Impact of Semiconductor Production Equipment The Tokyo Electron Group regards reducing the environmental impact of its semiconductor production equipment delivered to customers’ factories as one of its major social responsibilities. We invited three people from semiconductor manufacturers who are our customers to attend a roundtable meeting with our employees engaged in sales and equipment development. At the meeting, participants discussed the Group’s challenges and expectations from its customers, focusing on energy-saving equipment. Sharing Information with Semiconductor it contributed to energy efficiency and yield at your factory? Manufacturers Is Essential for Developing Energy- Mr. Kagino: Certainly there is a question of whether or not you can Saving Equipment obtain that kind of information, and even if you did, other semi- Mr. Ibuka (TEL): In recent years, environment-conscious design conductor manufacturers might not accept the same improve- has been attracting much attention. In particular, there are strong ment method. There have been cases where an improvement ini- demands for improvements in energy efficiency, and so the Tokyo tiative that worked well at Factory A for a certain semiconductor man- Electron Group is trying to contribute to the earth and society by pro- ufacturer did not work or was not accepted at the same manufac- viding more energy-efficient equipment. Today, we would like to ask turer‘s Factory B. As the background to this, semiconductor pro- you, the users of our equipment, for your honest opinions. We duction equipment is customized for each customer. However, I think will incorporate your opinions into future product development. -

NOTICE of FISCAL YEAR 2018 (The 55Th FY) ANNUAL GENERAL MEETING of SHAREHOLDERS

㻝㻌 World Headquarters 3-1 Akasaka 5-chome, Minato-ku Tokyo 107-6325, Japan ISIN JP3571400005 Tel:+81-3-5561-7000 SEDOL 6895675 TSE 8035 May 28, 2018 NOTICE OF FISCAL YEAR 2018 (the 55th FY) ANNUAL GENERAL MEETING OF SHAREHOLDERS To Our Shareholders: We are pleased to announce that the 55th Annual General Meeting of Shareholders (the “AGM”) of Tokyo Electron Ltd. (“TEL”) will be held on Tuesday, June 19, 2018, at 10:00 a.m. Japan standard time, at PALACE HOTEL TOKYO, located at 1-1 Marunouchi 1-chome, Chiyoda-ku, Tokyo. Shareholders will also be asked to vote upon the following Agenda: 1: Election of Twelve Corporate Directors 2: Payment of Bonuses to Corporate Directors for the 55th Fiscal Year 3: Issuance of Share Subscription Rights as Stock-Based Compensation to Corporate Directors 4: Issuance of Share Subscription Rights as Stock-Based Compensation to Executives of the Company and its Subsidiaries 5: Introduction of a Stock Compensation System as Medium-term Performance-linked Compensation for Corporate Directors of the Company As part of our ongoing effort to improve the quality of communications with our foreign investors and to increase the participation of those investors and to exercise your voting rights at the AGM, Tokyo Electron Ltd. has appointed IR Japan, Inc. as our Global Information Agent in connection with the shareholder meeting. We realize that many shareholders do not vote at Japanese Shareholders Meeting due to the volume of meetings and timing concerns. Therefore, we attach special importance to your vote, and hope that you will continue to distinguish yourselves from many institutions, who, unfortunately, do not participate. -

PDF Download [1

Annual Report 2002 TOKYO ELECTRON Profile Established in 1963, Tokyo Electron (TEL) is a world-leading supplier of semiconductor production equipment (SPE) and related services for the semiconductor industry. The Company develops, manufactures and markets a broad lineup of products, including oxidation/diffusion/LP-CVD systems, single wafer CVD and PVD systems, coater/developers, spin-on dielectric (SOD) coaters, etch systems, cleaning systems, wafer probers, and others. Tokyo Electron also uses its accumulated expertise in SPE to develop, manufacture and market coater/developers and etch/ash systems for the manufacture of Flat Panel Display (FPD). Most of the Company’s semiconductor and FPD production systems hold the leading share in their respective markets. Tokyo Electron also maintains a strong presence as a distributor, providing a wide array of semiconductor production systems, storage Disclaimer regarding area network and Internet related products for broadband solutions, and Forward-looking Statements electronic components in Japan from other leading suppliers. With a Matters discussed in this annual report, including network spanning 16 countries on three continents, Tokyo Electron forecasts of future business performance of Tokyo Electron, management strategies, beliefs provides superior products and services to its customers, and superior and other statements are based on the returns to its shareholders. Company’s assumption in light of information that is currently available. These forward-looking statements involve known -

Facilitation of Information Transfer on Chemicals in Products

Facilitation of Information Transfer on Chemicals in Products The Ministry of Economy, Trade and Industry (METI) developed ‘chemSHERPA’ [kémʃéərpə] as a new information transfer scheme for chemicals in products throughout their supply chains. METI hopes that the dissemination of chemSHERPA may contribute to reduce the workload of both providers and recipients of the information. From the beginning of the development of chemSHERPA, METI has been in communication with international bodies such as the IEC and the IPC, etc., with the aim of developing chemSHERPA into not only a Japanese standard but also an International standard. To make it a de-facto standard, METI has introduced this scheme to international organizations and governments of other countries for their active use. The Joint Article Management Promotion Consortium (JAMP) is a governing body for chemSHERPA from April 2016 and see a shift to chemSHERPA. We believe many companies are preparing towards implementing chemSHERPA. Based on the efforts mentioned above, the following companies and company groups have agreed with the dissemination of chemSHERPA, and METI will continue to work with JAMP and companies to spread the use of chemSHERPA to internal as well as external supply chains as needed.(Please contact us if any company or company group has interest in putting its name below.) It should be noted, the use of the provision of data entry support tools is free of charge in principle with the aim of promoting wider use of chemSHERPA. [Contact information] Chemical Management Policy Division Manufacturing Industries Bureau Ministry of Economy, Trade and Industry [email protected] 03-3501-0080 (direct) 03-3501-1511 (ex. -

Medium-Term Management Plan Progress and TEL Initiatives

Cyan R 0 G 169 B 224 Black R 20 G 20 B 20 Gray R 45 G 45 Medium-term Management Plan B 45 White Progress and TEL Initiatives R 255 G 255 B 255 Magenta May 31, 2017 R 218 G 24 B 132 Toshiki Kawai Purple R 128 Representative Director, President & CEO G 49 B 167 Turquoise R 0 G 178 B 169 Green R 120 G 190 B 32 Yellow R 238 G 220 B 0 Orange R 255 G 106 B 19 Cyan R 0 G 169 B 224 Black FY2017 Financial Highlights R 20 G 20 B 20 Operating Income and Net Sales and Gross Profit Margin Net Income and ROE Gray Operating Margin R 45 (Billion Yen) (Billion Yen) (Billion Yen) G 45 900 200 19.5% 20.0% 150 B 45 Net sales Operating income 799.7 17.6% Net income 19.1% White Gross profit margin Operating margin ROE R 255 155.6 G 255 663.9 14.4% B 255 150 15.0% 100 612.1 613.1 13.0% Magenta 600 39.6% 40.2% 40.3% 11.8% 116.7 R 218 497.2 G 24 B 132 33.0% 31.9% 100 10.0% 50 115.2 88.1 Purple 71.8 77.8 R 128 G 49 300 1.0% B 167 5.3% 6.0 50 5.0% 0 Turquoise 2.5% 32.2 -19.4 R 0 G 178 12.5 B 169 -3.3% 0 0 Green 0.0% -50 FY2013 FY2014 FY2015 FY2016 FY2017 FY2013 FY2014 FY2015 FY2016 FY2017 FY2013 FY2014 FY2015 FY2016 FY2017 R 120 G 190 B 32 . -

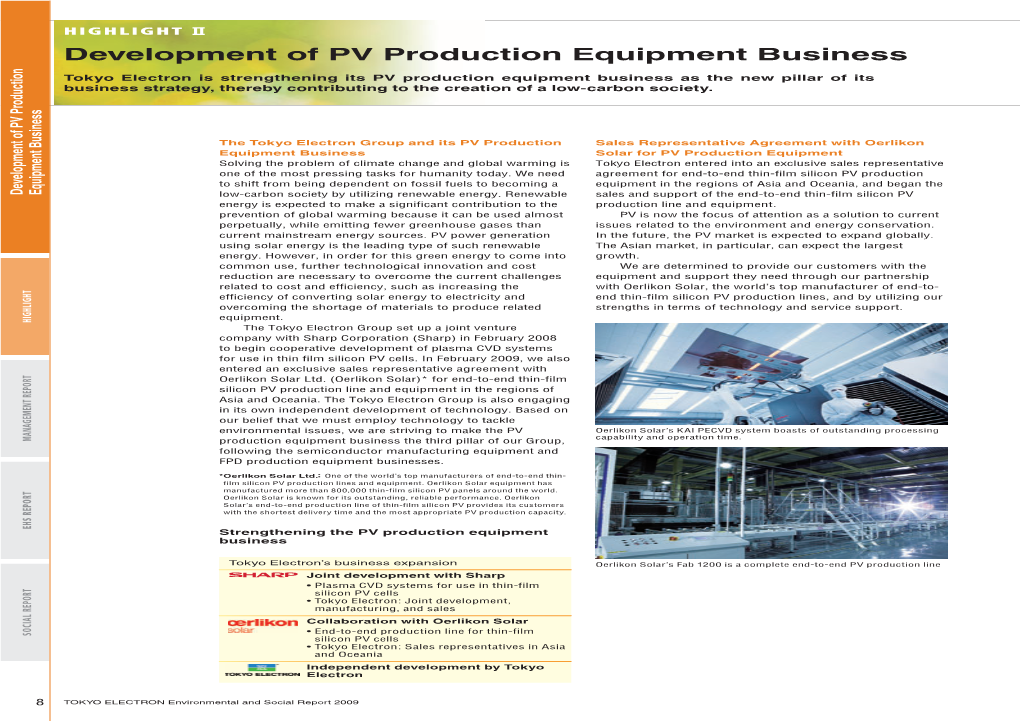

Development of the PV Cell Production Equipment Business

HIGHLIGHTS Production Equipment Business Development of the PV Cell Development of the PV Cell Production Equipment Business Amid growing public expectations for renewable energy, the Tokyo Electron Group has announced the launch of a PV cell production equipment business. What is PV Power Generation? PV Cell Production Thin-film Si PV Cell Production Solving the problem of climate change and global warming is the Equipment Market most pressing agenda for society. We need to shift from being Crystalline Si PV cells Thin-film Si PV cell production equipment dependent on fossil fuels to becoming a low carbon society by Thin-film Si PV cells utilizing renewable energy. Renewable energy is expected to make Production (GW) Market size (billions of yen) 100 1,800 significant contributions toward preventing global warming as it can be used semi-perpetually while emitting less greenhouse gases than 2007–2020 1,500 80 Average growth current mainstream energy sources. 2015–2020 25% 1,200 Average growth PV power generation using solar energy is the leading player of 60 37% such renewable energy. However, further technological innovations 900 2007–2020 and cost reductions are necessary for common use of this green 40 Average growth 600 2007–2015 energy in order to overcome present challenges, such as increase 52% Average growth H 20 IG in energy conversion efficiency (from solar energy to electricity), 300 44% H LIG shortage of materials to produce related equipment, and cost/ 0 0 H efficiency issues. 2007 2015 2020 20072015 2020 T Source: TEL’s calculations based on the power demand forecast. S The Group has started the PV cell production equipment business with a strong commitment to making contributions to environmental solutions through our technological excellence. -

Published on 7 October 2015 1. Constituents Change the Result Of

The result of periodic review and component stocks of TOPIX Composite 1500(effective 30 October 2015) Published on 7 October 2015 1. Constituents Change Addition( 80 ) Deletion( 72 ) Code Issue Code Issue 1712 Daiseki Eco.Solution Co.,Ltd. 1972 SANKO METAL INDUSTRIAL CO.,LTD. 1930 HOKURIKU ELECTRICAL CONSTRUCTION CO.,LTD. 2410 CAREER DESIGN CENTER CO.,LTD. 2183 Linical Co.,Ltd. 2692 ITOCHU-SHOKUHIN Co.,Ltd. 2198 IKK Inc. 2733 ARATA CORPORATION 2266 ROKKO BUTTER CO.,LTD. 2735 WATTS CO.,LTD. 2372 I'rom Group Co.,Ltd. 3004 SHINYEI KAISHA 2428 WELLNET CORPORATION 3159 Maruzen CHI Holdings Co.,Ltd. 2445 SRG TAKAMIYA CO.,LTD. 3204 Toabo Corporation 2475 WDB HOLDINGS CO.,LTD. 3361 Toell Co.,Ltd. 2729 JALUX Inc. 3371 SOFTCREATE HOLDINGS CORP. 2767 FIELDS CORPORATION 3396 FELISSIMO CORPORATION 2931 euglena Co.,Ltd. 3580 KOMATSU SEIREN CO.,LTD. 3079 DVx Inc. 3636 Mitsubishi Research Institute,Inc. 3093 Treasure Factory Co.,LTD. 3639 Voltage Incorporation 3194 KIRINDO HOLDINGS CO.,LTD. 3669 Mobile Create Co.,Ltd. 3197 SKYLARK CO.,LTD 3770 ZAPPALLAS,INC. 3232 Mie Kotsu Group Holdings,Inc. 4007 Nippon Kasei Chemical Company Limited 3252 Nippon Commercial Development Co.,Ltd. 4097 KOATSU GAS KOGYO CO.,LTD. 3276 Japan Property Management Center Co.,Ltd. 4098 Titan Kogyo Kabushiki Kaisha 3385 YAKUODO.Co.,Ltd. 4275 Carlit Holdings Co.,Ltd. 3553 KYOWA LEATHER CLOTH CO.,LTD. 4295 Faith, Inc. 3649 FINDEX Inc. 4326 INTAGE HOLDINGS Inc. 3660 istyle Inc. 4344 SOURCENEXT CORPORATION 3681 V-cube,Inc. 4671 FALCO HOLDINGS Co.,Ltd. 3751 Japan Asia Group Limited 4779 SOFTBRAIN Co.,Ltd. 3844 COMTURE CORPORATION 4801 CENTRAL SPORTS Co.,LTD. -

PDF Download

TOKYO ELECTRON ANNUAL REPORT 2020 For the Year Ended March 31, 2020 PR58-126 TOKYO ELECTRON ANNUAL REPORT 2020 PAGE 1 Business Overview Review of Operations Financial Section To Our Stakeholders Interview with the CEO Corporate Governance and Financial Highlights and Business Outlook Investor Information Contents Guide to Buttons Move Back to Previous Page Contents Move Forward to Next Page Corporate Philosophy Return to Last Page Opened 2 To Our Stakeholders We strive to contribute to the develop- Go to Contents Page ment of a dream-inspiring society 3 Business Overview and Financial Highlights through our leading-edge technologies 4 Interview with the CEO Search PDF Content and reliable service and support. 7 Review of Operations and Business Outlook Print 8 Message from the Chairman of the Board Zoom Vision 9 Corporate Governance 12 Directors, Audit & Supervisory Board Members and A truly global company generating Executive Officers high added value and profits 13 Financial Section in the semiconductor and 29 Consolidated Subsidiaries flat panel display industries through innovative technologies and 29 Investor Information groundbreaking proactive solutions that integrate diverse technologies. The Corporate Philosophy defines the pur- pose of Tokyo Electron’s existence and its mission in society. It represents Tokyo Disclaimer Electron’s basic way of thinking and forms Matters discussed in this annual report, including forecasts of future business performance of Tokyo Electron, management strategies, beliefs and other statements are based on Tokyo Electron’s assumptions in light of information that is currently the foundation for its corporate activities. available. These forward-looking statements involve known or unknown risks, uncertainties and other factors that could The Vision describes Tokyo Electron’s cause actual results to differ materially from those referred to in the forward-looking statements.