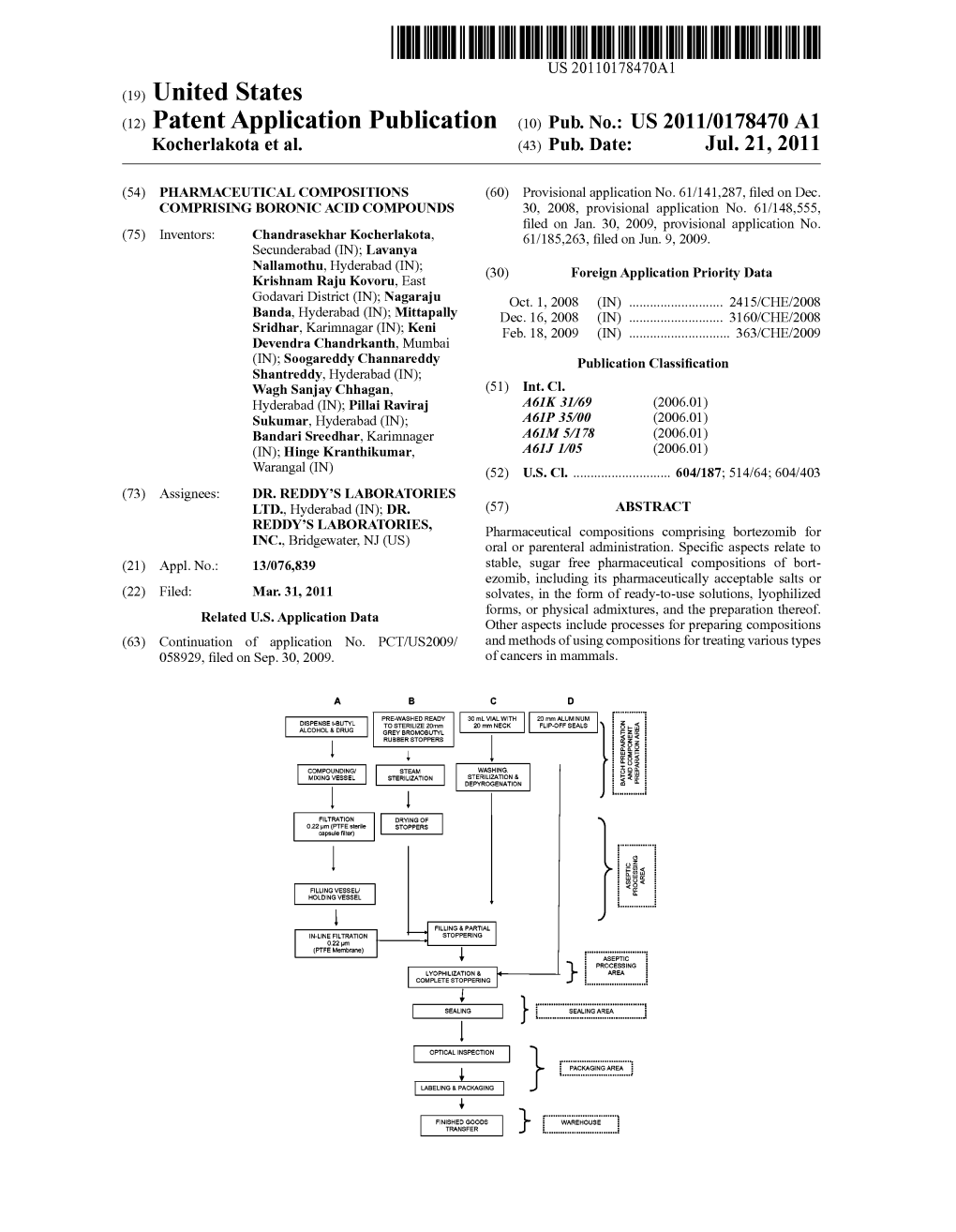

Batch Preparation and Component

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

“Polyols: a Primer for Dietetic Professionals” Is a Self-Study

1 “Polyols: A primer for dietetic professionals” is a self-study module produced by the Calorie Control Council, an accredited provider of continuing professional education (CPE) for dietetic professionals by the Commission on Dietetic Registration. It provides one hour of level 1 CPE credit for dietetic professionals. The full text of the module is in the notes section of each page, and is accompanied by summary points and/or visuals in the box at the top of the page. Directions for obtaining CPE are provided at the end of the module. 2 After completing this module, dietetic professionals will be able to: • Define polyols. • Identify the various types of polyols found in foods. • Understand the uses and health effects of polyols in foods. • Counsel clients on how to incorporate polyols into an overall healthful eating pattern. 3 4 Polyols are carbohydrates that are hydrogenated, meaning that a hydroxyl group replaces the aldehyde or ketone group found on sugars. Hydrogenated monosaccharides include erythritol, xylitol, sorbitol, and mannitol. Hydrogenated disaccharides include lactitol, isomalt, and maltitol. And hydrogenated starch hydrolysates (HSH), or polyglycitols (a wide range of corn syrups and maltodextrins), are formed from polysaccharides (Grabitske and Slavin 2008). 5 Nearly 54 percent of Americans are trying to lose weight, more than ever before. Increasingly, they are turning toward no- and low-sugar, and reduced calorie, foods and beverages to help them achieve their weight loss goals (78% of Americans who are trying to lose weight) (CCC 2010). Polyols, found in many of these foods, are becoming a subject of more interest. 6 They are incompletely digested , therefore are sometimes referred to as “low- digestible carbohydrates.” Polyols are not calorie free, as there is some degree of digestion and absorption of the carbohydrate. -

Novel Insights Into Mannitol Metabolism in the Fungal Plant

Novel insights into mannitol metabolism in the fungal plant pathogen Botrytis cinerea Thierry Dulermo, Christine Rascle, Geneviève Billon-Grand, Elisabeth Gout, Richard Bligny, Pascale Cotton To cite this version: Thierry Dulermo, Christine Rascle, Geneviève Billon-Grand, Elisabeth Gout, Richard Bligny, et al.. Novel insights into mannitol metabolism in the fungal plant pathogen Botrytis cinerea. Biochemical Journal, Portland Press, 2010, 427 (2), pp.323-332. 10.1042/BJ20091813. hal-00479283 HAL Id: hal-00479283 https://hal.archives-ouvertes.fr/hal-00479283 Submitted on 30 Apr 2010 HAL is a multi-disciplinary open access L’archive ouverte pluridisciplinaire HAL, est archive for the deposit and dissemination of sci- destinée au dépôt et à la diffusion de documents entific research documents, whether they are pub- scientifiques de niveau recherche, publiés ou non, lished or not. The documents may come from émanant des établissements d’enseignement et de teaching and research institutions in France or recherche français ou étrangers, des laboratoires abroad, or from public or private research centers. publics ou privés. Biochemical Journal Immediate Publication. Published on 05 Feb 2010 as manuscript BJ20091813 1 NOVEL INSIGHTS INTO MANNITOL METABOLISM IN THE FUNGAL PLANT 2 PATHOGEN BOTRYTIS CINEREA 3 4 Authors : Thierry Dulermo*†, Christine Rascle*, Geneviève Billon-Grand*, Elisabeth Gout‡, 5 Richard Bligny‡ and Pascale Cotton§ 6 7 Address 8 *Génomique Fonctionnelle des Champignons Pathogènes des Plantes, UMR 5240 9 Microbiologie, Adaptation -

Review of the Role of Mannitol in the Therapy of Children

18th Expert Committee on the Selection and Use of Essential Medicines (21 to 25 March 2011) Section 16: Diuretics -- Mannitol review (Children) Review of the role of mannitol in the therapy of children Dr Fatemeh Tavakkoli M.D. Pharm. D Candidate, University of Maryland, School of Pharmacy, Baltimore, Maryland, USA Contents Introduction......................................................................................................................................... 3 Background ......................................................................................................................................... 3 Table 1: available guidelines for Mannitol ................................................................................ 3 Public Health Burden.......................................................................................................................... 5 Table 2: Indications and dose regimens for Mannitol in children .............................................. 6 Search methods for identification of safety and efficacy data............................................................ 7 Results................................................................................................................................................. 8 Systematic reviews.............................................................................................................................. 8 Individual studies (categorized by therapeutic use of mannitol): ..................................................... 10 -

Sweet Sensations by Judie Bizzozero | Senior Editor

[Confections] July 2015 Sweet Sensations By Judie Bizzozero | Senior Editor By R.J. Foster, Contributing Editor For many, terms like “reduced-sugar” or “sugar-free” do not go with the word “candy.” And yet, the confectionery industry is facing growing demand for treats that offer the taste people have grown to love without the adverse health effects they’re looking to avoid. Thankfully, there is a growing palette of ingredients from which candy makers can paint a new picture of sweetness that will be appreciated by the even most discerning of confectionery critics. SUGAR ALCOHOLS Also referred to as polyols, sugar alcohols are a common ingredient in reduced-sugar and sugar-free applications, especially confections. Funny thing, they’re not sugars or alcohols. Carbohydrate chains composed of monomeric, dimeric and polymeric units, polyols resemble both sugars and alcohols, but do not contain an ethanol molecule. All but two sugar alcohols are less sweet than sugar. Being only partially digestible, though, replacing a portion of a formulation’s sugar with a sugar alcohol reduces total calories without losing bulk (which can occur when replacing sugar with high-intensity sweeteners). Unique flavoring, texturizing and moisture-controlling effects also make polyols well-suited for confectionery products. Two very common and very similar monomeric polyols are sorbitol and mannitol. Present in a variety of fruits and vegetables, both are derived from products of cornstarch hydrolysis. Sorbitol is made via hydrogenation of glucose, which is why sorbitol is sometimes referred to as glucitol. Mannitol is created when fructose hydrogenation converts fructose into mannose, for which the final product, mannitol, is named. -

Seaweed Bioethanol Production: a Process Selection Review on Hydrolysis and Fermentation

fermentation Review Seaweed Bioethanol Production: A Process Selection Review on Hydrolysis and Fermentation Felix Offei 1,*, Moses Mensah 2, Anders Thygesen 3 and Francis Kemausuor 1 1 Department of Agricultural and Biosystems Engineering, Kwame Nkrumah University of Science and Technology, AK-449-1916 Kumasi, Ghana; [email protected] 2 Department of Chemical Engineering, Kwame Nkrumah University of Science and Technology, AK-449-1916 Kumasi, Ghana; [email protected] 3 Department of Biotechnology and Biomedicine, Technical University of Denmark, DK2800 Lyngby, Denmark; [email protected] * Correspondence: [email protected]; Tel.: +233-267-766-644 Received: 31 October 2018; Accepted: 27 November 2018; Published: 29 November 2018 Abstract: The rapid depletion and environmental concerns associated with the use of fossil fuels has led to extensive development of biofuels such as bioethanol from seaweeds. The long-term prospect of seaweed bioethanol production however, depends on the selection of processes in the hydrolysis and fermentation stages due to their limiting effect on ethanol yield. This review explored the factors influencing the hydrolysis and fermentation stages of seaweed bioethanol production with emphasis on process efficiency and sustainable application. Seaweed carbohydrate contents which are most critical for ethanol production substrate selection were 52 ± 6%, 55 ± 12% and 57 ± 13% for green, brown and red seaweeds, respectively. Inhibitor formation and polysaccharide selectivity were found to be the major bottlenecks influencing the efficiency of dilute acid and enzymatic hydrolysis, respectively. Current enzyme preparations used, were developed for starch-based and lignocellulosic biomass but not seaweeds, which differs in polysaccharide composition and structure. Also, the identification of fermenting organisms capable of converting the heterogeneous monomeric sugars in seaweeds is the major factor limiting ethanol yield during the fermentation stage and not the SHF or SSF pathway selection. -

Chapter 1.1 Development of a Bladder Instillation of the Indoloquinone

CHAPTER 1 Pharmaceutical development, analysis & manufacture of EO-9 15 16 Chapter 1.1 Development of a bladder instillation of the indoloquinone anticancer agent EO-9 using tert-butyl alcohol as lyophilization vehicle S.C. van der Schoot, B. Nuijen, F.M. Flesch, A. Gore, D. Mirejovsky ,L. Lenaz, J.H. Beijnen Submitted for publication 17 18 Chapter 1.1 Abstract EO-9 is a bioreductive alkylating indoloquinone and an analogue of the antitumor antibiotic mitomycin C. EO-9 is an inactive prodrug, which is activated by reduction of the quinone moiety to semiquinone or hydroquinone, generating an intermediate with an electrophilic aziridine ring system, which serves as a target for nucleophilic DNA. For the treatment of superficial bladder cancer a pharmaceutical formulation for a bladder instillation with EO-9 was developed. To improve solubility and stability of EO-9, tert-butyl alcohol was chosen as co-solvent for the solution vehicle in the freeze-drying process. Because EO-9 is most stable at alkaline pH sodium bicarbonate was used as alkalizer. Stability and dissolution studies revealed an optimal formulation solution for freeze-drying composed of 4 mg/ml EO-9, 10 mg/ml sodium bicarbonate, and 25 mg/ml mannitol in 40% v/v tert-butyl alcohol in water for injection. Optimization of the freeze drying process was performed by determination of the freeze drying characteristics of tert-butyl alcohol/water systems and differential scanning calorimetry analysis of the formulation solution. Furthermore, the influence of the freeze drying process on crystallinity and morphology of the freeze dried product was determined with X-ray diffraction analysis and scanning electron microscopy, respectively. -

Clinical Efficacy of Mannitol 10% with Glycerol 10% Versus Mannitol 20% in Cerebral Edema

CLINICAL STUDY Indian Journal of Clinical Practice, Vol. 30, No. 5, October 2019 Clinical Efficacy of Mannitol 10% with Glycerol 10% versus Mannitol 20% in Cerebral Edema AVINASH SHANKAR*, SHUBHAM†, AMRESH SHANKAR‡, ANURADHA SHANKAR# ABSTRACT Introduction: Cerebral edema is a common cause of unconsciousness and a manifestation in cerebrovascular accident, head injury, convulsive disorder and encephalitis, either due to infection or toxin. Failure of energy-dependent sodium-potassium ATPase pump, results in accumulation of sodium and water. The release of free radicals and proteases due to activation of microglial cells disrupts cell membrane and capillaries. Objective of the study: Comparative assessment of clinical efficacy of mannitol 10% with glycerol 10% versus mannitol 20% in cerebral edema of varied origin. Material and methods: In this study, 1171 patients of cerebral edema of various etiology attending Medical Emergency of RA Hospital & Research Centre, Warisaliganj (Nawada), Bihar, were selected for comparative evaluation of mannitol 10% with glycerol 10% versus mannitol 20% intravenously to adjudge the clinical efficacy and safety profile. Results: Patients of Group A taking mannitol 10% with glycerol 10% had Grade I clinical response in 584/586 without any adversity, residual neurological deficit or mortality and morbidity while among patients of Group B on mannitol 20%, only 108/585 had Grade I clinical response with mortality in 92 cases and morbidity in 279 cases. Keywords: Cerebral edema, cerebrovascular accident, sodium potassium ATPase pump, free radicals, proteases, mortality, morbidity erebral edema is a common sequel of causes dysfunction but not necessarily permanent cerebrovascular accident (CVA), head injury, damage. Ultimately, hypoxia depletes the cells’ energy Cconvulsive disorder and infective or toxic stores and disables the sodium-potassium ATPase, involvement of brain. -

Biomaterials Formed by Nucleophilic Addition

(19) & (11) EP 1 181 323 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention (51) Int Cl.: of the grant of the patent: C08G 63/48 (2006.01) C08G 63/91 (2006.01) 29.06.2011 Bulletin 2011/26 C12N 11/02 (2006.01) C12N 11/04 (2006.01) C12N 11/06 (2006.01) C12N 11/08 (2006.01) (2006.01) (2006.01) (21) Application number: 00910049.6 G01N 33/544 G01N 33/545 G01N 33/546 (2006.01) G01N 33/549 (2006.01) A61K 9/00 (2006.01) A61K 9/06 (2006.01) (22) Date of filing: 01.02.2000 A61K 47/48 (2006.01) A61L 24/00 (2006.01) A61L 24/04 (2006.01) A61L 26/00 (2006.01) A61L 27/26 (2006.01) A61L 27/52 (2006.01) A61L 31/04 (2006.01) A61L 31/14 (2006.01) C08G 81/00 (2006.01) (86) International application number: PCT/US2000/002608 (87) International publication number: WO 2000/044808 (03.08.2000 Gazette 2000/31) (54) BIOMATERIALS FORMED BY NUCLEOPHILIC ADDITION REACTION TO CONJUGATED UNSATURATED GROUPS BIOMATERIALIEN DIE DURCH NUKLEOPHILE REAKTION AUF KONJUGIERTEN UNGESÄTTIGTEN GRUPPEN ADDIERT SIND BIOMATERIAUX FORMES PAR REACTION D’ADDITION NUCLEOPHILE A DES GROUPES NON SATURES CONJUGUES (84) Designated Contracting States: • LUTOLF, Matthias AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU CH-8005 Zurich (CH) MC NL PT SE • PRATT, Alison CH-8044 Zurich (CH) (30) Priority: 01.02.1999 US 118093 P • SCHOENMAKERS, Ronald CH-8044 Zurich (CH) (43) Date of publication of application: • TIRELLI, Nicola 27.02.2002 Bulletin 2002/09 CH-8006 Zurich (CH) • VERNON, Brent (60) Divisional application: CH-8157 Dielsdorf (CH) 10181654.4 / 2 311 895 (74) Representative: Klunker . -

Sugar Alcohols Fact Sheet

International Food Information Council Sugar Alcohols Fact Sheet September 2004 BACKGROUND Sugar alcohols or polyols, as they are also called, have a long history of use in a wide variety of foods. Recent technical advances have added to the range of sugar alcohols available for food use and expanded the applications of these sugar replacers in diet and health-oriented foods. They have been found useful in sugar-free and reduced-sugar products, in foods intended for individuals with diabetes, and most recently in new products developed for carbohydrate controlled eating plans. Sugar alcohols are neither sugars nor alcohols. They are carbohydrates with a chemical structure that partially resembles sugar and partially resembles alcohol, but they don’t contain ethanol as alcoholic beverages do. They are incompletely absorbed and metabolized by the body, and consequently contribute fewer calories. The polyols commonly used include sorbitol, mannitol, xylitol, maltitol, maltitol syrup, lactitol, erythritol, isomalt and hydrogenated starch hydrolysates. Their calorie content ranges from 1.5 to 3 calories per gram compared to 4 calories per gram for sucrose or other sugars. Most are approximately half as sweet as sucrose; maltitol and xylitol are about as sweet as sucrose. Sugar alcohols occur naturally in a wide variety of fruits and vegetables, but are commercially produced from other carbohydrates such as sucrose, glucose, and starch. Along with adding a sweet taste, polyols perform a variety of functions such as adding bulk and texture, providing a cooling effect or taste, inhibiting the browning that occurs during heating and retaining moisture in foods. While polyols do not actually prevent browning, they do not cause browning either. -

(T-Butanol) in Frozen and Freeze-Dried Formulations

WEBINAR TECH NOTE Role of Organic Co-Solvent (t-Butanol) in Frozen and Freeze-Dried Formulations hydrophobic drugs, decreased drying time, improved product Jayesh Sonje, Ph.D. Candidate stability and reconstitution characteristics2. Department of Pharmaceutics, University of Minnesota, USA TBA has a high freezing point of 24°C which means it is mostly April 22nd, 2021 crystalline at room temperature and sublimes during freezing. It can completely crystallize with long needle-shaped ice crystals during the freezing stage and produce a lower cake resistance In the last year, more than 40% of drugs approved by the FDA with a higher specific surface area during the drying stage. These have been lyophilized1. Lyophilization stabilizes the drug product properties help reduce drying times from 100 hours (with 5% w/v and enables a longer shelf life at room temperature with easier sucrose) to 10 hours (with 5% w/v sucrose plus 5% w/v TBA) which transportation. will significantly shorten the manufacturing of a drug product3. However, the processing steps (freezing, primary drying and In addition, TBA improves the stability of the drug as was secondary drying) involved in the lyophilization process can demonstrated for the approved Pfizer drug, Caverject® where the expose the proteins to various stress and harsh conditions, leading addition of 20% v/v TBA solution increased stabilization of the to denaturation, aggregation and sometimes a loss of functionality. active ingredient, alprostadil2. To overcome these stresses experienced by protein throughout freezing, drying and storage use of cryo- or lyo-protectants in Thermal Behavior of TBA-Water certain ratios is a central theme in formulation development. -

Etherification Process for Hexitols and Anhydrohexitols

Europâisches Patentamt è European Patent Office @ Publication number: 0 092 998 B1 Office européen des brevets EUROPEAN PATENT SPECIFICATION © Date of publication of the patent spécification : © mt. ci.*: C 07 C 41/16, C 07 C 43/10, 12.03.86 C 07 D 307/12, C 07 D 493/04 @ Application number: 83302312.0 @ Date of f iling : 22.04.83 H> Etherification process for hexitols and anhydrohexitols. © Priority: 28.04.82 US 372623 Proprietor: ICI AMERICAS INC, Concord Pike & New Murphy Road, Wilmington Delaware 19897 (US) Date of publication of application: 02.11.83 Bulletin 83/44 Inventor: Kruse, Walter Max, 1 Woodbury Court, Wilmington Delaware 19805 (US) Inventor: Stephen, John Fergus, 200 William Penn Blvd., Publication of the grant of the patent : West Chester, PA 19380 (US) 12.03.86 Bulletin 86/11 (74) Représentative: Colens, Alain M. G. M. et al, Impérial @ Designated Contracting States: Chemical Industries PLC Légal Department: Patents AT BE CH DE FR GB IT Ll LU NL SE P.O. Box 6 Bessemer Road, Welwyn Garden City Hertfordshire AL7 1 HD (GB) (§§) Références cited: AT- B- 258 870 DE-A-3038 996 DE -C -510423 GB -A- 988 123 ^ US-A-3840605 10 00 O) 0) CI o © Note: Within nine months from the publication of the mention of the grant of the European patent, any person may give notice to the European Patent Office of opposition to the European patent granted. Notice of opposition shall be f iled in a written reasoned A statement. It shall not be deemed to have been filed until the opposition fee has been paid (Art. -

A Randomized Clinical Trial Evaluating Mannitol, Lactitol, and Polyethylene Glycol Macrogol As Oral Solutions for Colonoscopy Preparation

International Journal of Gastroenterology 2020; 4(2): 54-62 http://www.sciencepublishinggroup.com/j/ijg doi: 10.11648/j.ijg.20200402.16 ISSN: 2640-1681 (Print); ISSN: 2640-169X (Online) A Randomized Clinical Trial Evaluating Mannitol, Lactitol, and Polyethylene Glycol Macrogol as Oral Solutions for Colonoscopy Preparation Lourianne Nascimento Cavalcante 1, 2, *, Adriana Ribas 1, Alexandre Pithon Lins 1, Luciana Rodrigues Leal da Silva 1, Flora Maria Lorenzo Fortes 1, Valdeck Sodre Bispo Jr 1, Marcus Vinicius Matos de Almeida 1, Maira Cintra de Oliveira 1, Camila Silveira 1, Marcos Clarencio Batista 1, Igelmar Barreto Paes 1, 2 1Hospital Geral Roberto Santos, Digestive Endoscopy and Gastroenterology Services, Salvador, Bahia, Brazil 2Medicine School, Federal University of Bahia, Salvador, Bahia, Brazil Email address: *Corresponding author To cite this article: Lourianne Nascimento Cavalcante, Adriana Ribas, Alexandre Pithon Lins, Luciana Rodrigues Leal da Silva, Flora Maria Lorenzo Fortes, Valdeck Sodre Bispo Jr, Marcus Vinicius Matos de Almeida, Maira Cintra de Oliveira, Camila Silveira, Marcos Clarencio Batista, Igelmar Barreto Paes. A Randomized Clinical Trial Evaluating Mannitol, Lactitol, and Polyethylene Glycol Macrogol as Oral Solutions for Colonoscopy Preparation. International Journal of Gastroenterology . Vol. 4, No. 2, 2020, pp. 54-62. doi: 10.11648/j.ijg.20200402.16 Received : August 11, 2020; Accepted : August 26, 2020; Published : September 23, 2020 Abstract: Colonoscopy is an important tool for diagnosing and treating bowel injuries and reducing colorectal cancer incidence. Adequate bowel preparation is necessary to ensure the effectiveness of the procedure for detecting injuries. In this trial the aim was to compare effectiveness of lactitol, mannitol, and polyethylene glycol (PEG) oral solutions for bowel cleansing prior to colonoscopy.