Logan Enhancement Project

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

RACQ Ipswich Motorway Policy Analysis

Policy Analysis 9/05 Economic & Public Policy Ipswich Motorway Introduction The Ipswich Motorway is a vital link between Brisbane and Ipswich. It connects Ipswich and Granard Roads at Rocklea to the Warrego and Cunningham Highways and Brisbane Road at Dinmore. For many years, it formed part of the National Highway System (NHS), which was a Commonwealth Government funding responsibility. Since the release of the Commonwealth’s AusLink land transport policy in June 2004, the Ipswich Motorway has been part of a broader National Network. The AusLink policy decreed that the states must share costs of the National Network, particularly in urban areas. The Ipswich Motorway is one of Queensland’s most congested roads, with stop-start conditions during morning and afternoon peak periods. It also has one of the highest vehicle accident rates in Queensland. Yet, the upgrading of this hopelessly inadequate and dangerous road has been subjected to extraordinary delays because of political bickering and dithering. This document summarises the history of recent proposals to upgrade the Ipswich Motorway, analyses Commonwealth and State Government policies regarding the road, and outlines RACQ’s position. Background The Ipswich Motorway upgrade project has been dogged by delays, conflict between governments, and political manoeuvring. In the meantime, road trauma and congestion continue to worsen on this very sub-standard stretch of the National Network. The following brief chronology highlights key events in this sad, sorry saga. 1997 The Integrated Regional Transport Plan for South East Queensland, which was released in 1997, proposed commencement in 1997-98 of a major investigation in respect of an Ipswich Motorway upgrade. -

Toll Roads - National Cover Australian Toll Roads

Toll Roads - National Cover Australian Toll Roads Roam Express offers a visitor e-pass which is valid for up Please be aware that toll fees apply on some roads in to 30 days on all Australian toll roads. Australia. A visitor E-Pass can be set up before or within 48 hours of You will likely encounter toll roads if you are driving through your first trip to cover travel on all Australian toll roads. Metropolitan New South Wales, Queensland and Victoria. When driving a thl rental vehicle in Australia you are responsible for paying toll fees, so it is important to be aware of these roads before you travel. As most toll roads in Australia Roam Contact Details are electronically tolled, you will not be able to stop and pay Ph: 13 76 26 cash. www.roamexpress.com.au Please refer to this brochure which provides an overview of all International Callers: +61 2 9086 6400 Australian toll roads as well as information on how to pay for toll travel. Bitte beachten Sie, dass einige Strassen Zahlungspflichtig 17 16 15 Castle Hill 14 sind in Australien. 13 Die Mautstrassen befinden sich in New South Wales, Queensland 18 10 12 M2 und Victoria. 11 9 Manly Wenn Sie ein Wohnmobil von thl gemietet haben in Australien 19 sind Sie verantwortlich die Gebuehren zu zahlen, deshalb ist es 44 20 Paramatta 8 wichtig dass Sie sich ueber diese Strassen informieren. Die moisten 21 7 Mautstrassen sind elektronisch und Sie koennen nicht Bar bezahlen 22 Harbour 6 oder anhalten. Eastern Bridge 5 Sydney 4 Bitte beachten Sie die Broschure die Sie in Ihren Unterlagen Creek M7 CBD 2 3 bekommen wo diese Strassen sind und wie Sie bezahlen koennen. -

F6 Integrated Transport and Movement

F6 Integrated Transport and Movement Vision Statement and Action Plan Framework - November 2005 IPSWICH2020ANDBEYOND IPSWICH2020ANDBEYOND Integrated Transport and Movement Ipswich City is the Motorway is now up to Ø Cunningham Highway to 6.2 Summary of Ø Identify and align the transport Strategy ITM 1.4 100 000 vehicles a day during the Warrego Highway connection priorities and objectives for well-serviced by busiest days of the week, The (pending Goodna Bypass and Goals and Ipswich of all stakeholders. A Safe Transport Network: Ensure mixture of cars and freight River Road Investigation). that residents feel safe travelling an integrated transport vehicles is problematic. Strategies - throughout Ipswich. Ø Extension of Centenary Strategy ITM 1.2 public transport To address the transport issues in Highway - Springfield to Ripley Integrated Ipswich a number of major Ø Develop and implement Bus and roads system to Yamanto. infrastructure projects have been Transport Connected Centres: Ensure that Stop and Station Design that effectively proposed in the State SEQ centres are connected and enable Guidelines. Infrastructure Plan and Program Ø Centenary Highway four and efficient movement between eliminates (2005) including: lanes - Ipswich Motorway to communities. Ø Provide real time service Springfield. Movement updates at major bus stops. congestion, Ø Ø Ipswich rail line third track Provide a loop bus service that conserves Corinda-Darra and Darra- Ø Western Ipswich Bypass ITM Goal 1 - connects major centres in Ø Identify and implement safety Ipswich. community Redbank. (Haigslea to Amberley). Connected measures around transport interchanges and rail stations. Ø character and Ø Springfield passenger rail line. Ø Cunningham Highway four Communities Investigate and implement lanes - Ripley Road to public transport services to Ø Improve security services on enhances Ebenezer. -

GREATER BRISBANE AERIAL MAP Brisbane

3 Port of GREATER BRISBANE AERIAL MAP Brisbane Br u c e Highway Brisbane Airport All roads lead to Greater Springfield... Pacific Ocean Greater Springfield has been designed to be accessed from all 4 directions North, South, East and West. Northern Access Route Allows Access to: • Brisbane and the inner city fringe suburbs can be • Ipswich, Ripley Valley, Toowoomba, Ebenezer (twice the • Brisbane CBD • Inner fringe suburbs accessed to the north, within a drive time of size of any other industrial area in close proximity to Brisbane 32 minutes via the Centenary Highway. Brisbane) and the inland port of Purga are accessible Brisbane River 17 to the west via the Centenary and Warrego Highway. CBD • Greenbank, Logan City and Jimboomba are Northern Access Route accessible to the south via the Springfield • Port of Brisbane and Brisbane Airport are accessible, Allows Access to: Greenbank Arterial and Mt Lindsay Highway. without having to through any traffic lights, via the Mount • Brisbane Airport Coot-Tha • Port of Brisbane Logan and Gateway Motorway. ay ew • Southport and the Gold Coast are accessed to the re F n east by the Logan Motorway and can be reached r e t s within a 50 minute drive time. e W Indooroopilly 1 y a w r S o o t u o t h M E B 15 y a r a i s w s t b e F t a r a y n e G a e e V w w a h a Tingalpa l g le i y y H Reservoir H y i r g a h n w Mt Gravatt e a t y n Regional Centre e Mount C Ommaney W torway 3 arrego H ch Mo ighway Ipswi ghway ego Hi Warr 54 Sunnybank s s a P p acifi y y a B w c Highway e h n Ipswich g a i sb H -

Table 4-1: 2019-2031 Projects – Base Scenario Key: Road / Public

Table 4-1: 2019-2031 Projects – Base Scenario Key: Road / Public & Active Transport No. Project Description Notes Transport Council Region Type 1 Sunshine Coast Light Rail (Stage 1) Kawana to the Maroochydore CBD via Project focused on connecting the northern Sunshine Coast Mooloolaba parts of the SCRC Enterprise Corridor 2 Sunshine Motorway Upgrade Upgrade to 4 lanes from Kawana Way to the MRI Sunshine Coast Projects and an upgrade to 6 lanes from the Mooloolaba Road interchange to the MRI 3 North Coast Rail Line Duplication Urban Passenger Rail Line Duplication for the Partial funding committed for the full Sunshine Coast (Beerburrum to Nambour Project) Beerburrum to Landsborough Section $722M project (B2N) 4 Bruce Highway Upgrade Projects 6 lane upgrade Bribie Island Road to Caloundra Moreton Bay; Sunshine Road and interchange upgrade at Deception Bay Coast; Somerset Road 5 North South Urban Arterial Pine River Crossing to Boundary Road (remaining Also related to the Strathpine East Arterial Moreton Bay (NSUA) sections) 6 North-West Transport Corridor Urban passenger rail and 4 lane urban motorway Brisbane; Moreton Bay (NWTC) from Bald Hills to Stafford Road (road) and Alderley Station (rail) 7 Cross River Rail Project Dutton Park to Mayne Rail Yards Fully committed funding Brisbane 8 Centenary Motorway Upgrade Moggill Road to Sumners Road Interchange 6 $65M for Sumners Road Interchange Brisbane; Ipswich Projects lanes; Logan Motorway to Springfield and Springfield to Yamanto (4 lane upgrade) 9 Cleveland Rail Line Duplication Manly to Cleveland Rail Line Duplication Redland 10 Norman Street Bridge New river crossing of the Bremer River in the Ipswich centre of Ipswich No. -

1 Approach and Highlights

Capital Statement 2020-21 1 Approach and highlights Features • The Queensland Government’s ongoing commitment to delivering and facilitating productivity-enhancing and catalytic infrastructure will continue to support economic recovery, resilience and future prosperity, as well as more broadly drive sustainable economic growth, increased employment opportunities and higher living standards. • The substantial capital program outlined in this Budget supports the Palaszczuk Government’s infrastructure commitment to invest $56.031 billion over four years throughout Queensland. This investment is critical to enhance business productivity, connectivity and overall long-term competitiveness, while ensuring that essential services, such as health care and education, are accessible to all Queensland communities and regions. • In 2020-21, the government will invest $14.835 billion on capital across the state. The capital program is important in directly supporting construction-related jobs in the short to medium term, with the capital program in 2020-21 estimated to support around 46,000 jobs, including 28,700 jobs outside of Greater Brisbane. • In 2020-21, the government will deliver a $6.267 billion investment in transformative transport infrastructure. Highlights of the 2020-21 transport capital program include $1.514 billion to continue construction work on Cross River Rail and substantial ongoing investment to fund major upgrades to the M1 Pacific Motorway and the Bruce Highway. • Capital expenditure to support the delivery of health services is $1.625 billion in 2020-21. The government is providing $265 million to build seven satellite hospitals to enable our acute hospitals to continue safely managing patients via alternative models of care across South East Queensland. -

WEEKLY HANSARD Hansard Home Page: E-Mail: [email protected] Phone: (07) 3406 7314 Fax: (07) 3210 0182

PROOF ISSN 1322-0330 WEEKLY HANSARD Hansard Home Page: http://www.parliament.qld.gov.au/hansard/ E-mail: [email protected] Phone: (07) 3406 7314 Fax: (07) 3210 0182 51ST PARLIAMENT Subject CONTENTS Page Thursday, 17 June 2004 PRIVILEGE ..................................................................................................................................................................................... 1509 Questions on Notice ........................................................................................................................................................... 1509 PETITIONS ..................................................................................................................................................................................... 1509 MINISTERIAL STATEMENT .......................................................................................................................................................... 1510 Cutting Edge ....................................................................................................................................................................... 1510 MINISTERIAL STATEMENT .......................................................................................................................................................... 1510 Proposed New Standing Orders; Mr C. Schneider ............................................................................................................. 1510 MINISTERIAL STATEMENT ......................................................................................................................................................... -

Rochedale-11-Interchange-IM.Pdf

Space for: going places ROCHEDALE MOTORWAY ESTATE UNIT 2, 11 INTERCHANGE PLACE, ROCHEDALE, QLD OVERVIEW 2 Opportunity Rochedale Motorway Estate is located within Brisbane’s newest industrial precinct on the Gateway Motorway providing unrivalled access to Brisbane’s metropolitan areas. Only one opportunity remains within the estate, with 2,753 sqm available for lease. Now is the time to join Woolworths, Chep, Beaumont Tiles, Amart Furniture, JFC Australia and be part of this brand new masterplanned estate. Franklyn’s 8,019 sqm warehouse, showroom Artist’s impression and national head office VIEW FROM ABOVE 3 Brisbane CBD Mount Gravatt-Capalaba Road Chep - under construction Franklyn Moreton Hire JFC Unit 2 Woolworths - under construction Gateway Motorway Beaumont Tiles Amart Furniture Keppel Logistics Gardner Road Artist’s impression VIEW FROM ABOVE 4 Woolworths Beaumont Tiles Keppel Logistics - under construction Chep Gardner Road - under construction Unit 2 Mount Gravatt-Capalaba Road Gateway Motorway Full 4-way Motorway Interchange Artist’s impression VIEW FROM ABOVE – UNIT 2, WOOLWORTHS AND CHEP 5 Brisbane CBD Chep - under construction Unit 2 Woolworths - under construction Artist’s impression VIEW FROM ABOVE – UNIT 2, WOOLWORTHS AND CHEP 6 Chep - under construction Woolworths - under construction Unit 2 Artist’s impression ACCESS 7 To/from Port of Brisbane To Brisbane CBD and Brisbane Airport Access from major arterials to Rochedale Motorway Estate Mackenzie Mount Gravatt Mount Gravatt-Capalaba Road G r ie v e Rochedale Motorway Estate -

South East Queensland Regional Plan 2017 Shapingseq

South East Queensland Regional Plan 2017 ShapingSEQ Consultation report August 2017 This report provides an overview of the statutory and non-statutory consultation undertaken on the draft South East Queensland Regional Plan 2016 (draft ShapingSEQ). The findings of this report have been considered by the Minister for Infrastructure and Planning, and where relevant have been incorporated into the final ShapingSEQ. © State of Queensland, August 2017. Published by the Department of Infrastructure, Local Government and Planning, 1 William Street, Brisbane Qld 4000, Australia. Licence: This work is licensed under the Creative Commons CC BY 4.0 Australia Licence. In essence, you are free to copy and distribute this material in any format, as long as you attribute the work to the State of Queensland (Department of Infrastructure, Local Government and Planning) and indicate if any changes have been made. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. Attribution: The State of Queensland, Department of Infrastructure, Local Government and Planning. The Queensland Government supports and encourages the dissemination and exchange of information. However, copyright protects this publication. The State of Queensland has no objection to this material being reproduced, made available online or electronically but only if it is recognised as the owner of the copyright and this material remains unaltered. The Queensland Government is committed to providing accessible services to Queenslanders of all cultural and linguistic backgrounds. If you have difficulty understanding this publication and need a translator, please call the Translating and Interpreting Service (TIS National) on 131 450 and ask them to telephone the Queensland Department of Infrastructure, Local Government and Planning on 13 QGOV (13 74 68). -

Queensland Transport and Roads Investment Program for 2021–22 To

Metropolitan 2,965 km2 Area covered by location1 32.10% Population of Queensland1 438 km Other state-controlled road network 89 km National Land Transport Network2 88 km National rail network See references section (notes for map pages) for further details on footnotes. Brisbane Office 313 Adelaide Street | Brisbane | Qld 4000 PO Box 70 | Brisbane | Qld 4000 (07) 3066 4338 | [email protected] Program Highlights • continue design and construction of the Salisbury Future Plans park ‘n’ ride upgrade We continue to plan for the future transport requirements of Metropolitan. In 2020–21 we completed: • complete construction of the Carseldine park ‘n’ ride upgrade In 2021–22 key planning includes: • the Ipswich Motorway (Rocklea – Darra) Stage 1 project, to upgrade the motorway from four to six • commence construction for the upgrade of • continue planning of the Boundary Road rail level lanes from just east of the Oxley Road roundabout Cleveland – Redland Bay Road between Anita Street crossing removal at Coopers Plains to the Granard Road interchange at Rocklea, jointly and Magnolia Parade, as part of the Queensland funded by the Australian Government and Queensland Government’s COVID-19 economic recovery response • continue planning of the Beams Road rail level Government crossing at Carseldine and Fitzgibbon • continue planning for the upgrade of the Centenary • the Sumners Road interchange upgrade over the Motorway and Logan Motorway interchange, as part • continue planning for six lanes on the Gateway Centenary Motorway of the Queensland Government’s COVID-19 economic Motorway from Bracken Ridge to Pine River recovery response • strengthening work on the Gateway Motorway Flyover, • continue planning for the Lindum station precinct. -

Logan Enhancement Project Newsletter

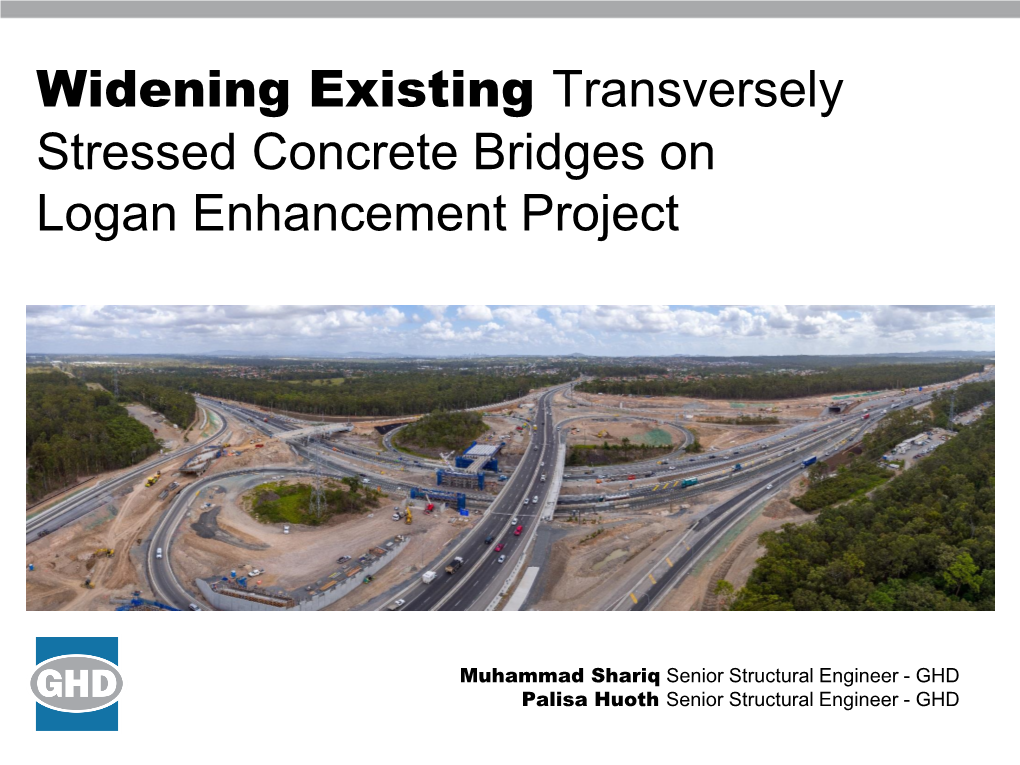

LOGAN ENHANCEMENT PROJECT NOVEMBER 2015 Delivering a safer and more efficient motorway The Logan Enhancement Project offers an integrated transport solution to unlock the economic potential of the Logan region. Through the life of the project, it will create more than 1,300 direct construction jobs, and will generate more than $1.2bn in economic benefits for Queenslanders. The project will deliver benefits for both motorists on the Logan Motorway, and for the wider road network, including: • a safer and more efficient motorway network by relieving local traffic congestion • reduced travel times • improved travel time reliability • reduced rat running on local streets by separating through traffic from local traffic • enhanced connectivity with other Driving jobs and major road networks. economic growth for FAST FACTS Queensland $450M PROJECT UPGRADES AT KEY CONGESTION Transurban Queensland, operator and manager of the HOT SPOTS go via network, in collaboration with the Queensland IMPROVED SAFETY, EFFICIENCY Government, has developed a proposal for an innovative AND PRODUCTIVITY FOR new road project set to drive jobs and economic growth for MOTORISTS Queensland—the $450 million Logan Enhancement Project. 1,300 DIRECT CONSTRUCTION JOBS CREATED If approved, the project will deliver key congestion hot spots along the a safer and more efficient motorway Logan Motorway, widening parts of network by relieving local traffic the Logan Motorway and Gateway congestion, reducing travel times Extension Motorway and constructing and enhancing connectivity -

Greater Brisbane Aerial Map Brisbane

3 Port of Greater Brisbane Aerial Map Brisbane Br uce Hi Brisbane ghway Airport All roads lead to Greater Springfield... Pacific Ocean Greater Springfield has been designed to be accessed from all 4 directions North, South, East and West. Northern Access Route • Brisbane and the inner city fringe suburbs can be • Port of Brisbane and Brisbane Airport are accessible, Allows Access to: • Brisbane CBD accessed to the north, within a drive time of without having to through any traffic lights, via the • Inner fringe suburbs 32 minutes via the Centenary Highway. Logan and Gateway Motorway. Brisbane River 17 Brisbane • Greenbank, Logan City and Jimboomba are • In February 2011, the State Government committed CBD Northern Access Route accessible to the south via the Springfield to extend the railway from Richlands to Springfield Greenbank Arterial and Mt Lindsay Highway. through the establishment of two railway stations Allows Access to: Mount • Brisbane Airport by 2013. • Port of Brisbane • Southport and the Gold Coast are accessed to the Coot-Tha y wa ree east by the Logan Motorway and can be reached F n r within a 50 minute drive time. e t s e • Ipswich, Ripley Valley, Toowoomba, Ebenezer (twice the W 1 Indooroopilly size of any other industrial area in close proximity to y a Brisbane) and the inland port of Purga are accessible w r o So t to the west via the Centenary and Warrego Highway. u o t h M 15 E B y a r a i s s t w b e F t a y r a n a e e e G w w V h a a Tingalpa g l i le y H y Reservoir y H r i a g h n e Mt Gravatt w t a n Regional