Gravitational Torsion Balance Manual Is Copyrighted and All Rights Reserved

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Measuring Gravity

Physics Measuring Gravity Sir Isaac Newton told us how important gravity is, but left some gaps in the story. Today scientists are measuring the gravitational forces on individual atoms in an effort to plug those gaps. This is a print version of an interactive online lesson. To sign up for the real thing or for curriculum details about the lesson go to www.cosmoslessons.com Introduction: Measuring Gravity Over 300 years ago the famous English physicist, Sir Isaac Newton, had the incredible insight that gravity, which we’re so familiar with on Earth, is the same force that holds the solar system together. Suddenly the orbits of the planets made sense, but a mystery still remained. To calculate the gravitational attraction between two objects Newton needed to know the overall strength of gravity. This is set by the universal gravitational constant “G” – commonly known as “big G” – and Newton wasn't able to calculate it. Part of the problem is that gravity is very weak – compare the electric force, which is 1040 times stronger. That’s a bigger di혯erence than between the size of an atom and the whole universe! Newton's work began a story to discover the value of G that continues to the present day. For around a century little progress was made. Then British scientist Henry Cavendish got a measurement from an experiment using 160 kg lead balls. It was astoundingly accurate. Since then scientists have continued in their attempts to measure G. Even today, despite all of our technological advances (we live in an age where we can manipulate individual electrons and measure things that take trillionths of a second), di혯erent experiments produce signicantly di혯erent results. -

Cavendish Weighs the Earth, 1797

CAVENDISH WEIGHS THE EARTH Newton's law of gravitation tells us that any two bodies attract each other{not just the Earth and an apple, or the Earth and the Moon, but also two apples! We don't feel the attraction between two apples if we hold one in each hand, as we do the attraction of two magnets, but according to Newton's law, the two apples should attract each other. If that is really true, it might perhaps be possible to directly observe the force of attraction between two objects in a laboratory. The \great moment" when that was done came on August 5, 1797, in a garden shed in suburban London. The experimenter was Lord Henry Cavendish. Cavendish had inherited a fortune, and was therefore free to follow his inclinations, which turned out to be scientific. In addition to the famous experiment described here, he was also the discoverer of “inflammable air", now known as hydrogen. In those days, science in England was often pursued by private citizens of means, who communicated through the Royal Society. Although Cavendish studied at Cambridge for three years, the universities were not yet centers of scientific research. Let us turn now to a calculation. How much should the force of gravity between two apples actually amount to? Since the attraction between two objects is proportional to the product of their masses, the attraction between the apples should be the weight of an apple times the ratio of the mass of an apple to the mass of the Earth. The weight of an apple is, according to Newton, the force of attraction between the apple and the Earth: GMm W = R2 where G is the \gravitational constant", M the mass of the Earth, m the mass of an apple, and R the radius of the Earth. -

Gravity and Coulomb's

Gravity operates by the inverse square law (source Hyperphysics) A main objective in this lesson is that you understand the basic notion of “inverse square” relationships. There are a small number (perhaps less than 25) general paradigms of nature that if you make them part of your basic view of nature they will help you greatly in your understanding of how nature operates. Gravity is the weakest of the four fundamental forces, yet it is the dominant force in the universe for shaping the large-scale structure of galaxies, stars, etc. The gravitational force between two masses m1 and m2 is given by the relationship: This is often called the "universal law of gravitation" and G the universal gravitation constant. It is an example of an inverse square law force. The force is always attractive and acts along the line joining the centers of mass of the two masses. The forces on the two masses are equal in size but opposite in direction, obeying Newton's third law. You should notice that the universal gravitational constant is REALLY small so gravity is considered a very weak force. The gravity force has the same form as Coulomb's law for the forces between electric charges, i.e., it is an inverse square law force which depends upon the product of the two interacting sources. This led Einstein to start with the electromagnetic force and gravity as the first attempt to demonstrate the unification of the fundamental forces. It turns out that this was the wrong place to start, and that gravity will be the last of the forces to unify with the other three forces. -

Probing Gravity at Short Distances Using Time Lens

Probing Short Distance Gravity using Temporal Lensing Mir Faizal1;2;3, Hrishikesh Patel4 1Department of Physics and Astronomy, University of Lethbridge, Lethbridge, AB T1K 3M4, Canada 2Irving K. Barber School of Arts and Sciences, University of British Columbia Okanagan Campus, Kelowna, V1V1V7, Canada 3Canadian Quantum Research Center, 204-3002, 32 Ave, Vernon, BC, V1T 2L7, Canada 4Department of Physics and Astronomy, University of British Columbia, 6224 Agricultural Road, Vancouver, V6T 1Z1, Canada Abstract It is known that probing gravity in the submillimeter-micrometer range is difficult due to the relative weakness of the gravitational force. We intend to overcome this challenge by using extreme temporal precision to monitor transient events in a gravitational field. We propose a compressed ultrafast photography system called T-CUP to serve this purpose. We show that the T-CUP's precision of 10 trillion frames per second can allow us to better resolve gravity at short distances. We also show the feasibility of the setup in measuring Yukawa and power-law corrections to gravity which have substantial theoretical motivation. 1 Introduction General Relativity (GR) has been tested at large distances, and it has been arXiv:2003.02924v2 [gr-qc] 29 Jun 2021 realized that we need a more comprehensive model of gravity that aligns with our measurements of gravity at long distances and short distances. Several ad- vances have been made in trying to understand gravity at long distances since the advent of multi-messenger astronomy [1, 2]. However, it is possible to relate the large distance corrections to the short distance corrections. In fact, several theories like MOND [3, 4] have been proposed to explain the large distance corrections to gravitational dynamics due to small accelerations. -

Universal Gravitational Constant EX-9908 Page 1 of 13

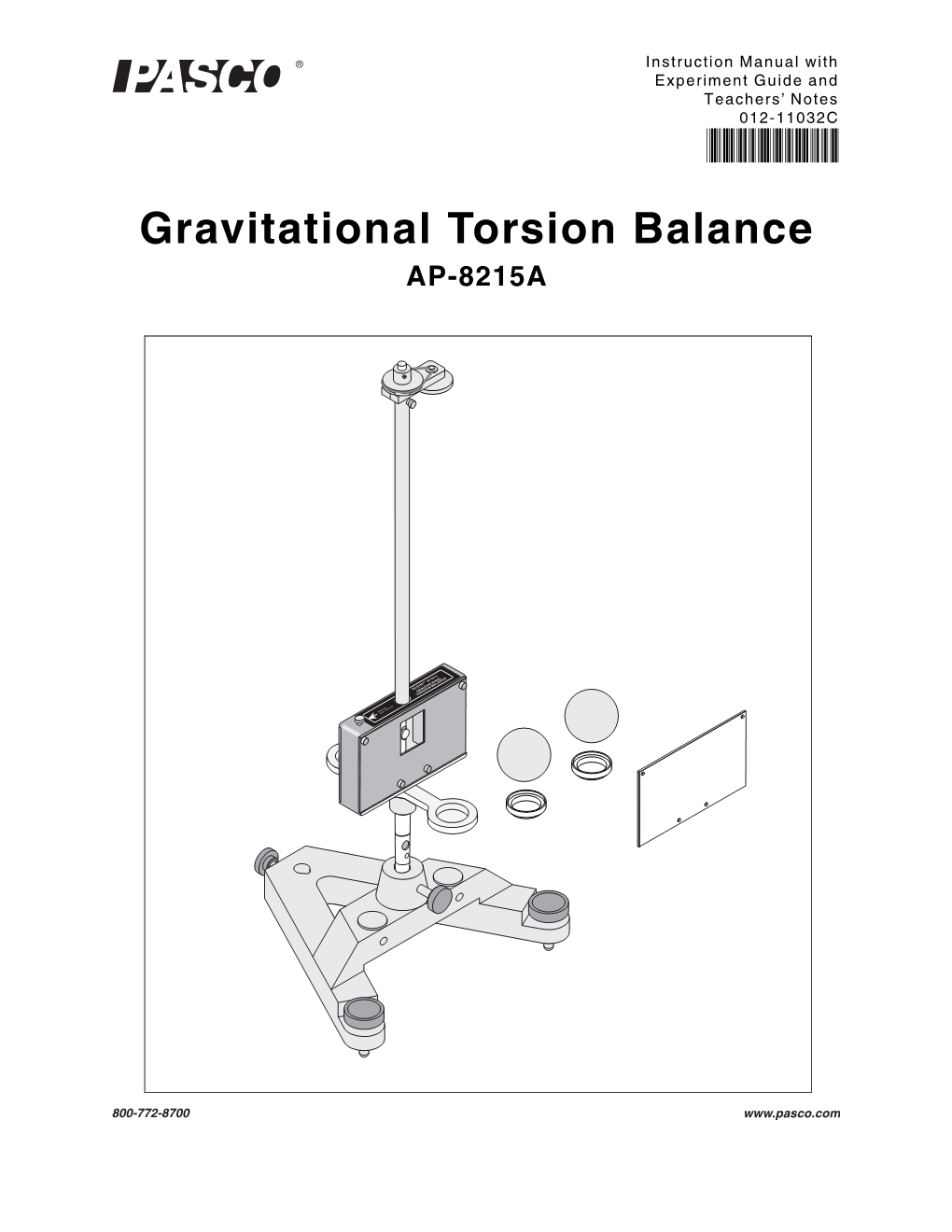

Universal Gravitational Constant EX-9908 Page 1 of 13 Universal Gravitational Constant EQUIPMENT 1 Gravitational Torsion Balance AP-8215 1 X-Y Adjustable Diode Laser OS-8526A 1 45 cm Steel Rod ME-8736 1 Large Table Clamp ME-9472 1 Meter Stick SE-7333 INTRODUCTION The Gravitational Torsion Balance reprises one of the great experiments in the history of physics—the measurement of the gravitational constant, as performed by Henry Cavendish in 1798. The Gravitational Torsion Balance consists of two 38.3 gram masses suspended from a highly sensitive torsion ribbon and two1.5 kilogram masses that can be positioned as required. The Gravitational Torsion Balance is oriented so the force of gravity between the small balls and the earth is negated (the pendulum is nearly perfectly aligned vertically and horizontally). The large masses are brought near the smaller masses, and the gravitational force between the large and small masses is measured by observing the twist of the torsion ribbon. An optical lever, produced by a laser light source and a mirror affixed to the torsion pendulum, is used to accurately measure the small twist of the ribbon. THEORY The gravitational attraction of all objects toward the Earth is obvious. The gravitational attraction of every object to every other object, however, is anything but obvious. Despite the lack of direct evidence for any such attraction between everyday objects, Isaac Newton was able to deduce his law of universal gravitation. Newton’s law of universal gravitation: m m F G 1 2 r 2 where m1 and m2 are the masses of the objects, r is the distance between them, and G = 6.67 x 10-11 Nm2/kg2 However, in Newton's time, every measurable example of this gravitational force included the Earth as one of the masses. -

Observing the Gravitational Constant G Underneath Two Pump Storage Reservoirs Near Vianden (Luxembourg)

Universität Stuttgart Geodätisches Institut Observing the gravitational constant G underneath two pump storage reservoirs near Vianden (Luxembourg) Function fit 1012 10 5 Function value 0 0 5 510 505 10 500 Water temperature 15 495 Water level Bachelorarbeit im Studiengang Geodäsie und Geoinformatik an der Universität Stuttgart Tobias Schröder Stuttgart, September 2017 Betreuer: Prof. Dr.-Ing. Nico Sneeuw Universität Stuttgart Prof. Dr. Olivier Francis Université du Luxembourg Erklärung der Urheberschaft Ich erkläre hiermit an Eides statt, dass ich die vorliegende Arbeit ohne Hilfe Dritter und ohne Benutzung anderer als der angegebenen Hilfsmittel angefertigt habe; die aus fremden Quellen direkt oder indirekt übernommenen Gedanken sind als solche kenntlich gemacht. Die Arbeit wurde bisher in gleicher oder ähnlicher Form in keiner anderen Prüfungsbehörde vorgelegt und auch noch nicht veröffentlicht. Stuttgart, 30. September 2017 Unterschrift III Abstract The aim of this thesis is to extract the gravitational constant G from relative gravity measure- ments underneath two artificial reservoirs in Vianden (Luxembourg). If one wants to deter- mine the Newtonian constant G from measurements many variables play a role, like water level, density and temperature. All of them are measured, while the gravimeter is measuring the gravitational attraction. To extract the gravitational constant G it is important to know the gravitational attraction of each point inside the reservoir. For this calculation the 3D models of the lakes are filled with tiny cubes, from which the exact integral to calculate their gravitational attraction to the gravimeter is known. Calculated values are compared to the measured ones which makes it possible to extract the searched gravitational constant G. -

The Cavendish Experiment

The Cavendish Experiment 1 Introduction In 1687 Newton published the Principia in which he presented a mathematical de- scription of the gravitational force. In Newton’s theory of gravitation the gravitational attraction, F , exerted by one object on another is expressed according to the relation- ship m m F = G l s : (1.1) R2 The quantities ml and ms are the masses of two objects whose spatial separation is R. The value of the constant of proportionality, G, was not known to Newton and, in fact, was not accurately determined until the latter half of the nineteenth century. The calculation of its value was based on the results of an experiment to determine the density of the earth performed by Henry Cavendish, and published in 1798.1 The purpose of this experiment is to perform a modern version of the Cavendish experiment, determine the gravitational constant, G, and compare it to its accepted value. 2 Theory The primary apparatus used to perform this experiment is the torsion balance which is shown in Figure 1. The torsion balance is depicted in Figure 2 with relevant compo- nents labeled for illustrative purposes. Initially, the internal boom is at rest. Then the two large masses are put in place and attract the two smaller masses causing a torque to be exerted on the internal boom so that the it rotates from its initial point of equilib- rium. As the boom rotates, the thin wire which is fixed at the top twists until the wire exerts a counter torque on the boom. If the rotational kinetic energy is dissipated, the boom will come to rest at a new point of equilibrium so that the following relationship for the the torques is satisfied: 2F d = kθD : (2.1) The term on the right of the equality is the counter torque resulting from the wire. -

The Cavendish Experiment 2 Weights

The Cavendish Experiment 2 weights ATTENTION!!! Entering the lab and approaching the setup, don’t touch anything until you study the handout thoroughly. Re-alignment and rebuilding of the apparatus will take more than 24 hours!!! References: Leybold, "Directions for use: Gravitation Torsion Balance" (available from the Resource Centre) Leybold Physics Leaflets: http://downloads.gphysics.net/leybold/EXP/HB/E/P1/P1131_E.PDF The references give some useful data about the apparatus; however, the description of the method should be taken from this handout. You will also need a textbook “Physics for Scientists and Engineers”, Volume 1, 8 th Edition, by R. A. Serway and J. W. Jewett; for theory of torsional pendulum in Chapter 15, p. 451; and theory of universal gravitation in Chapter 13. Introduction The Cavendish experiment was the first to allow a calculation of the gravitational constant (G) by measuring the force of gravity between two masses in a laboratory framework. The original experiment was proposed by John Michell (1724-1793), who first constructed a torsion balance apparatus. In 1793 the apparatus passed to Henry Cavendish who carried out a series of experiments published in 1798 1. The original apparatus included a 1.8 m wooden rod with metal spheres attached to each end, suspended from a wire. Five 350 lb (195 kg) lead balls were placed nearby. The gravitational force exerted on the end weights was enough to cause the wire to twist. From the twisting torque on the wire and the known masses of the spheres, Cavendish was able to calculate the value of the gravitational constant. -

The Cavendish Experiment Measurement of the Gravitational Constant

June 7, 2001 Massachusetts Institute of Technology Physics Department 8.13/8.14 2001/2002 Junior Physics Laboratory Experiment #006 The Cavendish Experiment Measurement of the Gravitational Constant PREPARATORY PROBLEMS 1. Derive from first priciples the differential equation for damped, simple, harmonic mo- tion. Derive the solution. 2. Compute the exact moment of inertia of two identical solid spheres of mass m and diameter d connected by a rod of mass µ and length l about an axis perpendicular to the rod. 3. Suppose the pendulum is at rest with the lead balls in rotated clockwise. Sketch the expected curve of angular displacement versus time from the moment when the balls are rotated counterclockwise. 1 INTRODUCTION According to Newton, two spherically symmetric bodies, A and B, with inertial masses, MA GMAMB and MB, attract one another with a force of magnitude r2 where r is the separation between the centers and G is the universal constant of gravity. The determination of G is obviously of fundamental importance in physics and astronomy. But gravity is the weakest of the forces, and the measurement of the gravity force between two bodies of measurable mass requires a delicate approach, with meticulous care to reduce perturbing influences such as air currents and electromagnetic forces. The first measurement of G was made by Henry Cavendish in 1798, a century after Newton’s discovery of the law of universal gravitation. He used a torsion balance invented by one Rev. John Michell and, independently, by Charles Coulomb. Michell died shortly after completing his device, never having had the opportunity to apply it to the measurement of small forces for which he had devised it. -

Gravitational Torsion Balance

Gravitational Torsion Balance Spencer Tomarken, Richard Helms, Med Webster, and Will Johns August 15, 2008, Revised October 7, 2008 1 Measurement of G 1.1 Background Suggested Reading: Ref. 1, pp. 75-92. In his work published in 1686, Principia Mathematica, Isaac Newton1 theorized that all masses exert a gravitational force on each other, and that the force is proportional to the masses of the two objects and inversely proportional to the square of the distance between them. Newton’s theory explained both the bodies falling on Earth and the motion of the planets. His law allowed mathematicians to correctly predict the existence of the planet Neptune, after astronomers noticed an irregularity in the orbit of the planet Uranus. Today’s form of Newton’s law of gravitation is expressed as GmM F = , (1) r2 but neither the gravitational constant G nor any of the astronomical masses was known until over a century after Newton. Consequently, all calculations in Newton’s time were performed by using the ratio of the mass of either the Sun or the Earth to that of the planet or satellite. Newton’s actual equation was of the form 4π2Km F = , (2) r2 where m is the mass of the object, r is the distance, and K is Kepler’s constant, which is the ratio of the cube of the radius of a planet’s orbit to the square of the period of revolution[2]. In 1798 Henry Cavendish2 set up an experiment[3] to measure the mass of the Earth. To accomplish this feat, he first found the value for G in Eq. -

The Attraction of the Pyramids: Virtual Realization of Hutton's Suggestion To

Hist. Geo Space Sci., 9, 1–7, 2018 https://doi.org/10.5194/hgss-9-1-2018 © Author(s) 2018. This work is distributed under the Creative Commons Attribution 4.0 License. The attraction of the pyramids: virtual realization of Hutton’s suggestion to improve Maskelyne’s 1774 Earth density estimate John R. Smallwood UCL Hazard Centre, Department of Earth Sciences, UCL, Gower Street, London WC1E 6BT, UK Correspondence: John R. Smallwood ([email protected]) Received: 11 September 2017 – Revised: 9 November 2017 – Accepted: 22 November 2017 – Published: 9 January 2018 Abstract. Charles Hutton suggested in 1821 that the pyramids of Egypt be used to site an experiment to measure the deflection of the vertical by a large mass. The suggestion arose as he had estimated the attraction of a Scottish mountain as part of Nevil Maskelyne’s (1774) “Schiehallion Experiment”, a demonstration of Isaac Newton’s law of gravitational attraction and the earliest reasonable quantitative estimate of Earth’s mean density. I present a virtual realization of an experiment at the Giza pyramids to investigate how Hutton’s concept might have emerged had it been undertaken as he suggested. The attraction of the Great Pyramid would have led to inward north–south deflections of the vertical totalling 1.8 arcsec (0.0005◦), and east–west deflections totalling 2.0 arcsec (0.0006◦), which although small, would have been within the contemporaneous detectable range, and potentially given, as Hutton wished, a more accurate Earth density measurement than he reported from the Schiehallion experiment. 1 Introduction 2 Background Following his analysis as part of Astronomer Royal Nevil In the late 17th century, Isaac Newton proposed two exper- Maskelyne’s experiment to measure Earth’s mean density on imental methods by which the mass of the Earth could be the Scottish mountain Schiehallion in 1774, Charles Hutton measured. -

PHYSICS 3900F/G the CAVENDISH EXPERIMENT 1. Introduction 2

PHYSICS 3900F/G THE CAVENDISH EXPERIMENT 1. Introduction The gravitational constant G is involved in the calculation of the gravitational force between two bodies of masses m1 and m2 according to Newton’s law of universal gravitation, Gm m 1 2 , (1) F = 2 r where r is the distance between the bodies. Despite the importance of G in, for example, orbital mechanics and the evolution of stars and galaxies, it is the least well-determined of any of the fundamental physical constants, with a relative uncertainty of 0.012% (compare this with the value of Planck’s constant, which is known to an accuracy of 2.3 x 10–6). The value of G was first measured by Henry Cavendish in 1798 by measuring the force between relatively small forces in the laboratory using a torsion balance. So well constructed was Cavendish’s apparatus, that the value of G derived from his results differs by only 1% from the currently accepted value. In this experiment, you will use a scaled-down version of the Cavendish apparatus to repeat the experiment for yourself. 2. Apparatus The Cavendish apparatus consists of a light horizontal rod suspended by a thin metal ribbon. Attached to each end of the rod is a lead ball of mass m, as shown in Fig. 1(a). If the rod is twisted from its equilibrium position, a torque due to the ribbon acts to return the rod to equilibrium. In order to minimize disturbances due to air currents, this torsional pendulum is enclosed in a box. Two larger lead balls, each of mass M are positioned outside of the box at the same height is the smaller masses.