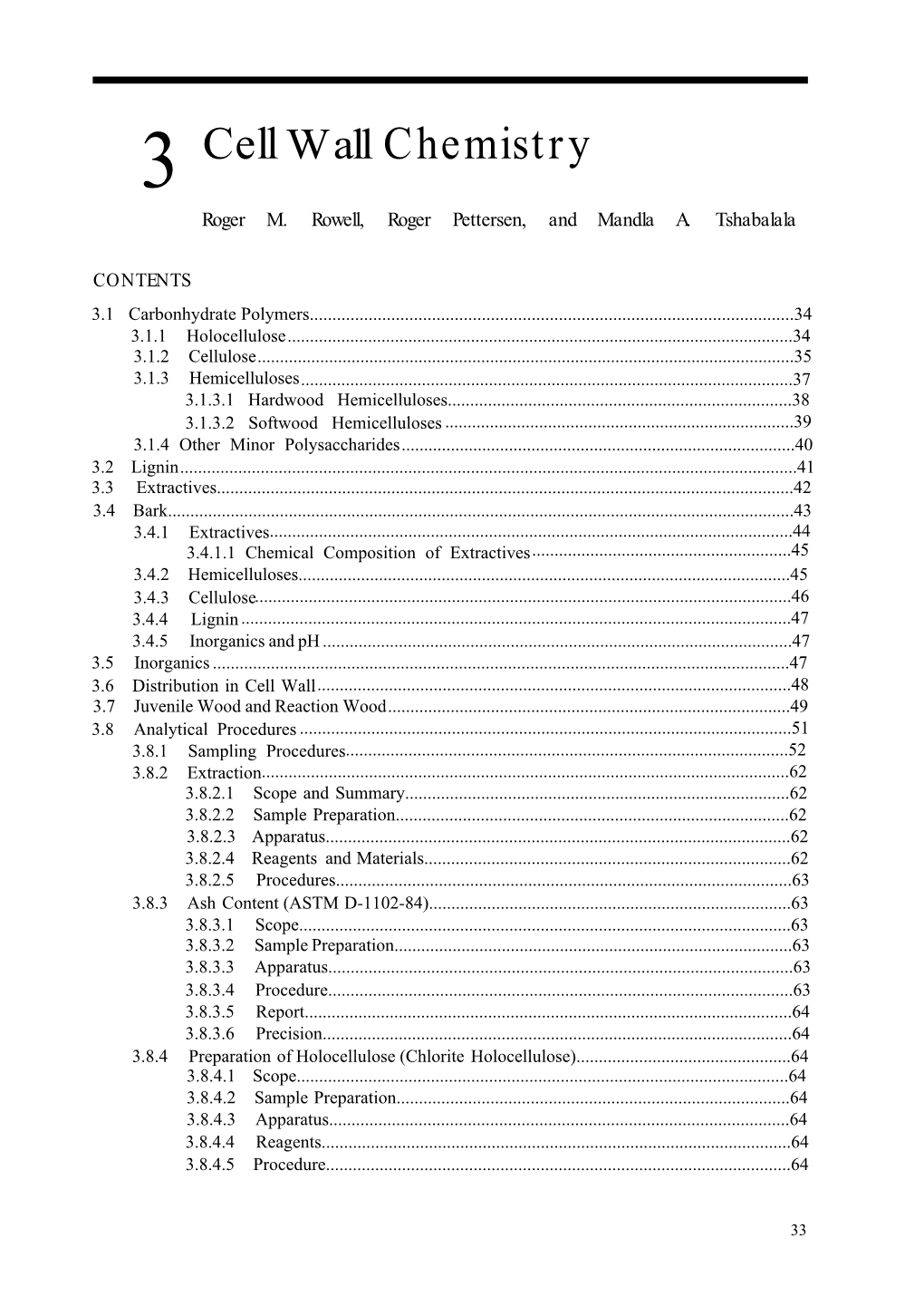

Cell Wall Chemistry, Chapter 3

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Development of Forest-Based Biorefineries: Implications for Market Behavior and Policy

The Development of Forest-based Biorefineries: Implications for Market Behavior and Policy Patrik Söderholm and Robert Lundmark Abstract and the use of biomass is expected to constitute a major In a forest-based biorefinery, the entire potential of share of the future total use of renewable energy sources forest raw materials and byproducts may be used to pro- in Europe (European Commission 1997, 2006). Essential duce a diverse set of products, including transport fuels, components of national energy policies in Europe, there- chemicals, and pulp and paper products. This paper ana- fore, include not only direct promotion of renewable ener- lyzes the general impact on forest raw material markets gy technologies (e.g., investment and R&D support), but following an increased diffusion of biorefineries and high- also carbon dioxide taxes and emissions trading in carbon lights a number of related public policy issues. The analy- dioxide allowances that discourage the use of fossil fuels. The transition from a fossil fuel-based to a carbon-free sis indicates that the character of forest raw material sup- energy system may have important consequences for the ply, in particular the distinction between main products use of raw materials in society, not the least in cases of and byproducts, will have a major influence on the func- agricultural and forest-based resources. Increases in the tioning and the organization of future forest products mar- relative prices of fossil fuels affect a large number of indus- kets. Moreover, the advent of new uses of forest-based bio- trial and end-use sectors of the economy. -

Laval University

LAVAL UNIVERSITY FACULTY OF FORESTRY AND GEOMATICS Department of Wood and Forest Sciences Sponsored by the International Development Center (IDRC) Ottawa, Canada “The Hidden World that Feeds Us: the Living Soil” Seminars given at the International Institute for Trropical Agriculture (ITA) Univeristy of Ibadan, Nigeria at the International Centre of Research in Agroforestry (ICRAF) Nairobi, Kenya and at the Ukrainian Academy of Agricultural Sciences Kiev, Ukraine by Professor Gilles Lemieux Department of Wood and Forestry Science ORIGINAL FRENCH PUBLICATION Nº 59b http://forestgeomat.ffg.ulaval.ca/brf/ edited by Coordination Group on Ramial Wood Depatment of Wood and Forestry Science Québec G1K 7P4 QUÉBEC CANADA TABLE OF CONTENTS I. A brief history: the evolution of ecosystems and man’s anthropocentric behaviour 1 II. The importance of the forest in tropical climates 2 III. The basic composition of wood 3 1. Lignin and its derivatives and their role in doil dynamic 5 IV. Stem wood and ramial wood 6 1. Stem wood and its lignin 6 2. Ramial wood and its lignin 6 3. Agricultural and forestry trials using ramial wood 7 V. “Organic Matter”, one of the basic principles in agriculture 9 1. Some a posteriori thoughts 10 2. The rationale for chipping 10 3. More like a food than a fertilizer 11 4. The principles behind chipping 11 VI. Lignin 13 1.The nutrients question 14 2.The biological cycling of water in tropical climates 15 3.“Chemical” nutrients 15 4.Nitrogen 15 5.Phosphorus 16 VII. A tentative theory 17 1.Too much or too little water 17 2.The soil-structuring role of lignin 17 3.The role of trophic web 18 4.Living beyond the soil’s chemical constraints 18 5.The major cause of tropical soils degradation. -

Corrugated Board Structure: a Review M.C

ISSN: 2395-3594 IJAET International Journal of Application of Engineering and Technology Vol-2 No.-3 Corrugated Board Structure: A Review M.C. Kaushal1, V.K.Sirohiya2 and R.K.Rathore3 1 2 Assistant Prof. Mechanical Engineering Department, Gwalior Institute of Information Technology,Gwalior, Assistant Prof. Mechanical Engineering 3 Departments, Gwalior Engineering College, Gwalior, M. Tech students Maharanapratap College of Technology, Gwalior, [email protected] [email protected] [email protected] ABSTRACT Corrugated board is widely used in the packing industry. The main advantages are lightness, recyclability and low cost. This makes the material the best choice to produce containers devoted to the shipping of goods. Furthermore examples of structure design based on corrugated boards can be found in different fields. Structural analysis of paperboard components is a crucial topic in the design of containers. It is required to investigate their strength properties because they have to protect the goods contained from lateral crushing and compression loads due to stacking. However in this paper complete and detailed information are presented. Keywords: - corrugated boards, recyclability, compression loads. Smaller flutes offer printability advantages as well as I. INTRODUCTION structural advantages for retail packaging. Corrugated board is essentially a paper sandwich consisting of corrugated medium layered between inside II. HISTORY and outside linerboard. On the production side, corrugated In 1856 the first known corrugated material was patented is a sub-category of the paperboard industry, which is a for sweatband lining in top hats. During the following four sub-category of the paper industry, which is a sub-category decades other forms of corrugated material were used as of the forest products industry. -

The Use of Old Corrugated Board in the Manufacture of High Quality White Papers

Western Michigan University ScholarWorks at WMU Paper Engineering Senior Theses Chemical and Paper Engineering 12-1983 The Use of Old Corrugated Board in the Manufacture of High Quality White Papers Rene H. Kapik Western Michigan University Follow this and additional works at: https://scholarworks.wmich.edu/engineer-senior-theses Part of the Wood Science and Pulp, Paper Technology Commons Recommended Citation Kapik, Rene H., "The Use of Old Corrugated Board in the Manufacture of High Quality White Papers" (1983). Paper Engineering Senior Theses. 209. https://scholarworks.wmich.edu/engineer-senior-theses/209 This Dissertation/Thesis is brought to you for free and open access by the Chemical and Paper Engineering at ScholarWorks at WMU. It has been accepted for inclusion in Paper Engineering Senior Theses by an authorized administrator of ScholarWorks at WMU. For more information, please contact wmu- [email protected]. THE USE OF OLD CORRUGATED BOARD IN THE MANUFACTURE OF HIGH QUALITY WHITE PAPERS by Rene' H. Kapik A Thesis submitted in partial fulfillment of the course requirements for The Bachelor of Science Degree Western Michigan University Kalamazoo, Michigan December, 1983 ABSTRACT Clean corrugated board waste was fractionated into its softwood/ hardwood fiber components, repulped using a kraft pulping process, and bleached using a CEHD bleaching sequence in an effort to produce high brightness fiber suitable for use in medium to high quality white paper. The papers produced had almost equivalent mechanical strengths and opacity, but possessed unsatisfactory brightness and cleanliness when compared to commercially manufactured,:. bleached kraft pulps of identical softwood/hardwood contents. Based on this experimental data, the use of recycled fiber from corrugated board as a fiber substitute in the manufacture of high quality printing and writing papers is not recommended due to its inferior brightness and cleanliness. -

Xylan Utilization in Human Gut Commensal Bacteria Is Orchestrated by Unique Modular Organization of Polysaccharide-Degrading Enzymes

Xylan utilization in human gut commensal bacteria is orchestrated by unique modular organization of polysaccharide-degrading enzymes Meiling Zhanga,b,c,1,2, Jonathan R. Chekand,1, Dylan Dodda,b,e,1,3, Pei-Ying Hongc,4, Lauren Radlinskia,b,e, Vanessa Revindrana,b, Satish K. Nairb,d,5, Roderick I. Mackiea,b,c,5, and Isaac Canna,b,c,e,5 aEnergy Biosciences Institute, bInstitute for Genomic Biology, and Departments of cAnimal Sciences, dBiochemistry, and eMicrobiology, University of Illinois at Urbana-Champaign, Urbana, IL 61801 Edited by Arnold L. Demain, Drew University, Madison, NJ, and approved July 29, 2014 (received for review April 19, 2014) Enzymes that degrade dietary and host-derived glycans represent One of the most important functional roles specific to the lower the most abundant functional activities encoded by genes unique gut microbiota is the degradation and fermentation of dietary fiber to the human gut microbiome. However, the biochemical activities that is resistant to digestion by human enzymes. The enzymes in- of a vast majority of the glycan-degrading enzymes are poorly volved in breaking down polysaccharides are members of carbo- understood. Here, we use transcriptome sequencing to under- hydrate active enzymes (CAZymes) and are categorized into stand the diversity of genes expressed by the human gut bacteria families of carbohydrate-binding modules (CBMs), carbohydrate Bacteroides intestinalis and Bacteroides ovatus grown in monocul- esterases (CEs), glycoside hydrolases (GHs), glycoside transferases ture with the abundant dietary polysaccharide xylan. The most (GTs), or polysaccharide lyases (PLs) (14). The CAZy gene cat- highly induced carbohydrate active genes encode a unique glycoside alog of the human genome pales in comparison with that of the gut hydrolase (GH) family 10 endoxylanase (BiXyn10A or BACINT_04215 microbiota, which exceeds the total number of human CAZymes and BACOVA_04390) that is highly conserved in the Bacteroidetes by at least 600-fold (15). -

Judging Permanence for Reformatting Projects: Paper and Inks

ConserveO Gram September 1995 Number 19/14 Judging Permanence For Reformatting Projects: Paper And Inks Many permanently valuable NPS documents fibered, high alpha-cellulose cotton and linen such as correspondence, drawings, maps, plans, rags. Early rag papers were strong, stable, and reports were not produced using permanent and durable with relatively few impurities. and durable recording media. When selecting In the mid-17th century, damaging alum paper items for preservation duplication, items sizing was added to control bacteria and marked on the list below with a " - " are at mold growth in paper. By 1680, shorter highest risk and should have special priority for fiber rag papers were being produced due to duplication. Document types marked with a the use of mechanical metal beaters to shred "+" are lower priorities for reformatting as they the rag fibers. By about 1775, damaging tend to be more stable and durable. See chlorine bleaches were added to rag papers Conserve O Gram 19/10, Reformatting for to control the paper color. Acidic alum Preservation and Access: Prioritizing Materials rosin sizing was introduced around 1840 to for Duplication, for a full discussion of how to speed the papermaking process thus leading select materials for duplication. NOTE: Avoid to even shorter-lived papers. Rag papers using materials and processes marked " - " when became less common after the introduction producing new documents. of wood pulp paper around 1850. Compared to rag paper, most wood pulp papers have Paper much poorer chemical chemical and mechanical strength, durability, and stability. All permanently valuable original paper - documents should be produced on lignin-free, Ground or mechanical wood pulp paper: high alpha-cellulose papers with a pH between After 1850, most paper produced was 7.5 and 8.0, specifically those papers meeting machine-made paper with a high proportion the American National Standards Institute of short-fibered and acidic wood pulp. -

The Decomposition of Forest Products in Landfills

International Biodeterioration & Biodegradation Vol. 39, No. 2–3 (1997) 145–158 Published by Elsevier Science Limited Printed in Great Britain PII:S0964-8305(96)00039-X 0964-8305/97 $17.00 + .00 ELSEVIER The Decomposition of Forest Products in Landfills J. A. Micales & K. E. Skog USDA Forest Service, Forest Products Laboratory, One Gifford Pinchot Drive, Madison, WI 53705, USA (Received 3 April 1996; revised version received 25 June 1996; accepted 22 July 1996) Large quantities of forest products are disposed of in landfills annually. The fate of this vast pool of carbon is important since carbon sequestration and the generation of landfill gases have important implications for global warming. Published estimates of methane yields were used to estimate the amount of carbon released into the atmosphere from landfilled forest products. These calculations suggest that maximally only 30%, of the carbon from paper and 0- 3% of the carbon from wood are ever emitted as landfill gas. The remaining carbon, approximately 28 Tg in 1993, remains in the landfill indefinitely. Some of this carbon may be removed during leachate treatment, but a large portion is permanently sequestered where its impact on global warming is negligible. The placement of forest products in landfills serves as a significant carbon sink, and its importance in the global carbon balance should not be overlooked. Published by Elsevier Science Limited INTRODUCTION warming? President Clinton’s Climatic Change Action Plan (Clinton & Gore, 1993) sets a US In 1993, the US Environmental Protection Agency objective of restraining carbon emission growth (EPA) (1994) estimated that 50 Tgl of paper and and increasing sequestration by a total of 100 Tg/ 18.6 Tg of wood were discarded in the United year by the year 2000. -

Influence of Hemicelluloses Content on the Paper Quality Produced with Eucalyptus Globulus Fibres

CORE Metadata, citation and similar papers at core.ac.uk Provided by Repositório Científico do Instituto Politécnico de Castelo Branco Proceedings of Progress in Paper Physics Seminar 2004, Norway, Trondheim, 21 a 24 de Junho, p. 50-52 Influence of hemicelluloses content on the paper quality produced with Eucalyptus globulus fibres. Ofélia Anjos1, António Santos2, and Rogério Simões2 1Escola Superior de Agrária – 6001-909 Castelo Branco, Portugal, [email protected] 2Universidade da Beira Interior, 6201-001 Covilhã, Portugal, [email protected] Abstract The raw-material composition and the cooking conditions determine the pulp composition and this affect the behaviour of the pulp in the beating process and the papermaking potential. However, at industrial scale the variability of the pulp composition, for a given raw material and a given process, is relatively low and usually it is difficult to quantify the impacts of pulp composition on beating and papermaking. In the present study E. globulus bleached pulps were produced under different cooking conditions by the kraft process in order to obtain pulps with significant different hemicelluloses content (19% versus 14.5%). The behaviour of the pulps in beating and the papermaking potential were investigated under two beating intensities in the PFI mill and at four beating times. The pulp suspensions were characterised in terms of drainability, fibre morphology, wet fibre flexibility and relative bonded area. The paper produced was evaluated in terms of structural, superficial, mechanical and optical properties. The results showed the clear effect of the hemicelluloses content on the beating rate as well as on the paper properties. -

Conservation of Coated and Specialty Papers

RELACT HISTORY, TECHNOLOGY, AND TREATMENT OF SPECIALTY PAPERS FOUND IN ARCHIVES, LIBRARIES AND MUSEUMS: TRACING AND PIGMENT-COATED PAPERS By Dianne van der Reyden (Revised from the following publications: Pigment-coated papers I & II: history and technology / van der Reyden, Dianne; Mosier, Erika; Baker, Mary , In: Triennial meeting (10th), Washington, DC, 22-27 August 1993: preprints / Paris: ICOM , 1993, and Effects of aging and solvent treatments on some properties of contemporary tracing papers / van der Reyden, Dianne; Hofmann, Christa; Baker, Mary, In: Journal of the American Institute for Conservation, 1993) ABSTRACT Museums, libraries, and archives contain large collections of pigment-coated and tracing papers. These papers are produced by specially formulated compositions and manufacturing procedures that make them particularly vulnerable to damage as well as reactive to solvents used in conservation treatments. In order to evaluate the effects of solvents on such papers, several research projects were designed to consider the variables of paper composition, properties, and aging, as well as type of solvent and technique of solvent application. This paper summarizes findings for materials characterization, degradative effects of aging, and some effects of solvents used for stain reduction, and humidification and flattening, of pigment-coated and modern tracing papers. Pigment-coated papers have been used, virtually since the beginning of papermaking history, for their special properties of gloss and brightness. These properties, however, may render coated papers more susceptible to certain types of damage (surface marring, embedded grime, and stains) and more reactive to certain conservation treatments. Several research projects have been undertaken to characterize paper coating compositions (by SEM/EDS and FTIR) and appearance properties (by SEM imaging of surface structure and quantitative measurements of color and gloss) in order to evaluate changes that might occur following application of solvents used in conservation treatments. -

Timber Bridges Design, Construction, Inspection, and Maintenance

Timber Bridges Design, Construction, Inspection, and Maintenance Michael A. Ritter, Structural Engineer United States Department of Agriculture Forest Service Ritter, Michael A. 1990. Timber Bridges: Design, Construction, Inspection, and Maintenance. Washington, DC: 944 p. ii ACKNOWLEDGMENTS The author acknowledges the following individuals, Agencies, and Associations for the substantial contributions they made to this publication: For contributions to Chapter 1, Fong Ou, Ph.D., Civil Engineer, USDA Forest Service, Engineering Staff, Washington Office. For contributions to Chapter 3, Jerry Winandy, Research Forest Products Technologist, USDA Forest Service, Forest Products Laboratory. For contributions to Chapter 8, Terry Wipf, P.E., Ph.D., Associate Professor of Structural Engineering, Iowa State University, Ames, Iowa. For administrative overview and support, Clyde Weller, Civil Engineer, USDA Forest Service, Engineering Staff, Washington Office. For consultation and assistance during preparation and review, USDA Forest Service Bridge Engineers, Steve Bunnell, Frank Muchmore, Sakee Poulakidas, Ron Schmidt, Merv Eriksson, and David Summy; Russ Moody and Alan Freas (retired) of the USDA Forest Service, Forest Products Laboratory; Dave Pollock of the National Forest Products Association; and Lorraine Krahn and James Wacker, former students at the University of Wisconsin at Madison. In addition, special thanks to Mary Jane Baggett and Jim Anderson for editorial consultation, JoAnn Benisch for graphics preparation and layout, and Stephen Schmieding and James Vargo for photographic support. iii iv CONTENTS CHAPTER 1 TIMBER AS A BRIDGE MATERIAL 1.1 Introduction .............................................................................. l- 1 1.2 Historical Development of Timber Bridges ............................. l-2 Prehistory Through the Middle Ages ....................................... l-3 Middle Ages Through the 18th Century ................................... l-5 19th Century ............................................................................ -

Cellulose Containerboard US Safety Data Sheet Section 1. Product And

Cellulose Containerboard US Safety Data Sheet Section 1. Product and Company Identification Product Group : Cellulose Containerboard Trade Names or Grades : EnduraLiner™, EnduraLiner™ HP Max, EnduraLiner™ Wet Strength, EnduraLiner™ GR, DiamondTop™, DiamondTop™ HP, DiamondTop™ 1C, DiamondTop™ 2C, DiamondTop™ GR, EnduraFlute™, TechniFlute™, Linerboard, White Top Liner, Medium, Bleached Linerboard, Coated White Top Linerboard, RockmaX, Grease Resistant Liner, White Top Grease Resistant Liner, Natural Kraft Linerboard, Bleached Linerboard, Wet Strength linerboard, Premium White Top Liner, Recycled Linerboard, Recycled Medium, Fluting, White Top Kraft Liner Synonyms : Corrugating Medium, Linerboard Chemical Name/Class : Cellulose Paperboard Company : WestRock 1000 Abernathy Road NE Atlanta GA 30328 770-448-2193 Emergency Phone : (800) 424-9300 (CHEMTREC) Section 2. Hazards Identification This product as sold is a solid product which is not regulated under WHMIS 2015. During processing, combustible dust may be generated and the following information applies under OSHA HazCom 2012: GHS Classification : Combustible Dust (OSHA Defined Hazard) Signal Word : Warning Hazard Statement(s) : May form combustible dust concentrations in air, if small particles are formed during processing, handling, or by other means. Hazard Pictogram : None Precautionary Statement(s) : Keep away from all ignition sources including heat, sparks and open flames. Prevent dust accumulations to minimize explosion hazard. Hazards Not Otherwise : None. Classified Ingredients of Unknown : Not applicable Acute Toxicity (>1%) Section 3. Composition and Information on Ingredients No hazardous ingredients. SDS WR001 Page 1 of 8 Rev. 02/12/2019 Cellulose Containerboard US Safety Data Sheet Section 4. First Aid Measures Inhalation : Excessive dust concentrations may cause unpleasant obstruction in the nasal passages. Remove to fresh air. -

Cellulose Was Discovered in 1838 by the French Chemist Anselme Payen, Who Isolated It from Plant Matter and Determined Its Chemical Formula

Cellulose structure: The history of cellulose: Cellulose was discovered in 1838 by the French chemist Anselme Payen, who isolated it from plant matter and determined its chemical formula. Cellulose was used to produce the first successful thermoplastic polymer, celluloid, by Hyatt Manufacturing Company in 1870. Production of rayon ("artificial silk") from cellulose began in the 1890s and cellophane was invented in 1912. Hermann Staudinger determined the polymer structure of cellulose in 1920. The compound was first chemically synthesized (without the use of any biologically derived enzymes) in 1992, by Kobayashi and Shoda How it is synthesized commercially or biologically: Cellulose is a source of energy for several types of microbes. Large amounts of cellulose is degraded to glucose by both bacterial and fungal microbes. The glucose derived from cellulose degradation is then used by other microbes as a carbon source to produce energy. Many fungi, specifically the members of Basidiomycetes perform critical ecological function by degrading cellulose present in decaying wood. Some animals can digest cellulose. When an herbivore, say a cow, consumes a plant, like grass, bacteria in their intestinal tract are able to break down the cellulose into smaller parts that the cow's own digestive system can absorb. Some bacteria can actually produce their own cellulose, making a kind of film. The acetic acid bacteria used in the production of wine and beers is one of these types. The synthesized cellulose forms a film around the bacterial cell and becomes a kind of matrix, called a pellicle, which helps the acetic acid bacteria to float on the surface and access oxygen needed for their survival.