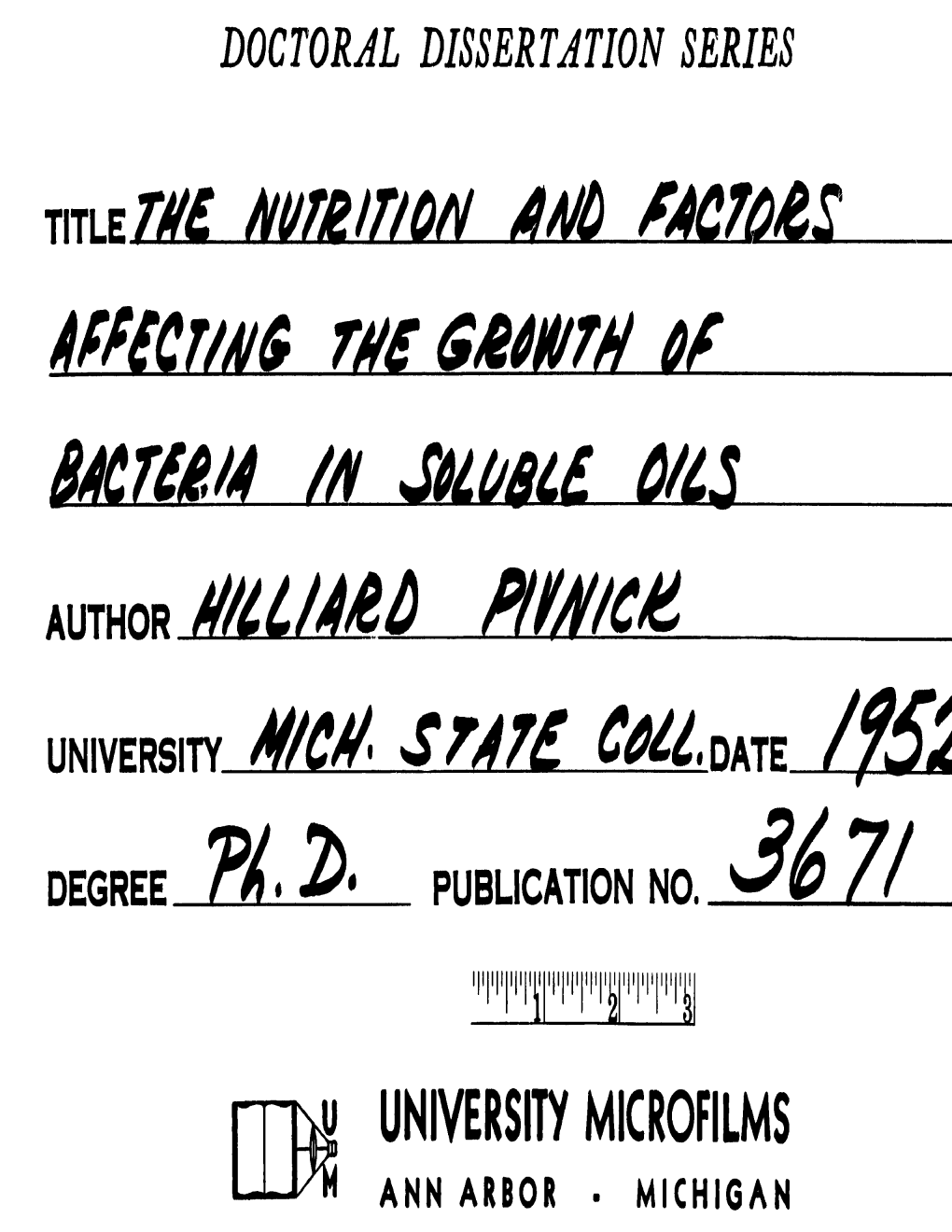

TITLETHE Mjwtlofi AMD Tffic Rm the S

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Selling Mercury Cosmetics and Pharmaceuticals (W-Hw4-22)

www.pca.state.mn.us Selling mercury cosmetics and pharmaceuticals Mercury-containing skin lightening creams, lotions, soaps, ointments, lozenges, pharmaceuticals and antiseptics Mercury is a toxic element that was historically used in some cosmetic, pharmaceutical, and antiseptic products due to its unique properties and is now being phased out of most uses. The offer, sale, or distribution of mercury-containing products is regulated in Minnesota by the Minnesota Pollution Control Agency (MPCA). Anyone offering a mercury-containing product for sale or donation in Minnesota is subject to these requirements, whether a private citizen, collector, non-profit organization, or business. Offers and sales through any method are regulated, whether in a store or shop, classified advertisement, flea market, or online. If a mercury-containing product is located in Minnesota, it is regulated, regardless of where a purchaser is located. Note: This fact sheet discusses the requirements and restrictions of the MPCA. Cosmetics and pharmaceuticals may also be regulated for sale whether they contain mercury or not by other state or federal agencies, including the Minnesota Board of Pharmacy and the U.S. Food & Drug Administration. See More information on page 2. What are the risks of using mercury-containing products? Use of mercury-containing products can damage the brain, kidneys, and liver. Children and pregnant women are at increased risk. For more information about the risks of mercury exposure, visit the Minnesota Department of Health. See More information on the page 2. If you believe you have been exposed to a mercury-containing product, contact your health care provider or the Minnesota Poison Control Center at 1-800-222-1222. -

(12) Patent Application Publication (10) Pub. No.: US 2012/0115729 A1 Qin Et Al

US 201201.15729A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0115729 A1 Qin et al. (43) Pub. Date: May 10, 2012 (54) PROCESS FOR FORMING FILMS, FIBERS, Publication Classification AND BEADS FROM CHITNOUS BOMASS (51) Int. Cl (75) Inventors: Ying Qin, Tuscaloosa, AL (US); AOIN 25/00 (2006.01) Robin D. Rogers, Tuscaloosa, AL A6II 47/36 (2006.01) AL(US); (US) Daniel T. Daly, Tuscaloosa, tish 9.8 (2006.01)C (52) U.S. Cl. ............ 504/358:536/20: 514/777; 426/658 (73) Assignee: THE BOARD OF TRUSTEES OF THE UNIVERSITY OF 57 ABSTRACT ALABAMA, Tuscaloosa, AL (US) (57) Disclosed is a process for forming films, fibers, and beads (21) Appl. No.: 13/375,245 comprising a chitinous mass, for example, chitin, chitosan obtained from one or more biomasses. The disclosed process (22) PCT Filed: Jun. 1, 2010 can be used to prepare films, fibers, and beads comprising only polymers, i.e., chitin, obtained from a suitable biomass, (86). PCT No.: PCT/US 10/36904 or the films, fibers, and beads can comprise a mixture of polymers obtained from a suitable biomass and a naturally S3712). (4) (c)(1), Date: Jan. 26, 2012 occurring and/or synthetic polymer. Disclosed herein are the (2), (4) Date: an. AO. films, fibers, and beads obtained from the disclosed process. O O This Abstract is presented solely to aid in searching the sub Related U.S. Application Data ject matter disclosed herein and is not intended to define, (60)60) Provisional applicationpp No. 61/182,833,sy- - - s filed on Jun. -

United States Patent (19) 11 Patent Number: 5,753,634 Ebetino Et Al

USOO5753634A United States Patent (19) 11 Patent Number: 5,753,634 Ebetino et al. 45 Date of Patent: May 19, 1998 54 QUATERNARY NITROGEN CONTAINING 4.011777 10/1990 Germany. PHOSPHONATE COMPOUNDS, WO 90/12017 10/1990 WIPO PHARMACEUTICAL COMPOSTIONS, AND WO 91/10646 7/1991 WIPO. METHODS FOR TREATING ABNORMAL Primary Examiner-Amelia Owens CALCUMAND PHOSPHATE METABOLISM Attorney, Agent, or Firm-Richard A. Hake; Karen F. Clark; William J. Winter 75 Inventors: Frank Hallock Ebetino; Marion David Francis, both of Cincinnati, 57 ABSTRACT Ohio; Susan Mary Kaas, Sherburne, Disclosed are quaternary nitrogen-containing, saturated or N.Y. unsaturated monocyclic and bicyclic ring-containing bis 73 Assignee: The Procter & Gamble Company, phosphonate compounds, and pharmaceutically-acceptable Cincinnati, Ohio salts and esters thereof. These compounds, which are useful for treating or preventing disorders of calcium and phos 21) Appl. No.: 52,694 phate metabolism, have the following general structure: 22) Filed: Apr. 30, 1993 (R), (CR2), (CR,): NY R Related U.S. Application Data 63 Continuation-in-part of Ser. No. 891,487, May 29, 1992, abandoned. 51 Int. Cl. ... A61K 31/675; A61K 31/66 52) U.S. Cl. ............................ 514/81: 514/91; 514/109: wherein 546/23: 548/111; 562/21 (a) each X and Y are independently selected from nil, O, 58 Field of Search ............................... 546/23: 514/80, S, NR' and N*(R); if no R' is N'(R), then at least 514/82, 91, 109; 548/111; 562/21 one of X or Y must be N(R); References Cited (b) m and n and m+n are integers from 0 to 5; p and q and 56 p+q are integers from 0 to 3; U.S. -

Tepzz 459659B T

(19) TZZ _T (11) EP 2 459 659 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention (51) Int Cl.: C09D 7/00 (2006.01) C09D 7/14 (2006.01) of the grant of the patent: C09D 5/16 (2006.01) 17.07.2013 Bulletin 2013/29 (86) International application number: (21) Application number: 10737728.5 PCT/US2010/043382 (22) Date of filing: 27.07.2010 (87) International publication number: WO 2011/017097 (10.02.2011 Gazette 2011/06) (54) REMOVABLEANTIMICROBIAL COATING COMPOSITIONS CONTAINING CATIONIC RHEOLOGY AGENT AND METHODS OF USE ABLÖSBARE ANTIMIKROBIELLE BESCHICHTUNGSZUSAMMENSETZUNGEN MIT KATIONISCHEM RHEOLOGISCHEM ADDITIV UND ANWENDUNGSVERFAHREN COMPOSITIONS DE REVÊTEMENT ANTIMICROBIENNES, APTES À ÊTRE RETIRÉES, CONTENANT UN AGENT DE RHÉOLOGIE CATIONIQUE, ET PROCÉDÉS D’UTILISATION (84) Designated Contracting States: (74) Representative: Dannenberger, Oliver Andre et al AL AT BE BG CH CY CZ DE DK EE ES FI FR GB Abitz & Partner GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO Patentanwälte PL PT RO SE SI SK SM TR Postfach 86 01 09 81628 München (DE) (30) Priority: 27.07.2009 US 228707 P 27.07.2009 US 228711 P (56) References cited: 27.07.2009 US 228715 P WO-A2-2007/100653 WO-A2-2007/100654 27.07.2009 US 228723 P 26.07.2010 US 843120 • Akzo Nobel Surface Chemistry: "Thickening with polymers"[Online] 1 January 2010 (2010-01-01), (43) Date of publication of application: XP002609717 Akzo Nobel Technical Information 06.06.2012 Bulletin 2012/23 Retrieved from the Internet: URL:http: //www.akzonobel.com/surface/syste m/images/ (73) Proprietor: E. -

(12) Patent Application Publication (10) Pub. No.: US 2002/0102215 A1 100 Ol

US 2002O102215A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2002/0102215 A1 Klaveness et al. (43) Pub. Date: Aug. 1, 2002 (54) DIAGNOSTIC/THERAPEUTICAGENTS (60) Provisional application No. 60/049.264, filed on Jun. 6, 1997. Provisional application No. 60/049,265, filed (75) Inventors: Jo Klaveness, Oslo (NO); Pal on Jun. 6, 1997. Provisional application No. 60/049, Rongved, Oslo (NO); Anders Hogset, 268, filed on Jun. 7, 1997. Oslo (NO); Helge Tolleshaug, Oslo (NO); Anne Naevestad, Oslo (NO); (30) Foreign Application Priority Data Halldis Hellebust, Oslo (NO); Lars Hoff, Oslo (NO); Alan Cuthbertson, Oct. 28, 1996 (GB)......................................... 9622.366.4 Oslo (NO); Dagfinn Lovhaug, Oslo Oct. 28, 1996 (GB). ... 96223672 (NO); Magne Solbakken, Oslo (NO) Oct. 28, 1996 (GB). 9622368.0 Jan. 15, 1997 (GB). ... 97OO699.3 Correspondence Address: Apr. 24, 1997 (GB). ... 9708265.5 BACON & THOMAS, PLLC Jun. 6, 1997 (GB). ... 9711842.6 4th Floor Jun. 6, 1997 (GB)......................................... 97.11846.7 625 Slaters Lane Alexandria, VA 22314-1176 (US) Publication Classification (73) Assignee: NYCOMED IMAGING AS (51) Int. Cl." .......................... A61K 49/00; A61K 48/00 (52) U.S. Cl. ............................................. 424/9.52; 514/44 (21) Appl. No.: 09/765,614 (22) Filed: Jan. 22, 2001 (57) ABSTRACT Related U.S. Application Data Targetable diagnostic and/or therapeutically active agents, (63) Continuation of application No. 08/960,054, filed on e.g. ultrasound contrast agents, having reporters comprising Oct. 29, 1997, now patented, which is a continuation gas-filled microbubbles stabilized by monolayers of film in-part of application No. 08/958,993, filed on Oct. -

Bulk Drug Substances Nominated for Use in Compounding Under Section 503B of the Federal Food, Drug, and Cosmetic Act

Updated June 07, 2021 Bulk Drug Substances Nominated for Use in Compounding Under Section 503B of the Federal Food, Drug, and Cosmetic Act Three categories of bulk drug substances: • Category 1: Bulk Drug Substances Under Evaluation • Category 2: Bulk Drug Substances that Raise Significant Safety Risks • Category 3: Bulk Drug Substances Nominated Without Adequate Support Updates to Categories of Substances Nominated for the 503B Bulk Drug Substances List1 • Add the following entry to category 2 due to serious safety concerns of mutagenicity, cytotoxicity, and possible carcinogenicity when quinacrine hydrochloride is used for intrauterine administration for non- surgical female sterilization: 2,3 o Quinacrine Hydrochloride for intrauterine administration • Revision to category 1 for clarity: o Modify the entry for “Quinacrine Hydrochloride” to “Quinacrine Hydrochloride (except for intrauterine administration).” • Revision to category 1 to correct a substance name error: o Correct the error in the substance name “DHEA (dehydroepiandosterone)” to “DHEA (dehydroepiandrosterone).” 1 For the purposes of the substance names in the categories, hydrated forms of the substance are included in the scope of the substance name. 2 Quinacrine HCl was previously reviewed in 2016 as part of FDA’s consideration of this bulk drug substance for inclusion on the 503A Bulks List. As part of this review, the Division of Bone, Reproductive and Urologic Products (DBRUP), now the Division of Urology, Obstetrics and Gynecology (DUOG), evaluated the nomination of quinacrine for intrauterine administration for non-surgical female sterilization and recommended that quinacrine should not be included on the 503A Bulks List for this use. This recommendation was based on the lack of information on efficacy comparable to other available methods of female sterilization and serious safety concerns of mutagenicity, cytotoxicity and possible carcinogenicity in use of quinacrine for this indication and route of administration. -

Bulk Drug Substances Nominated for Use in Compounding Under Section 503B of the Federal Food, Drug, and Cosmetic Act

Updated July 30, 2020 Bulk Drug Substances Nominated for Use in Compounding Under Section 503B of the Federal Food, Drug, and Cosmetic Act Three categories of bulk drug substances: • Category 1: Bulk Drug Substances Under Evaluation • Category 2: Bulk Drug Substances that Raise Significant Safety Risks • Category 3: Bulk Drug Substances Nominated Without Adequate Support Notice of Updates to Categories of Substances Nominated for the 503B Bulk Drug Substances List • Additions to category 1: Betahistine Hydrochloride L-Proline Citrulline Papaverine Hydrochloride* Copper Gluconate Phosphatidylcholine Diiodohydroxyquinoline Podophyllum Resin Glucosamine Sulfate Potassium Chloride Sodium Molybdate Glucosamine Sulfate Sodium Chloride Sodium Nitroprusside Hydrochloric Acid* Sodium Selenite/Sodium Selenite Pentahydrate* Ibutamoren Mesylate Trichloroacetic Acid* L-Citrulline* Ubidecarenone (Coenzyme Q10)* L-Lysine * Bulk drug substance is currently in Category 3 and is being moved to Category 1. • Minor revision to entry in Category 1 to correct a misspelling: o Correct the misspelling of “cimatidine” to “cimetidine” 1 Updated July 30, 2020 503B Category 1: Bulk Drug Substances Under Evaluation • 5-Methyltetrahydrofolate Calcium • Chromic Chloride • 17-alpha-Hydroxyprogesterone • Chromium chloride/ Chromium Chloride • Acetylcysteine Hexahydrate • Acyclovir • Ciclopirox Oleate • Adapalene • Cimetidine • Adenosine • Ciprofloxacin HCl • Allantoin • Citric Acid Anhydrous • Alpha Lipoic Acid • Citrulline/L-Citrulline • Alprostadil • Clindamycin Phosphate -

Assessment of the Antibiotic Resistance Effects of Biocides

Scientific Committee on Emerging and Newly Identified Health Risks SCENIHR Assessment of the Antibiotic Resistance Effects of Biocides The SCENIHR adopted this opinion at the 28th plenary on 19 January 2009 after public consultation. 1 Antibiotic Resistance Effects of Biocides About the Scientific Committees Three independent non-food Scientific Committees provide the Commission with the scientific advice it needs when preparing policy and proposals relating to consumer safety, public health and the environment. The Committees also draw the Commission's attention to the new or emerging problems which may pose an actual or potential threat. They are: the Scientific Committee on Consumer Products (SCCP), the Scientific Committee on Health and Environmental Risks (SCHER) and the Scientific Committee on Emerging and Newly Identified Health Risks (SCENIHR), and are made up of external experts. In addition, the Commission relies upon the work of the European Food Safety Authority (EFSA), the European Medicines Evaluation Agency (EMEA), the European Centre for Disease prevention and Control (ECDC) and the European Chemicals Agency (ECHA). SCENIHR Questions concerning emerging or newly-identified risks and on broad, complex or multi- disciplinary issues requiring a comprehensive assessment of risks to consumer safety or public health and related issues not covered by other Community risk-assessment bodies. In particular, the Committee addresses questions related to potential risks associated with interaction of risk factors, synergic effects, cumulative effects, antimicrobial resistance, new technologies such as nanotechnologies, medical devices, tissue engineering, blood products, fertility reduction, cancer of endocrine organs, physical hazards such as noise and electromagnetic fields and methodologies for assessing new risks. -

Disinfection of Gutta-Percha Cones Prior to Obturation: a Smattering of Historical Perspectives with a Focus on Contemporary Considerations

REVIEW ARTICLE James L. Gutmann, Vivian Manjarrés Disinfection of gutta-percha cones prior to obturation: a smattering of historical perspectives with a focus on contemporary considerations KEY WORDS antibiotics, atomic force microscopy, chlorhexidine, culturing, decontamination, disinfection, glutaraldehyde, gutta-percha, NaOCl ABSTRACT The use of gutta-percha in dentistry and in particular root canal procedures has a long and tortu- ous history; its use has been the preferred obturation material of choice for well over a century, in spite of attempts to eliminate it for other entities that were erroneously perceived to be superior. However, because of the importance of asepsis and bacteriological control in the delivery of qual- ity root canal procedures, the clinical disinfection of gutta-percha cones has arisen as a controver- sial issue as to its need and the use of the most effective agent for rapid chairside management. This review will touch upon a brief history of the material and subsequently delve into the issues surrounding the decontamination/disinfection of this material in the hope to establish the best evidence for the clinical choice of managing this challenge. Introduction Royal Society of Arts, London, in 1843, for his con- tribution3. In 1845, Hancock and Bewley formed Gutta-percha comes from the trees of the genus the Gutta- Percha Company in the United King- Palaquium in the family Sapotaceae1, with the dom, and began to expand the uses of this material rigid natural latex produced from the sap of these over and above medical applications into a wide trees, in particular from Palaquium gutta. The variety of entities, with golf balls a prime product word gutta-percha is based on the plant’s name for over 50 years3. -

Colloidal Dispersions

0356 ch 021(293-318).ps 3/7/05 8:14 AM Page 293 CHAPTER 21 Colloidal Dispersions Bill J Bowman, PhD Clyde M Ofner III, PhD Hans Schott, PhD The British chemist Thomas Graham applied the term “colloid” An appreciable fraction of atoms, ions, or molecules of col- (derived from the Greek word for glue) ca 1850 to polypeptides loidal particles are located in the boundary layer between the such as albumin and gelatin; polysaccharides such as acacia, particle and the dispersion medium. The boundary layer be- starch, and dextrin; and inorganic compounds such as gelati- tween a particle and air is commonly referred to as a surface; nous metal hydroxides and Prussian blue (ferric ferrocyanide). whereas, the boundary layer between a particle and a liquid or Contemporary colloid and surface chemistry deals with an un- solid is commonly referred to as an interface. The ions/molecules usually wide variety of industrial and biological systems. A few within the particle and within the medium are surrounded on all examples include catalysts, lubricants, adhesives, latexes for side by similar ions/molecules and have balanced force fields; paints, rubbers and plastics, soaps and detergents, clays, ink, however, the ions/molecules at surfaces or interfaces are sub- packaging films, cigarette smoke, liquid crystals, drug delivery jected to unbalanced forces of attraction. Consequently, a surface systems, cell membranes, blood, mucous secretions, and aque- free energy component is added to the total free energy of col- ous humors.1–3 loidal particles and becomes important as the particles become smaller and a greater fraction of their atoms, ions, or molecules are located in the surface or interfacial region. -

Kinetic and Mass-Spectrometric Studies of Atmospherically Relevant

Kinetic and mass-spectrometric studies of atmospherically relevant mercury-bromine chemistry Elise-Andrée Guérette Department of Chemistry McGill University Montréal, Québec, Canada October 2010 A thesis submitted to McGill University in partial fulfilment of the require ments of the degree of Master of Science ©Elise-Andrée Guérette, 2010. All Rights Reserved. Acknowledgements My thanks go out to Dr. Daniel Deeds for his help with everything having to do with atmospheric pressure chemical ionization mass spectrometry. Working with you was always a pleasure. Alain Tessier from CBAMS at Concordia Univer sity was immensely helpful and creative in his problem solving. Thanks also to Graydon Snider for helpful discussions and helping me get started with the kinetic work. Edward Hudson, Nermin Eltouny, Daniel Deeds, Graydon Snider and Ma hamud Subir all proofread this thesis and provided helpful comments. I would also like to extend grateful thanks to my supervisor, Parisa Ariya, for her understanding and patience, and for providing me with this opportunity. Thanks also for reading this thesis before its submission and for providing valu able comments. Fred Kluck, Rick Rossi and George Kopp from the Department of Chemistry deserve mention for their help building and repairing things, often at short notice. Thanks also to FQRNT, the Department of Chemistry at McGill, and the Dr. and Mrs. Milton Leong fund for providing personal financial assistance during the course of my studies. Thanks last, but perhaps most of all, to my spouse, Craig Titchener, who stood by me every step of the way. Thank you. II Abstract Bromine radicals are thought to play an important role in the chemistry of atmospheric elemental mercury, however uncertainties remain concerning the rate and the mechanism of the reaction. -

Kinetic and Mass-Spectrometric Studies of Atmospherically Relevant Mercury-Bromine Chemistry Elise-Andrée Guérette Department

Kinetic and mass-spectrometric studies of atmospherically relevant mercury-bromine chemistry Elise-Andrée Guérette Department of Chemistry McGill University Montréal, Québec, Canada October 2010 A thesis submitted to McGill University in partial fulfilment of the require ments of the degree of Master of Science ©Elise-Andrée Guérette, 2010. All Rights Reserved. Acknowledgements My thanks go out to Dr. Daniel Deeds for his help with everything having to do with atmospheric pressure chemical ionization mass spectrometry. Working with you was always a pleasure. Alain Tessier from CBAMS at Concordia Univer sity was immensely helpful and creative in his problem solving. Thanks also to Graydon Snider for helpful discussions and helping me get started with the kinetic work. Edward Hudson, Nermin Eltouny, Daniel Deeds, Graydon Snider and Ma hamud Subir all proofread this thesis and provided helpful comments. I would also like to extend grateful thanks to my supervisor, Parisa Ariya, for her understanding and patience, and for providing me with this opportunity. Thanks also for reading this thesis before its submission and for providing valu able comments. Fred Kluck, Rick Rossi and George Kopp from the Department of Chemistry deserve mention for their help building and repairing things, often at short notice. Thanks also to FQRNT, the Department of Chemistry at McGill, and the Dr. and Mrs. Milton Leong fund for providing personal financial assistance during the course of my studies. Thanks last, but perhaps most of all, to my spouse, Craig Titchener, who stood by me every step of the way. Thank you. II Abstract Bromine radicals are thought to play an important role in the chemistry of atmospheric elemental mercury, however uncertainties remain concerning the rate and the mechanism of the reaction.