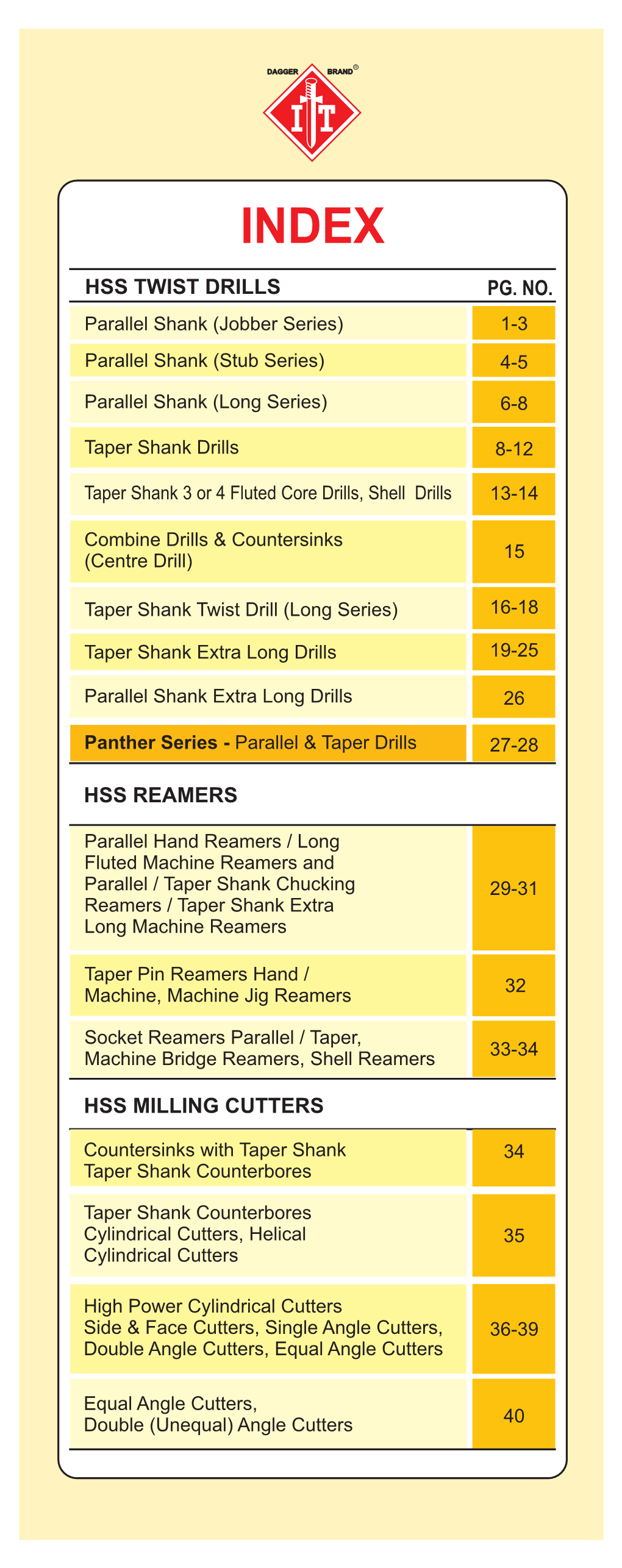

Hss Twist Drills Hss Reamers Pg. No. Hss Milling Cutters

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Accessories for Sherline

© 2012, LatheCity Endmill Holder www.LatheCity.com Accessories for Sherline Sherline Accessories Safety & Manual & Catalog LatheCity 1 © 2012, LatheCity Endmill Holder www.LatheCity.com 2 © 2012, LatheCity Endmill Holder www.LatheCity.com Various benchtop screw-on mill tool holders. Fast tool change system for benchtop milling machines. For current prices see our website. Product description and specifications: means of the set screw at the flat of the Aluminum screw-on-type holders for various endmill. Make sure that the set screw is tight. mill cutting and boring tools. The holders screw- Otherwise, the eventually heavy vibrations of on the spindle of a milling machine/lathe. The the mill may loosen the set screw and the tool holders fit endmills, center drills, deburrs, endmill. Jacobs drill chucks, etc. Add a fast tool change system to your benchtop milling machine. Available sizes A holder fits on a 3/4-16 spindle of a benchtop mill. Screw-on holders for cutting Endmills. Tool holders for 3/8 and 1/4 in. tools of 1 mm to 1/2 in. O.D. shank size are O.D. double- or single-ended endmills will fit. In available (English or Metric sizes). The detailed stock. P/N list is given below. Center drills. Tool holders for #1, #2, and #3 Adapters are tested on Sherline’s tabletop center drills are available. #1 and #2 adapters systems only and are restricted to a maximum are longer than endmill holders and have revolution per minute (rpm) of 2800 for light narrower noses. In stock. metal work on a benchtop/tabeltop system. -

LESSON PLAN Trade: Machinist & Operator Advance Machine Tool

LESSON PLAN Trade: Machinist & Operator Advance Machine Tool Module/Unit: 2 Date: 15.02.2021 Time: 45 minutes Lesson No: 8 I.PREPARATION: Title: NOMENCLATURE OF DRILL 1. Objectives: At the end of the lesson the trainees will be able to: Identify the parts of twist drill & state the function of each part. Identify the various angles of twist drill and state its functions. 2. Teaching Aids: White board, Marker, Pointer, Duster, Chart, Model, Visualizer, Projector etc. 3. Introduction a. Review: In the previous lesson, we took the information about types of drill & its functions. b. Motivation: Motivate about drilling process. II.PRESENTATION: Developments / Information Points Hints Topics Parts of twist drill & Main parts of twist drill are: its function Point - is the cone shaped end, which Show models & chart does the cutting. Consist of dead center, lips or cutting edge & heel. Tang - provided on taper shank drills, for driving the drill. Flutes — are the spiral grooves on the length of drill. Helps to form cutting edges, to curl the chips & to flow the coolant. Shank — driving end of the drill, which is fitted on the machine. Taper shank is used for large diameter drills & straight shank is used for small diameter drills. Land/margin - is the narrow strip, extends to the flutes of drill. The diameter of the drill is measured across the land. Body clearance - is the part of the body, which is reduced in diameter to cut down the friction. Web - separates the flutes. Increases in thickness towards shanks. Angles of twist drill Like all cutting tool drills are provided with Show chart of and its functions certain angles for efficiency in drilling recommended drills for different materials Point/cutting angle - is the angle between the cutting edges. -

Study Unit Toolholding Systems You’Ve Studied the Process of Machining and the Various Types of Machine Tools That Are Used in Manufacturing

Study Unit Toolholding Systems You’ve studied the process of machining and the various types of machine tools that are used in manufacturing. In this unit, you’ll take a closer look at the interface between the machine tools and the work piece: the toolholder and cutting tool. In today’s modern manufacturing environ ment, many sophisti- Preview Preview cated machine tools are available, including manual control and computer numerical control, or CNC, machines with spe- cial accessories to aid high-speed machining. Many of these new machine tools are very expensive and have the ability to machine quickly and precisely. However, if a careless deci- sion is made regarding a cutting tool and its toolholder, poor product quality will result no matter how sophisticated the machine. In this unit, you’ll learn some of the fundamental characteristics that most toolholders have in common, and what information is needed to select the proper toolholder. When you complete this study unit, you’ll be able to • Understand the fundamental characteristics of toolhold- ers used in various machine tools • Describe how a toolholder affects the quality of the machining operation • Interpret national standards for tool and toolholder iden- tification systems • Recognize the differences in toolholder tapers and the proper applications for each type of taper • Explain the effects of toolholder concentricity and imbalance • Access information from manufacturers about toolholder selection Remember to regularly check “My Courses” on your student homepage. Your instructor -

Grinding Machines: (14 Metal Buildup:And (15) the (Shipboard) Repair Department and Repair Work

DOCUMENT RESUME ED 203 130 CE 029 243 AUTHOR Bynum, Michael H.: Taylor, Edward A. TITLE Machinery Repairman 3 6 2. Rate TrainingManual and Nonresident Career Course. Revised. INSTITUTION Naval Education and Training Command,Washington, D.C. REPORT NO NAVEDTRA-10530-E PUB DATE 81 NOTE 671p.: Photographs andsome diagrams will not reproduce well. EDRS PRICE MF03/PC27 Plus Postage. DESCRIPTORS Behavioral Objectives; CorrespondenceStudy; *Equipment Maintenance: Rand Tools;Independent Study: Instructional Materials: LearningActivities: Machine Repairers: *Machine Tools;*Mechanics (Process): Military Training: Postsecondary Education: *Repair: Textbooks: *Tradeand Industrial Education IDENTIFIERS Navy ABSTRACT This Rate Training Manual (textbook)and Nonresident Career Course form a correspondence self-studypackage to teach the theoretical knowledge and mental skillsneeded by the Machinery Repairman Third Class and Second Class. The15 chapters in the textbook are (1)Scope of the Machinery Repairman Rating:(2) Toolrooms and Tools:(3) Layout and Benchwork: (4) Metals and Plastics:(51 Power Saws and Drilling Machines:(6) Offhand Grinding of Tools:(7) Lathes and Attachments:(8) Basic Engine Lathe Operations:(9) Advanced Engine Lathe Operations: (10)Turret Lathes and Turret Lathe Operations:(11) Milling Machines and Milling Operations:(121 Shapers, Planers, and Engravers: (13)Precision Grinding Machines: (14 Metal Buildup:and (15) The (Shipboard) Repair Department and Repair Work. Appendixesinclude Tabular Tnformation of Benefit to Machinery Repairman(23 tables), Formulas. for Spur Gearing, Formulas for DiametralPitch System, and Glossary. The Nonresident Career Course follows theindex. It contains T1 assignments, which are organized into thefollowing format: textbook assignment and learning objectives withrelated sets of teaching items to be answered. (YLB) *********************************************************************** Peproductions supplied by EDRSare the best that can be made from the original document. -

Portable Mini Wood Lathe Machine Umakant Mahajan1, Mayank Patidar2, Shubham Viswakarma3, Shubham Wasnik4, Atal Singh5, Akash Khare6, Ashish Chaturvedi7

INTERNATIONAL JOURNAL OF INNOVATIVE TRENDS IN ENGINEERING (IJITE) ISSN: 2395-2946 ISSUE: 61, VOLUME 40, NUMBER 01, APRIL 2018 Portable Mini Wood Lathe Machine Umakant Mahajan1, Mayank Patidar2, Shubham Viswakarma3, Shubham Wasnik4, Atal Singh5, Akash Khare6, Ashish Chaturvedi7 1-6Research Scholar, 7Research Guide Department Of Mechanical Engineering, Oriental College Of Technology Bhopal. Abstract -To achieve the aim of producing a functional Portable consist of a ball bearing which is allowed to free rotation wood lathe machine. We analyzed and as well synthesized the and support of job from the other side. It also consist a different possible design solutions and concepts. We carried out holder to hold the desired tool and this holder can slide the analysis of different component part of the machine to over bed in parallel to axis of job rotation. We use chuck determine their suitable dimensions based on loading and attached to drilling machine shaft in order to rotate the job. stresses due to them. We used available local material and tool from workshop. We also made use of some machine tools in the The machine is build to hold the work piece and move the college workshop. Finally, the parts were assemble and the tool in sliding mechanism, so as to achieve a desired machine test – run. To ensure the achievement of best operations. The machine outer face is design to hold the performance, interactive procedures, were carried out. The work piece firmly with tool in place so as to achieve material, labour and overhead costs were determined to get the desired operations with ease. -

Ln1w / Ln2w Control

WIRE EDM MACHINE OPERATION TRAINING LN1W / LN2W CONTROL (AQ400L, AQ600L, AD360L, All with FJ AWT) Part Number 6300015 January, 2012 (AQ400L, AQ600L, AD360L, All with FJ AWT) Copyright notice: The entire contents of this manual are protected under copyright laws. All rights reserved. Sodick Inc. 1605 N. Penny Lane Schaumburg, IL 60173 (847) 310-9000 Table Of Contents DESCRIPTION OF THIS MANUAL vi Chapter 1 DESCRIPTION OF THE EDM PROCESS 1 GENERAL EDM FACTORS 2 WIRE DIAMETER AND WIRE GUIDES 2 WIRE TYPE 3 FLUSHING & NOZZLES 3 WATER RESISTIVITY 5 Chapter 2 MACHINE LAYOUT DESCRIPTION 6 CONTROL PANEL SWITCHES 7 MACHINE PANEL SWITCHES 11 ADDITIONAL ITEMS 12 UNDERSTANDING WORK COORDINATE SCREENS 13 Chapter 3 MAINTENANCE 15 DISPLAY MAINTENANCE SCREEN 15 MAINTENANCE CHECKLIST 16 Daily Inspection Items 16 Weekly Inspection Items 16 Monthly Inspection Items 16 MAINTENANCE DESCRIPTIONS 17 DI BOTTLE 17 WORKTANK AND WORKTABLE 17 WATER LEVEL 17 WIRE GUIDES 20 LOWER WIRE ROLLER ASSEMBLY 20 WIRE EJECTION ROLLERS 21 WAY LUBRICATION 22 WIRE GUIDE ASSEMBLY DRAWINGS 22 LOWER HEAD ALIGNMENT PROCEDURE 24 Lower Head Alignment 24 Chapter 4 WIRE AND PART SETUP PROCEDURES 26 CHANGING WIRE SIZE SETTINGS ON THE MACHINE 26 SPOOL WEIGHT SETTING 27 VERTICAL WIRE ALIGNMENT 28 Copyright January 2012 Sodick Inc. VERTICAL ALIGNMENT MANUAL PROCEDURE 28 VERTICAL ALIGNMENT AUTOMATIC PROCEDURE 30 AWT ADJUSTMENTS ALIGNMENT PROCEDURE 31 MANUAL TILT OFFSET 33 AUTO TILT OFFSET 34 APPROACH FACE 35 EDGE FIND USING G80 36 EDGE FIND BY USING THE ST KEY 37 WIDTH CENTERING 38 CORNER FIND -

Characteristics of Speed Line Cutter and Fringe Analysis of Workpiece Surface

SHS Web of Conferences 4, 01005 (2014) DOI: 10.1051/shsconf/20140401005 C Owned by the authors, published by EDP Sciences, 2014 Characteristics of Speed Line Cutter and Fringe Analysis of Workpiece Surface Wang Shuai Shenyang Aerospace University, Shenyang Liaoning 110136 Abstract: Easy to operate, speed line cutter has a high machining cost performance, so is very popular among the majority of users. The precision of guide rails, screws and nuts used in most of the machines is not high, and the machine control cannot compensate for the screw pitch error, clearance during the transmission and machining error due to electrode wear. Furthermore, control signal may also be lost in control process. The development of speed line cutter focuses on the quality and machining stability of CNC speed line cutter. This article makes an analysis about the impact of machine’s inherent characteristics on machining workpiece surface, and concludes that analysis shall be made on the irregular fringe, therefore to heighten the machining precision. Keywords: speed line; multiple cutting; precision; fringe With the development of mold and die industry, the affect the guide rail. For instance, the unparalleled axial increasing proportion of precision mold manufacturing direction of screws with guide rail, inconsistent central eagerly requires electrospark cutting machining to height for screws and guide rail or, as a torsion may be ensure its fast speed, fairly good surface machining applied between them or as the screws bend, will quality and relatively high machining precision. The forcefully interfere in and disrupt the linear motion of changes in space and shape for wire-electrode analyzed guide rail during screws motional process. -

139 Prospekt WA ENG.Pdf

Multiple awards OUR PERFORMANCE makes THE DIFFERENCE Version 9.0 Englisch - English THE ORIGINALL Made in Germany Tool change systems Tool arena 4.0 Tool arena linear Tool arenas with aggregate handling PATENT Compact arena by demmeler Demmeler Tool Arena – The combination of power, effi ciency and dynamics! The advantages highest availability due to the integration of industrial robots which have been tried and tested thousands of times very high adaptability to various machine controls due to freely programmable PC-based systems large number of tools; up to approx.500 handling of all standard tool holders: HSK 100A / HSK 125B / SK50 / SK60 / CAPTO C6 / CAPTO C8; additional holders on request tools very large in diameter and length are possible; diameter up to 400 mm, bridge-type tools up to 800 mm, length of tools up to 1500 mm the number of tool places is retrofi ttable and can be upgraded shape and size of tool magazine can be adapted modularly to the machine short tool pre select time due to double gripper system, thus rapid change times time of tool change approx. 5 sec (depending on specifi cation) very heavy tools, depending on type of robot, up to 150 kg; this makes it also possible to put in multi-spindle devices, angle heads, additional drive systems of HSC spindles tool change into various spindles possible – horizontally and vertically and in angle positions one unit for tool pre selection and tool change. In the case of smaller machines, it is possible to use the robot only for tool pre selection parallel grippers incl. -

SOUTH BEND LATHE F

SOUTH BEND LATHE f l'A!taiog 5600, Copyright 1955 by the South Bend L"the Works. All rights reserved. I 9 0 6 50th Anniversary 1956 It was in the fall of 1906 that twin brothers John J. and Miles W. O'Brien set up shop in a small building at South Bend, Indiana and began to design and build precision machine tools. Although bringing with them a rich heritage of Yankee ingenuity, their products were a success only after years of hard, painstaking effort and financial hardship. Both brothers had served toolmaker apprenticeships in some of the finest of the old New England shops. Later they supplemented their practical training with engineering courses at Purdue Univer sity and gained wide business experience with several well established machine tool manufacturers and distributors. Recognizing the advantage of specialization, one of the first and most important decisions of the O'Brien brothers was to restrict their products to precision machine tools. It was this policy that enabled them to produce a b~tter machine at a better price. Through half a century there has been no devia tion from this policy. Today, as in 1906, the entire resources and facilities of South Bend Lathe are devoted exclusively to the production of precision machine tools. PLANT NO. 2 Operated first as a partnership and incorporated in 1914, the South Bend Lathe Works remained a closely held corpora tion until 1936 when its stock was first listed on the Chicago Stock Exchange, now the Midw:est Stock Exchange of Chicago. The stock is now owned by a diversified group of shareholders residing in all parts of the United States and several outside this country. -

Always Excel EXCELLENT QUALITY - VALUE - CUSTOMER CARE EXCELLENT QUALITY - VALUE - CUSTOMER CARE - CUSTOMER - VALUE QUALITY EXCELLENT

SUPERIOR QUALITY PROFESSIONAL MACHINE TOOLS MAIN CATALOGUE 2021 Always Excel EXCELLENT QUALITY - VALUE - CUSTOMER CARE - CUSTOMER - VALUE QUALITY EXCELLENT EXCELLENT QUALITY - VALUE - CUSTOMER CARE - CUSTOMER - VALUE QUALITY EXCELLENT Cnc Machines, Grinders, Lathes, Shears, Drills, Mills, Guillotines, Saws, Plate Bending Rolls, Press Brakes, Lots More! Visit : www.excelmachinetools.co.uk INDEX by Categories CNC LATHES 12-18 'Always Excel' CNC Lathe Tooling 19 ADDRESS: Excel Machine Tools Colliery Lane CNC MILLS 20-26 Exhall Coventry CNC Mill Tooling 27-33 CV7 9NW UK MANUAL LATHES 34-59 NATIONAL CONTACT Tooling for Lathes 60-80 TEL: 0247 636 5255 FAX: 0247 636 6666 MANUAL MILLS 81-104 INTERNATIONAL Tooling for Mills 105-132 CONTACT TEL: +44 (24) 7636 5255 FAX: +44 (24) 7636 6666 DRILLING M/C 133-153 EXTENSIONS Tooling for Drills 154-164 Option 1 for Sales Option 2 for Spares & Services Option 3 for Credit Control Option 4 for Purchase Ledger GRINDING M/C 165-196 Option 5 for General Enquiries Accessories 197 EXTENSIONS 5823 - Lisa SAWING M/C 198-222 5824 - Elaine 5826 - Geoff Accessories 223 5828 - Jag 5830 - Glenys FABRICATION EMAIL ADDRESSES MACHINES 224-256 [email protected] [email protected] [email protected] [email protected] LIFTING, MOVING & SANDBLASTING 257-267 OPENING TIMES 8.30 - 5.00 Mon - Thur 8.30 - 4.00 Friday Weekend & after hour appointments WOODWORKING 268-285 available by request 2 Alphabetical INDEX Metalworking Machines AINDEX Collets 5C 60 G Abrasive Saws 222 -

Capital Machine Technologies, Inc. the South’S Leading Distributor of Metal Fabrication Machine Tools and Robotic Welding Solutions

MACHINE CAPITAL Capital Machine Technologies Capital Machine Technologies, Inc. The South’s leading distributor of Metal Fabrication Machine Tools And Robotic Welding solutions. In 1984, Capital Machine Technologies, Inc. (CMT) was established in Tampa, FL and founded on the concept of helping clients produce tomorrow’s quality products in today’s competitive global marketplace. Our operations have since expanded to service the entire southern U.S. with additional showrooms in Atlanta, GA and Dallas, TX. Our list of services includes Preventive Maintenance & Repair Services, Installation Supervision, Operator Training and Programming Training. All of our technicians are factory-trained, full-time (not part-time or contracted), employees. We back the innovation of our world-class machine builders with personalized service and support. By having our staff of over 20 plus service engineers strategically placed throughout the region, Capital Machine provides more service and support than any other vendor. MACHINE Capital offers substantial advantages over all competitors, we have the ability and experience to handpick partnerships with many of the world’s top leading machine builders, specializing in key areas of expertise. This enables us to offer our customers specific solutions packaged to meet their fabrication and robotic welding needs. Capital gives you options, control, and support. We give you the “Capital Advantage.” We believe the “human-side” of business is just as important as the technology and innovation it relies on. Our Sales Team is experienced, qualified and backed up by a strong group of professionals providing many years of consultative experiences. Combined, this group will help you achieve the maximum return on your new machinery investments. -

Metric Jobber Drills

INDEX DRILLS Jobber Length Drills........................................................ 01 DIN338 HSS Hex Shank Drills.......................................... 83 Heavy Duty 135º Split Point Drills................................... 04 Annular Cutters.................................................................... 84 HSS Left Hand Jobber Drills............................................ 07 Metric TCT Annular Cutters................................................. 86 HSS Fast & Slow Spiral Jobber Drills.............................. 08 Combined Drills & Countersinks.......................................... 87 Parabolic Flute Jobber Drills........................................... 09 Metric Center Drill-DIN333.................................................. 88 Metric Jobber Drills.......................................................... 10 Solid Carbide Center Drills.................................................. 89 JIS B4301-97 HSS Metric Straight Shank Twist Drill Right Hand...................................................................... 14 COUNTERBORES DIN338 Metric HSS Left Hand Jobber Drills.................... 16 Capscrew Counterbores....................................................... 90 Screw Machine Drills....................................................... 16 Flat Countersink Fixed Guide (DIN 373).............................. 90 Left Hand Screw Machine Drills...................................... 20 Taper Shank Flat Countersink Fixed Guide (DIN375).......... 91 Taper Length Drills.........................................................