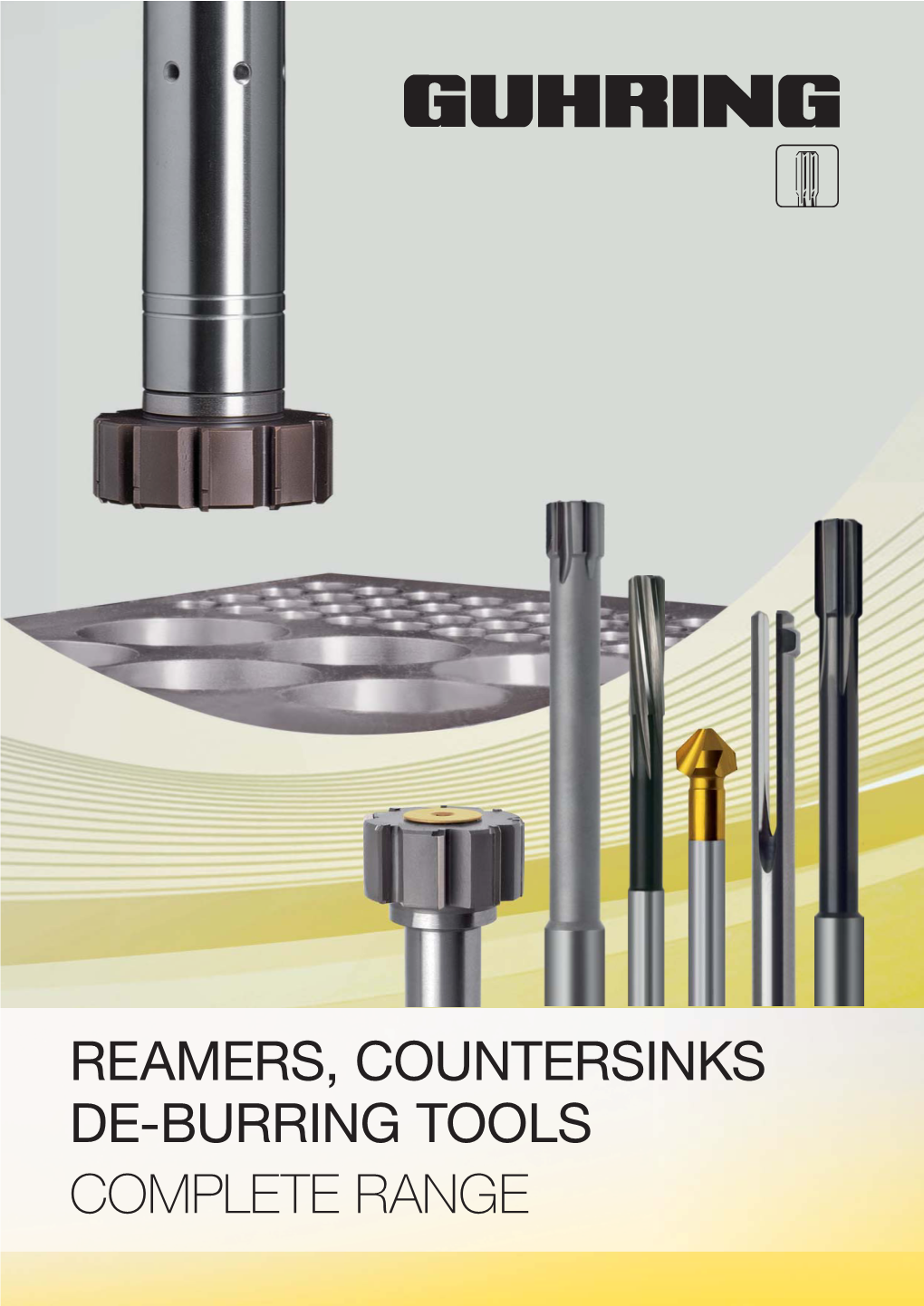

Reamers, Countersinks De-Burring Tools Complete Range Hr 500 High-Performance Reamers

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Accessories for Sherline

© 2012, LatheCity Endmill Holder www.LatheCity.com Accessories for Sherline Sherline Accessories Safety & Manual & Catalog LatheCity 1 © 2012, LatheCity Endmill Holder www.LatheCity.com 2 © 2012, LatheCity Endmill Holder www.LatheCity.com Various benchtop screw-on mill tool holders. Fast tool change system for benchtop milling machines. For current prices see our website. Product description and specifications: means of the set screw at the flat of the Aluminum screw-on-type holders for various endmill. Make sure that the set screw is tight. mill cutting and boring tools. The holders screw- Otherwise, the eventually heavy vibrations of on the spindle of a milling machine/lathe. The the mill may loosen the set screw and the tool holders fit endmills, center drills, deburrs, endmill. Jacobs drill chucks, etc. Add a fast tool change system to your benchtop milling machine. Available sizes A holder fits on a 3/4-16 spindle of a benchtop mill. Screw-on holders for cutting Endmills. Tool holders for 3/8 and 1/4 in. tools of 1 mm to 1/2 in. O.D. shank size are O.D. double- or single-ended endmills will fit. In available (English or Metric sizes). The detailed stock. P/N list is given below. Center drills. Tool holders for #1, #2, and #3 Adapters are tested on Sherline’s tabletop center drills are available. #1 and #2 adapters systems only and are restricted to a maximum are longer than endmill holders and have revolution per minute (rpm) of 2800 for light narrower noses. In stock. metal work on a benchtop/tabeltop system. -

Horizontal Directional Drilling

Secoroc Rock Drilling Tools Horizontal Directional Drilling Pilot Bits and Hole Openers H orizontal Something oriented horizontally; parallel to or in the plane of the horizon or a base line. D irectional Relating to or indicating a direction; a goal; showing the way by conducting or leading. D rilling Drilling is the cutting of a hole into a solid. Directional boring, commonly called horizontal directional drilling or HDD, is a steerable trenchless method of installing underground pipes, conduits and cables in a shallow arc along a prescribed bore path, by using a surface launched drilling rig, with minimal impact on the surrounding area. Atlas Copco Secoroc can take your HDD business in a new direction! Secoroc Horizontal Directional Drilling Products Atlas Copco has been in the mining and construction market for many years and is committed to innovative, productive, market leading solutions. Atlas Copco Secoroc has over Texas, USA. The production the years set the standard on plant is ISO 9001 and API certi- many Horizontal Directional fied ensuring world class quality Drilling projects involving Hard is delivered to the HDD market. Rock and difficult conditions. You can rely on our technical ex- pertise – any time – anywhere. Our HDD equipment range includes: Our products are the result of – Pilot Bits in all sizes and types decades of drilling research and development and are manufactu- – "Split Bit" Hole Openers in- red in our world class manufac- corporating a common, random turing facility in Grand Prairie, bit third HDD product range Atlas Copco Secoroc Direct ShotTM pilot bits, Sealed Bearing random bit third cutters and Random bit third hole openers are specifically designed for the rigors of HDD applications. -

Introduction to Turning Tools and Their Application Identification and Application of Cutting Tools for Turning

Introduction to Turning Tools and their Application Identification and application of cutting tools for turning The variety of cutting tools available for modern CNC turning centers makes it imperative for machine operators to be familiar with different tool geometries and how they are applied to common turning processes. This course curriculum contains 16-hours of material for instructors to get their students ready to identify different types of turning tools and their uses. ©2016 MachiningCloud, Inc. All rights reserved. Table of Contents Introduction .................................................................................................................................... 2 Audience ..................................................................................................................................... 2 Purpose ....................................................................................................................................... 2 Lesson Objectives ........................................................................................................................ 2 Anatomy of a turning tool............................................................................................................... 3 Standard Inserts .............................................................................................................................. 3 ANSI Insert Designations ............................................................................................................. 3 Insert Materials -

Manufacturing Glossary

MANUFACTURING GLOSSARY Aging – A change in the properties of certain metals and alloys that occurs at ambient or moderately elevated temperatures after a hot-working operation or a heat-treatment (quench aging in ferrous alloys, natural or artificial aging in ferrous and nonferrous alloys) or after a cold-working operation (strain aging). The change in properties is often, but not always, due to a phase change (precipitation), but never involves a change in chemical composition of the metal or alloy. Abrasive – Garnet, emery, carborundum, aluminum oxide, silicon carbide, diamond, cubic boron nitride, or other material in various grit sizes used for grinding, lapping, polishing, honing, pressure blasting, and other operations. Each abrasive particle acts like a tiny, single-point tool that cuts a small chip; with hundreds of thousands of points doing so, high metal-removal rates are possible while providing a good finish. Abrasive Band – Diamond- or other abrasive-coated endless band fitted to a special band machine for machining hard-to-cut materials. Abrasive Belt – Abrasive-coated belt used for production finishing, deburring, and similar functions.See coated abrasive. Abrasive Cutoff Disc – Blade-like disc with abrasive particles that parts stock in a slicing motion. Abrasive Cutoff Machine, Saw – Machine that uses blade-like discs impregnated with abrasive particles to cut/part stock. See saw, sawing machine. Abrasive Flow Machining – Finishing operation for holes, inaccessible areas, or restricted passages. Done by clamping the part in a fixture, then extruding semisolid abrasive media through the passage. Often, multiple parts are loaded into a single fixture and finished simultaneously. Abrasive Machining – Various grinding, honing, lapping, and polishing operations that utilize abrasive particles to impart new shapes, improve finishes, and part stock by removing metal or other material.See grinding. -

1. Hand Tools 3. Related Tools 4. Chisels 5. Hammer 6. Saw Terminology 7. Pliers Introduction

1 1. Hand Tools 2. Types 2.1 Hand tools 2.2 Hammer Drill 2.3 Rotary hammer drill 2.4 Cordless drills 2.5 Drill press 2.6 Geared head drill 2.7 Radial arm drill 2.8 Mill drill 3. Related tools 4. Chisels 4.1. Types 4.1.1 Woodworking chisels 4.1.1.1 Lathe tools 4.2 Metalworking chisels 4.2.1 Cold chisel 4.2.2 Hardy chisel 4.3 Stone chisels 4.4 Masonry chisels 4.4.1 Joint chisel 5. Hammer 5.1 Basic design and variations 5.2 The physics of hammering 5.2.1 Hammer as a force amplifier 5.2.2 Effect of the head's mass 5.2.3 Effect of the handle 5.3 War hammers 5.4 Symbolic hammers 6. Saw terminology 6.1 Types of saws 6.1.1 Hand saws 6.1.2. Back saws 6.1.3 Mechanically powered saws 6.1.4. Circular blade saws 6.1.5. Reciprocating blade saws 6.1.6..Continuous band 6.2. Types of saw blades and the cuts they make 6.3. Materials used for saws 7. Pliers Introduction 7.1. Design 7.2.Common types 7.2.1 Gripping pliers (used to improve grip) 7.2 2.Cutting pliers (used to sever or pinch off) 2 7.2.3 Crimping pliers 7.2.4 Rotational pliers 8. Common wrenches / spanners 8.1 Other general wrenches / spanners 8.2. Spe cialized wrenches / spanners 8.3. Spanners in popular culture 9. Hacksaw, surface plate, surface gauge, , vee-block, files 10. -

Machining Magnesium – Datasheet

DATASHEET DATASHEET • Machining Magnesium 254 † Magnesium is the lightest structural metal and Table 1. Relative power and comparative machinability of metals. exhibits excellent machinability. Some of the AISI - B1112 Relative advantages of machining magnesium compared to Metal machinability power other commonly used metals include: index (%) Magnesium alloys 1.0 500 • Low power required – approximately 55% of that Aluminium alloys 1.8 300 required for Al Mild steel 6.3 50 • Fast machining – employing the use of high cutting speeds, large feed rates and greater depths of cut Titanium alloys 7.6 20 • Excellent surface finish – extremely fine and smooth surface achieved Speeds, feeds and depths of cut • Well broken chips – due to the free-cutting qualities of magnesium The potential for high speed machining of • Reduced tool wear – leading to increased tool life magnesium alloys is usually only limited by the stability of the component in the clamping device, To fully exploit and enjoy the advantages of chip extraction or the rotation speed or accuracy machining magnesium, it is important that the unique limits of the tool or machine. Some relative cutting characteristics of the metal are understood. speeds using HSS tools are given in Table 2. Cutting speeds are also dependant on the tool material. Cutting power and machinabilty Higher speeds can be enjoyed with the use of carbide or poly-crystalline diamond (PCD) tooling. The mean specific cutting force (ks1.1) of magnesium is 280 N/mm2, this is much lower than that of In general, cutting speeds are between aluminium (approx 640 N/mm2). The result of this 200 – 1800 m/min with feed rates greater than means that there is a reduced load on the cutter and 0.25 mm/rev for turning and boring operations. -

LESSON PLAN Trade: Machinist & Operator Advance Machine Tool

LESSON PLAN Trade: Machinist & Operator Advance Machine Tool Module/Unit: 2 Date: 15.02.2021 Time: 45 minutes Lesson No: 8 I.PREPARATION: Title: NOMENCLATURE OF DRILL 1. Objectives: At the end of the lesson the trainees will be able to: Identify the parts of twist drill & state the function of each part. Identify the various angles of twist drill and state its functions. 2. Teaching Aids: White board, Marker, Pointer, Duster, Chart, Model, Visualizer, Projector etc. 3. Introduction a. Review: In the previous lesson, we took the information about types of drill & its functions. b. Motivation: Motivate about drilling process. II.PRESENTATION: Developments / Information Points Hints Topics Parts of twist drill & Main parts of twist drill are: its function Point - is the cone shaped end, which Show models & chart does the cutting. Consist of dead center, lips or cutting edge & heel. Tang - provided on taper shank drills, for driving the drill. Flutes — are the spiral grooves on the length of drill. Helps to form cutting edges, to curl the chips & to flow the coolant. Shank — driving end of the drill, which is fitted on the machine. Taper shank is used for large diameter drills & straight shank is used for small diameter drills. Land/margin - is the narrow strip, extends to the flutes of drill. The diameter of the drill is measured across the land. Body clearance - is the part of the body, which is reduced in diameter to cut down the friction. Web - separates the flutes. Increases in thickness towards shanks. Angles of twist drill Like all cutting tool drills are provided with Show chart of and its functions certain angles for efficiency in drilling recommended drills for different materials Point/cutting angle - is the angle between the cutting edges. -

Study Unit Toolholding Systems You’Ve Studied the Process of Machining and the Various Types of Machine Tools That Are Used in Manufacturing

Study Unit Toolholding Systems You’ve studied the process of machining and the various types of machine tools that are used in manufacturing. In this unit, you’ll take a closer look at the interface between the machine tools and the work piece: the toolholder and cutting tool. In today’s modern manufacturing environ ment, many sophisti- Preview Preview cated machine tools are available, including manual control and computer numerical control, or CNC, machines with spe- cial accessories to aid high-speed machining. Many of these new machine tools are very expensive and have the ability to machine quickly and precisely. However, if a careless deci- sion is made regarding a cutting tool and its toolholder, poor product quality will result no matter how sophisticated the machine. In this unit, you’ll learn some of the fundamental characteristics that most toolholders have in common, and what information is needed to select the proper toolholder. When you complete this study unit, you’ll be able to • Understand the fundamental characteristics of toolhold- ers used in various machine tools • Describe how a toolholder affects the quality of the machining operation • Interpret national standards for tool and toolholder iden- tification systems • Recognize the differences in toolholder tapers and the proper applications for each type of taper • Explain the effects of toolholder concentricity and imbalance • Access information from manufacturers about toolholder selection Remember to regularly check “My Courses” on your student homepage. Your instructor -

Guide to Machining Carpenter Specialty Alloys Guide to Machining Carpenter Special Ty All O Ys

GUIDE TO MACHINING CARPENTER SPECIAL GUIDE TO MACHINING CARPENTER SPECIALTY ALLOYS Carpenter Technology Corporation TY ALL Wyomissing, PA 19610 U.S.A. 1-800-654-6543 Visit us at www.cartech.com O YS For on-line purchasing in the U.S., visit www.carpenterdirect.com GUIDE TO MACHINING CARPENTER SPECIALTY ALLOYS Carpenter Technology Corporation Wyomissing, Pennsylvania 19610 U.S.A. Copyright 2002 CRS Holdings, Inc. All Rights Reserved. Printed in U.S.A. 9-02/7.5M The information and data presented herein are suggested starting point values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his/her own evaluation and are not intended as warranties, either express or implied, of fitness for these or other purposes. There is no representation that the recipient of this literature will receive updated editions as they become available. Unless otherwise noted, all registered trademarks are property of CRS Holdings, Inc., a subsidiary of Carpenter Technology Corporation. ISO 9000 and QS-9000 Registered Headquarters - Reading, PA Guide to Machining CARPENTER SPECIALTY ALLOYS Contents Introduction ............................................................................. 1 General Stainless Material and Machining Characteristics .... 3 Classification of Stainless Steels .............................................. 5 Basic Families and Designations ........................................ 5 Austenitic -

Instrumente Für Hüftprothesen Instruments for Hip Prosthesis

Instrumente für Hüftprothesen Instruments for Hip Prosthesis 11.1 11.2 Instrumente für Hüftprothesen Instruments for Hip Prosthesis Instrumentation for Austin Moore Hip Prosthesis 11-076 Moore Rasp for Standard Stem 11-078 Moore Rasp for Narrow Stem 11-080 Mortising chisel 11-082 Prosthesis extractor 11-084 Femoral Head Extractor 11.3 Instrumente für Hüftprothesen Instruments for Hip Prosthesis 11-086 Prosthesis Driver 11-087 Head Only 11-088 Murphy Lane Bone Skid 11-260 Thompson Rasp 11.4 Instrumente für Hüftprothesen Instruments for Hip Prosthesis Instrumentation for Selflocking Prosthesis Rasps, stainless steel Order No: Head ø mm 11-2400 7.5 11-2402 10.0 11-2404 12.5 11-2406 15.0 11-2408 17.5 11-2410 20.0 11.5 Instrumente für Hüftprothesen Instruments for Hip Prosthesis Acetabulum-Fräser-System Acetabulum Reamer System Standard AO Ansatz Fräseraufsatz mit Schnellverschluss 11-3470 11-3472 Reamer with quick locking device 11-3440 ø 40 mm 11-3442 ø 42 mm 11-3444 ø 44 mm Acetabulumfräser: 11-3446 ø 46 mm Die Fräseraufsätze werden schlüssellos mit 11-3448 ø 48 mm dem Fräserschaft gekuppelt. Es ist nur ein 11-3450 ø 50 mm Schaft für das Sytstem erforderlich. 11-3452 ø 52 mm 11-3454 ø 54 mm Acetabulum reamer: 11-3456 ø 56 mm The reamer heads are coupled with shafts 11-3458 ø 58 mm without a key. Only one shaft is necessary 11-3460 ø 60 mm for the system. 11-3462 ø 62 mm 11-3464 ø 64 mm 11.6 Instrumente für Hüftprothesen Instruments for Hip Prosthesis 11-4200 Cup Positioning Guides complete 11-4201 Position Guide 40 11-4210 32 mm Plastic Cap for Cup Introducer 11-4212 28 mm Plastic Cap for Cup Introducer C.D.H. -

Orthopaedics CAPENER CHISEL

Orthopaedics CAPENER CHISEL PN0463 PN0137 CODE DESCRIPTION LENGTH WIDTH PN0460 Capener Chisel, Straight 260 6 PN0977 Capener Chisel, Straight 260 8 PN0461 Capener Chisel, Straight 260 10 PN0462 Capener Chisel, Straight 260 12 PN0463 Capener Chisel, Straight 260 15 PN0464 Capener Chisel, Straight 260 20 PN0465 Capener Chisel, Straight 260 25 PN0978 Capener Chisel, Straight 260 30 PN0137 Capener Chisel, Curved 260 6 PN0979 Capener Chisel, Curved 260 8 PN0980 Capener Chisel, Curved 260 10 PN0981 Capener Chisel, Curved 260 12 PN0982 Capener Chisel, Curved 260 15 PN0983 Capener Chisel, Curved 260 20 PN0984 Capener Chisel, Curved 260 25 PN0985 Capener Chisel, Curved 260 30 158 CAPENER OSTEOTOME PN0451 PN0458 CODE DESCRIPTION LENGTH WIDTH PN0451 Capener Osteotome, Straight 260 6 PN0089 Capener Osteotome, Straight 260 8 PN0313 Capener Osteotome, Straight 260 10 PN0314 Capener Osteotome, Straight 260 12 PN0452 Capener Osteotome, Straight 260 15 PN0315 Capener Osteotome, Straight 260 20 PN0311 Capener Osteotome, Straight 260 25 PN0312 Capener Osteotome, Straight 260 30 PN0702 Capener Osteotome, Straight 260 40 PN0453 Capener Osteotome, Curved 260 6 PN0987 Capener Osteotome, Curved 260 8 PN0454 Capener Osteotome, Curved 260 10 PN0455 Capener Osteotome, Curved 260 12 PN0456 Capener Osteotome, Curved 260 15 PN0457 Capener Osteotome, Curved 260 20 PN0458 Capener Osteotome, Curved 260 25 PN0459 Capener Osteotome, Curved 260 30 PN0988 Capener Osteotome, Curved 260 40 159 CAPENER GOUGE PN0466 CODE DESCRIPTION LENGTH WIDTH PN0466 Capener Gouge, Straight -

Spin-Drift Roller Reamer

Spin-Drift Roller Reamer Cutter Selections Used for low torque stabilization Standard cutting structure design in both vertical and directional for medium to medium hard drilling, this "frictionless reamer" formations with optimum cartridged is hardened and tugnsten carbide insert quantity Spin-Drift carburized for long service life. and placement, with a tapered Roller Reamer profile for bi-direction reaming. The low torque solution to a smoother wellbore For soft clay, limestome and Applicable for extremely hard and shale applications a steel tooth abrasive formations, such as hard cartridge with plasma hardface sands, chert or granite, these cutting edges is an economical cutters are are fitted with an yet effect solution for many increased quantity of premium applications. tungsten carbide inserts. Tools Specifications Hole Size Body OD Body ID Fishing Neck Fishing Neck Overall Length Dressed Body (in) (in) (in) Length (in) Diameter (in) (in) Weight (lbs)* 5 7/8 - 6 1/2 4 3/4 1 1/4 - 1 3/4 40 4 3/4 80 225 to 250 7 7/8 - 8 3/4 6 1/2 2 1/4 45 6 1/2 95 450 - 575 9 7/8 6 1/2 - 8 2 13/16 50 6 1/2 - 8 110 775 11 8 2 13/16 55 8 125 1000 12 1/8 - 12 1/4 8 or 9 1/2 2 13/16 60 8 - 9 1/2 130 1250 14 3/4 to 26 9 1/2 2 13/16 70 9 1/2 150 1800 - 4000 * Approximate To learn more about how the Spin-Drift Roller Reamer can improve your well bore quality and lower your overall costs, contact your nearest BesteBit representative.