| Hai Lala at Tatan Mula Ment

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Information to Users

INFORMATION TO USERS This manuscript has been reproduced from the microfilm master. UMI films the text directly from the original or copy submitted. Thus, some thesis and dissertation copies are in typewriter face, while others may be from any type of computer printer. The quality of this reproduction is dependent upon the quality of the copy submitted. Broken or indistinct print, colored or poor quality illustrations and photographs, print bleedthrough, substandard margins, and improper alignment can adversely affect reproduction. In the unlikely event that the author did not send UMI a complete manuscript and there are missing pages, these will be noted. Also, if unauthorized copyright material had to be removed, a note will indicate the deletion. Oversize materials (e.g., maps, drawings, charts) are reproduced by sectioning the original, beginning at the upper left-hand corner and continuing from left to right in equal sections with small overlaps. Each original is also photographed in one exposure and is included in reduced form at the back of the book. Photographs included in the original manuscript have been reproduced xerographically in this copy. Higher quality 6" x 9" black and white photographic prints are available for any photographs or illustrations appearing in this copy for an additional charge. Contact UMI directly to order. University Microfilms International A Beil & Howell Information Company 300 North Zeeb Road, Ann Arbor, Ml 48106-1346 USA 313/761-4700 800/521-0600 Order Number 0201633 The interaction of imidazolinone herbicides with selected adsorbents Che, Ming-Daw, Ph.D. The Ohio State University, 1991 UMI 300 N. -

Gene Encoding Acetolactic Acid Synthase Gene

Europäisches Patentamt *EP001347056A1* (19) European Patent Office Office européen des brevets (11) EP 1 347 056 A1 (12) EUROPEAN PATENT APPLICATION published in accordance with Art. 158(3) EPC (43) Date of publication: (51) Int Cl.7: C12N 15/60, C12N 9/88, 24.09.2003 Bulletin 2003/39 C12N 5/14, A01H 5/00 (21) Application number: 01982810.2 (86) International application number: PCT/JP01/10014 (22) Date of filing: 16.11.2001 (87) International publication number: WO 02/044385 (06.06.2002 Gazette 2002/23) (84) Designated Contracting States: • NAGAYAMA, Kozo AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU Kakegawa-shi, Shizuoka 436-0004 (JP) MC NL PT SE TR • FUKUDA, Atsunori Designated Extension States: Tsukuba-shi, Ibaraki 305-0031 (JP) AL LT LV MK RO SI • TANAKA, Yoshiyuki Tsukuba-shi, Ibaraki 305-0031 (JP) (30) Priority: 29.11.2000 JP 2000362630 • KAKU, Koichiro Iwata-shi, Shizuoka 437-1207 (JP) (71) Applicant: KUMIAI CHEMICAL INDUSTRY CO., LTD. (74) Representative: Taito-ku Tokyo 110-8782 (JP) Denison, Christopher Marcus et al Mewburn Ellis (72) Inventors: York House • SHIMIZU, Tsutomu 23 Kingsway Ogasa-gun, Shizuoka 439-0031 (JP) London WC2B 6HP (GB) • NAKAYAMA, Ishizue Fujieda-shi, Shizuoka 426-0067 (JP) (54) GENE ENCODING ACETOLACTIC ACID SYNTHASE GENE (57) The present invention provides a gene encod- SEQ ID NO: 1 by substitution, deletion or addition ing ALS protein which shows extremely high level of re- of at least one or more amino acids, has resistance sistance to PC herbicides. The gene of the present in- to a pyrimidinyl carboxy herbicide and has acetol- vention encodes the following protein (a) or (b): actate synthase activity. -

The Absorption and Translocation of Imazaquin in Green Manures Acta Scientiarum

Acta Scientiarum. Agronomy ISSN: 1679-9275 [email protected] Universidade Estadual de Maringá Brasil Garcia Florido, Flávia; Monquero, Patrícia Andrea; Ribeiro Dias, Ana Carolina; Tornisielo, Valdemar Luiz The absorption and translocation of imazaquin in green manures Acta Scientiarum. Agronomy, vol. 36, núm. 3, julio-septiembre, 2014, pp. 291-300 Universidade Estadual de Maringá Maringá, Brasil Available in: http://www.redalyc.org/articulo.oa?id=303031287004 How to cite Complete issue Scientific Information System More information about this article Network of Scientific Journals from Latin America, the Caribbean, Spain and Portugal Journal's homepage in redalyc.org Non-profit academic project, developed under the open access initiative Acta Scientiarum http://www.uem.br/acta ISSN printed: 1679-9275 ISSN on-line: 1807-8621 Doi: 10.4025/actasciagron.v36i3.17035 The absorption and translocation of imazaquin in green manures Flávia Garcia Florido1, Patrícia Andrea Monquero1*, Ana Carolina Ribeiro Dias2 and Valdemar Luiz Tornisielo3 1Centro de Ciências Agrárias, Universidade Federal de São Carlos, Rod. Anhanguera, km 174, Cx. Postal 153, Araras, São Paulo, Brazil. 2Departamento de Produção Vegetal, Escola Superior de Agricultura “Luiz de Queiroz”, Universidade de São Paulo, Piracicaba, São Paulo, Brazil. 3Laboratório de Ecotoxicologia, Centro de Energia Nuclear na Agricultura, Piracicaba, São Paulo, Brazil. *Author for correspondence. E-mail: [email protected] ABSTRACT. Green manure species that are tolerant to the herbicide imazaquin can be used in crop rotation schemes that aim to reduce herbicide carryover to sensitive plants such as sunflower or corn. Three different doses of imazaquin (0, 0.15 and 0.28 kg ha-1) were applied during the pre-emergence growth stage to Dolichos lablab, Cajanus cajan, Canavalia ensiformis, Crotalaria juncea, C. -

Imazapyr Human Health and Ecological Risk Assessment FINAL REPORT

SERA TR-052-29-03a Imazapyr Human Health and Ecological Risk Assessment FINAL REPORT Submitted to: Paul Mistretta, COR USDA/Forest Service, Southern Region 1720 Peachtree RD, NW Atlanta, Georgia 30309 USDA Forest Service Contract: AG-3187-C-06-0010 USDA Forest Order Number: AG-43ZP-D-11-0012 SERA Internal Task No. 52-29 Submitted by: Patrick R. Durkin Syracuse Environmental Research Associates, Inc. 8125 Solomon Seal Manlius, New York 13104 E-Mail: [email protected] Home Page: www.sera-inc.com December 16, 2011 Table of Contents LIST OF FIGURES ...................................................................................................................... vii LIST OF TABLES ........................................................................................................................ vii LIST OF APPENDICES ............................................................................................................... vii ACRONYMS, ABBREVIATIONS, AND SYMBOLS .............................................................. viii COMMON UNIT CONVERSIONS AND ABBREVIATIONS .................................................... x CONVERSION OF SCIENTIFIC NOTATION ........................................................................... xi EXECUTIVE SUMMARY .......................................................................................................... xii 1. INTRODUCTION ...................................................................................................................... 1 1.1. Chemical Specific Information -

Impact of Agricultural Chemicals on Wetland Habitats and Associated Biota with Special Reference to Migratory Birds: a Selected and Annotated Bibliography C

South Dakota State University Open PRAIRIE: Open Public Research Access Institutional Repository and Information Exchange South Dakota State University Agricultural Bulletins Experiment Station 3-1-1991 Impact of Agricultural Chemicals on Wetland Habitats and Associated Biota with Special Reference to Migratory Birds: A Selected and Annotated Bibliography C. F. Facemire Follow this and additional works at: http://openprairie.sdstate.edu/agexperimentsta_bulletins Recommended Citation Facemire, C. F., "Impact of Agricultural Chemicals on Wetland Habitats and Associated Biota with Special Reference to Migratory Birds: A Selected and Annotated Bibliography" (1991). Bulletins. Paper 713. http://openprairie.sdstate.edu/agexperimentsta_bulletins/713 This Bulletin is brought to you for free and open access by the South Dakota State University Agricultural Experiment Station at Open PRAIRIE: Open Public Research Access Institutional Repository and Information Exchange. It has been accepted for inclusion in Bulletins by an authorized administrator of Open PRAIRIE: Open Public Research Access Institutional Repository and Information Exchange. For more information, please contact [email protected]. B 708 Impact of Agricultural Chemicals on Wetland Habitats and Associated Biota with Special Reference to Migratory Birds: A Selected and Annotated Bibliography U.S. Fish and Wildlife Service Region 6 Environmental Contaminants Program North and South Dakota Fish and Wildlife Enhancement Offices South Dakota Cooperative Fish and Wildlife Research Unit and South Dakota Agricultural Experiment Station South Dakota State University Published in accordance with an act passed in 1881 by the 14th Legislative Assembly, Dakota Territory, establishing the Dakota Agricultural College and with the act of re-organization passed in 1887 by the 17th Legislative Assembly, which established the Agricultural Experiment Station at South Dakota State University. -

Recommended Classification of Pesticides by Hazard and Guidelines to Classification 2019 Theinternational Programme on Chemical Safety (IPCS) Was Established in 1980

The WHO Recommended Classi cation of Pesticides by Hazard and Guidelines to Classi cation 2019 cation Hazard of Pesticides by and Guidelines to Classi The WHO Recommended Classi The WHO Recommended Classi cation of Pesticides by Hazard and Guidelines to Classi cation 2019 The WHO Recommended Classification of Pesticides by Hazard and Guidelines to Classification 2019 TheInternational Programme on Chemical Safety (IPCS) was established in 1980. The overall objectives of the IPCS are to establish the scientific basis for assessment of the risk to human health and the environment from exposure to chemicals, through international peer review processes, as a prerequisite for the promotion of chemical safety, and to provide technical assistance in strengthening national capacities for the sound management of chemicals. This publication was developed in the IOMC context. The contents do not necessarily reflect the views or stated policies of individual IOMC Participating Organizations. The Inter-Organization Programme for the Sound Management of Chemicals (IOMC) was established in 1995 following recommendations made by the 1992 UN Conference on Environment and Development to strengthen cooperation and increase international coordination in the field of chemical safety. The Participating Organizations are: FAO, ILO, UNDP, UNEP, UNIDO, UNITAR, WHO, World Bank and OECD. The purpose of the IOMC is to promote coordination of the policies and activities pursued by the Participating Organizations, jointly or separately, to achieve the sound management of chemicals in relation to human health and the environment. WHO recommended classification of pesticides by hazard and guidelines to classification, 2019 edition ISBN 978-92-4-000566-2 (electronic version) ISBN 978-92-4-000567-9 (print version) ISSN 1684-1042 © World Health Organization 2020 Some rights reserved. -

Behaviour of Ionisable Pesticides in Soils Mélanie Kah, Colin D

Behaviour of ionisable pesticides in soils Mélanie Kah, Colin D. Brown To cite this version: Mélanie Kah, Colin D. Brown. Behaviour of ionisable pesticides in soils. Earth Sciences. The University of York, 2007. English. tel-00185485 HAL Id: tel-00185485 https://tel.archives-ouvertes.fr/tel-00185485 Submitted on 6 Nov 2007 HAL is a multi-disciplinary open access L’archive ouverte pluridisciplinaire HAL, est archive for the deposit and dissemination of sci- destinée au dépôt et à la diffusion de documents entific research documents, whether they are pub- scientifiques de niveau recherche, publiés ou non, lished or not. The documents may come from émanant des établissements d’enseignement et de teaching and research institutions in France or recherche français ou étrangers, des laboratoires abroad, or from public or private research centers. publics ou privés. PhD Thesis 2007 BEHAVIOUR OF IONISABLE PESTICIDES IN SOILS Mélanie Kah Supervisor: Professor Colin D. Brown University of York Environment Department This thesis is submitted in partial fulfillment of the requirements for the degree of Doctor of Philosophy. Abstract ABSTRACT Ionisable pesticides can be partially ionised within the range of natural soil pH and this strongly influences their reactivity in soils. This group includes important, worldwide contaminants of groundwater and surface waters. It is essential that their specific behaviour is recognised within risk assessment procedures. Experiments were carried out with ten pesticides (six acids and four bases) and nine arable soils (range in pH, texture and organic matter content) to advance the understanding and prediction of the behaviour of ionisable pesticides in soils. The main conclusions can be summarised as follows: • Adsorption of ionisable pesticides tends to be stronger in soils with lower pH and containing more organic carbon. -

Poa Annua L.) Herbicide Resistance and Its Control on Golf Courses Robert Cross Clemson University, [email protected]

Clemson University TigerPrints All Dissertations Dissertations 12-2014 Ecological, Physiological, and Molecular Characterization of Annual Bluegrass (Poa annua L.) Herbicide Resistance and Its Control on Golf Courses Robert Cross Clemson University, [email protected] Follow this and additional works at: https://tigerprints.clemson.edu/all_dissertations Part of the Agriculture Commons Recommended Citation Cross, Robert, "Ecological, Physiological, and Molecular Characterization of Annual Bluegrass (Poa annua L.) Herbicide Resistance and Its Control on Golf Courses" (2014). All Dissertations. 1431. https://tigerprints.clemson.edu/all_dissertations/1431 This Dissertation is brought to you for free and open access by the Dissertations at TigerPrints. It has been accepted for inclusion in All Dissertations by an authorized administrator of TigerPrints. For more information, please contact [email protected]. ECOLOGICAL, PHYSIOLOGICAL, AND MOLECULAR CHARACTERIZATION OF ANNUAL BLUEGRASS (Poa annua L.) HERBICIDE RESISTANCE AND ITS CONTROL ON GOLF COURSES A Dissertation Presented to the Graduate School of Clemson University In Partial Fulfillment of the Requirements for the Degree Doctor of Philosophy Plant and Environmental Science by Robert Billings Cross, III December 2014 Accepted by: Dr. L. B. McCarty, Committee Chair Dr. W. C. Bridges Dr. J. S. McElroy Dr. N. Tharayil Dr. T. Whitwell ABSTRACT Annual bluegrass (Poa annua L.) is one of the most pervasive, adaptable, and variable plant species in the world and is the most problematic winter annual weed in managed turfgrass. Its prolific seedhead production regardless of mowing height, clumping growth habit, and lack of tolerance to stress reduces turfgrass aesthetic quality and playability on golf courses. Its ability to germinate almost year-round influences cultural practices and herbicide use. -

Thesis Rests with Its Author

University of Bath PHD Studies into the modification of herbicide activity by chemical safeners and synergists Polge, Nicholas D. Award date: 1989 Awarding institution: University of Bath Link to publication Alternative formats If you require this document in an alternative format, please contact: [email protected] General rights Copyright and moral rights for the publications made accessible in the public portal are retained by the authors and/or other copyright owners and it is a condition of accessing publications that users recognise and abide by the legal requirements associated with these rights. • Users may download and print one copy of any publication from the public portal for the purpose of private study or research. • You may not further distribute the material or use it for any profit-making activity or commercial gain • You may freely distribute the URL identifying the publication in the public portal ? Take down policy If you believe that this document breaches copyright please contact us providing details, and we will remove access to the work immediately and investigate your claim. Download date: 10. Oct. 2021 STUDIES INTO THE MODIFICATION OF HERBICIDE ACTIVITY BY CHEMICAL SAFENERS AND SYNERGISTS Submitted by Nicholas D Polge for the degree of Ph.D. of the University of Bath 1989 COPYRIGHT Attention is drawn to the fact that copyright of this thesis rests with its author. This copy of the thesis has been supplied on condition that anyone who consults it is understood to recognise that its copyright rests with the author and that no quotation from the thesis and no information derived from it may be used without the prior written consent of the author. -

Federal Register/Vol. 70, No. 248/Wednesday

Federal Register / Vol. 70, No. 248 / Wednesday, December 28, 2005 / Notices 76825 II. Background EPA is applying the principles of Register. In the absence of substantive public participation to all pesticides comments requiring changes, the A. What Action is the Agency Taking? undergoing reregistration and tolerance decisions reflected in the TRED will be EPA has reassessed the uses of reassessment. The Agency’s Pesticide implemented as presented. These imazaquin and the one existing Tolerance Reassessment and decisions may be supplemented by risk tolerances or legal residue limits. On Reregistration; Public Participation mitigation measures when EPA December 20, 2005, EPA reached a Process, published in the Federal considers its cumulative assessment of tolerance reassessment decision for this Register of May 14, 2004 (69 FR 26819) the cumulative group pesticides. low risk pesticide. Imazaquin is an (FRL–7357–9) explains that in B. What is the Agency’s Authority for imidazolinone herbicide which controls conducting these programs, the Agency Taking this Action? weeds by inhibiting the synthesis of is tailoring its public participation specific amino acids (valine, leucine process to be commensurate with the Section 408(q) of the FFDCA, 21 and isoleucine) necessary for plant level of risk, extent of use, complexity U.S.C. 346a(q), requires EPA to review growth. It is registered as a pre-plant, of issues, and degree of public concern tolerances and exemptions for pesticide preemergence and early postemergence associated with each pesticide. EPA can residues in effect as of August 2, 1996, herbicide for use on soybeans, primarily expeditiously reach decisions for to determine whether the tolerance or across the central Midwest from pesticides like imazaquin, which pose exemption meets the requirements of Kentucky to Illinois and across the mid- no risk concerns, and require no risk section 408(b)(2) or (c)(2) of FFDCA. -

List of Industrial Herbicides Research

4/6/2020 Herbicide - an overview | ScienceDirect Topics Herbicide Herbicides are a broad class of pesticides that are used to remove nuisance plants, such as grasses and weeds, that may compromise the growth and yield of desired crops that are in close proximity. From: Handbook of Clinical Neurology, 2015 Related terms: Toxic Injury, Protein, Fungicide, Pesticide, Glyphosate, Insecticide, Toxicity, Atrazine, Simazine, Paraquat Herbicides M. Manno, in Human Toxicology, 1996 INTRODUCTION Herbicides are chemicals used to kill or damage unwanted plants or parts of them. The term derives from the Latin words herbs and caedo, meaning plant-killer. Since the early observation in 1895–1897 of the selective herbicidal properties of copper sulphate against Sinapis arvensis [1], many chemicals have been used or tested as weed-killers. Among these are sulphuric acid, sodium chlorate, borate and arsenite, arsenic trioxide and dinitro-orthocresol. In the middle and late 1930s a growing interest in developing selective herbicidal properties stimulated research for new compounds, leading to the introduction, a few years later, of a class of effective chemicals, the phenoxyacids. In the 1950s another group of compounds, the triazines, with selective herbicidal properties and a much lower acute toxicity than that of phenoxyacids, was developed. In 1962 paraquat, the first of an important class of non-selective contact herbicides, the bipyridylium compounds, was introduced. In the last decades the production and use of modern herbicides has increased faster than those of any other class of pesticides. The world production of herbicides is more than double that of all insecticides, and more than triple that of fungicides. -

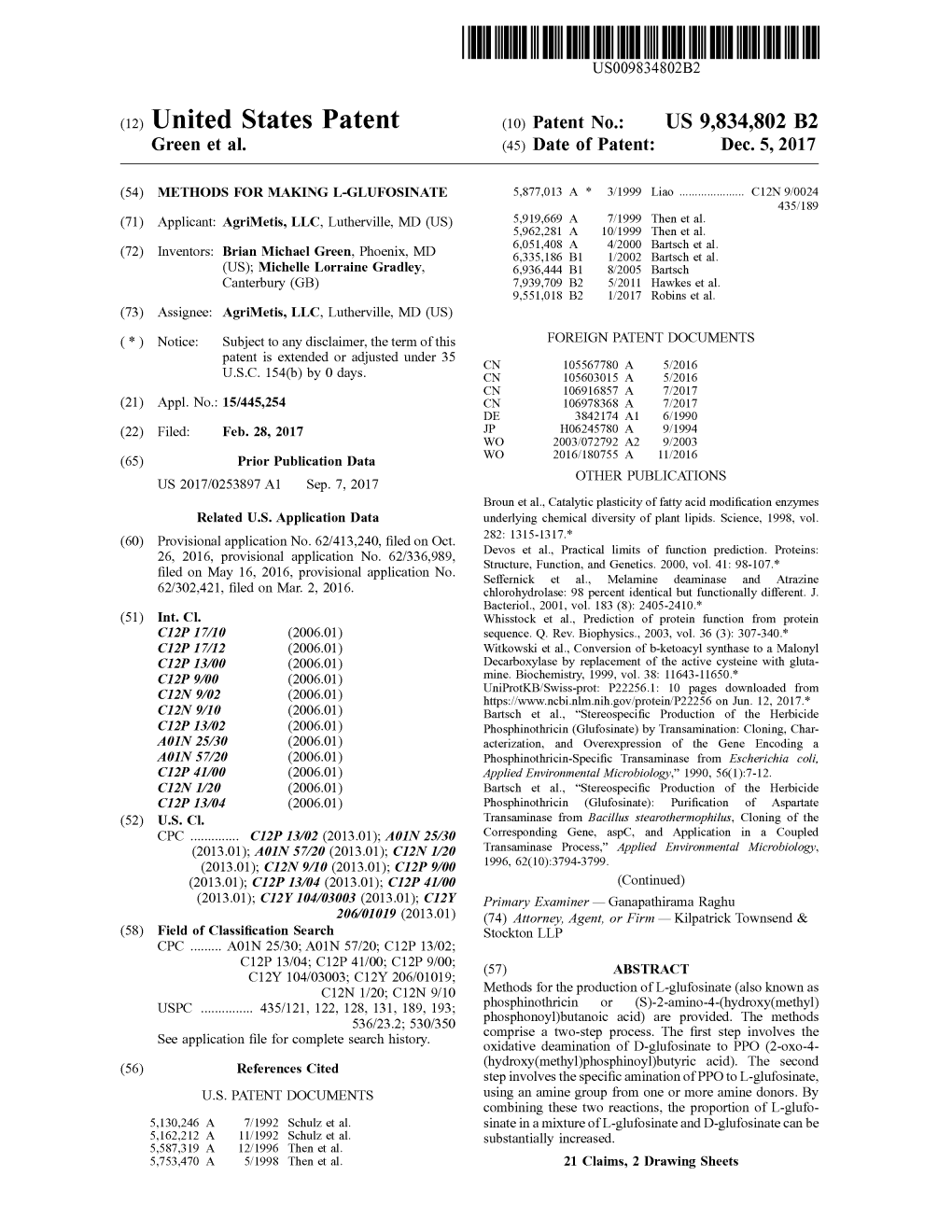

WO 2017/151573 Al 8 September 2017 (08.09.2017) P O P C T

(12) INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT) (19) World Intellectual Property Organization International Bureau (10) International Publication Number (43) International Publication Date WO 2017/151573 Al 8 September 2017 (08.09.2017) P O P C T (51) International Patent Classification: (81) Designated States (unless otherwise indicated, for every C12P 9/00 (2006.01) A01N 57/20 (2006.01) kind of national protection available): AE, AG, AL, AM, C12P 13/04 (2006.0 1) C12N 1/21 (2006.0 1) AO, AT, AU, AZ, BA, BB, BG, BH, BN, BR, BW, BY, CUP 41/00 (2006.0 1) C12N 9/1 0 (2006.0 1) BZ, CA, CH, CL, CN, CO, CR, CU, CZ, DE, DJ, DK, DM, DO, DZ, EC, EE, EG, ES, FI, GB, GD, GE, GH, GM, GT, (21) International Application Number: HN, HR, HU, ID, IL, IN, IR, IS, JP, KE, KG, KH, KN, PCT/US20 17/0 19871 KP, KR, KW, KZ, LA, LC, LK, LR, LS, LU, LY, MA, (22) International Filing Date: MD, ME, MG, MK, MN, MW, MX, MY, MZ, NA, NG, 28 February 2017 (28.02.2017) NI, NO, NZ, OM, PA, PE, PG, PH, PL, PT, QA, RO, RS, RU, RW, SA, SC, SD, SE, SG, SK, SL, SM, ST, SV, SY, (25) Filing Language: English TH, TJ, TM, TN, TR, TT, TZ, UA, UG, US, UZ, VC, VN, (26) Publication Language: English ZA, ZM, ZW. (30) Priority Data: (84) Designated States (unless otherwise indicated, for every 62/302,421 2 March 2016 (02.03.2016) US kind of regional protection available): ARIPO (BW, GH, 62/336,989 16 May 2016 (16.05.2016) US GM, KE, LR, LS, MW, MZ, NA, RW, SD, SL, ST, SZ, 62/413,240 26 October 20 16 (26.