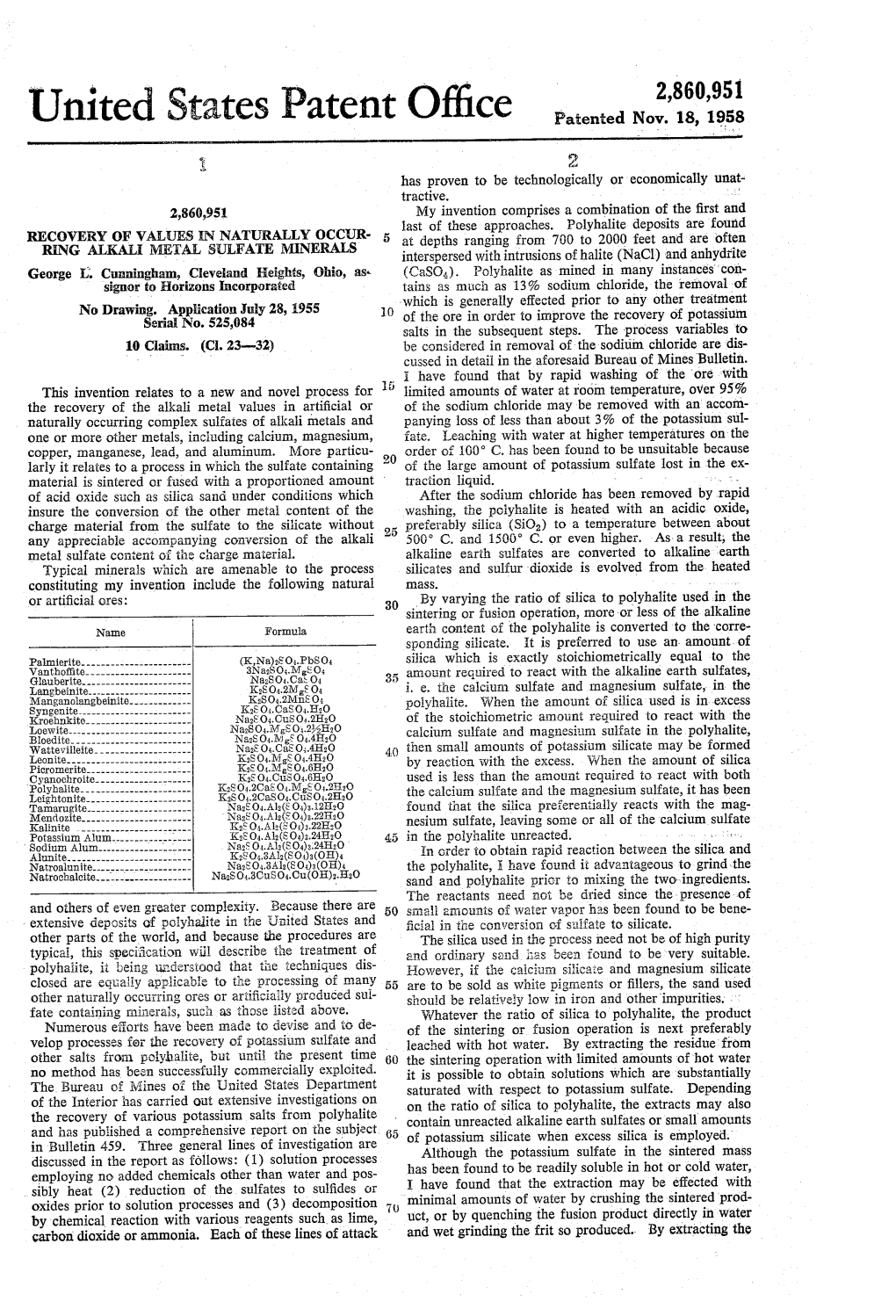

United States Patent Office Patented Nov

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Picromerite K2mg(SO4)2 • 6H2O C 2001-2005 Mineral Data Publishing, Version 1

Picromerite K2Mg(SO4)2 • 6H2O c 2001-2005 Mineral Data Publishing, version 1 Crystal Data: Monoclinic. Point Group: 2/m. Equant crystals, to 5 cm, showing {001}, {010}, {100}, {110}, {011}, {201}, {111}, several other forms; incrusting other salts; massive. Physical Properties: Cleavage: On {201}, perfect (synthetic). Hardness = 2.5 D(meas.) = 2.028 (synthetic). D(calc.) = 2.031 Soluble in H2O, taste bitter. Optical Properties: Transparent. Color: Colorless or white; pale red, pale yellow, gray due to impurities; colorless in transmitted light. Luster: Vitreous. Optical Class: Biaxial (+). Orientation: Y = b; X ∧ a =–1◦. Dispersion: r> v,weak. α = 1.461 β = 1.463 γ = 1.476 2V(meas.) = 47◦540 Cell Data: Space Group: P 21/a (synthetic). a = 9.066 b = 12.254 c = 6.128 β = 104◦470 Z=2 X-ray Powder Pattern: Synthetic. 3.71 (100), 4.06 (95), 4.16 (85), 3.06 (70), 2.964 (60), 3.16 (40), 2.813 (40) Chemistry: (1) (2) SO3 39.74 39.76 MgO 10.40 10.01 K2O 23.28 23.39 Cl 0.28 H2O 26.87 26.84 −O=Cl2 [0.06] Total [100.51] 100.00 • (1) Leopoldshall, Germany. (2) K2Mg(SO4)2 6H2O. Mineral Group: Picromerite group. Occurrence: Principally occurs in oceanic bedded salt deposits; a volcanic sublimate in fumaroles; in a sulfate-rich hydrothermal ore deposit. Association: Halite, anhydrite, kainite, epsomite (oceanic salt deposits); hohmannite, metavoltine, metasideronatrite (Chuquicamata, Chile). Distribution: From Vesuvius, Campania, Italy. In Germany, in Saxony-Anhalt, from the Leopoldshall-Stassfurt district, and at Aschersleben; large crystals from the Ellers mine, Neuhof, near Fulda, Hessen; in the Adolfsgl¨uck mine, Schwarmstedt, Lower Saxony. -

Mineralogical Chemistry

View Article Online / Journal Homepage / Table of Contents for this issue 282 ABSTRACTS OF CHEMICAL PAPERS. Downloaded on 22 February 2013 Published on 01 January 1900 http://pubs.rsc.org | doi:10.1039/CA9007805282 Mineralogical Chemistry. Roumanian Petroleuws. By A LFONS 0. SALIGNY(Chem. Centy., 1900, 60 ; from Bul. Bozcmccnie, 8, 351 --365).-In the original paper, the physical and chemical properties of 12 kinds of Roumanian MINERALOGICAL CHEMISTRY View Article Online283 petroleum are described and tabulated. The flash points of the various fractions are given, and their suitability for use as burning oils is also discussed. These petroleums contain very variable amounts of volatile oils, and ethylisobutane and isopropane were found in the fractions boiling below 70”. E. w. w. Melonite from South Australia. By ALFREDJ. HIGGIN(Trans. Roy. Xoc. South Austdia, 1899, 23, 21 1-212).-This mineral, pre- viously only known from California, has now been found with quartz and calcite at Worturpa, South Australia. The thin lamells have a brilliant metallic lustre; the cleavage planes are silver-white to reddish- brown. H- 1.5 ; sp. gr., 7.6. Analyses I and IT: agree with the formula Ni,Te, (compare this vol., ii, 22). Te. Xi. Au. Insol. Total. I. 74.49 22.99 0.329 2.091 99.90 11. 71.500 21.274 0.018 7*319 100.11 Traces of bismuth and lead are present. On dissolving the mineral in nitric acid, the gold is left as bright spangles. L. J. S. Titaniferous Magnetites. By JAMESF. KENP(School of Mines Quart., 1899, 20, 323-356 ; 21, 56-65).-Titaniferous magnetites, with the exception of the occnrrences in sands, are almost invariably found associated with rocks of the gabbro type, and have originated by a process of segregation from the magma, The mineral, as a rule, contains vanadium, cbromium, nickel and cobalt, which together may amount to several per cent. -

The Mineralogy of the British Permian Evaporites

460 The mineralogy of the British Permian evaporites By F. H. STEWART Department of Geology, University of Edinburgh Summary. The occurrence of the minerals is reviewed. Consideration of their genesis leads to a tentative list of primary minerals, and of early diagenetie, later diagenetic and geothermal metamorphic, and late near-surface changes. N 1943 Professor Tilley recorded the occurrence of po]yhalite in the I rocks of the D'Arcy Exploration Company's E.2 borehole at Aislaby, near Whitby; this was the first published record of a potassium-bearing salt in British evaporites. The occurrence of rocks containing sylvine (Lees and Taitt, 1946) prompted further exploration by Imperial Chemical Industries and Fisons Ltd. after the war, and this showed the presence of large deposits of potassium ores in the Whitby region. There is now a considerable literature related to these, and it seems timely to give a short review of the mineralogy of the British Permian evaporites. The writer is most grateful to Fisons Ltd. who have kindly allowed him to use unpublished information from his study of their boreholes F.1 at Robin Hood's Bay, F.2 at Staintondale, F.3 at Little Beck, and F.4 at Hawsker, in the Whitby Scarborough district. The position of these and the other boreholes mentioned in this paper can be found in the map of Dunham (1960). Dist~'ibution of the minerals The evaporites occur in two principal areas east and west of the Pennine Hills. In the western area (the Vale of Eden, west Cumberland, and the Furness district of Lancashire), where four evaporite beds have been recognized (Hollingworth, 1942), the mineralogy is relatively simple; carbonates, anhydrite, and gypsum are the main constituents. -

Newsletter of the New York Microscopical Society

Newsletter Of the New York Microscopical Society 1 Prospect Village Plaza (66F Mt. Prospect Avenue) Clifton, New Jersey 07013-1918 GPS: Latitude 40.8648N, Longitude 74.1540W Nov-Dec 2016 Editor: (201) 791-9826 Volume 10 (30) Number 9 NYMS ANNUAL BANQUET DECEMBER 11, 2016 What: Enjoy a wonderful Buffet Luncheon, including soft beverages (cash bar available) and desserts, with your fellow-members and guests. Enjoy an exciting presentation by Asst. Professor Nicholas Petraco, MS, D-ABC John Jay College of Criminal Justice (See page 3 for add’l info). An overall jolly time at one of the oldest restaurants in mid-town Manhattan; The Landmark Tavern. When: Sunday December 11, 2016, from noon until 3:30pm. Where: Landmark Tavern, 626 11th Ave., at W. 46th St New York City, NY Tel: 212-247-2562. Cost: $35.00 per person. How: Reserve your place now* by filling in the Reservation Request form below and mailing it along with your check to the Treasurer (see address below). *Reservation requests must be received on or before November 28, 2016 ------------------------------------------------------------------------------------------------------------------------ Number attending _________ @ $35/each = (write check amount) _______ Member name______________________________________________ Address____________________________________________________ Phone__________________ eMail____________________ ________________________________________________________________ Send this form and payment to: NYMS Banquet 2016 c/o Mel Pollinger, Treasurer 18-04 Hillery Street Fair Lawn, NJ 07410-5207 For additional information contact Mel Pollinger (201) 791-9826 or email: [email protected] Space is limited, so rush your reservation request in to reserve your place(s) asap. A Not-For-Profit Educational Organization, (nyms.org) Save a Tree: Get The Extended Newsletter: By Email Only New York Microscopical Society Board of Managers (Officers Term 2016-2017) President, John Scott, [email protected]; (646)339-6566, Curator, Archivist. -

Modeling and Mineralogical Analyses of Potential Martian Chloride Brines. P. E. Martin, M. S. Gilmore, and J. P. Greenwood, Dept

45th Lunar and Planetary Science Conference (2014) 2543.pdf Modeling and Mineralogical Analyses of Potential Martian Chloride Brines. P. E. Martin, M. S. Gilmore, and J. P. Greenwood, Dept. of Earth and Environmental Sciences, Wesleyan University, Middletown, CT 06459 (pemar- [email protected]) Introduction: The discovery of salts in the Viking ined using X-ray diffraction (XRD) and VNIR (0.35- soils prompted investigation into the stability and 2.5 µm) spectra collected by an ASD FR spectrometer. composition of theoretical martian brines [e.g., 1, 2]. Results: The evaporation of the brines generally Such brines may be metastable on modern Mars and took place over a two to five week period, which de- have been invoked in the formation of modern fluvial pended on the concentration of the brine and its com- features on Mars such as gullies and slope lineae [3-5]. nposition (i.e. more deliquescent solutions took more The evaporation of such brines should result in the time). CLM, and SDJ remained in solution and were formation of mineral deposits that could potentially be not analyzed further. TPR did not fully evaporate, but recognized in visible-near-infrared (VNIR) spectra crystals formed, and these were harvested and put in a collected by the CRISM instrument on the Mars Re- dessicator for analysis. Many samples (MKS, KS, connaisance Orbiter, although this has not yet occurred TB1, TPR, TB5, CV2, CV3) contained residual water, [3]. In this work, we measure the VNIR spectra of ana- possibly due to deliquescence. MKS, KS, and TB1 logue chloride-rich martian evaporite assemblages in were analyzed with the water still present, while TPR, an attempt to better understand which minerals are TB5, CV2, and CV3, were placed in a dessicator to detectable using CRISM and how well VNIR spectra facilitate evaporation before analysis. -

9Th International Conference on Durability of Building Materials And

In: Proc. Of: SWBSS- Salt Weathering on Buildings and Stone Sculptures. Technical University of Denmark, Copenhagen, 2008. Sulfation of a decrepit Portland cement mortar and its adjacent masonry. Sara Pavía Department of Civil Engineering, Trinity College Dublin. Dublin 2. Ireland. Abstract This paper concentrates in the phenomenon of sulfate formation within an old cement paste dating from c.1878, leading to damage of the mortar and its adjacent masonry. Samples of mortar and salt efflorescence were taken for XRD, XRF, petrographic and SEM/EDAX analyses. SEM/EDAX revealed detail on the clinker microstructure and the presence and arrangement of sulfates including kieserite, syngenite and calcium langbeinite. Gypsum, thenardite, picromerite, aphthitalite, ettringite, niter and potassium calcium carbonate were detected by XRD analysis. Under the petrographic microscope, the mortars displayed strong damage by expansion with abundant, fractured, residual cement clinkers, extensive sulfate replacement, carbonation and alkali-agregate reaction. The paper concludes that damage is caused by sulfation (mainly by gypsum and thenardite). Sulfate damage is closely related to the location of the portland cement (PC) repair, suggesting that the sulfate source is internal, originating from a suphur- rich clinker phase in the cement. However, ground contamination is probably a further source for sulfate. Based on the nearly total absence of ettringite and other calcium sulfoaluminates and the abundance of alkali sulfates such as thenardite and aphthitalite, the paper suggests that the original cement clinker was low in aluminium and probably high in alkalis. Gypsum was the most common phase recorded in the solid mortars whereas thenardite was the most abundant phase in the efflorescence. -

Data of Geochemistry

Data of Geochemistry * Chapter Y. Marine Evaporites GEOLOGICAL SURVEY PROFESSIONAL PAPER 440-Y Data of Geochemistry ' MICHAEL FLEISCHER, Technical Editor Chapter Y. Marine Evaporites By FREDERICK H. STEWART GEOLOGICAL SURVEY PROFESSIONAL PAPER 440-Y UNITED STATES GOVERNMENT PRINTING OFFICE, WASHINGTON : 1963 UNITED STATES DEPARTMENT OF THE INTERIOR STEWART L. UDALL, Secretary GEOLOGICAL SURVEY Thomas B. Nolan, Director REPRINTED 1964 For sale by the Superintendent of Documents, U.S. Government Printing Office Washington, D.C., 20402 - Price 60 cents (paper cover) DATA OF GEOCHEMISTRY, SIXTH EDITION Michael Fleischer, Technical Editor The first edition of the Data of Geochemistry, by F. W. Clarke, was published in 1908 as U.S. Geological Survey Bulletin 330. Later editions, also by Clarke, were published in 1911, 1916, 1920, and 1924 as Bulletins 491, 616, 695, and 770. This, the sixth edition, has been written by several scientists in the Geological Survey and in other institutions in the United States and abroad, each preparing a chapter on his special field. The current edition is being published in individual chapters, titles of which are listed below. Chapters already published are indicated by boldface. CHAPTER A. The chemical elements B. Cosmochemistry C. Internal structure and composition of the Earth D. Composition of the earth's crust E. Chemistry of the atmosphere F. Chemical composition of subsurface waters, by Donald E. White, John D. Hem, and G. A. Waring G. Chemical composition of rivers and lakes, by Daniel A. Livingstone H. Chemistry of the oceans I. Geochemistry of the biosphere J. Chemistry of rock-forming minerals K. Volcanic emanations, by Donald E. -

Evaporite Geology of Fifth Ore Zone Carlsbad District Southeastern New Mexico

Evaporite Geology of Fifth Ore Zone Carlsbad District Southeastern New Mexico GEOLOGICAL SURVEY BULLETIN 1252-B Evaporite Geology of Fifth Ore Zone Carlsbad District Southeastern New Mexico By CHARLES L. JONES and BETH M. MADSEN CONTRIBUTIONS TO ECONOMIC GEOLOGY GEOLOGICAL SURVEY BULLETIN 1252-B A study of complex evaporite stratigraphy and potash occurrences UNITED STATES GOVERNMENT PRINTING OFFICE, WASHINGTON : 1968 UNITED STATES DEPARTMENT OF THE INTERIOR STEWART L. UDALL, Secretary GEOLOGICAL SURVEY William T. Pecora, Director For sale by the Superintendent of Documents, U.S. Government Printing Office Washington, D.C. 20402 CONTENTS Page Abstract _____________________________ 1 Introduction _____________________________________ 1 Purpose and scope ______________________________ 1 Area of investigation ____________________________ 2 Method of study and presentation ___________________ 2 Acknowledgments _____________________________ 6 Previous work _______________________________ 6 Synopsis of evaporite geology __________________________ 7 Geology of Fifth ore zone _________________________ 10 Stratigraphy _______________________________. 10 Lithology ______________________________ _. 12 Internal structure _________________________. 14 Thickness _______________________________. 15 Stratigraphic relations ______________________. 15 Potash occurrences __________________________. 16 Massive deposits ____________________________. 16 Disseminated deposits ____________________. 39 References cited ________________________________. 20 ILLUSTRATIONS -

Standard X-Ray Diffraction Powder Patterns

NATIONAL INSTITUTE OF STANDARDS & TECIiNOLOGY Research Information Center Gaitliersburg, MD 20899 UNITED STATES DEPARTMENT OF COMMERCE • Maurice H. Stans, Secretary NATIONAL BUREAU OF STANDARDS • Lewis M. Branscomb, Director Standard X-ray Diffraction Powder Patterns H. E. Swanson, H. F. McMurdie, M. C. Morris, and E. H. Evans Institute for Materials Research National Bureau of Standards Washington, D.C. 20234 * \ TT~.—7 of Standards, 25 Section ) National Bureau Monograph — 8 {} Nat. Bur. Stand. (U.S.), Monogr. 25—Section 8, 171 pages (Sept. 1970) CODEN: NBSMA Issued September 1970 For sale by the Superintendent of Documents, U.S. Government Printing Office, Washington, D.C. 20402 (Order by SD Catalog No. C13.44:25/Sec. 8), Price % 1.50. STANDARDS NATIONAL BUREAU OF FEB 1 2 1371 ^ . • ; Library of Congress Catalog Card Number: 53-61386 Page Page Introduction 1 Rubidium Magnesium Chromium Oxide Experimental patterns: Hydrate, Rb Mg(CrO ,) , •6H ,0 68 Ammonium Cadmium Sulfate Hydrate, Rubidium Magnesium Sulfate Hydrate, (NH,)^Cd(SO,), -GH.0 5 Rb,Mg(SO,)o-6H,0 70 Ammonium Calcium Sulfate, Rubidium Nickel Sulfate, Rb.Ni, (SO, ) ,,... 72 (NH,) ,Ca,(SO,)3 7 Rubidium Nickel Sulfate Hydrate, Ammonium Cobalt Fluoride, NH4 CoF , ... 9 Rb,Ni(S0,).:-6H,0 74 Ammonium Magnesium Chromium Oxide Rubidium Potassium Chloride, Hydrate, (NH ,),Mg(CrO ,),.6H:0 10 Rb„.-, K,,., CI 76 Ammonium Manganese Sulfate Hydrate, Samarium Tin Oxide, SmjSnjO; 77 (NH,),Mn(S0,),-6H,0 12 Silver Potassium Cyanide, AgK(CN) > 78 Ammonium Mercury Chloride, NH,HgCl., Silver Sodium Chloride, Ag„ Na„.,Cl 79 (revised) 14 Strontium Tin Oxide, SrSnO , 80 Ammonium Nickel Chromium Oxide Thallium Azide, TIN, 82 Hydrate, (NH , Ni(CrO -GH, O 16 Thallium Cadmium Sulfate, Tl,Cd,(SO ,) ;. -

Physical Properties Data for Rock Salt QC100 .U556 V167;1981 C.2 NBS-PUB-C 1981

NATL INST OF STANDARDS & TECH R.I.C. NBS ,11100 161b7a PUBLICATIONS All 100989678 /Physical properties data for rock salt QC100 .U556 V167;1981 C.2 NBS-PUB-C 1981 NBS MONOGRAPH 167 U.S. DEPARTMENT OF COMMERCE / National Bureau of Standards NSRDS *f»fr nun^^ Physical Properties Data for Rock Salt NATIONAL BUREAU OF STANDARDS The National Bureau of Standards' was established by an act of Congress on March 3, 1901. The Bureau's overall goal is to strengthen and advance the Nation's science and technology and facilitate their effective application for public benefit. To this end, the Bureau conducts research and provides: (1) a basis for the Nation's physical measurement system, (2) scientific and technological services for industry and government, (3) a technical basis for equity in trade, and (4) technical services to promote public safety. The Bureau's technical work is per- formed by the National Measurement Laboratory, the National Engineering Laboratory, and the Institute for Computer Sciences and Technology. THE NATIONAL MEASUREMENT LABORATORY provides the national system of physical and chemical and materials measurement; coordinates the system with measurement systems of other nations and furnishes essential services leading to accurate and uniform physical and chemical measurement throughout the Nation's scientific community, industry, and commerce; conducts materials research leading to improved methods of measurement, standards, and data on the properties of materials needed by industry, commerce, educational institutions, and Government; provides advisory and research services to other Government agencies; develops, produces, and distributes Standard Reference Materials; and provides calibration services. The Laboratory consists of the following centers: Absolute Physical Quantities^ — Radiation Research — Thermodynamics and Molecular Science — Analytical Chemistry — Materials Science. -

Database Release Notes

OLI Software 9.6.1 Databank Updates February 23, 2017 Mixed-solvent electrolyte databanks: MSEPUB Potash systems Binary system MgSO4 including (revised): MgSO4·12H2O MgSO4·7H2O (epsomite) MgSO4·6H2O (hexahydrite) MgSO4·5H2O (pentahydrite) MgSO4·4H2O (starkeyite) MgSO4·1H2O (kieserite) Ternary systems MgSO4 – MgCl2 (revised) MgSO4 – K2SO4 including double salts: K2Mg(SO4)2·6H2O (schoenite, picromerite) K2Mg(SO4)2·4H2O (leonite) K2Mg2(SO4)3 (langbeinite) CaSO4 – K2SO4 including double salts (revised) K2Ca(SO4)2·H2O (syngenite) K2Ca5(SO4)6·H2O (gorgeyite, pentasalt) MgSO4 – Na2SO4 including double salts Na2SO4·MgSO4·4H2O (blödite) Na2SO4·MgSO4·2.5H2O 3Na2SO4·MgSO4 MgSO4 – H2SO4 including acid/double salts (revised) Mg(HSO4)2·2H2O Mg(HSO4)2·2H2SO4 CaSO4 – MgSO4 (revised) CaSO4 – MgCl2 (revised) Quaternary systems Mg – K – Cl – SO4 including double/multiple salts: KMg(SO4)Cl·3H2O (kainite) KMgCl3·6H2O (carnallite) K2Mg(SO4)2·6H2O (schoenite, picromerite) K2Mg(SO4)2·4H2O (leonite) K2Mg2(SO4)3 (langbeinite) Mg – Na – Cl – SO4 including double/multiple salts: 9Na2SO4·MgSO4·NaCl Na2SO4·MgSO4·4H2O (blödite) Na2SO4·MgSO4·2.5H2O 3Na2SO4·MgSO4 Mg – K – Ca – SO4 including double/multiple salts: K2Ca2Mg(SO4)4·2H2O (polyhalite) K2Ca(SO4)2·H2O (syngenite) K2Ca5(SO4)6·H2O (gorgyite, pentasalt) K2Mg(SO4)2·6H2O (schoenite, picromerite) K2Mg(SO4)2·4H2O (leonite) K2Mg2(SO4)3 (langbeinite) Zinc chemistry ZnS – NaCl – pH dependence ZnS – NaCl – H2S – pH dependence ZnS – NaHS – H2S ZnO - KOH, including electrical conductivity Lead chemistry - revised PbS – HCl -

Background and Methods Spectral Group 3

(—THIS SIDEBAR DOES NOT PRINT—) QUICK START (cont.) DESIGN GUIDE Modeling and Analysis of Potenal Maran Chloride Brines How to change the template color theme This PowerPoint 2007 template produces a 44”x44” You can easily change the color theme of your poster by going to presentation poster. You can use it to create your research the DESIGN menu, click on COLORS, and choose the color theme of poster and save valuable time placing titles, subtitles, text, P. E. Marn, M. S. Gilmore, and J. P. Greenwood your choice. You can also create your own color theme. and graphics. We provide a series of online tutorials that will guide you Dept. of Earth and Environmental Sciences, Wesleyan University, Middletown, CT, [email protected] through the poster design process and answer your poster production questions. To view our template tutorials, go online to PosterPresentations.com and click on HELP DESK. Background and Methods Spectral Group 1- Na/Mg/K, Cl/SO4 Brines Spectral Group 2- Na/Mg/K, Cl/SO4/HCO3 When you are ready to print your poster, go online to Brines depress the freezing point and may allow liquid water to • Group 1 contains CMM [8], CAM [8], MKC [5], and CV1 [7]. Modeling • Group 2 is comprised of KS [12], MKS [5], TB2 [10], and CV1 [7]. exist at Mars temperatures [1]. Recent modeling efforts have made You can also manually change the color of your background by going PosterPresentations.com predicts: halite, thenardite (Na2SO4), hexahydrite, bloedite • Modeling predicts: halite, bischofite, carnallite (KMgCl ·6H O), 3 2 to VIEW > SLIDE MASTER.