The University of Minnesota Minneapolis/St. Paul, Minnesota

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

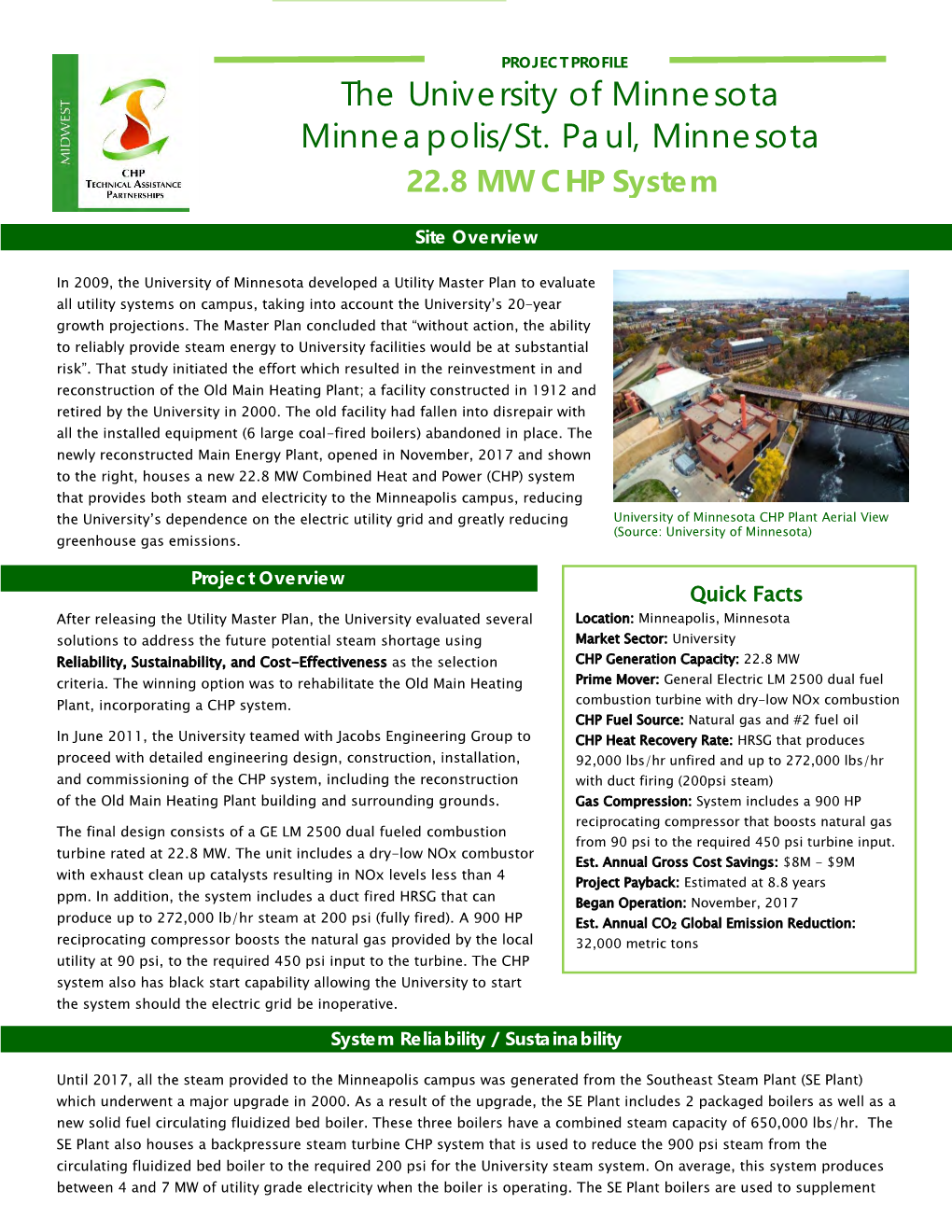

-

MILL RUINS PARK RESEARCH STUDY Expansion of The

MILL RUINS PARK RESEARCH STUDY Expansion of the Waterpower Canal (1885) and Rebuilding of Tailrace Canals (1887-1892) Prepared for Minneapolis Park and Recreation Board 3800 Bryant Avenue South Minneapolis, Minnesota 55409-1029 Prepared by Hess, Roise and Company, Historical Consultants Marjorie Pearson, Ph.D., Principal Investigator Penny A. Petersen Nathan Weaver Olson The Foster House, 100 North First Street, Minneapolis, Minnesota 55401 With curriculum program by Dawn Peterson Ann Ericson May 2003 Expansion of the Waterpower Canal (1885) and Rebuilding of Tailrace Canals (1887-1892) The Construction of the Expanded Waterpower Canal and Rebuilding of the Tailrace Canals By the mid-1880s, the increasing number of mills and the demand for waterpower was jeopardizing the availability of that power, particularly as the height and flow of the Mississippi fluctuated from season to season. In 1883, the Minneapolis Mill Company hired William de la Barre as an engineer and agent for the waterpower works. A number of the mills had installed auxiliary steam engines to supplement the waterpower. Meanwhile De la Barre proposed to solve the waterpower problem by increasing the head and fall available. Working on the West Side canal (Minnesota Historical Society) According to Kane, “De la Barre undertook to deepen the canal and lower the tailraces under his jurisdiction, while the millers promised to lower their wheel pits, tailraces, and headraces. Before the year ended, De la Barre had deepened the canal from 14 to 20 feet and lengthened it from 600 to 950 feet. The expansion increased its flowage capacity from 30 to 40 per cent and raised the water level to produce more power by bring water to the lessees’ wheels at a greater head. -

Transportation on the Minneapolis Riverfront

RAPIDS, REINS, RAILS: TRANSPORTATION ON THE MINNEAPOLIS RIVERFRONT Mississippi River near Stone Arch Bridge, July 1, 1925 Minnesota Historical Society Collections Prepared by Prepared for The Saint Anthony Falls Marjorie Pearson, Ph.D. Heritage Board Principal Investigator Minnesota Historical Society Penny A. Petersen 704 South Second Street Researcher Minneapolis, Minnesota 55401 Hess, Roise and Company 100 North First Street Minneapolis, Minnesota 55401 May 2009 612-338-1987 Table of Contents PROJECT BACKGROUND AND METHODOLOGY ................................................................................. 1 RAPID, REINS, RAILS: A SUMMARY OF RIVERFRONT TRANSPORTATION ......................................... 3 THE RAPIDS: WATER TRANSPORTATION BY SAINT ANTHONY FALLS .............................................. 8 THE REINS: ANIMAL-POWERED TRANSPORTATION BY SAINT ANTHONY FALLS ............................ 25 THE RAILS: RAILROADS BY SAINT ANTHONY FALLS ..................................................................... 42 The Early Period of Railroads—1850 to 1880 ......................................................................... 42 The First Railroad: the Saint Paul and Pacific ...................................................................... 44 Minnesota Central, later the Chicago, Milwaukee and Saint Paul Railroad (CM and StP), also called The Milwaukee Road .......................................................................................... 55 Minneapolis and Saint Louis Railway ................................................................................. -

The University of Minnesota Twin Cities Combined Heat and Power Project

001 p-bp15-01-02a 002 003 004 005 MINNESOTA POLLUTION CONTROL AGENCY RMAD and Industrial Divisions Environment & Energy Section; Air Quality Permits Section The University of Minnesota Twin Cities Combined Heat and Power Project (1) Request for Approval of Findings of Fact, Conclusions of Law, and Order and Authorization to Issue a Negative Declaration on the Need for an Environmental Impact Statement; and (2) Request for Approval of Findings of Fact, Conclusion of Law, and Order, and Authorization to Issue Permit No. 05301050 -007. January 27, 2015 ISSUE STATEMENT This Board Item involves two related, but separate, Citizens’ Board (Board) decisions: (1) Whether to approve a Negative Declaration on the need for an Environmental Impact Statement (EIS) for the proposed University of Minnesota Twin Cities Campus Combined Heat and Power Project (Project). (2) If the Board approves a Negative Declaration on the need for an EIS, decide whether to authorize the issuance of an air permit for the Project. The Minnesota Pollution Control Agency (MPCA) staff requests that the Board approve a Negative Declaration on the need for an EIS for the Project and approve the Findings of Fact, Conclusion of Law, and Order supporting the Negative Declaration. MPCA staff also requests that the Board approve the Findings of Fact, Conclusions of Law, and Order authorizing the issuance of Air Emissions Permit No. 05301050-007. Project Description. The University of Minnesota (University) proposes to construct a 22.8 megawatt (MW) combustion turbine generator with a 210 million British thermal units (MMBTU)/hr duct burner to produce steam for the Twin Cities campus. -

University of Minnesota A..""1Nual Record

UNIVERSITY OF MINNESOTA A..""1NUAL RECORD 1979-80 June 30, 1980 TABLE OF CONTENTS page BOARD OF REGENTS ............................................. 1 OFFICE OF TilE PRESIDENT. • • . • . • . • . • . • . • . • . 3 Office of Equal Opportunity and Affirmative Action ......• 4 University Relations . • . • . • . • . • . 5 University of Minnesota, Duluth ..............•.....•...•. 6 School of Business and Economics ...........•.....•.... 8 College of Education ...•....•.......•..•••...•........ 10 School of Fine Arts . • . • . • . • . 12 College of Letters and Science .......••.•.•.••......•. 14 School of Medicine •.•....•....••..•.•.......•...•....• 16 School of Social Development ••..•..••.•..••.....•..•.. 17 University of Minnesota, Morris ...•...•.•.....•....•..... 19 University of Minnesota Technical College, Crookston ...•. 21 University of Minnesota Technical College, Waseca .•...... 24 DIVISIONS OF ACADEMIC AFFAIRS ...•.•••....•..•......•...•.•.. 26 Institute of Agriculture, Forestry, and Home Economics ... 27 College of Agriculture • • . • . • • . • . • • . • . 28 College of Forestry •..............•....•••••.......... 29 College of Home Economics . • . • . • . • . • . • • . • . • . 30 Agricultural Experiment Station ........•••••.........• 31 Agricultural Extension Service ..•••......••...•....•.• 32 College of Biological Sciences ..•...•.......•............ 33 College and Graduate School of Business Administration ... 34 Continuing Education and Extension ...•...•.•....•.•.....• 36 College of Education ...............••.•.....••..•..•....• -

MPCA's Annual Environmental Permitting

This document is made available electronically by the Minnesota Legislative Reference Library as part of an ongoing digital archiving project. http://www.leg.state.mn.us/lrl/lrl.asp Environmental Permitting Minnesota Pollution Control Agency’s Annual Permitting Efficiency Report August 1, 2015 Legislative charge Minn. Stat. § 116.03, subd. 2b. Report to Legislature The commissioner shall prepare an annual permitting efficiency report that includes statistics on meeting the goal in paragraph (a) and the criteria for Tier 1 and Tier 2 by permit categories. The report is due August 1 each year. For permit applications that have not met the goal, the report must state the reasons for not meeting the goal. In stating the reasons for not meeting the goal, the commissioner shall separately identify delays caused by the responsiveness of the proposer, lack of staff, scientific or technical disagreements, or the level of public engagement. The report must specify the number of days from initial submission of the application to the day of determination that the application is complete. The report must aggregate the data for the year and assess whether program or system changes are necessary to achieve the goal. The report must be posted on the agency's Web site and submitted to the governor and the chairs and ranking minority members of the house of representatives and senate committees having jurisdiction over environment policy and finance. Authors/Contributors Estimated cost of preparing this Jeff Smith Melissa Rauner report (as required by Minn. Stat. § 3.197) Nick Boeke Don Smith Lisa Thorvig John Morrill Total staff time: 100 hrs. -

Scale and Regionality of Nonelectric Markets for U.S. Nuclear Light Water Reactors

INL/EXT-20-57885 Revision 0 Scale and Regionality of Nonelectric Markets for U.S. Nuclear Light Water Reactors L. Todd Knighton, Daniel Wendt, Abdalla Jaoude, Cristian Rabiti, and Richard Boardman (INL), Amgad Elgowainy, Krishna Reddi, and Adarsh Bafana (ANL), Brian D. James, Brian Murphy, Julia Scheerer, and Fred Peterson (Strategic Analysis) March 2020 The INL is a U.S. Department of Energy National Laboratory operated by Battelle Energy Alliance DISCLAIMER This information was prepared as an account of work sponsored by an agency of the U.S. Government. Neither the U.S. Government nor any agency thereof, nor any of their employees, makes any warranty, expressed or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness, of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. References herein to any specific commercial product, process, or service by trade name, trade mark, manufacturer, or otherwise, does not necessarily constitute or imply its endorsement, recommendation, or favoring by the U.S. Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the U.S. Government or any agency thereof. INL/EXT-20-57885 Scale and Regionality of Nonelectric Markets for U.S. Nuclear Light Water Reactors L. Todd Knighton, Daniel Wendt, Abdalla Jaoude, Cristian Rabiti, and Richard Boardman (INL), Amgad Elgowainy, Krishna Reddi, and Adarsh Bafana (ANL), Brian D. James, Brian Murphy, Julia Scheerer, and Fred Peterson (Strategic Analysis) March 2020 Idaho National Laboratory Idaho Falls, Idaho 83415 http://www.inl.gov Prepared Under DOE Idaho Operations Office Contract DE-AC07-05ID14517 EXECUTIVE SUMMARY Nuclear energy is increasingly being recognized as a valuable low-carbon, low-emissions energy source that can help meet clean energy targets being set by states, commissions, and utilities in the United States. -

Southeast Gateway and Campus Utility Master Plan Study Non‐Mandatory Pre‐Proposal Meeting 2:30 P.M

Southeast Gateway and Campus Utility Master Plan Study Non‐Mandatory Pre‐Proposal Meeting 2:30 p.m. Thursday, June 2, 2016 Rooms 317/318, Donhowe Building, East Bank University of Minnesota Twin Cities Campus Please sign in and leave your business card! Please Note: • Non‐Mandatory Pre‐Proposal Meeting –Please sign in and leave your business card. • Please turn off or silence mobile devices. • All maps and graphics are intended to be used for planning and reference use only and shall not be relied upon where a survey or further investigation is required. The information is this document may not be disclosed, reproduced, or altered without University of Minnesota authorization. • All RFP, addenda, notifications, and supplementary information can be found at the following UMN website: http://purchasing.umn.edu/construction/advertisements.html University Project # 01‐000‐16‐1268 SE Gateway and Campus Utility Master Plan Study http://purchasing.umn.edu/construction/advertisements.html Agenda: • Project Description • Introductions‐ Points of Contact • Project Overview (Phase 1 + Phase 2) • Campus Master Plan Forecast Assumptions‐ Cindy Harper • Utility Infrastructure Overview‐ Jerome Malmquist Steam –Dave Christiansen Electric‐ Kevin DeRuyscher Sanitary/Stormwater/Water‐ Cathy Abene Chilled Water‐ Scott McCord/ Jared Satrom • Project Goals, Objectives + Deliverables • Questions University Project # 01‐000‐16‐1268 SE Gateway and Campus Utility Master Plan Study Introductions: Capital Planning & Project Management + Energy Management • CPPM – -

\\\\Fii\Lm\Mill\\\\ . 30307Ooo18~EBESTA BLOMBERG

This document is made available electronically by the Minnesota Legislative Reference Library as part of an ongoing digital archiving project. http://www.leg.state.mn.us/lrl/lrl.asp \\\\fiI\lm\mill\\\\ . 30307ooo18~EBESTA BLOMBERG Utility Master Plan Re.port· For the i 1,. SEBESTA BLOMBERG Providing•Technical & Business Solutions Sebesta Blomberg Project No. 2049.00 '/ . " December 5,2002 2002 Minn. Laws Chap. 397 Sec. 18 Subd. 4 GV Sebesta Blomberg & Associates, Inc. 416 .M56 2381 Rosegate 2002fx Roseville, MN 55113 Phone: (651) 634-0775 Fax: (651) 634-7400 or I Contact: Tom Kukulski, PE E-mail: H, __ L.1.-L'=-""I_.,_~- -~~ SEBESTA BLOMBERG Providing Technical &Business Solutions M/W 2 9 UTILITY MASTER PLAN REPORT Proposed Joint-Use Football Stadium Minneapolis, Minnesota Prepared for the: UNIVERSITY OF MINNESOTA and the MINNESOTA VIKINGS December 5, 2002 Prepared by: Sebesta Blomberg & Associates, Inc. 2381 Rosegate Roseville, Minnesota 55113 Phone: (651) 634-0775 Fax: (651) 634-7400 Website: www.sebesta.com SEBESTA BLOMBERG ProvIding Technical6Svsrness Solutions (il TABLE OF CONTENTS I. BACKGROUND...................•.•....••...........................! ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••3 A. Basis ofDesign : 3 II. Condition Assessment of Impacted University Utilities 5 A. Facilities and Utilities Currently in District... 5 B. Steam 6 C. Chilled Water 6 D. Electric 6 III. Outline of Required Improvements For Each Utility 8 A. Stadium Utility Requirements 8 B. District Utility Requirements 10 IV. Heating System Analysis 13 A. Heating System Alternatives 13 B. Discussion ofAlternatives 13 V. Central Chilled 'Vater Plant Analysis 24 A. Cooling System Discussions 24 VI. Electric Power 27 A. Electrical Power Requirements 27 B. Evaluate Sources ofPower 27 C. -

The University of Minnesota Twin Cities Combined Heat and Power

p-bp15-01-02b ATTACHMENT 1 STATE OF MINNESOTA MINNESOTA POLLUTION CONTROL AGENCY IN THE MATTER OF THE DECISION ON THE NEED FOR AN ENVIRONMENTAL FINDINGS OF FACT IMPACT STATEMENT FOR THE PROPOSED CONCLUSIONS OF LAW UNIVERSITY OF MINNESOTA TWIN CITIES AND ORDER COMBINED HEAT AND POWER (CHP) PROJECT MINNEAPOLIS, HENNEPIN COUNTY, MINNESOTA This matter came before the Minnesota Pollution Control Agency (MPCA) Citizens’ Board (Board) at a regular meeting held in St. Paul, Minnesota on January 27, 2015. Based on the information gathered during the Environmental Assessment Worksheet (EAW) process, the comments received on the EAW, input from MPCA staff, and other information in the record, the MPCA hereby makes the following Findings of Fact, Conclusions of Law, and Order. FINDINGS OF FACT Project Description 1. The University of Minnesota Twin Cities Campus (University) is a teaching and research institution covering an area of approximately 1,154 acres and containing about 22 million square feet of buildings. 2. The University of Minnesota Board of Regents proposes to construct a new combined heat and power (CHP) project (“Project”) to provide steam for the Twin Cities campus steam distribution system and electricity. The Project includes the following equipment: a. A 22.8MW Combustion Turbine Generator (CTG) (EU 161); the CTG will use a stage, dry low NOx combustor; b. A 210 MMBTU/hr duct burner system (EU 162); c. A 270,000 lb steam/hr heat recovery steam generator (HRSG) using exhaust gases from the system; d. An aqueous ammonia-based selective catalytic reduction (SCR) system to control nitrogen oxides; e. -

District Energy / First Quarter 2018 © 2018 International District Energy Association

COVER STORY |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||| Powering the future from remains of the past Facing a boiler capacity shortage, the University of Minnesota rehabilitated a retired, antiquated steam plant into a model of modern efficiency and sustainability. Chris Farr, PE, Project Manager, Jacobs Engineering Group Inc. Courtesy University of Minnesota. he University of Minnesota Twin Cities encompasses Until 2017, all steam provided to the Minneapolis campus – divided by the approximately 24 million gross sq ft throughout 250 Mississippi River into east and west bank buildings across two campuses – in Minneapolis and areas – was generated at the Southeast Steam Plant (SE Plant). The plant had been TSt. Paul – approximately 3 miles apart. This flagship of acquired by the university in 1977 and the University of Minnesota system comprises 19 colleges and received major upgrades in 2000. The upgrades included a solid-fuel circulat- schools, with sister campuses in Crookston, Duluth, Morris and ing fluidized bed boiler and two dual-fuel (natural gas/No. 2 fuel oil) package boilers. Rochester. Two older coal-fired boilers were also re- tained to provide backup steam capacity. Energy Management, a division of Facilities Management within Prior to the acquisition of the SE Plant, University Services, oversees the production and distribution of steam for the Minneapolis campus was heating, cooling and electricity services to approximately 70,000 produced at a facility known as the Old Main Heating Plant. Originally constructed students and staff across the Twin Cities campuses. These include in 1912 and expanded/renovated many times over its life, this plant is located on • centralized steam production and distribution systems the East Bank of the Mississippi River at delivering high-pressure (200-psig) steam; the base of a former rock quarry excava- tion. -

Architecture and Historic Preservation on the Minneapolis Riverfront

ARCHITECTURE AND HISTORIC PRESERVATION ON THE MINNEAPOLIS RIVERFRONT Meader-Farnham House, Nicollet Island Prepared for Prepared by The Saint Anthony Falls Heritage Board Penny A. Petersen Research Historian Minnesota Historical Society 704 South Second Street Marjorie Pearson, Ph.D Minneapolis, Minnesota 55401 Principal Investigator Hess, Roise and Company March 2007 100 North First Street Minneapolis, Minnesota 55401 612-338-1987 Funding for this project was provided by the Saint Anthony Falls Heritage Board PROJECT BACKGROUND AND METHODOLOGY The Minneapolis Riverfront District has selected “Architecture and Historic Preservation on the Riverfront ” as its promotional theme for 2007, to coincide with the National Trust for Historic Preservation Conference being held in the Twin Cities between October 2 and 6, 2007. The Minnesota Historical Society, with funding from the Saint Anthony Falls Heritage Board, hired Hess, Roise and Company to conduct historical research on the architectural heritage and the story of historic preservation of the Minneapolis Riverfront District. The study concentrates on three categories: • The most significant examples of historic architecture in the project area • The most significant examples of historic preservation in the project area • The most significant examples of new construction in the project area Most of the examples discussed were specified in the RFP issued by the Minnesota Historical Society. Forty-five sites, several of which encompass more than one building (such as the residential area of Nicollet Island), are keyed to the maps and compiled in the list on pages 107- 117. Each section is subdivided into the following areas: East Side Milling District, Nicollet Island, West Side Milling District, and Warehouse District. -

The University of Minnesota, Twin Cities – Combined Heat and Power (CHP) Project Doc Type: Public Notice

Notice of Availability of an Environmental Assessment Worksheet (EAW) The University of Minnesota, Twin Cities – Combined Heat and Power (CHP) Project Doc Type: Public Notice Public Comment Information EAW Public comment period begins: October 27, 2014 EAW Public comment period ends: 4:30 p.m. on November 26, 2014 Notice published in the EQB Monitor: October 27, 2014 Permit public comment period begins sometime during the week of October 27th or November 3rd. Permit public comment period ends 30 days after comment period begins. Facility Specific Information Facility name and location: Facility contact: Old Main Steam Plant University of Minnesota, Twin Cities 1180 Main Street SE Roger Wegner Minneapolis, MN 55455 Project Manager SW ¼, SE ¼, Section 24, T29N, R24W 319 15th Avenue SE Minneapolis Township Minneapolis, MN 55455 Hennepin County, MN Phone: 612-626-4646 Fax: 612-625-0770 Email: [email protected] MPCA Contact Information MPCA EAW contact person: MPCA Permit contact person: Kim Grosenheider Bruce Braaten Resource Management and Assistance Division Industrial Division Minnesota Pollution Control Agency Minnesota Pollution Control Agency 520 Lafayette Road North 18 Wood Lake Drive SE St. Paul, MN 55155 Rochester, MN 55904 Phone: 651-757-2170 Phone: 507-206-2607 Fax: 651-297-2343 Fax: 507-280-5513 Email: [email protected] Email: [email protected] Admin staff phone: 651-757-2100 General Information The Minnesota Pollution Control Agency (MPCA) is distributing this Environmental Assessment Worksheet (EAW) for a 30-day review and comment period pursuant to the Environmental Quality Board (EQB) rules. The MPCA uses the EAW and any comments received to evaluate the potential for significant environmental effects from the project and decide on the need for an Environmental Impact Statement (EIS).