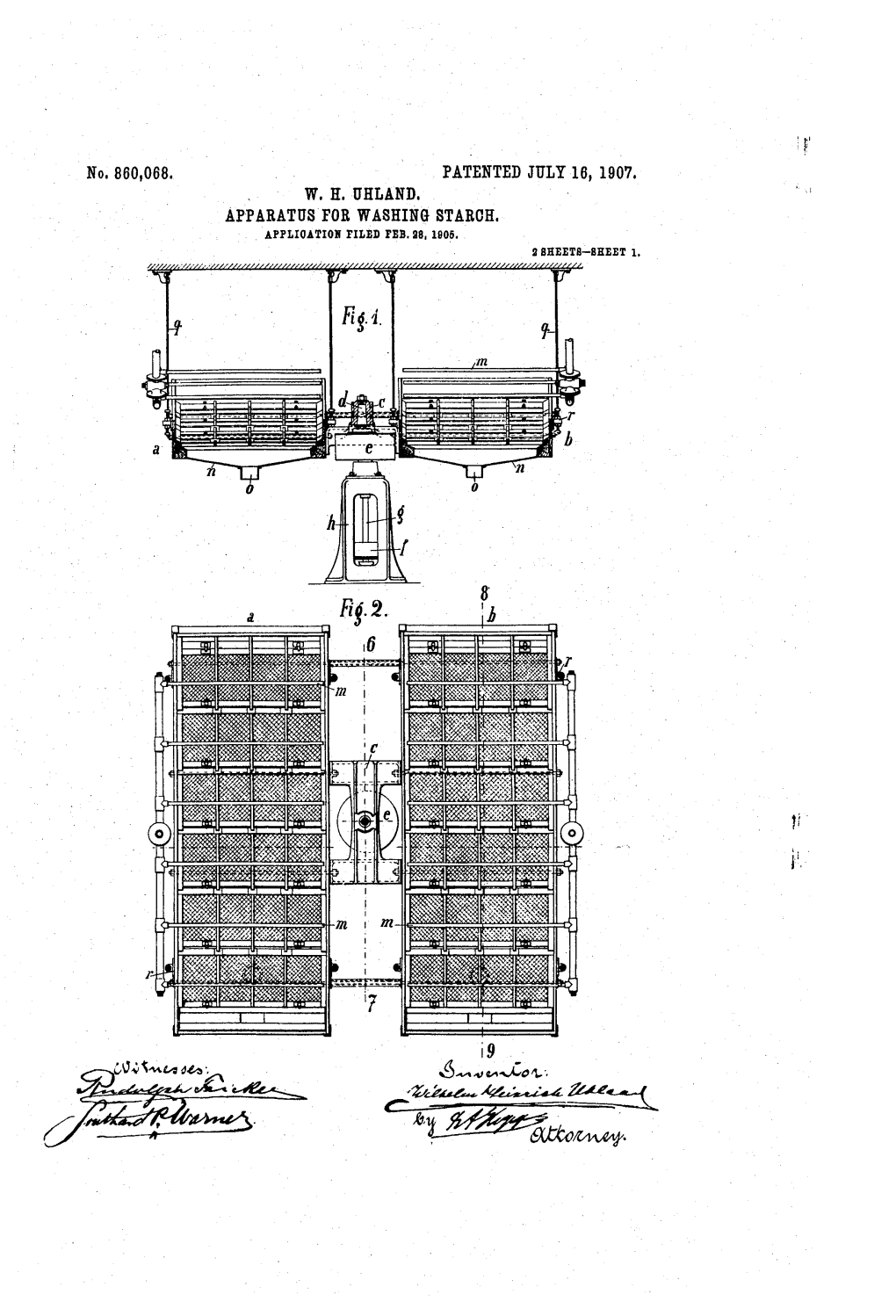

Apparatus'for Washing Stargh

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

LVB Netzplan Tag.Pdf

A B Zone C Zone D E F Zone 251 > Bitterfeld / 196 > Bad Düben 162 164 Wittenberg 164 504 Hohenheida, Hohenheida, Gottscheina, Göbschelwitz 86 Gasthof Am Anger Siedlung 215 > Eilenburg / Cottbus Gewerbegebiet Sachsenpark Seehausen, 504 Leipzig/Halle Breitenfeld, Parkring Podelwitz 85 Alte Mühle Hohenheida, 176 > Taucha > Halle (Saale) Flughafen 190 > Delitzsch Gottscheina, 86 Breitenfeld, Kutscherweg Breitenfeld, Pelzgasse Lindengasse Am Ring Tierheim 87 88 Wiederitzsch-Nord, Seehausener Future Electronics Radefeld, An der Huf- Autohaus 85 Seehausen, 82 86 Transport & Service Allee Schule Zone Zur schmiede Linden- Breitenfeld, Gut Ferag 195/197 > Eilenburg An der Linden- Salzhandelsstr. BMW Werk, 176 > Hohenheida allee Gewerbegebiet Alte Dübener Seehausen Radefeld, GVZ/ Lindenthal, Schule höhe 88 86 Einfahrt Zentralgebäude 86 Porsche Gemeindeamt Landstr. Sachsenpark Plaußig, 163 Lindenthal, Wiederitzscher BMW Werk, 83 Taucha, M.-Erz- Tor 1 Gewerbegebiet berger-Str. Radefeld, GVZ/ An der Windmühle Landstr. 196 Congress- Am Obstgut 176 173·175 > Borsdorf Sophienstr. G.-Herwegh- Deutsche Post AG Lindenthaler Str. 86 Center Am Kellerberg 1 Hauptstr. Wiederitzsch, Portitz- Plaußiger 1 Bürgeramt mühlweg Dorfstr. 81 Taucha, Lindnerstr. Wiederitzsch- Messe- 81 R.-Breitscheid-Str. Lange Trift 16 82 Mitte Bf. Messe gelände Alte Theklaer Grundstr. 90 87/88 90 87 87 Messe- Taucha, Bahnhof verwaltung Teschstr. Str. Taucha, Äußerer Zeisigweg Melissenweg Bf. Wiederitzsch Dachauer Str. Taucha, 173 175 176 195 3 Zone W.-Pfennig-Str. 79 80 81 82 83 83 Cradefelder Str. Zur An der Bürgerruhe Landsberger/ Siedlerweg Martinshöhe Am alten Radefeld, GVZ/ Flughafen Waldenau Am Exer Bahnhofstr. Parthe Krätzbergstr. 195 Freilig- 162 Zeisigweg Zone Thekla W.-Götze-Str. rathstr. Wilhelmstr. Gohlis, Klinikum Mockau- Schild- 9 Am langen Teiche Th.-Körner- Bogumils Garten 4 St. -

The Role of Music in European Integration Discourses on Intellectual Europe

The Role of Music in European Integration Discourses on Intellectual Europe ALLEA ALLEuropean A cademies Published on behalf of ALLEA Series Editor: Günter Stock, President of ALLEA Volume 2 The Role of Music in European Integration Conciliating Eurocentrism and Multiculturalism Edited by Albrecht Riethmüller ISBN 978-3-11-047752-8 e-ISBN (PDF) 978-3-11-047959-1 e-ISBN (EPUB) 978-3-11-047755-9 ISSN 2364-1398 Library of Congress Cataloging-in-Publication Data A CIP catalog record for this book has been applied for at the Library of Congress. Bibliographic information published by the Deutsche Nationalbibliothek The Deutsche Nationalbibliothek lists this publication in the Deutsche Nationalbibliografie; detailed bibliographic data are available in the Internet at http://dnb.dnb.de. © 2017 Walter de Gruyter GmbH, Berlin/Boston Cover: www.tagul.com Typesetting: Konvertus, Haarlem Printing: CPI books GmbH, Leck ♾ Printed on acid free paper Printed in Germany www.degruyter.com Foreword by the Series Editor There is a debate on the future of Europe that is currently in progress, and with it comes a perceived scepticism and lack of commitment towards the idea of European integration that increasingly manifests itself in politics, the media, culture and society. The question, however, remains as to what extent this report- ed scepticism truly reflects people’s opinions and feelings about Europe. We all consider it normal to cross borders within Europe, often while using the same money, as well as to take part in exchange programmes, invest in enterprises across Europe and appeal to European institutions if national regulations, for example, do not meet our expectations. -

Urban Shrinkage in Leipzig and Halle, the Leipzig-Halle Urban Region, Germany

shrink smart GGoovveerrrnnaannccee oofff SShhrrriiinnkkaaggee WWiiittthhiiinn aa EEuurrrooppeeaann CCoonnttteexxttt Work package 2 Urban shrinkage in Leipzig and Halle, the Leipzig-Halle urban region, Germany Research report D4 Comparable research report 30 March 2010 Dieter Rink () Annegret Haase Matthias Bernt Thomas Arndt Johanna Ludwig The views expressed are the authors’ alone and do not necessarily correspond to those of other Shrink Smart partners or the European Commission. Comments and enquiries should be addressed to: Prof. Dr. Dieter Rink, Helmholtz Centre for Environmental Research – UFZ, Leipzig, Germany. Tel: +49 341 2351744. Email: [email protected] Contents Part A – Leipzig 6 A.1. EXECUTIVE SUMMARY 6 A.2. REASONS AND PREMISES OF URBAN SHRINKAGE 8 Introduction 8 Demographic development 10 Economic development 17 Settlement system 21 A.3. IMPACTS AND CONSEQUENCES OF URBAN SHRINKAGE 28 A.3.1. Patterns of segregation and social cohesion 28 A.3.2. Business and employment 36 A.3.3. Social infrastructure and education 36 A.3.4. Housing 39 A.3.5. Technical infrastructure 46 A.3.6. Land use and environmental quality 47 A.3.7. Municipal finances and budget 51 A.4. ANNEX: DATABASE LEIPZIG 57 Part B – Halle 68 B.1. EXECUTIVE SUMMARY 68 B.2. REASONS AND PREMISES OF URBAN SHRINKAGE 70 Introduction 70 Demographic development 72 Economic development 80 Settlement system 83 B.3. IMPACTS AND CONSEQUENCES OF URBAN SHRINKAGE 87 B.3.1. Patterns of segregation and social cohesion 87 B.3.2. Business and employment 92 B.3.3. Social infrastructure and education 92 B.3.4. Housing 94 B.3.5. -

Agatha Christie's the Mysterious Affair at Styles

AGATHA CHRISTIE’S THE MYSTERIOUS AFFAIR AT STYLES: A CASE STUDY IN DUTCH AND GERMAN TRANSLATION CULTURES USING CORPUS LINGUISTIC TOOLS by MARJOLIJN STORM A thesis submitted to the University of Birmingham for the degree of DOCTOR OF PHILOSOPHY School of Languages, Cultures, Art History and Music College of Arts and Law University of Birmingham June 2012 University of Birmingham Research Archive e-theses repository This unpublished thesis/dissertation is copyright of the author and/or third parties. The intellectual property rights of the author or third parties in respect of this work are as defined by The Copyright Designs and Patents Act 1988 or as modified by any successor legislation. Any use made of information contained in this thesis/dissertation must be in accordance with that legislation and must be properly acknowledged. Further distribution or reproduction in any format is prohibited without the permission of the copyright holder. Abstract Rooted in the field of Descriptive Translation Studies, the thesis combines such different areas as (corpus) linguistics, literary, cultural, media and socio-historical studies of the UK, the Netherlands and Germany. Five translations (three German and two Dutch) of Agatha Christie’s first detective novel The Mysterious Affair at Styles are analysed. Using the theories by Itamar Even-Zohar (Polysystem Theory) and Gideon Toury (Translation Norms), the different approaches translators have taken to the text are examined and their translation decisions explained by looking at the status and position translations from English, detective stories as such, and the writer Agatha Christie had in the country and at the time these translations were published. -

Chronology Adolf Bleichert & Co

CHRONOLOGY ADOLF BLEICHERT & CO Founding in Schkeuditz and move to Leipzig 1874 July 1 Engineers Adolf Bleichert & Theodor Otto establish in Schkeuditz, Saxony, Germany, an Engineering Office for the design of rope ways. Company name: Bleichert & Otto Engineering Office (“only specialty: Construction of rope ways”) Relocation of the company to Leipzig, Weststrasse 55 (today abt.Friedrich Ebert Strasse) 1st.floor. 1876 August 23 Bleichert and Otto separate. The company is now known as Adolf Bleichert Engineering Office (Works for Rope ways?) 1877 October 1 Appointment of Heinrich Piel as a director. Rented workshop in Neuschönfeld near Leipzig, Eisenbahnstr.3. (20 workers) 1878 October 1 Relocation of the offices (6 employees) within Leipzig to Humboldtstrasse 30, 3rd floor. 1 Relocation to Gohlis 1881 Piel becomes a partner and the firm operates as an open partnership (OHG = Offene Handelsgesellschaft) under the name Adolf Bleichert & Co. in Gohlis, Works for Rope ways. 1881 October 1 Company moves to Gohlis near Leipzig, Feldstr.1, Germany (Office staff 20, Workers 70) celebrating both the move and the sale of the 100th Rope Ways. Architect of the factory complex: Max Bösenberg 1881 October 28 Registration of Incorporation at the Leipzig County Court. The company remains at the Feldstr.1 location. However, the street name changes: 1899 to Kaiser-Friedrich-Strasse 34 (the final house Number), 1945 to Victor-Adler-Strasse, since 1953 Lützowstrasse. In 1890 Gohlis was annexed to Leipzig 1887 July 30 Heinrich Piel dies. His widow Anna Piel, nee Bleichert, a sister of Adolf Bleichert (with her children as “Piel heirs”) assumes partnership. 1882 April A new street leading from Gohlis to Eutritzsch is named “Bleichert Street” 1887 December 1 Expansion of Gohlis facility 1888 September 8 Piel (and with it his heirs) left partnership as co-owner (as per notation in the Trade Registry). -

Beloved Sisters

presents BELOVED SISTERS a film by Dominik Graf In German with English Subtitles 2014 Official Oscar® Entry – Germany Best Foreign Language Film Awards 2014 Bavarian Film Awards – Winner: Best Cinematography Official Selection 2014 Berlin International Film Festival 2014 New York Film Festival 2014 Vancouver International Film Festival 2014 Chicago International Film Festival 170 min., Germany/Austria, 2014. Press materials: http://www.musicboxfilms.com/beloved-sisters-press Official site: http://www.musicboxfilms.com/beloved-sisters NY Publicity: LA Publicity: Sophie Gluck & Associates Marina Bailey Film Publicity Sophie Gluck Marina Bailey [email protected] [email protected] Aimee Morris Sara Tehrani [email protected] [email protected] 212-595-2432 323-962-7511 Music Box Films Marketing/Publicity: Distribution Contact: Brian Andreotti/Rebecca Gordon Andrew Carlin 312-508-5361/312-508-5362 312-508-5360 [email protected] [email protected] [email protected] Awards Contact: Fredell Pogodin & Associates [email protected] 323-931-7300 SYNOPSIS BELOVED SISTERS depicts the unconventional romance between two devoted aristocratic sisters and a rebellious poet who took the European literary world by storm in the late eighteenth century. As the German Enlightenment flourishes in Weimar, vibrant Caroline von Beulwitz (Hannah Herszsprung) finds herself in an unhappy marriage to provide for her mother and shy younger sister Charlotte von Lengefeld (Henriette Confurius). When both sisters fall for outspoken writer Friedrich Schiller (Florian Stetter), their desire ignites a journey of shared passion and creativity. Charlotte and Schiller marry so that the lovers may pursue their ménage- à-trois under the guise of convention, but as Caroline reveals herself to be a talented author in her own right, the trio's fragile equilibrium is threatened and the sisters’ once unbreakable bond is irrevocably changed. -

Excursions to the Sites of the Bauhaus and Modernism

Excursions to the Visit the Sites of the Bauhaus Sites of and the Bauhaus Modernism A group travel planner and Modernism! ↘ bauhaus100.de/en # bauhaus100 The UNESCO World Heritage Sites and the Sites of Bauhaus Modernism Hamburg P. 31 Celle Bernau P. 17 P. 29 Potsdam Berlin P. 13 Caputh P. 17 P. 17 Alfeld Luckenwalde Goslar Wittenberg P. 29 P. 17 Dessau P. 29 P. 10 Quedlinburg P. 10 Essen P. 10 P. 27 Krefeld Leipzig P. 27 P. 19 Düsseldorf Löbau Zwenkau Weimar P. 19 P. 27 Dornburg Dresden P. 19 Gera P. 19 P. 7 P. 7 P. 7 Künzell P. 23 Frankfurt P. 23 Kindenheim P. 25 Ludwigshafen P. 25 Völklingen P. 25 Karlsruhe Stuttgart P. 21 P. 21 Ulm P. 21 Bauhaus institutions that maintain collections Modernist UNESCO World Heritage Sites Additional modernist sites 3 100 years of bauhaus The Bauhaus shaped an era and ushered in the idea of functional design and modern construction. Although it started in Germany, the influence of the Bauhaus has spread worldwide. To this day, the dream of a Gesamtkunstwerk—a complete work of art that synthesises fine and applied art, architecture and design, dance and theatre—continues to provide impulses for our cultural creations and living environments. The year 2019 marks the 100 th anniversary of the historical institution, but the allure of an idea that founding of the Bauhaus. Established in Weimar in transcends both time and borders. The centenary 1919, the Bauhaus relocated to Dessau in 1925 before is being marked by an extensive programme of ex being closed under pressure from National Socialists hibitions and events about architecture and design, in Berlin in 1933. -

Projekt Lebendige Luppe: Die Vielfalt Des Auwalds Bewahren

Projekt Lebendige Luppe: Die Vielfalt des Auwalds bewahren Leipzigs Geschichte ist eng mit der Geschichte der großen Gewässer der Region verbunden: Weiße Elster, Parthe und Pleiße sind maßgeblich dafür verantwortlich, dass sich Leipzig zu einer pulsierenden und wirtschaftsstarken Stadt entwickelte. Denn einst waren Wasserwege ein Schlüssel zu Mobilität, Möglichkeit zu Transport und Warenaustausch. Das Umland der Flüsse war fruchtbar und für Ackerbau und Landwirtschaft bestens geeignet. Heute spielen diese Faktoren nur noch eine untergeordnete Rolle, doch attraktiv macht die Flussaue die Messestadt und dessen Umland noch immer: Das auentypische Mosaik aus Wald-, Wiesen- und Wasserflächen verknüpft die wachsende Großstadt mit Naturerleben fast vor der Haustür. Die Auenlandschaft ist bedroht Doch zahlreiche wasserbauliche Maßnahmen haben zu einer stetigen Austrocknung des Auwalds geführt. Besonders einschneidend war der Bau der Neuen Luppe in den 1930er- bis 1950er-Jahren. Der Kanal trennt den nordwestlichen Auwald von seiner wichtigen Wasserversorgung ab und entzieht der Umgebung durch seine tiefe Gewässersohle zusätzlich Grundwasser. Doch zeigen Hohlformen überall in den hiesigen Auwäldern noch den Verlauf alter, trockener Flussläufe. Das Projekt Lebendige Luppe möchte solche Relikte verbinden, wieder mit Wasser versorgen und eine wichtige Lebensader in der Aue wiederherstellen, um die große Struktur-, Lebensraum- und Artenvielfalt der Auenlandschaft zu erhalten. Umgesetzt wird das Projekt seit 2012 durch die Städte Leipzig und Schkeuditz, die Universität Leipzig, das Helmholtz-Zentrum für Umweltforschung (UFZ) und den NABU Sachsen. Den Wert der Aue bewusst machen Ein wichtiger Projektbaustein ist die Öffentlichkeits- und Umweltbildungsarbeit. Seit Mai 2013 erarbeiten Projektmitarbeiterinnen im Kontaktbüro Lebendige Luppe in Gohlis (Coppistraße neben Nr. 69) Broschüren, Unterrichtsmaterialien und Ausstellungsmedien zu den Themen Auwald, Leipziger Gewässerknoten und Projektfortschritt, bieten außerdem Infoveranstaltungen und Exkursionen an. -

Excursions to the Sites of the Bauhaus and Modernism

Excursions to the Visit the Sites of the Bauhaus Sites of the and Bauhaus Modernism A travel planner for groups and individual travellers and Modernism ↘ bauhaus100.com # bauhaus100 The UNESCO- World Heritage Sites and the Sites of the Bauhaus and Modernism Hamburg P. 31 Celle Bernau P. 17 P. 29 Potsdam Berlin P. 13 Caputh P. 17 P. 17 Alfeld Luckenwalde Goslar Wittenberg P. 29 P. 17 Dessau P. 29 P. 10 Quedlinburg P. 10 Essen P. 10 P. 27 Krefeld Leipzig P. 27 P. 19 Düsseldorf Löbau Zwenkau Weimar P. 19 P. 27 Dornburg Dresden P. 19 Gera P. 19 P. 7 P. 7 P. 7 Künzell P. 23 Frankfurt P. 23 Kindenheim P. 25 Ludwigshafen P. 25 Völklingen P. 25 Karlsruhe Stuttgart P. 21 P. 21 Ulm P. 21 Bauhaus institutions that maintain collections The UNESCO-World Heritage Sites of Modernism Additional modernist sites 2 3 100 years of bauhaus The Bauhaus: an idea that has really caught on. Not just in Germany, but also worldwide. Functional design and modern construction have shaped an era. The dream of a Gesamtkunst- werk – a total work of art that synthesises fine and applied art, architecture and design, dance and theatre – continues to this day to provide impulses for our cultural creation and our living environments The year 2019 marks the 100th anniversary of the ion, but the allure of an idea that transcends both founding of the Bauhaus. Established in Weimar in time and borders. The centenary year is being mar- 1919, relocated to Dessau in 1925 and closed in Ber- ked by an extensive programme with a multitude of lin under pressure from the National Socialists in exhibitions and events about architecture and design, 1933, the Bauhaus existed for only 14 years. -

Knowledge Transfer with Citizen Science: Luft-Leipzig Case Study

sustainability Article Knowledge Transfer with Citizen Science: Luft-Leipzig Case Study Liina Tõnisson *, Jens Voigtländer, Michael Weger, Denise Assmann, Ralf Käthner, Bernd Heinold and Andreas Macke Leibniz Institute for Tropospheric Research, 04318 Leipzig, Germany; [email protected] (J.V.); [email protected] (M.W.); [email protected] (D.A.); [email protected] (R.K.); [email protected] (B.H.); [email protected] (A.M.) * Correspondence: [email protected] Abstract: Community-based participatory research initiatives such as “hackAir”, “luftdaten.info”, “senseBox”, “CAPTOR”, “CurieuzeNeuzen Vlaanderen”, “communityAQ”, and “Healthy Air, Health- ier Children” campaign among many others for mitigating short-lived climate pollutants (SLCPs) and improving air quality have reported progressive knowledge transfer results. These research initiatives provide the research community with the practical four-element state-of-the-art method for citizen science. For the preparation-, measurements-, data analysis-, and scientific support-elements that collectively present the novel knowledge transfer method, the Luft-Leipzig project results are presented. This research contributes to science by formulating a novel method for SLCP mitigation projects that employ citizen scientists. The Luft-Leipzig project results are presented to validate the four-element state-of-the-art method. The method is recommended for knowledge transfer purposes beyond the scope of mitigating short-lived climate pollutants (SLCPs) and improving air quality. Citation: Tõnisson, L.; Voigtländer, J.; Weger, M.; Assmann, D.; Käthner, R.; Keywords: knowledge transfer; short-lived climate pollutants; air quality; black carbon; particulate Heinold, B.; Macke, A. Knowledge matter; citizen science Transfer with Citizen Science: Luft-Leipzig Case Study. Sustainability 2021, 13, 7855. https://doi.org/10.3390/su13147855 1. -

Social Crisis Management in the Coal and Steel Industries • European Models and Experiences •

'I ~ Commission of the European Union {': -~····:r r~·-- European Commission Delegation Library Manual 2300 M Street, NW Washington, DC 20037 Social Crisis Management in the Coal and Steel Industries • European Models and Experiences • by Hans-Werner Franz __. \ ' ( ._· Published by the Commission of the European Union Directorate-General V Employment, Industrial Relations and Social Affairs ECSC Readaptation and Social Aspects of Iron and Steel Policies B-1 049 Brussels The case studies forming the basis of Section E of the manual, "Models for social crisis management", were produced by the following persons and institutes: Belgium: Martine Wouters (HIVA, Leuven), Lieven Denolf (KU Leuven), Eline Staelens (BLM, Limburg); Germany: Cornelia Auxel, Andreas Davids (BASIS Dresden), Hans-Werner Franz, Uwe Jlirgenhake, Rainer Lichte, Rainer OHmann, Jiirgen Schulze, Oliver Steigerwald, Detlef Ullenboom, Beate Winter (sfs, Dortmund); France: Raphael Garcia (CEDRES, Paris); United Kingdom: William Rees (City of London Polytechnic), Barry Thomas (University of Durham); Italy: Rolf Uesseler(Rome); Luxembourg: Uwe Jiirgenhake (sfs, Dortmund); Spain: Xavier Matheu, Jaume Benavent, Josep M. Navarro ( CIREM, Barcelona) Coordination of the case studies and of the project: Hans-Werner Franz, Sozialforschungsstelle Dortmund, a member institute of euroNET:WORK&EDUCATION. Luxembourg: Office for Official Publications of the European Communities 1994 ISBN 92-826-5796-5 © ECSC-EEC-EAEC, Brussels-Luxembourg, 1994 Reproduction is authorised, except for commercial purposes, provided the source is acknowledged Printed in Germany Foreword by the editor Since 1980 alone, over 800.000 workers have been forced to leave their jobs as a result of restructuring in the Community coal and steel industries. The European Community has contributed significantly, through financial and various other means, to the social measures implemented to cushion the impact of this restructuring on the workers involved. -

It Is Not Enough We Have Lost the War – Now We Have to Watch It!” Cinemagoers’ Attitudes in the Soviet Occupation Zone of Germany (A Case Study from Leipzig)

. Volume 8, Issue 2 November 2011 “It is not enough we have lost the war – now we have to watch it!” Cinemagoers’ attitudes in the Soviet occupation zone of Germany (a case study from Leipzig) Pavel Skopal Masaryk University, Brno, Czech Republic / Hochschule für Film und Fernsehen “Konrad Wolf”, Potsdam, Germany Abstract The immediate post-WWII years represented a period of turbulent change in many European cinema cultures – and for the Soviet Occupation Zone of Germany it held true even more than for any other part of Europe. This case study examines both the new distribution system the Soviet occupation power brought to the zone and the reception of Soviet and German movies by German audiences. A collection of reports about the reaction of audiences to the Soviet movies facilitates research into attitudes to Soviet production. These reports are used for the first time for a historical research on cinema reception and give us a unique opportunity to analyse the behaviour and opinions of the post-WWII audiences through the cinemagoer´s written statements, their oral expressions written down by the cinema managers, and observations made by employees of the cinemas. The general problem Soviet production (as, in a less extreme form, any other foreign production) faced on the German market was its cultural difference and the already established expectations based on the implicit norms of a “well made movie”. The prevailing evaluation of the Soviet cinema as primitive one and good enough only for children offered a chance to invert the relation between the occupier and the occupied, the custodian and the reformed, and to (re)capture the stand of cultural superiority.