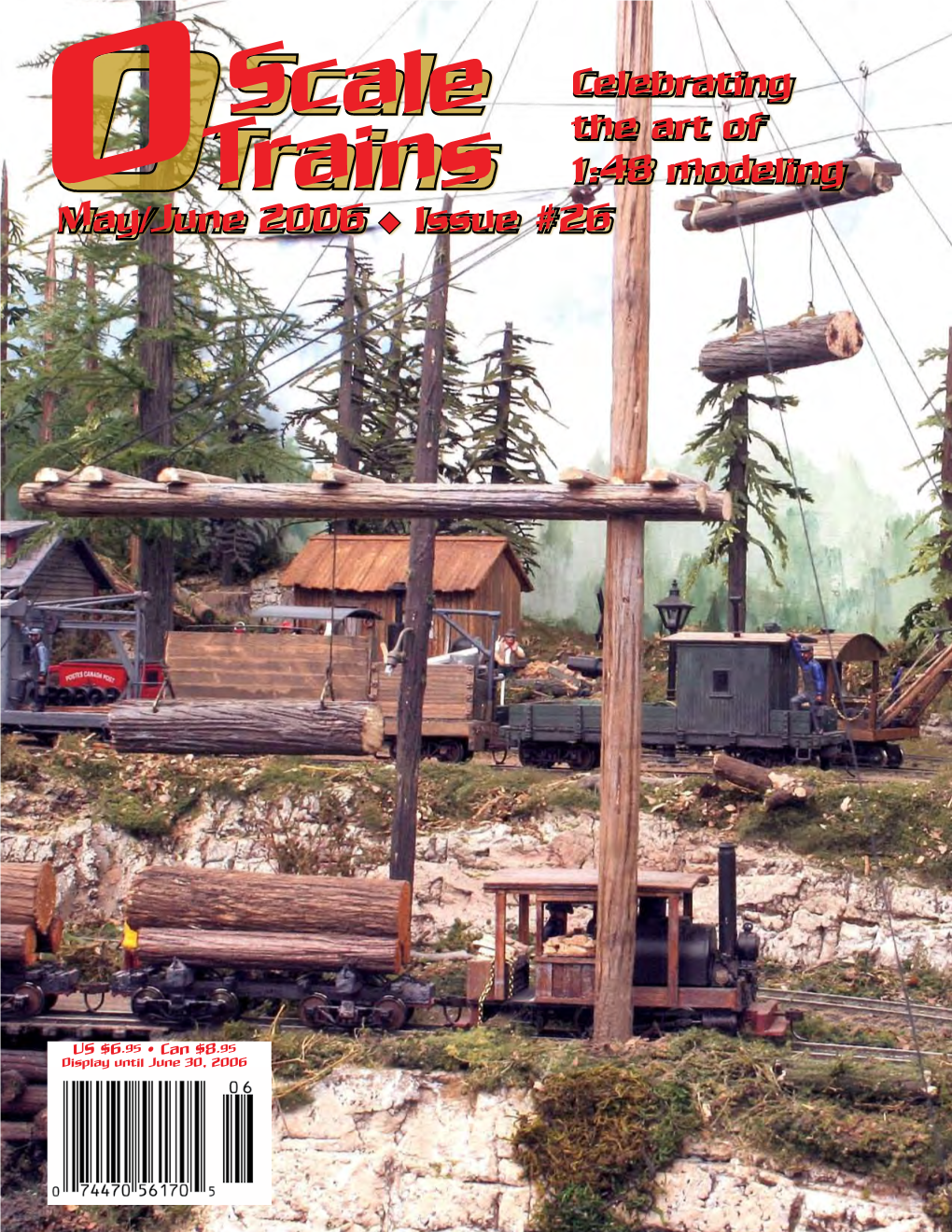

Celebrating the Art of 1:48 Modeling May/June 2006 U Issue

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

EMD E8 A-A Diesel

2010 volume 2 - part1.qxp 4/9/2010 12:20 PM Page 24 Features - Colorful Paint Scheme EMD E8 A-A Diesel Set - Metal Chassis - Metal Wheels, Axles and Gears - Die-Cast Truck Sides, Pilots and Fuel Tank - (2) Precision Flywheel- Equipped Motors - Intricately Detailed ABS Bodies - (2) Remotely Controlled Proto-Couplers™ - Directionally Controlled Headlight - Metal Horn - Locomotive Speed Control In Scale MPH Increments - Proto-Sound 2.0 With The Digital Command System Featuring Passenger Station Proto-Effects - Unit Measures: 29 3/4” x 2 1/2” x 3 1/2” - Operates On O-31 Curves B-Unit Features - Intricately Detailed ABS Body - Metal Wheels and Axles - Colorful Paint Scheme - Die-Cast Truck Sides - Metal Chassis - Metal Horn - Unit Measures: 13 1/2” x 2 1/2” x 3 1/2” - Operates On O-31 Curves 24 2010 volume 2 - part1.qxp 4/9/2010 12:20 PM Page 25 In the mid-1930's, as the Electro-Motive Division of General Motors was trying to inter- est railroads in diesel passenger power, it experimented a lot with exterior design. Looking at EMD's worm-like yellow and brown Union Pacific M-10000, its gleaming stainless steel Burlington Zephyr, or the boxy, Amtrak - E8 A-A Diesel Engine Set just-plain-ugly early Santa Fe units, it's appar- 30-2996-1 w/Proto-Sound 2.0 $349.95 Add a Matching ent that here was a new function looking for Amtrak - E8 B-Unit Passenger Set 30-2996-3 Non-Powered $119.95 its form. The first generation of road diesels See Page 48 found its form in 1937 when the initial E- units, built for the B&O, inaugurated the clas- sic "covered wagon" cab unit design that would last for decades on both freight and passenger diesels. -

WU Editorials & Model Stop

volume one, number two a supplement to walthers ho, n&z and big trains reference books CLASSICS Model Power Acquires Mantua Model Power is pleased to announce its acquisition of Mantua Industries. A respected manufacturer of locomotives and rolling stock for model railroaders since 1926, Mantua is headquartered in Woodbury, New Jersey. Together these manufacturers have a total of over 110 years of experience and service to the model railroad industry. Model Power has purchased all HO tooling, molds, parts and dies from Mantua Industries and retains rights to the name “Mantua.” Model Power will also be forming a new division called Mantua Classics whose initial production plans for 2003 include the following locomotives: Pacific, Berkshire, 2-6-6-2, 2-6-6-0, Camelback and 0-6-0 Tank. The overall goal will be to produce quality products, fine-tune performance, enhance detail and dramatically cut the prices of steam locomotives. For modelers concerned about what this acquisition means in terms of products and customer service, here are steps now being taken by Model Power: 1. Most parts are or will be in stock 2. Metal boiler locomotives will be made with extra details not previously included 3. Steam locomotives will be DCC compatible with an 8-prong receiver 4. Tenders will be made with electrical pickup 5. Drive trains for F7s will be flywheel driven and carry the high-tech F7 metal body used in Model Power’s MetalTrain™ Model Power is proud to offer its customers more—more details, more quality and performance, more choices— with Mantua Classics. -

Walthers September 2018 Flyer

lyerlyer SEPTEMBER 2018 GIVEGIVE YOURYOUR HOHO LL AYOU AYOU T T AA LIFT!LIFT! SALE ENDS 10-15-18 Find a Hobby Shop Near You! Visit walthers.com or call 1-800-487-2467 September2018 Flyer Cover.indd 1 7/31/18 5:08 PM WELCOME CONTENTS Good things in It’s time to hit the books, and you’ll want to study this Walthers Flyer First Products Pages 4-12 issue from cover-to-cover to learn about the latest new New from Walthers Pages 13-17 packages! product news, great deals and must-have modeling supplies inside! SceneMaster Containers Sale Page 18-22 Sure, good things do come in small packages, but these days, they’re likely to arrive in very big boxes first! While they might ® Walthers 2019 Reference Book Page 23 Power up with the newest WalthersMainline SD70ACe not have ribbons and fancy gift-wrapping, today’s trailers and New From Our Partners Pages 24 & 25 diesels, including three brand-new Norfolk Southern containers do wear a rainbow of colors, and the tremendous Heritage schemes! See the latest HO releases on page 4. The Bargain Depot Pages 26 & 27 variety of types handles everything from liquids to frozen Make tracks to your dealer – more WalthersMainline HO Scale Pages 28-33, 36-49 food. Moved by ship, road or rail, these hard-working freight boxcars are coming soon, including classic 40' PS-1s and N Scale Pages 50-54 forwarders can be seen just about everywhere these days, contemporary 60' Plate F cars! Take a look at page 5. -

Advance Reservations LOCOMOTIVES TRAIN SETS FREIGHT CARS

advance reservations LOCOMOTIVES 141-1609 C&O #7087 & 7543 Expected HO USRA 2-6-6-2 STEAM POWERED STEWART HOBBIES 12/02 254.98 W/TENDER EXPECTED 11/03 349.00 691-5218 HO Diesel F3A Phase II Early A See Your Dealer for Roadname Availability ARISTO-CRAFT TRAINS HO DIESEL EMD F3A POWERED Unit Only Powered WM/Fireball Expected 614-84001 G Brass Rail Car 1/20.3 Scale LIMITED-RUN HO EMD SD45 DIESEL POWERED 11/02 115.00 Limited Run Expected 04/03 365.00 141-2010 Western Pacific #802A EXPECTED TBA 85.00 691-5633 HO Diesel EMD F7 Phase I Early A (Passenger) Expected TBA 129.98 See Your Dealer for Roadname Availability (Powered) B (Dummy) Set WM/Fireball G UNDECORATED STEAM LOCOMOTIVES 141-2011 Phase IV Atlantic Coast Line #386 Expected 11/02 150.00 POWERED W/PACIFIC STYLE TENDER (purple) Expected 11/02 124.98 N EMD SD45 DIESEL POWERED 691-5634 HO Diesel EMD F7 Phase I Early A EXPECTED TBA 550.00 Unit Only Powered WM/Fireball Expected HO DIESEL EMD F3A-B SET POWERED EXPECTED 11/03 90.00 614-21499 Pacific 4-6-2 See Your Dealer for Roadname Availability 11/02 115.00 614-21599 Steam Mikado 2-8-2 LIMITED-RUN EXPECTED TBA 239.98 See Your Dealer for Roadname Availability USA TRAINS G RAIL DIESEL CAR (RDC-3) POWERED HO 55-TON CLASS B 2-TRUCK CLIMAX EXPECTED TBA TBA ATLAS POWERED EXPECTED TBA 250.00 G DIESEL EMD GP7 POWERED See Your Dealer for Roadname Availability See Your Dealer for Roadname Availability EXPECTED TBA 299.95 HO DIESEL EMD GP7 POWERED HO 80-TON CLASS C 3-TRUCK CLIMAX See Your Dealer for Roadname Availability ATHEARN EXPECTED 02/03 94.95 -

Railroad Collectibles

Celebrating Scale the art of OTrains 1:48 modeling Nov/Dec 2006 u Issue #29 US $6.95 • Can $8.95 Display until Dec. 31, 2006 Celebrating the art of 1:48 modeling Issue #29 Nov/Dec 2006 Vol. 5 - No. 6 Publisher Joe Giannovario [email protected] Features Art Director 4 The Latest Stop on My O Gauge Journey Jaini Giannovario [email protected] A spectacular HiRail layout by Norm Charbonneau. Editor 14 A Turntable for the Cincinnati & West Virginia Brian Scace [email protected] Need a way to turn your locomotives? Ron Gribler shows how he did it. 31 Build a Small O Scale Layout — Part 12 Advertising Manager Mike Culham continues construction of the building he started in Part 11. Jeb Kriigel [email protected] 42 Scratchbuild a Gas Station A small structure to fit any size layout designed and built by Tom Houle. Customer Service Spike Beagle 63 OST 2K6 Digital Photo Contest Winners A fine selection of photos won this year’s contest prizes. CONTRIBUTORS TED BYRNE HOBO D. HIRAILER BObbER GIbbS ROGER C. PARKER MIKE COUGILL GENE CLEMENS Departments CAREY HINch Subscription Rates: 6 issues US - Standard Mail Delivery US$35 9 Easements for the Learning Curve – Brian Scace US - First Class Delivery (1 year only) US$45 Canada/Mexico US$55 12 Modern Image – Gene Clemens Overseas US$80 Visa, MC, AMEX & Discover accepted 23 Confessions of a HiRailer – Hobo D. Hirailer Call 610-363-7117 during Eastern time business hours 27 Reader Feedback – Letters to the Editor Dealers contact Kalmbach Publishing, 800-558- 1544 ext 818 or email [email protected] 35 The Art of Finescale – Mike Cougill Advertisers call for info. -

Transportation Trips, Excursions, Special Journeys, Outings, Tours, and Milestones In, To, from Or Through New Jersey

TRANSPORTATION TRIPS, EXCURSIONS, SPECIAL JOURNEYS, OUTINGS, TOURS, AND MILESTONES IN, TO, FROM OR THROUGH NEW JERSEY Bill McKelvey, Editor, Updated to Mon., Mar. 8, 2021 INTRODUCTION This is a reference work which we hope will be useful to historians and researchers. For those researchers wanting to do a deeper dive into the history of a particular event or series of events, copious resources are given for most of the fantrips, excursions, special moves, etc. in this compilation. You may find it much easier to search for the RR, event, city, etc. you are interested in than to read the entire document. We also think it will provide interesting, educational, and sometimes entertaining reading. Perhaps it will give ideas to future fantrip or excursion leaders for trips which may still be possible. In any such work like this there is always the question of what to include or exclude or where to draw the line. Our first thought was to limit this work to railfan excursions, but that soon got broadened to include rail specials for the general public and officials, special moves, trolley trips, bus outings, waterway and canal journeys, etc. The focus has been on such trips which operated within NJ; from NJ; into NJ from other states; or, passed through NJ. We have excluded regularly scheduled tourist type rides, automobile journeys, air trips, amusement park rides, etc. NOTE: Since many of the following items were taken from promotional literature we can not guarantee that each and every trip was actually operated. Early on the railways explored and promoted special journeys for the public as a way to improve their bottom line. -

US $5.95 • Can $7.95 Display Until April 30Th

US $5.95 • Can $7.95 Display until April 30th Celebrating the art of 1:48 modeling Issue #19 Mar/Apr 2005 Vol. 4, No. 2 Publisher Joe Giannovario Features [email protected] Art Director Jaini Giannovario 4 The Texas Midland Railway – Dallas Division [email protected] Brady McGuire and the boys show us how they do a club Texas-style. Editor Brian Scace [email protected] 18 Building a Small O Scale Layout – Part 2 Advertising Manager A multi-part series on building a small O Scale layout to fit an apart- Jeb Kriigel ment. Watch as Mike Culham rebuilds his Great Central Railway. [email protected] Contributors 28 O Scale Influences – Glen Davis Ted Byrne An on-going series about people who have made a difference in other Gene Deimling Bobber Gibbs O Scaler’s lives. Stanley Harper contributed this article about Mr. Davis. Carey Hinch Hobo D. Hirailer Jace Kahn 42 Scratchbuilding a Simple Steam Service Site Neville Rossiter Tom Houle is back with another of his excellent scratchbuilding articles. Subscription Rates: 6 issues This one focuses on easy to build service facilities for small steam. US - Standard Mail Delivery US$30 US - First Class Delivery (1 year only) US$40 Canada/Mexico US$50 Overseas US$75 Visa, MC, AMEX & Discover accepted Call 610-363-7117 during Eastern time business hours Departments Dealers write for terms. 10 Easements for the Learning Curve – Brian Scace Advertisers write for information or visit our website. 12 The Modern Image - Carey Hinch O Scale Trains ISSN 1536-9528 23 The Workshop – Neville Rossiter www.oscalemag.com Published bimonthly (6 times a year) by O Scale Trains Magazine 24 Narrow Minded – Bobber Gibbs PO Box 238, Lionville PA 19353-0238 © 2005 OST All Rights Reserved 40 Reader Feedback – Letters to the Editor Printed in the U.S.A. -

Pne 197607.Pdf

cpc JUL Y, 1976 $1.00 \ '. \ . \ \ \ , COLORADO RAIL Annual NUMBER NINE Enjoy the COLOR & SOUND of THE AMERICAN FREEDOM TRAIN Number Nine in our On a more modern Track of the Cats details by popular series of Colorado note, the Prospector is the establishment of the Rail Annuals features the account of the Rio State-owned operation QNTERURBAN four different articles on Grande's ov ernight for the same D&RG nar 'PILMS Colorado railroad history . streamliner on the Den row gauge line that Jukes ver - Moffat Tunnel- Salt had photographed a half Tin Feathers & Gaso Lake City run - diesel century earlier. line Fumes is the story of powered and deluxe, and th e uniqu e Galloping 126 pages, 8112 x II. the pride of the Railroad. Geese motor trains that thoroughly research ed once plied the rails of the and profusely illustrated. Rio Grande Southern, the A Tribute to Fred Jukes legendary narrow gauge is a pictorial biography of Clothbound Deluxe POSTPAID that threaded through the great early-day pho rugged western slope tographer of the D&RG mountain terrain. narrow gauge, while $9.75 DEPT. N, BOX 10, Colorado Railroad Museum, GOLDEN COLO. 80401 Photo by F. Nicas Even with your silent projector, you can GREAT NEW BOOKS FROM INTERURBANS! enjoy the sights and sounds of being in the 2... cab and on the platform of this famous train, pulled by S.P. 4449, on its historical journey TReLLEYS Te THE SURF from Bakersfield, via the Tehachapi Loop and Mohave. BEFORE THE RED CARS CAME 'he G,.en CO" TROLLEYS TO THE SURF by W;II;om A. -

Railroad Collectibles Tri-State Traction-Interurban Trolleys of SW MO, SE KS & NE OK.27.50 86 W

Celebrating Scale the art of Trains 1:48 modeling O u Mar/Apr 2006 Issue #25 US $6.95 • Can $8.95 Display until Apr. 30, 2006 Celebrating the art of 1:48 modeling Issue #25 Mar/Apr 2006 Vol. 5 - No. 2 Publisher Joe Giannovario [email protected] Features 4 Bay Ridge Harbor – Revisited Art Director There’s been a lot of changes since we last looked at Neville Rossiter’s Jaini Giannovario great model railroad in Perth, Australia. [email protected] 16 Building a Small O Scale Layout – Part 8 Editor Mike Culham starts to add structures to his new GCRR. Brian Scace [email protected] 21 Lenses and Portholes A simple way to fill those openings, by Marty Iftody. Advertising Manager 29 Running Trains with Their Own Fuel Jeb Kriigel Bob Boelter’s solution to command control is batteries. [email protected] 35 Growing Up O Scale More info about the 2006 O Scale National Convention. Customer Service Spike Beagle 40 Track as Scenery Our resident Finescale Modeler, Mike Cougill, examines track as an element of scenery. CONTRIBUTORS 49 Quench Your Loco’s Thirst TED BYRNE HOBO D. HIRAILER Thoughts on building Water Tanks by C. Victor Robart. BObbER GIbbS JACE KAHN MIKE COUGILL ROGER C. PARKER 64 Index to O Scale Trains Volume 3, Jan. - Dec. 2004 CAREY HINch NEVILLE ROSSITER Subscription Rates: 6 issues US - Standard Mail Delivery US$35 US - First Class Delivery (1 year only) US$45 Canada/Mexico US$55 Departments Overseas US$80 Visa, MC, AMEX & Discover accepted 11 Easements for the Learning Curve – Brian Scace Call 610-363-7117 during 13 The Good Old Days – Jace Kahn Eastern time business hours Dealers contact Kalmbach Publishing, 800-558- 25 The Workshop – Neville Rossiter 1544 ext 818 or email [email protected] 26 The Art of Finescale – Mike Cougill Advertisers call for info. -

Rmj 200210.Pdf

PRECISION RAILROAD MODELS rior l ng, ures an autos are mod For the railroad personnel working your railroad, for the railfan chasin' your trains, for the citizenry of your community ...our Oenny's® restaurant structure is "always open." Factory-assembled and molded in color, with parking lot and landscape details, this instantly recognized structure is a great addition to your N scale model railroad layout. Available now from your local hobby shop. Be sure to also take a look at our new Residential Series structures. Available in Stores NOWSD8DMAC and SD90/43MAC 2nd Production Collectors and modern-era modelers ... three all new roadnames CSX, Norfolk Southern, CEFX Leasing and a unique all-new paint scheme for Union Pacific are in stores now! With Bright-White™ LED headlight, automatic couplers. printed numberboards and DCC-friendly mechanism. Upcoming Model Release Update - HO Business Car (late September], N SD40 (late October), N ROC Railcar with UN/TRACK, with special offer (November/December), HO SD45 (December/January) Visit us on the worldwide web at IiTT 'T1I KATO U.S.A., Inc. Remington Road· Schaumburg, . U.S.A. 100 IL 60173 OfficialSponsor www.katousa.com BUILT FOR PO-wrER Constructed 01 metal, the HO 2-Rail DC Big Boy is the largest HO steam locomotive ever built by IHIX. Built specifically for North American 2-Rail DC model railroaders, the limited edition TRIX Big Boy has a TRIX HO scale length of 18-5/16" and weighs over 2 Ibs. 10 oz. Representing a level of craftsmanship only found previously on brass models at a much higher price, the TRIX Big Boy has a manufacturer's suggested retail price of only $598. -

HO-Scale Conversion List Handout

® HO-SCALE COUPLER CONVERSION LIST 7-8-21 The Coupler People Most of the below listings have conversion drawing and instructions on our web site at www.kadee.com/hocc.htm Newer models that have factory installed knuckle couplers are easily converted by using our standard head #148 or scale head #158 Whisker® Couplers. Always check the coupler heights with either our #205 or newer #206 Coupler Height Gauge. This coupler conversion list is our suggested starting coupler for the conversion. (Typically requiring the least modification to a model utilizing our newest couplers even though other couplers also work for the model). Our conversion’s based on only one model from a production run, there may be inconsistencies in a model’s production run that require a different coupler or model modifications to achieve the proper coupler height for coupler function. ACCURAIL ARISTO - CRAFT ATHEARN "GENESIS" All Rolling Stock .........................................NO.5® or 148 STEAM STEAM AHM (RIVAROSSI) All Steam Locomotives (Generic) ..............NO.5® or 148 USRA 2-8-2 Lt. Mikado (road pilot) .............................. STEAM ATHEARN .........................................36 Pilot, NO.5® or 148 Tender 0-4-0 Dockside .................. (Early model) 34 Pilot, 31 Rear STEAM USRA 2-8-2 Lt. Mikado (step pilot) .............................. 0-4-0 Dockside .................(Late model) 34 Pilot, 34 Rear 0-4-2 T "Little Monster" ..............................NO.5® or 148 .........................................34 Pilot, NO.5® or 148 Tender 0-4-0 Switcher w/Tender ......................................... 37 0-6-0 Switcher with Tender ........................NO.5® or 148 4-6-2 Pacific .....................36 Pilot, NO.5® or 148 Tender 0-8-0 Switcher .................38 Pilot, NO.5® or 148 Tender 4-6-2 Pacific ...............................................NO.5® or 148 4-8-2 Mt-4 ..................................................NO.5® or 148 2-4-0 Bowker (Tender only) .................................... -

Chesapeake and Ohio Historical Society

Chesapeake and Ohio Historical Society Strategic Plan July 2020 1 COHS Strategic Plan – July 2020 Introduction This work is the end result of input from members of the C&O HS Board of Directors, interviews with key operational staff and the staff at the Headquarters in Clifton Forge, VA. The goal is to provide overarching guidance and goals for the effective management of the Society over an extended period of time. It is not meant to be a fixed end point but rather something that should be periodically revised to reflect changes to internal and external conditions. As part of this process a review of other strategic plans from various historical societies was conducted in an attempt to understand the key issues other like organizations have been faced with. Further, the long proven tools used by many organizations has been applied so that we can be as thorough as possible. Finally, the goals provided are done so in a way that can be measured and compared so progress and success can be readily determined. Prepared by Rick Gartrell, Director [email protected] 843.347.7995 2 COHS Strategic Plan – July 2020 TOPICS 1. Society Vision …………………………………………………………………. P. 4 2. The Archives …………………………………………………………………… P. 5 3. Retail Sales Operation …………………………………………………….. P. 6 4. Publications …………………………………………………………………….. P. 8 5. Staff, Business Office, & Member Services ………………………. P. 10 6. The Heritage Center ………………………………………………………… P. 18 7. Conference and Events ……………………………………………………. P. 21 8. External Partnerships & Opportunities …………………………….. P. 22 Appendices: A. Strengths, Weaknesses, Opportunities, Threats Analysis ….. P. 24 B. Heritage Center Exhibits Interpretative Plan ……………………… P. 27 C. Heritage Center Master Facility Concepts ………………………….