Exploring Horsepower and Torque

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Locomotive Dedication Ceremony

The American Society of Mechanical Engineers REGIONAL MECHANICAL ENGINEERING HERITAGE COLLECTION LOCOMOTIVE DEDICATION CEREMONY Kenefick Park • Omaha, Nebraska June 7, 1994 Locomotives 4023 and 6900 are examples of the world’s largest motive power in the steam and diesel eras. These locomotives are on permanent display at Kenefick Park, which was established in 1989 in honor of noted former Union Pacific chairman, John C. Kenefick. The 4023 was one of twenty-five famous “Big Boy” type simple articulated locomotives Locomotive 4023 was a feature display lauded in the industry and press as the highest horsepower, heaviest and longest steam at the Omaha Shops locomotives ever built, developing seven thousand horsepower at their seventy miles until being moved to per hour design speed. Kenefick Park. 2 World’s largest The Big Boy type was designed at the Omaha headquarters of Union Pacific under the single unit diesel personal direction of the road’s noted mechanical head, Otto Jabelmann. The original locomotives required four axle trucks to distribute twenty locomotives of this type were built by American Locomotive Company in their heavy weight and Schenectady, New York, in the fall of 1941. They were built in preparation for the nation’s keep within track probable entry into World War II because no proven diesel freight locomotive was yet loading limits. in production. These 4-8-8-4 type locomotives were specifically designed to haul fast, heavy eastbound freight trains between Ogden, Utah, and Green River, Wyoming, over the 1.14 percent eastbound grade. The 4023 was one of five additional units built in 1944 under govern- ment authority in preparation for a twenty-five percent increase in traffic due to the shift from European to Pacific war operations. -

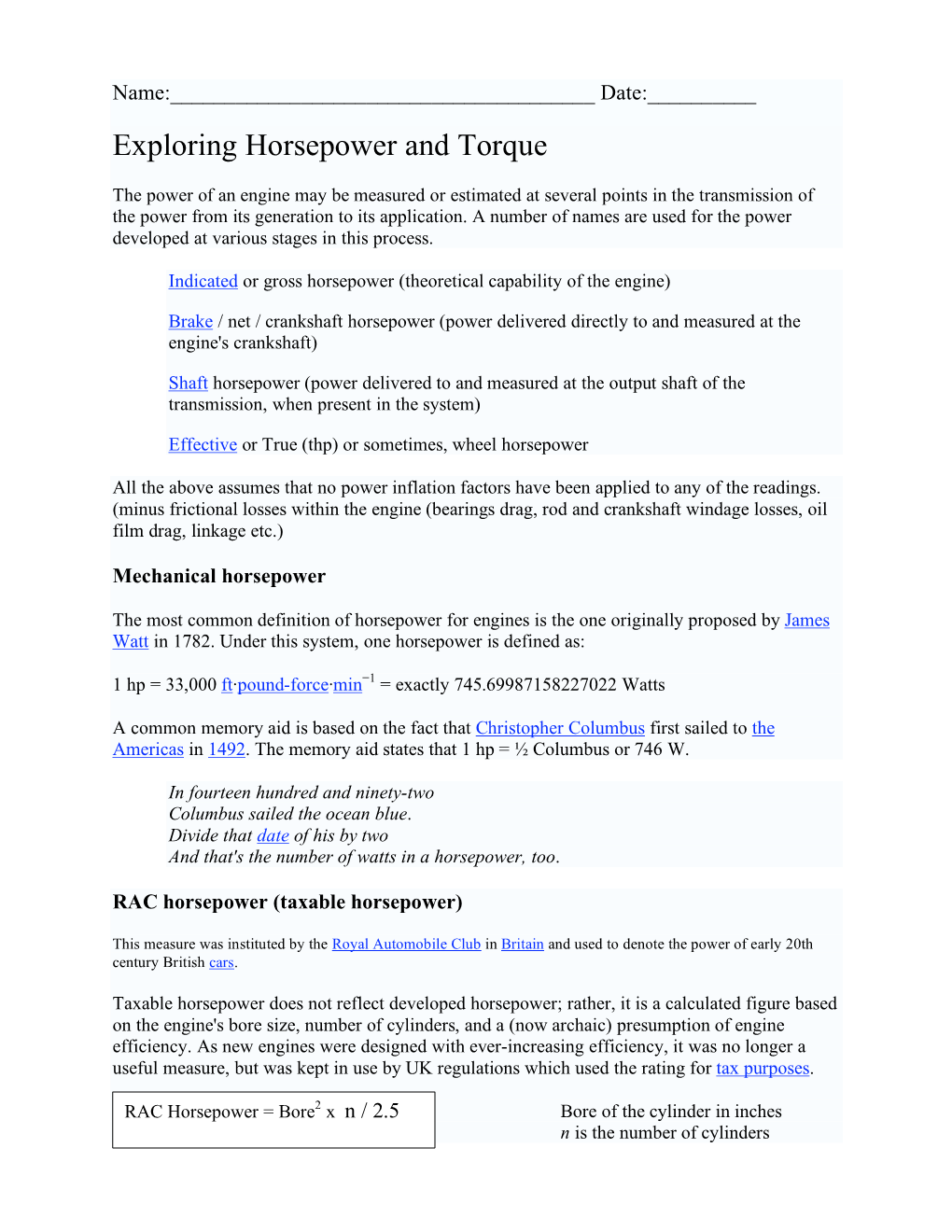

Engineering Info

Engineering Info To Find Given Formula 1. Basic Geometry Circumference of a circle Diameter Circumference = 3.1416 x diameter Diameter of a circle Circumference Diameter = Circumference / 3.1416 2. Motion Ratio High Speed & Low Speed Ratio = RPM High RPM Low RPM Feet per Minute of Belt RPM = FPM and Pulley Diameter .262 x diameter in inches Belt Speed Feet per Minute RPM & Pulley Diameter FPM = .262 x RPM x diameter in inches Ratio Teeth of Pinion & Teeth of Gear Ratio = Teeth of Gear Teeth of Pinion Ratio Two Sprockets or Pulley Diameters Ratio = Diameter Driven Diameter Driver 3. Force - Work - Torque Force (F) Torque & Diameter F = Torque x 2 Diameter Torque (T) Force & Diameter T = ( F x Diameter) / 2 Diameter (Dia.) Torque & Force Diameter = (2 x T) / F Work Force & Distance Work = Force x Distance Chain Pull Torque & Diameter Pull = (T x 2) / Diameter 4. Power Chain Pull Horsepower & Speed (FPM) Pull = (33,000 x HP)/ Speed Horsepower Force & Speed (FPM) HP = (Force x Speed) / 33,000 Horsepower RPM & Torque (#in.) HP = (Torque x RPM) / 63025 Horsepower RPM & Torque (#ft.) HP = (Torque x RPM) / 5250 Torque HP & RPM T #in. = (63025 x HP) / RPM Torque HP & RPM T #ft. = (5250 x HP) / RPM 5. Inertia Accelerating Torque (#ft.) WK2, RMP, Time T = WK2 x RPM 308 x Time Accelerating Time (Sec.) Torque, WK2, RPM t = WK2 x RPM 308 x Torque WK2 at motor WK2 at Load, Ratio WK2 Motor = WK2 Ratio2 6. Gearing Gearset Centers Pd Gear & Pd Pinion Centers = ( PdG + PdP ) / 2 Pitch Diameter No. of Teeth & Diametral Pitch Pd = Teeth / DP Pitch Diameter No. -

History of a Forgotten Engine Alex Cannella, News Editor

POWER PLAY History of a Forgotten Engine Alex Cannella, News Editor In 2017, there’s more variety to be found un- der the hood of a car than ever. Electric, hybrid and internal combustion engines all sit next to a range of trans- mission types, creating an ever-increasingly complex evolu- tionary web of technology choices for what we put into our automobiles. But every evolutionary tree has a few dead end branches that ended up never going anywhere. One such branch has an interesting and somewhat storied history, but it’s a history that’s been largely forgotten outside of columns describing quirky engineering marvels like this one. The sleeve-valve engine was an invention that came at the turn of the 20th century and saw scattered use between its inception and World War II. But afterwards, it fell into obscurity, outpaced (By Andy Dingley (scanner) - Scan from The Autocar (Ninth edition, circa 1919) Autocar Handbook, London: Iliffe & Sons., pp. p. 38,fig. 21, Public Domain, by the poppet valves we use in engines today that, ironically, https://commons.wikimedia.org/w/index.php?curid=8771152) it was initially developed to replace. Back when the sleeve-valve engine was first developed, through the economic downturn, and by the time the econ- the poppet valves in internal combustion engines were ex- omy was looking up again, poppet valve engines had caught tremely noisy contraptions, a concern that likely sounds fa- up to the sleeve-valve and were quickly becoming just as miliar to anyone in the automotive industry today. Charles quiet and efficient. -

Feeling Joules and Watts

FEELING JOULES AND WATTS OVERVIEW & PURPOSE Power was originally measured in horsepower – literally the number of horses it took to do a particular amount of work. James Watt developed this term in the 18th century to compare the output of steam engines to the power of draft horses. This allowed people who used horses for work on a regular basis to have an intuitive understanding of power. 1 horsepower is about 746 watts. In this lab, you’ll learn about energy, work and power – including your own capacity to do work. Energy is the ability to do work. Without energy, nothing would grow, move, or change. Work is using a force to move something over some distance. work = force x distance Energy and work are measured in joules. One joule equals the work done (or energy used) when a force of one newton moves an object one meter. One newton equals the force required to accelerate one kilogram one meter per second squared. How much energy would it take to lift a can of soda (weighing 4 newtons) up two meters? work = force x distance = 4N x 2m = 8 joules Whether you lift the can of soda quickly or slowly, you are doing 8 joules of work (using 8 joules of energy). It’s often helpful, though, to measure how quickly we are doing work (or using energy). Power is the amount of work (or energy used) in a given amount of time. http://www.rdcep.org/demo-collection page 1 work power = time Power is measured in watts. One watt equals one joule per second. -

AP-42, Vol. I, 3.3: Gasoline and Diesel Industrial Engines

3.3 Gasoline And Diesel Industrial Engines 3.3.1 General The engine category addressed by this section covers a wide variety of industrial applications of both gasoline and diesel internal combustion (IC) engines such as aerial lifts, fork lifts, mobile refrigeration units, generators, pumps, industrial sweepers/scrubbers, material handling equipment (such as conveyors), and portable well-drilling equipment. The three primary fuels for reciprocating IC engines are gasoline, diesel fuel oil (No.2), and natural gas. Gasoline is used primarily for mobile and portable engines. Diesel fuel oil is the most versatile fuel and is used in IC engines of all sizes. The rated power of these engines covers a rather substantial range, up to 250 horsepower (hp) for gasoline engines and up to 600 hp for diesel engines. (Diesel engines greater than 600 hp are covered in Section 3.4, "Large Stationary Diesel And All Stationary Dual-fuel Engines".) Understandably, substantial differences in engine duty cycles exist. It was necessary, therefore, to make reasonable assumptions concerning usage in order to formulate some of the emission factors. 3.3.2 Process Description All reciprocating IC engines operate by the same basic process. A combustible mixture is first compressed in a small volume between the head of a piston and its surrounding cylinder. The mixture is then ignited, and the resulting high-pressure products of combustion push the piston through the cylinder. This movement is converted from linear to rotary motion by a crankshaft. The piston returns, pushing out exhaust gases, and the cycle is repeated. There are 2 methods used for stationary reciprocating IC engines: compression ignition (CI) and spark ignition (SI). -

Energy and Power Units and Conversions

Energy and Power Units and Conversions Basic Energy Units 1 Joule (J) = Newton meter × 1 calorie (cal)= 4.18 J = energy required to raise the temperature of 1 gram of water by 1◦C 1 Btu = 1055 Joules = 778 ft-lb = 252 calories = energy required to raise the temperature 1 lb of water by 1◦F 1 ft-lb = 1.356 Joules = 0.33 calories 1 physiological calorie = 1000 cal = 1 kilocal = 1 Cal 1 quad = 1015Btu 1 megaJoule (MJ) = 106 Joules = 948 Btu, 1 gigaJoule (GJ) = 109 Joules = 948; 000 Btu 1 electron-Volt (eV) = 1:6 10 19 J × − 1 therm = 100,000 Btu Basic Power Units 1 Watt (W) = 1 Joule/s = 3:41 Btu/hr 1 kiloWatt (kW) = 103 Watt = 3:41 103 Btu/hr × 1 megaWatt (MW) = 106 Watt = 3:41 106 Btu/hr × 1 gigaWatt (GW) = 109 Watt = 3:41 109 Btu/hr × 1 horse-power (hp) = 2545 Btu/hr = 746 Watts Other Energy Units 1 horsepower-hour (hp-hr) = 2:68 106 Joules = 0.746 kwh × 1 watt-hour (Wh) = 3:6 103 sec 1 Joule/sec = 3:6 103 J = 3.413 Btu × × × 1 kilowatt-hour (kWh) = 3:6 106 Joules = 3413 Btu × 1 megaton of TNT = 4:2 1015 J × Energy and Power Values solar constant = 1400W=m2 1 barrel (bbl) crude oil (42 gals) = 5:8 106 Btu = 9:12 109 J × × 1 standard cubic foot natural gas = 1000 Btu 1 gal gasoline = 1:24 105 Btu × 1 Physics 313 OSU 3 April 2001 1 ton coal 3 106Btu ≈ × 1 ton 235U (fissioned) = 70 1012 Btu × 1 million bbl oil/day = 5:8 1012 Btu/day =2:1 1015Btu/yr = 2.1 quad/yr × × 1 million bbl oil/day = 80 million tons of coal/year = 1/5 ton of uranium oxide/year One million Btu approximately equals 90 pounds of coal 125 pounds of dry wood 8 gallons of -

Internal Combustion Engines Collection of Stationary

ASME International THE COOLSPRING POWER MUSEUM COLLECTION OF STATIONARY INTERNAL COMBUSTION ENGINES MECHANICAL ENGINEERING HERITAGE COLLECTION Coolspring Power Museum Coolspring, Pennsylvania June 16, 2001 The Coolspring Power Museu nternal combustion engines revolutionized the world I around the turn of th 20th century in much the same way that steam engines did a century before. One has only to imagine a coal-fired, steam-powered, air- plane to realize how important internal combustion was to the industrialized world. While the early gas engines were more expensive than the equivalent steam engines, they did not require a boiler and were cheap- er to operate. The Coolspring Power Museum collection documents the early history of the internal- combustion revolution. Almost all of the critical components of hundreds of innovations that 1897 Charter today’s engines have their ori- are no longer used). Some of Gas Engine gins in the period represented the engines represent real engi- by the collection (as well as neering progress; others are more the product of inventive minds avoiding previous patents; but all tell a story. There are few duplications in the collection and only a couple of manufacturers are represent- ed by more than one or two examples. The Coolspring Power Museum contains the largest collection of historically signifi- cant, early internal combustion engines in the country, if not the world. With the exception of a few items in the collection that 2 were driven by the engines, m Collection such as compressors, pumps, and generators, and a few steam and hot air engines shown for comparison purposes, the collection contains only internal combustion engines. -

Premium Efficiency Motor Selection and Application Guide

ADVANCED MANUFACTURING OFFICE PREMIUM EFFICIENCY MOTOR SELECTION AND APPLICATION GUIDE A HANDBOOK FOR INDUSTRY DISCLAIMER This publication was prepared by the Washington State University Energy Program for the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy. Neither the United States, the U.S. Department of Energy, the Copper Development Association, the Washington State University Energy Program, the National Electrical Manufacturers Association, nor any of their contractors, subcontractors, or employees makes any warranty, express or implied, or assumes any legal responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process described in this guidebook. In addition, no endorsement is implied by the use of examples, figures, or courtesy photos. PREMIUM EFFICIENCY MOTOR SELECTION AND APPLICATION GUIDE ACKNOWLEDGMENTS The Premium Efficiency Motor Selection and Application Guide and its companion publication, Continuous Energy Improvement in Motor-Driven Systems, have been developed by the U.S. Department of Energy (DOE) Office of Energy Efficiency and Renewable Energy (EERE) with support from the Copper Development Association (CDA). The authors extend thanks to the EERE Advanced Manufacturing Office (AMO) and to Rolf Butters, Scott Hutchins, and Paul Scheihing for their support and guidance. Thanks are also due to Prakash Rao of Lawrence Berkeley National Laboratory (LBNL), Rolf Butters (AMO and Vestal Tutterow of PPC for reviewing and providing publication comments. The primary authors of this publication are Gilbert A. McCoy and John G. Douglass of the Washington State University (WSU) Energy Program. Helpful reviews and comments were provided by Rob Penney of WSU; Vestal Tutterow of Project Performance Corporation, and Richard deFay, Project Manager, Sustainable Energy with CDA. -

General Conversion Table in Alphabetical Order

General Conversion Table In Alphabetical Order UNIT x FACTOR = UNIT UNIT x FACTOR = UNIT Acceleration gravity 9.80665 meter/second2 british thermal unit (BTU) 1054.35 watt-seconds Acceleration gravity 32.2 feet/second2 british thermal unit (BTU) 10.544 x 103 ergs Acceleration gravity 9.80665 meter/second2 british thermal unit (BTU) 0.999331 BTU (IST) Acceleration gravity 32.2 feet/second2 BTU/min 0.01758 kilowatts acre 4,046.856 meter2 BTU/min 0.02358 horsepower acre 0.40469 hectare byte 8.000001 bits acre 43,560.0 foot2 calorie, g 0.00397 british thermal unit acre 4,840.0 yard2 calorie, g 0.00116 watt-hour acre 0.00156 mile2 (statute) calorie, g 4184.00 x 103 ergs acre 0.00404686 kilometer2 calorie, g 3.08596 foot pound-force acre 160 rods2 calorie, g 4.184 joules acre feet 1,233.489 meter2 calorie, g 0.000001162 kilowatt-hour acre feet 325,851.0 gallon (US) calorie, g 42664.9 gram-force cm acre feet 1,233.489 meter3 calorie, g/hr 0.00397 btu/hr acre feet 325,851.0 gallon calorie, g/hr 0.0697 watts acre-feet 43560 feet3 candle/cm2 12.566 candle/inch2 acre-feet 102.7901531 meter3 candle/cm2 10000.0 candle/meter2 acre-feet 134.44 yards3 candle/inch2 144.0 candle/foot2 ampere 1 coulombs/second candle power 12.566 lumens ampere 0.0000103638 faradays/second carats 3.0865 grains ampere 2997930000.0 statamperes carats 200.0 milligrams ampere 1000 milliamperes celsius 1.8C°+ 32 fahrenheit ampere/meter 3600 coulombs celsius 273.16 + C° kelvin angstrom 0.0001 microns centimeter 0.39370 inch angstrom 0.1 millimicrons centimeter 0.03281 foot atmosphere -

Pto Torque and Horsepower Ratings

PTO TORQUE AND HORSEPOWER RATINGS Intermittent service refers to an On-Off operation under load. If maximum HP and/or torque is used for extended periods of time, (5 min. or more every 15 min.) this is considered “Continuous Service” and HP rating of PTO should be reduced by multiplying intermittent value below by .70. Applications with PTO output shaft speeds above 2,000 RPM, regardless of duration, are to be considered “Continuous” duty. MAX rated output shaft speed for all Muncie Power PTOs is 2,500 RPM. Fire Pump applications are calculated within a different category listed on page 3 and are derated by multiplying intermittent value below by .80. Below is a chart showing the Intermittent and calculated continuous Torque rating of the PTOs included in this catalog. The Application pages may have lower ratings for these PTOs listed. The Application page rating may be adjusted to limit the PTO output to a rating which will not exceed the transmission manufacturers rating. The transmission manufacturer does not differentiate between Intermittent and Continuous; therefore, the Application page rating is never to be exceeded. Refer to this page when there is a question of the rating (Intermittent or Continuous) for the PTO as it is manufactured. PTO SERIES SPEED RATIO INTERMITTENT HP@1000 RPM INTERMITTENT TORQUE LBS.FT. CONTINUOUS TORQUE LBS.FT. INTERMITTENT [KW]@1000 RPM INTERMITTENT TORQUE [NM] ONTINUOUS TORQUE [NM] PTO SERIES SPEED RATIO INTERMITTENT HP@1000 RPM INTERMITTENT TORQUE LBS.FT. CONTINUOUS TORQUE LBS.FT. INTERMITTENT [KW]@1000 -

2002 Model Railroading ▼ 5 Serving Ohio Bound and the Nation Acy Road of Service Acy V Es 845

▼ PASSENGER OPERATIONS ▼ CONTAINERS KSCU TO MATS ▼ DIESEL DETAIL: SP PA/PBs ▼ January 2002 $4.50 Higher in Canada VerticalVertical AccessAccess HatchesHatches Page 42 VirginiaVirginia SouthernSouthern Page 36 “Painted“Painted On”On” SignsSigns SOU RC Car Page 40 01 > EMDEMD GP40sGP40s Page 28 Seaboard Page 21 Page 28 0 7447 0 91672 7 I Asthe nation's box car fleet began to age in the early 1970's, it NEW SIECO BOX CARS became time for the birth of a brand new generation of freight cars. The Sieco exterior post plate C 50 foot boxcar was developed to fit SO' SIECO BOX CARS ITEM # DESCRIPTION the needs of both Class One and independent per diem short lines G4200 UNDECORATED and has performed yeoman service for more than three decades. G4201 B&M #1 Our Genesis 50' Sieco Boxcar provides the modern age model G4202 B&M #2 railroader with a wealth of prototypical fidelity. Stand alone details, G4203 MILWAUKEE #1 machined metal wheel sets with true-to-scale bearing cups that G4204 MILWAUKEE #2 actually rotate and photo-documented razor sharp graphics are a G4205 N&W#1 G4206 N&W#2 just a few of the benefits of this exceptional boxcar. This makes it a G4207 P&LE #1 "must have" for the realism inspired model rai lroad enthusiast or G4208 P&LE #2 the model railroader who demands that thei r rolling stock be as G4209 ST. LAWRENCE # 1 close to real as it gets. G4210 ST. LAWRENCE #2 January 2002 40 VOLUME 32 NUMBER 1 Photo by James A. -

The Journal of the Gauge O Guild

pp01-16 Vol18.2-Feb2010 16/01/2011 10:54 Page 1 February 2011 Volume 18 No 2 GAZETTEThe Journal of the Gauge O Guild Arthur in the garden see page 11 pp01-16 Vol18.2-Feb2010 16/01/2011 10:54 Page 2 QUALITY BRASS MODELS IN GAUGES 00, 0 AND 1 Hear the chime whistle, the safety valves and the 3 cylinder beat! Golden Age Models A4 and Pullmans A2 sample in brass A1 sample BR Green LNER coaches with choice of liveries Triplet Restaurant Car set Pullman coaches LNER Dynamometer Car Coronation Observation Car Rebuilt Observation Car A4 Silver Fox and other names A4 Sir Nigel Gresley All brass models beautifully painted with choice of liveries. Photos by Tony Wright Other projects started, please enquire Please contact for details of full range and prices www.goldenagemodels.net to view our photos and DVD with sound Golden Age Models Limited, P.O. Box No. 888, Swanage, Dorset, BH19 9AE Tel: 01929 480210 (with answerphone) E-mail: [email protected] 2 GAUGE O GUILD GAZETTE pp01-16 Vol18.2-Feb2010 16/01/2011 10:54 Page 3 The Gauge ‘O’ Guild Gazette is published quarterly by the Gauge ‘O’ Guild Ltd. The Gauge O Guild Guild website: www.gauge0guild.com Registered Office: Vale & West, Victoria House, 26 Queen Victoria Street, Reading, Berks RG1 1TG GAZETTE Board of Directors: R Alderman, P Bevan, S Gorski, S Harper, M Marritt, B Pinchbeck, Volume 18 No 2 February 2011 G Sheppard, N Smith, B Sumsion, R Walley. Useful Addresses Gazette Editor: John Kneeshaw Hope Cottage, 5 London Street, Godmanchester, Huntingdon PE29 2HU CONTENTS Email: [email protected]